-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 09. 2025, 18:45:00

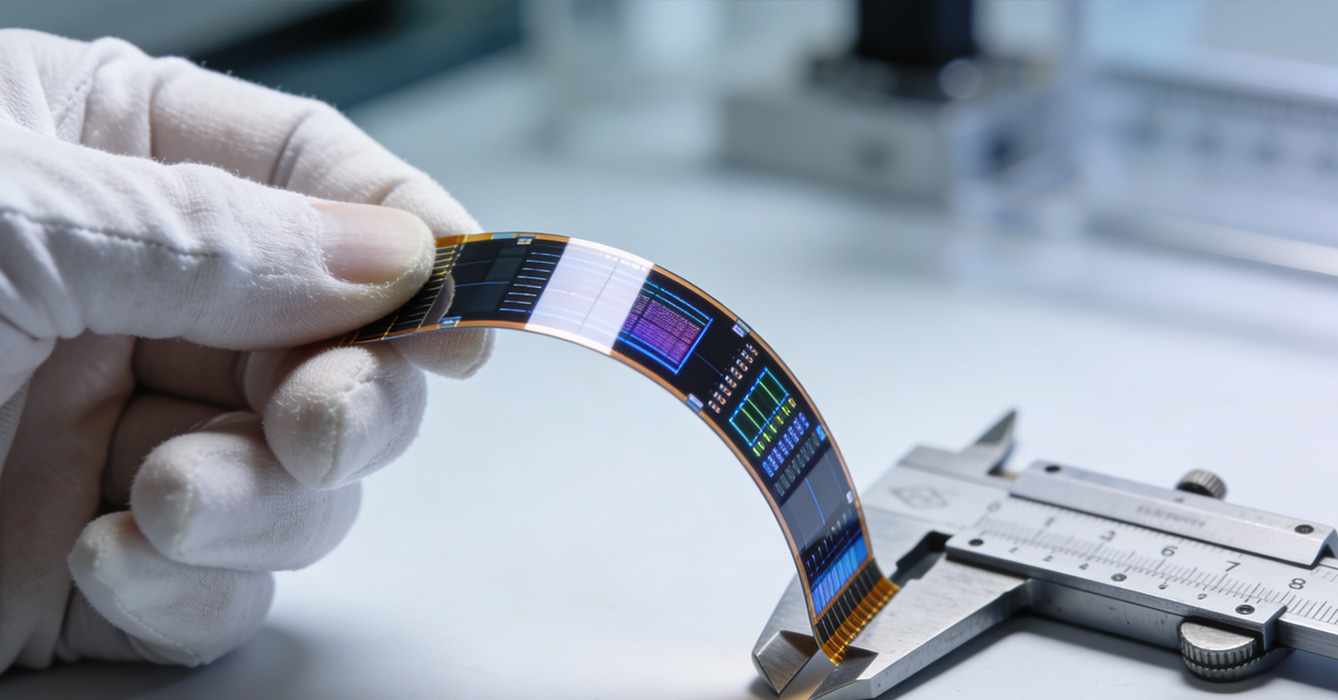

As flexible display technologies—represented by foldable OLED, rollable AMOLED, and bendable micro-LED—redefine the form factors of electronic devices, a professional Flexible Display FPC Supplier has become an indispensable cornerstone of the display innovation ecosystem. Specializing in flexible printed circuits (FPCs) engineered for the dynamic operating demands of flexible displays, these suppliers bridge the gap between bold morphological designs (fold, roll, bend) and consistent, long-term performance. Unlike generic FPC suppliers, a Flexible Display FPC Supplier focuses on bend-resistant material integration, dynamic circuit optimization, and multi-form factor adaptability, ensuring FPCs can withstand millions of bending cycles while maintaining stable signal transmission. For display brands and device manufacturers aiming to lead in the flexible display market, partnering with a reputable Flexible Display FPC Supplier is critical to translating innovative design concepts into market-ready products.

The competitive edge of a top Flexible Display FPC Supplier lies in its mastery of specialized technologies tailored to the unique challenges of flexible display operation:

- Bend-Resistant Material Engineering: Flexible displays require FPCs that can endure repeated mechanical stress without material fatigue or circuit damage. Leading suppliers select high-flex-endurance substrate materials (e.g., enhanced polyimide films with high tear resistance) and adopt flexible adhesive systems that prevent delamination during bending. They also optimize coverlay materials to balance flexibility and protection, ensuring the FPC can adapt to tight bend radii (as small as 1–2mm for foldable displays) while resisting scratches and environmental erosion.

- Dynamic Circuit Design & Stress Dispersion: Traditional rigid circuit designs fail in flexible scenarios due to stress concentration. Flexible Display FPC Suppliers use advanced EDA tools to design dynamic circuit layouts—such as curved routing in bend zones, staggered component placement, and variable trace widths—to disperse mechanical stress during folding or rolling. This design minimizes the risk of circuit breakage or signal interruption, ensuring stable data transmission between the display panel and driver IC even under dynamic deformation.

- Reinforced Bend Zone & Edge Protection: The bend zones and edges of FPCs are the most vulnerable to damage. Suppliers implement targeted reinforcement technologies, such as局部 lamination of flexible steel sheets or high-strength polymer layers in bend zones, to enhance mechanical stability. They also adopt precision edge-sealing processes to prevent moisture ingress and reduce edge fraying, extending the FPC’s service life in daily use scenarios.

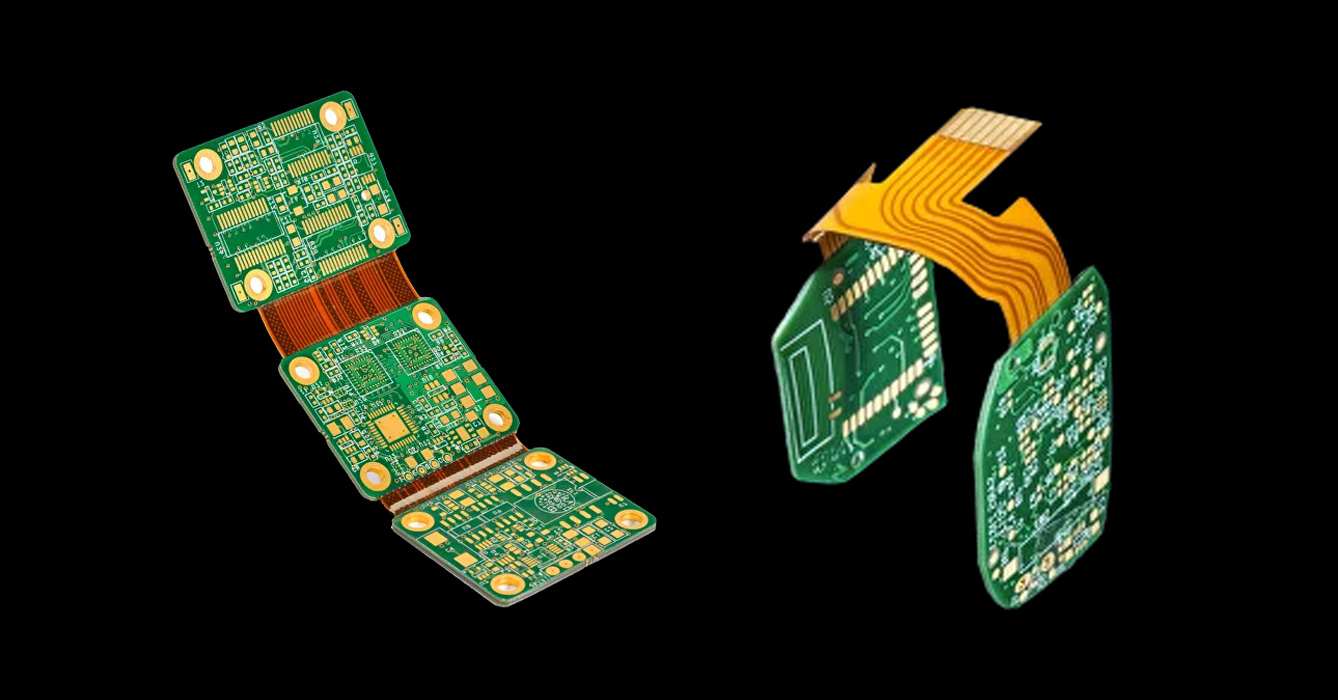

A professional Flexible Display FPC Supplier tailors solutions to the distinct requirements of various flexible display form factors, supporting diverse device innovations:

- Foldable Display FPC Solutions: For clamshell and book-style foldable devices (smartphones, laptops), suppliers develop FPCs optimized for dual-fold or multi-fold scenarios. These FPCs feature ultra-high flex endurance (up to 2 million+ folding cycles) and are designed to fit within the narrow hinge space of foldable devices. They also integrate signal buffering circuits to avoid display flicker or lag during folding operations.

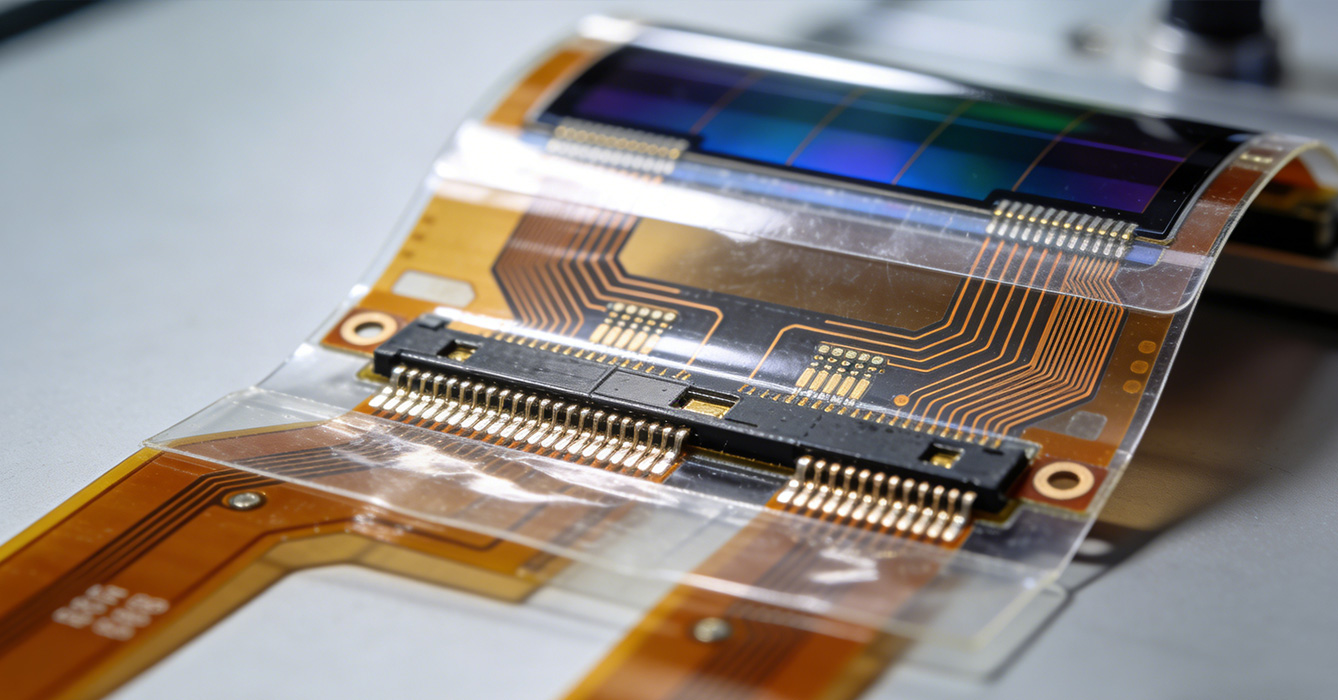

- Rollable Display FPC Solutions: Rollable displays (smartphones, tablets, commercial signage) require FPCs that can extend and retract smoothly without structural damage. Suppliers design ultra-thin, lightweight FPCs with low friction coatings, enabling seamless rolling movement. The FPCs also support long-distance signal transmission to accommodate the variable length of rollable displays, ensuring consistent display quality across the entire screen area.

- Bendable & Wearable Display FPC Solutions: For wearable devices (smartwatches, AR glasses) and curved automotive displays, suppliers develop conformable FPCs that can fit the curved contours of human bodies or vehicle interiors. These FPCs are ultra-compact, low-power, and resistant to sweat, temperature fluctuations, and UV radiation, aligning with the harsh operating conditions of wearable and automotive applications.

Flexible Display FPC Suppliers act as strategic partners, providing end-to-end collaborative support to streamline the development and production of flexible display devices:

- Early-Stage Morphological Co-Design: Suppliers participate in the early R&D phase of flexible display devices, working closely with display and device engineers to optimize FPC design for specific form factors. They provide DFM (Design for Manufacturability) insights on bend zone placement, FPC thickness, and material selection, ensuring the FPC design aligns with the device’s morphological goals and production feasibility.

- Rapid Prototyping & Performance Validation: To match the fast innovation cycle of flexible display technologies, suppliers offer high-speed prototyping services. They leverage flexible production lines to deliver functional FPC prototypes within 3–5 days, enabling manufacturers to quickly validate design feasibility and conduct flex endurance tests. This rapid iteration capability shortens the time-to-market for new flexible display devices.

- Mass Production Scalability & Quality Consistency: After prototype validation, suppliers ensure seamless scaling to mass production with strict quality control systems. They use AI-driven 3D AOI and X-ray inspection technologies to detect micro-defects (e.g., micro-cracks in bend zones, poor solder joints) and implement full batch traceability to guarantee consistent quality across millions of units—critical for maintaining brand reputation in the competitive flexible display market.

To ensure FPCs meet the strict performance requirements of flexible displays, suppliers implement comprehensive dynamic reliability testing and comply with global industry standards:

- Dynamic Mechanical Testing: Key tests include accelerated flex endurance cycling (simulating years of daily use), bend radius testing (validating compatibility with tight folds), and torsion testing (for wearable and curved displays). These tests validate the FPC’s mechanical durability under dynamic deformation scenarios.

- Environmental Adaptability Testing: Tests include thermal cycling (to simulate temperature extremes from -40°C to 85°C), humidity aging, and sweat resistance testing (for wearables). These tests ensure the FPC maintains performance in harsh operating environments, preventing material degradation or signal failure.

- Global Industry Compliance: Suppliers comply with international standards such as IPC-6012/2221 (FPC quality), RoHS/REACH (environmental protection), and automotive-specific IATF 16949 (for in-vehicle flexible displays). They also meet display industry-specific requirements for electromagnetic compatibility (EMC) and low-power consumption, facilitating manufacturers’ global market expansion.

In conclusion, a Flexible Display FPC Supplier is a pivotal enabler of flexible display innovation, leveraging specialized bend-resistant technologies, multi-form factor adaptation, and full-cycle collaborative support to unlock the potential of next-gen screen designs. As the demand for flexible, portable, and innovative display devices continues to grow across consumer electronics, automotive, and wearable sectors, the strategic value of partnering with a professional Flexible Display FPC Supplier will become increasingly prominent. Their ability to balance morphological flexibility, dynamic reliability, and production scalability makes them indispensable in the evolving flexible display ecosystem.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB