-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 09. 2025, 18:49:00

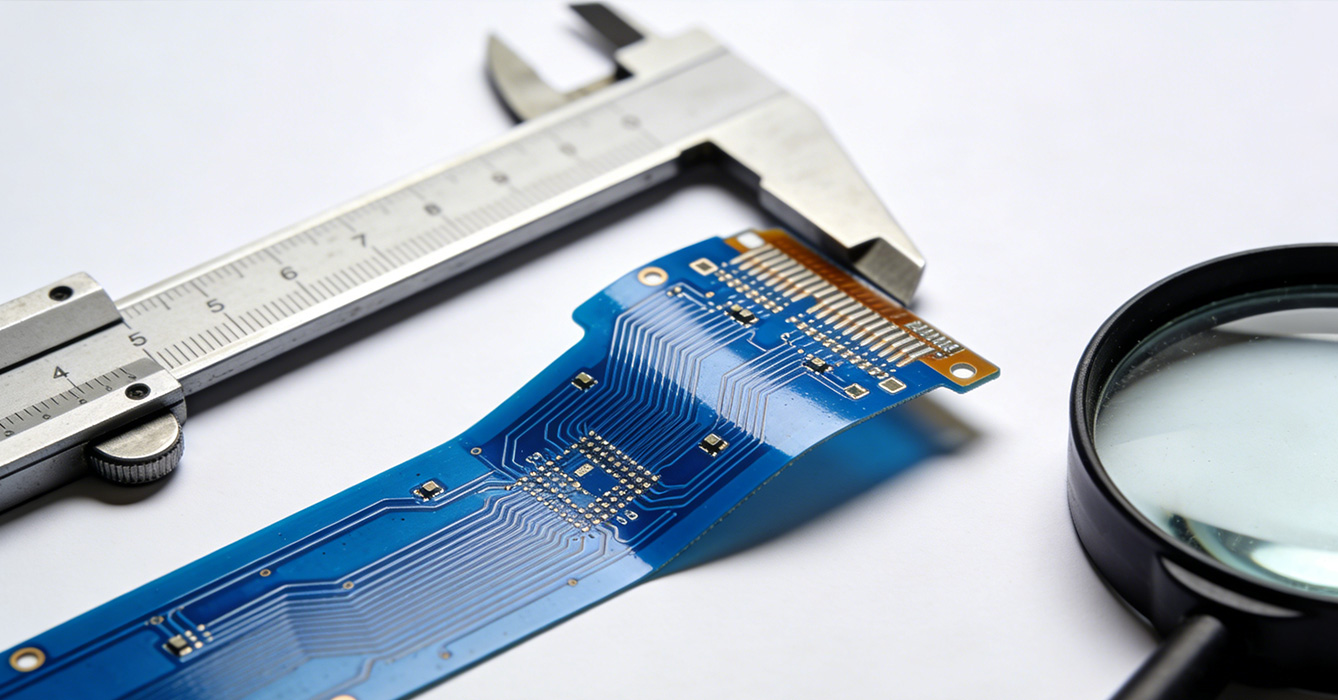

As display technologies evolve at a rapid pace—spanning OLED, LCD, mini/micro-LED, and emerging transparent displays—professional Display FPC manufacturers have become the backbone of the global display industry. Specializing in flexible printed circuits (FPCs) tailored to the diverse operational and design demands of display products, these manufacturers go beyond generic component supply: they adapt to the unique technical characteristics of different display types, balancing signal integrity, structural compatibility, and long-term reliability. Unlike niche FPC suppliers focused on single display segments, a comprehensive Display FPC manufacturer caters to consumer electronics, commercial signage, automotive displays, and industrial monitors, enabling display brands to bring innovative, high-performance products to market. For enterprises aiming to excel in the competitive display ecosystem, partnering with a versatile Display FPC manufacturer is a strategic imperative.

The competitive edge of a leading Display FPC manufacturer lies in its ability to tailor solutions to the distinct technical requirements of evolving display technologies:

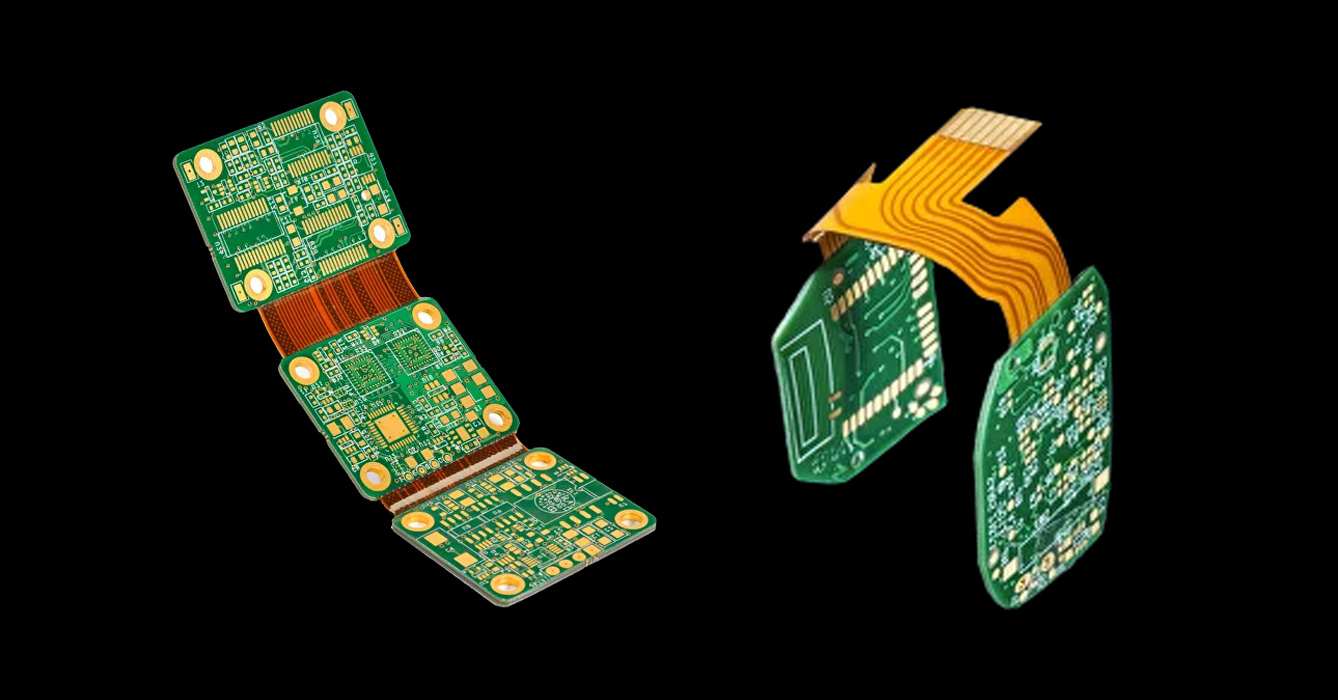

- OLED & Flexible Display Adaptation: For OLED and flexible displays (foldable, rollable), manufacturers develop ultra-thin, high-flexibility FPCs using enhanced polyimide substrates and flexible adhesive systems. These FPCs are engineered to withstand repeated bending cycles without signal disruption, with optimized circuit routing to disperse mechanical stress. They also integrate low-loss materials to ensure stable signal transmission for high-resolution OLED panels, supporting vivid color reproduction and fast refresh rates.

- Mini/Micro-LED Display Support: Mini/micro-LED displays demand FPCs with ultra-fine circuit lines and high-current-bearing capacity to drive dense LED arrays. Display FPC manufacturers leverage precision laser etching technologies to achieve sub-20μm line-width/space, ensuring uniform current distribution across thousands of micro-LEDs. They also integrate heat-dissipating structures to manage the thermal output of high-density LED clusters, preventing display flicker or performance degradation.

- LCD & Large-Format Display Optimization: For traditional LCD and large-format commercial displays (e.g., digital billboards, conference screens), manufacturers focus on signal integrity and structural stability. They design FPCs with robust shielding layers to minimize electromagnetic interference (EMI) in complex environments, and modular layouts to facilitate easy integration with large display panels. These FPCs also support long-distance signal transmission, ensuring consistent display quality across large screen areas.

A professional Display FPC manufacturer tailors its offerings to the unique needs of diverse display application scenarios:

- Consumer Electronics Displays: For smartphones, tablets, and smart TVs, manufacturers develop compact, lightweight FPCs that fit within slim device form factors. These FPCs support high-resolution (4K/8K) and high-refresh-rate (120Hz+) displays, with low-power designs to extend battery life. They also integrate touch sensor circuits and driver IC interfaces, reducing component count and simplifying device assembly.

- Automotive Displays: In-car infotainment systems, digital instrument clusters, and HUDs require FPCs that withstand harsh automotive environments. Display FPC manufacturers produce automotive-grade FPCs compliant with IATF 16949 standards, using heat-resistant, flame-retardant materials to resist temperature fluctuations, vibration, and UV radiation. These FPCs also support high-contrast, low-latency display performance critical for driver safety.

- Commercial & Industrial Displays: For commercial signage, industrial control monitors, and outdoor displays, manufacturers develop ruggedized FPCs with weather-resistant coatings and corrosion-resistant materials. These FPCs can operate reliably in extreme temperatures, high humidity, and dusty environments, ensuring 24/7 performance for mission-critical applications.

Leading Display FPC manufacturers act as strategic partners, fostering collaboration across the display industry chain to drive innovation:

- Co-Development with Display Panel Makers: Manufacturers participate in the early R&D phase of new display panels, working closely with panel makers to optimize FPC design for pixel layout, driver IC compatibility, and form factor. This co-development ensures FPCs fully unlock the performance potential of new display technologies, reducing time-to-market for innovative products.

- Synergy with Chip & Material Suppliers: By collaborating with semiconductor manufacturers and material suppliers, Display FPC manufacturers stay ahead of technology trends. They integrate the latest low-loss substrates, conductive materials, and packaging technologies into FPC designs, enhancing performance and reliability. This synergy also accelerates the adoption of emerging materials such as bio-based polyimides for sustainable display solutions.

- Customized R&D Support for Customers: Beyond standard solutions, manufacturers offer customized R&D services to address unique customer challenges. For example, they develop specialized FPCs for transparent displays or AR/VR headsets, leveraging their expertise in material science and circuit design to push the boundaries of display innovation.

To ensure the reliability of display products, Display FPC manufacturers implement comprehensive quality control systems and comply with global standards:

- Display-Specific Performance Testing: Key tests include signal integrity analysis (to ensure sharp, artifact-free visuals), thermal cycling (to validate temperature resistance), and mechanical durability testing (for flexible and automotive displays). For mini/micro-LED FPCs, additional tests verify current uniformity and heat dissipation efficiency.

- Full-Lifecycle Quality Tracking: Manufacturers establish digital traceability systems to track FPCs from raw material procurement to delivery. This ensures full visibility of production processes and enables rapid localization of any quality issues, minimizing impact on customers.

- Global Regulatory Compliance: They comply with international standards such as IPC-6012/2221 (FPC quality), RoHS/REACH (environmental protection), and industry-specific certifications (UL 8750 for lighting displays, IATF 16949 for automotive). This compliance facilitates customers’ access to global markets.

In conclusion, a professional Display FPC manufacturer is a critical enabler of display technology innovation, leveraging adaptive solutions, scenario-specific customization, and industry collaboration to support the diverse needs of the display ecosystem. As display technologies continue to advance toward higher resolution, flexibility, and intelligence, the role of Display FPC manufacturers in bridging technical gaps and driving market competitiveness will become increasingly prominent. For display brands aiming to lead in the global market, partnering with a versatile and innovative Display FPC manufacturer is a strategic investment in long-term success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB