-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 29. 2025, 11:37:26

Choosing the right PCB (Printed Circuit Board) manufacturer is crucial for ensuring that your electronic projects are successful. With the wide variety of options available, finding the right manufacturer that fits your needs can be a daunting task. In this guide, we'll walk you through the key factors to consider when selecting a PCB manufacturer, from design capabilities to assembly services, ensuring you make an informed decision.

Before diving into the selection process, it's important to understand what PCB manufacturing involves. PCBs are the backbone of most electronic devices, providing the physical foundation for mounting and connecting electronic components. The manufacturing process includes several steps such as design, fabrication, and assembly.

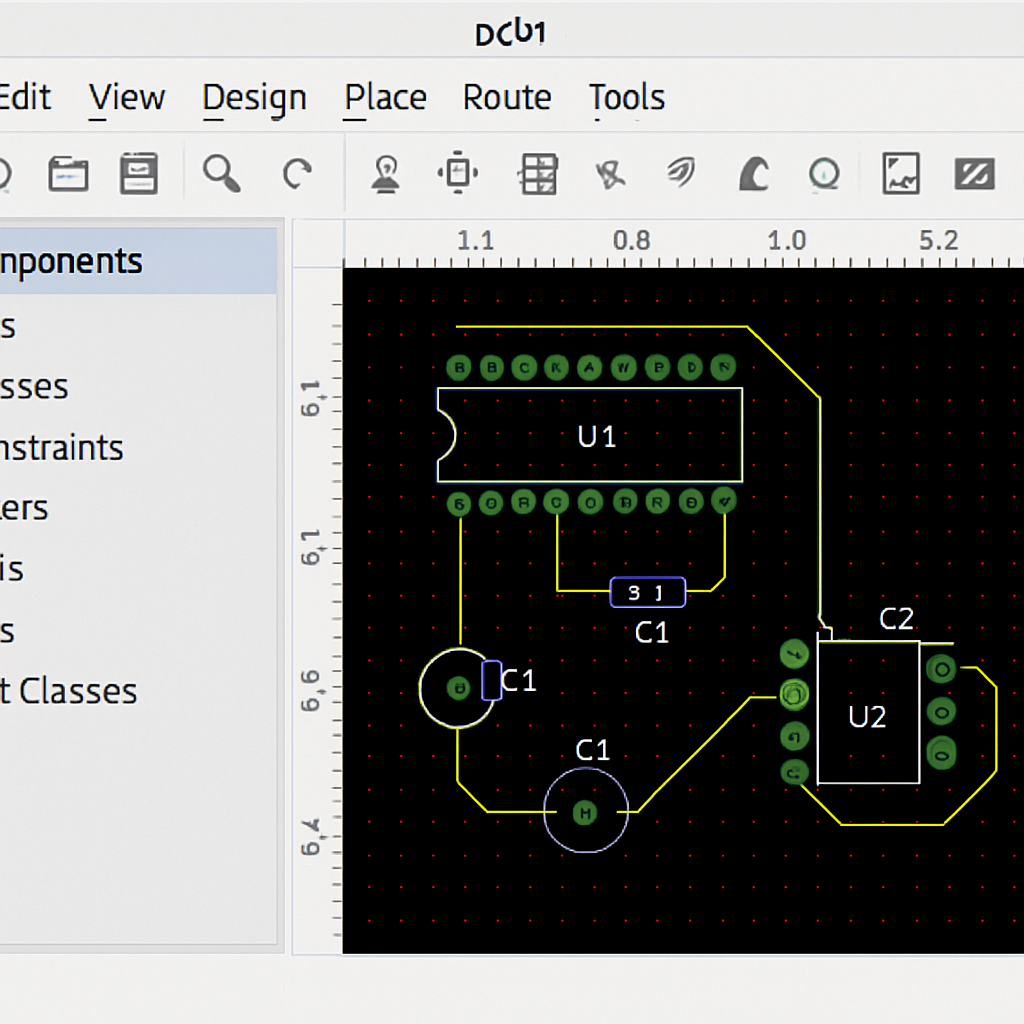

The design phase is critical as it determines the layout and functionality of the PCB. It involves creating a schematic diagram and designing the board layout using specialized software. When choosing a manufacturer, ensure they have the capability to handle your specific design requirements, whether it's a simple single-layer board or a complex multi-layer design.

The quality of a PCB can significantly impact the performance of your electronic device. Look for manufacturers that adhere to industry standards and have certifications such as ISO 9001. A reliable manufacturer will have a proven track record of producing high-quality PCBs with consistent performance.

Different projects require different types of PCBs. Some manufacturers specialize in certain types of boards, such as rigid, flexible, or rigid-flex. Make sure the manufacturer you choose can produce the type of PCB you need. Additionally, consider their capacity for handling large orders if your project requires high-volume production.

A good PCB manufacturer should offer design support and customization options to meet your specific needs. This includes the ability to handle complex designs, offer various materials and finishes, and provide technical support throughout the design process.

Time is often a critical factor in electronic projects. Inquire about the manufacturer's lead times and ensure they can meet your deadlines. Some manufacturers offer expedited services for an additional fee, which can be beneficial if you're working on a tight schedule.

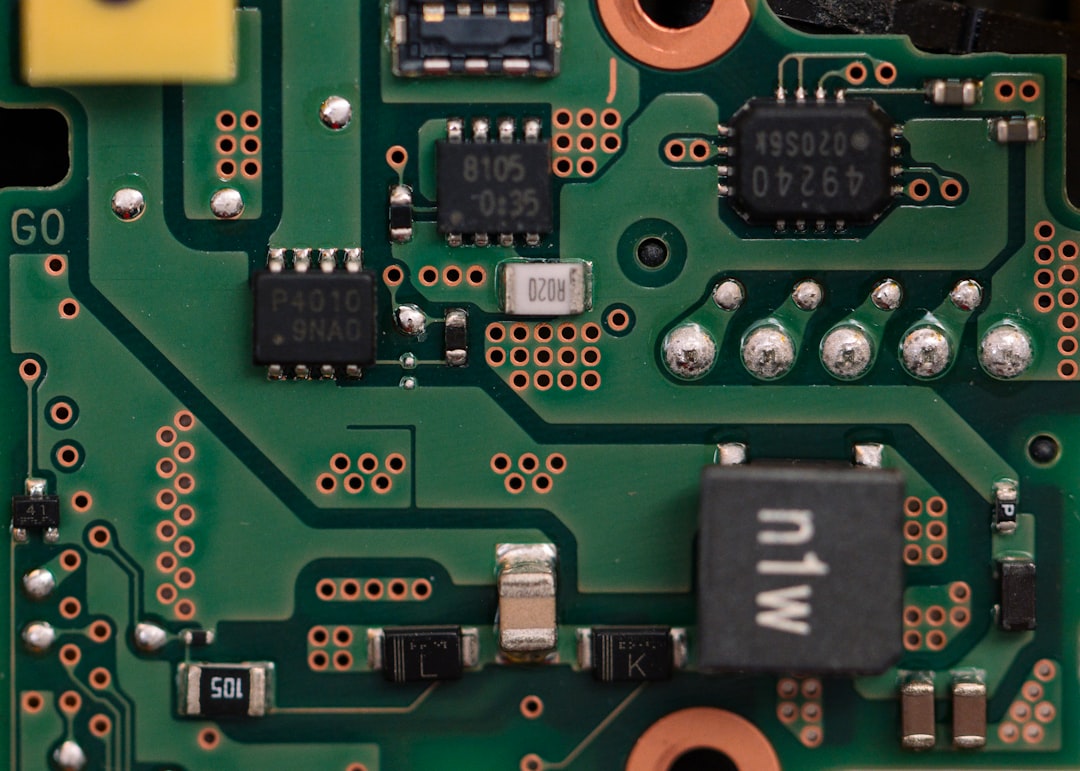

PCB assembly is the process of placing and soldering components onto the board. When choosing a manufacturer, it's important to consider whether they offer assembly services and the quality of those services.

Some manufacturers offer in-house assembly services, while others outsource to third-party providers. In-house assembly can provide better quality control and faster turnaround times. However, outsourced assembly may offer cost savings. Weigh the pros and cons based on your specific requirements.

Ensure that the manufacturer has the necessary equipment and expertise to handle your assembly needs. This includes the ability to work with various component types, such as surface-mount and through-hole components, and the capability to perform automated assembly for large orders.

Cost is always a significant factor in manufacturing decisions. While it's important to find a manufacturer that fits your budget, it's equally important not to compromise on quality. Cheap PCBs can lead to costly failures down the line.

Choose a manufacturer that offers transparent pricing and provides detailed quotes. This should include costs for design, fabrication, assembly, and any additional services. Be wary of hidden fees that can inflate the final cost.

Some manufacturers offer value-added services such as design reviews, testing, and logistics support. These services can enhance the overall quality and reliability of your PCBs and may justify a higher price point.

Before making a decision, research the manufacturer's reputation within the industry. Look for reviews and testimonials from previous customers to gauge their satisfaction with the manufacturer's products and services. Consider reaching out to colleagues or industry contacts for recommendations.

Check if the manufacturer complies with industry standards and holds relevant certifications. This can be an indicator of their commitment to quality and reliability. Certifications to look for include ISO 9001, IPC-A-610 for assembly quality, and RoHS compliance for environmental standards.

Choosing the right PCB manufacturer requires careful consideration of multiple factors. By evaluating potential manufacturers based on quality, capabilities, cost, and reputation, you can make an informed choice that aligns with your project's needs.

Here's a quick checklist to help you in your decision-making process:

Quality and reliability of PCBs

Manufacturing capabilities and specialization

Design support and customization options

Turnaround time and delivery reliability

Assembly services and capabilities

Cost and pricing transparency

Manufacturer's reputation and certifications

Selecting the right PCB manufacturer is a critical step in ensuring the success of your electronic projects. By thoroughly evaluating your options and considering the key factors outlined in this guide, you can partner with a manufacturer that will deliver high-quality PCBs that meet your specific needs. Remember, a reliable PCB manufacturer is not just a supplier but a valuable partner in your product development journey.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB