-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 17. 2025, 10:28:39

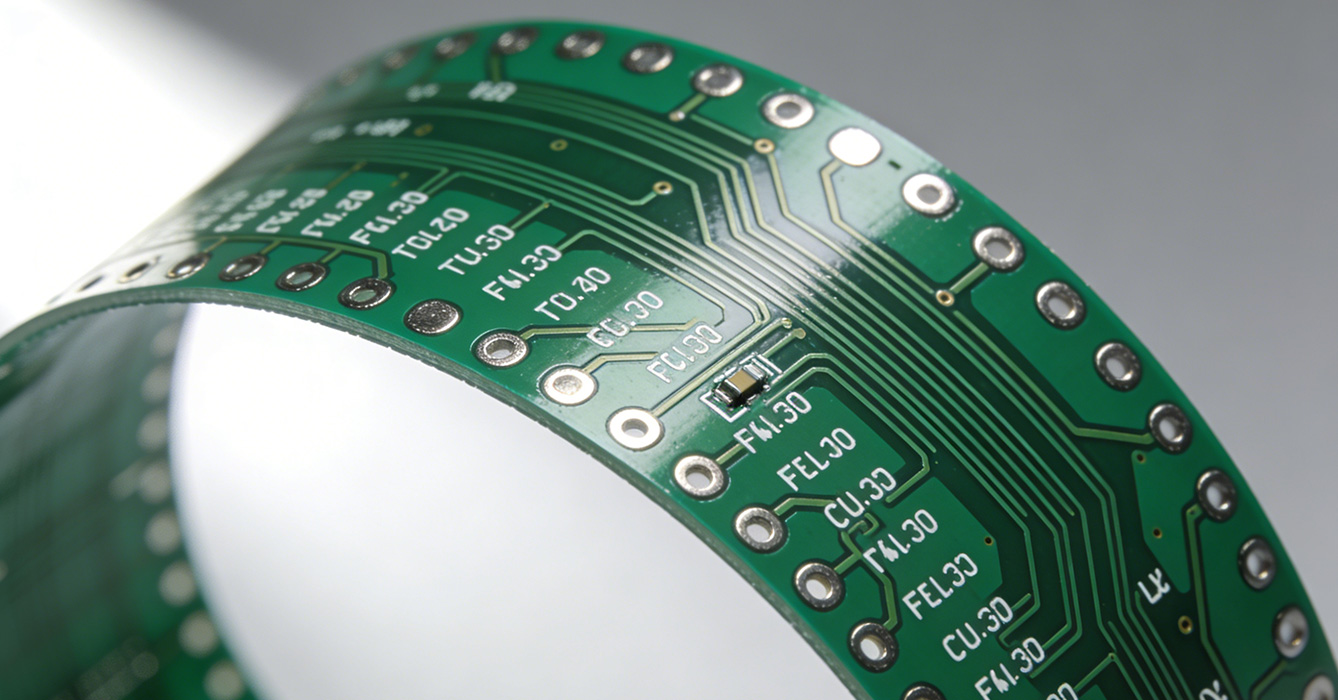

As the global electronics industry shifts toward miniaturization, intelligence, and multi-scenario adaptation, flexible PCB has evolved from a supporting component in consumer electronics to a core enabler of cross-sector innovation. Beyond its inherent advantages of thinness, light weight, and bendability, modern flexible PCB is driving a dual-wheel growth pattern centered on consumer electronics and automotive electronics, while penetrating emerging fields such as AR/VR and industrial control. Unlike rigid PCBs or early flexible circuits, today’s advanced flexible PCB integrates high-performance materials, precision manufacturing, and modular design, meeting the stringent requirements of diverse high-end applications. For electronic manufacturers, grasping the technological evolution and application expansion of flexible PCB is crucial to seizing market opportunities in the era of electronic industry upgrading.

The steady growth of flexible PCB is primarily fueled by the dual impetus of consumer electronics and automotive electronics, where it addresses unique application challenges and enables product innovation:

- Consumer Electronics: Enabling Slim & Foldable Innovations: In consumer electronics such as smartphones, foldable devices, and AR/VR headsets, flexible PCB is a key component for realizing slim designs and complex functions. For foldable smartphones, it provides reliable electrical connections between folded screens and main boards, withstanding tens of thousands of bending cycles without performance degradation. In high-end AR/VR devices, flexible PCB’s lightweight and high-density interconnection capabilities support the integration of multiple sensors and display modules, reducing device weight while ensuring stable signal transmission—critical for enhancing user comfort and immersive experience.

- Automotive Electronics: Powering Electrification & Intelligence: The electrification and intelligence of automobiles have significantly boosted demand for flexible PCB. In new energy vehicles, it is widely used in power battery modules, on-board cameras, and lidar systems. Compared with traditional wire harnesses, flexible PCB enables lightweight vehicle design, improves assembly efficiency, and enhances safety performance by reducing short-circuit risks. For autonomous driving systems, it ensures high-speed data transmission between multiple sensors and control units, withstanding harsh automotive environments such as high temperatures, vibrations, and electromagnetic interference.

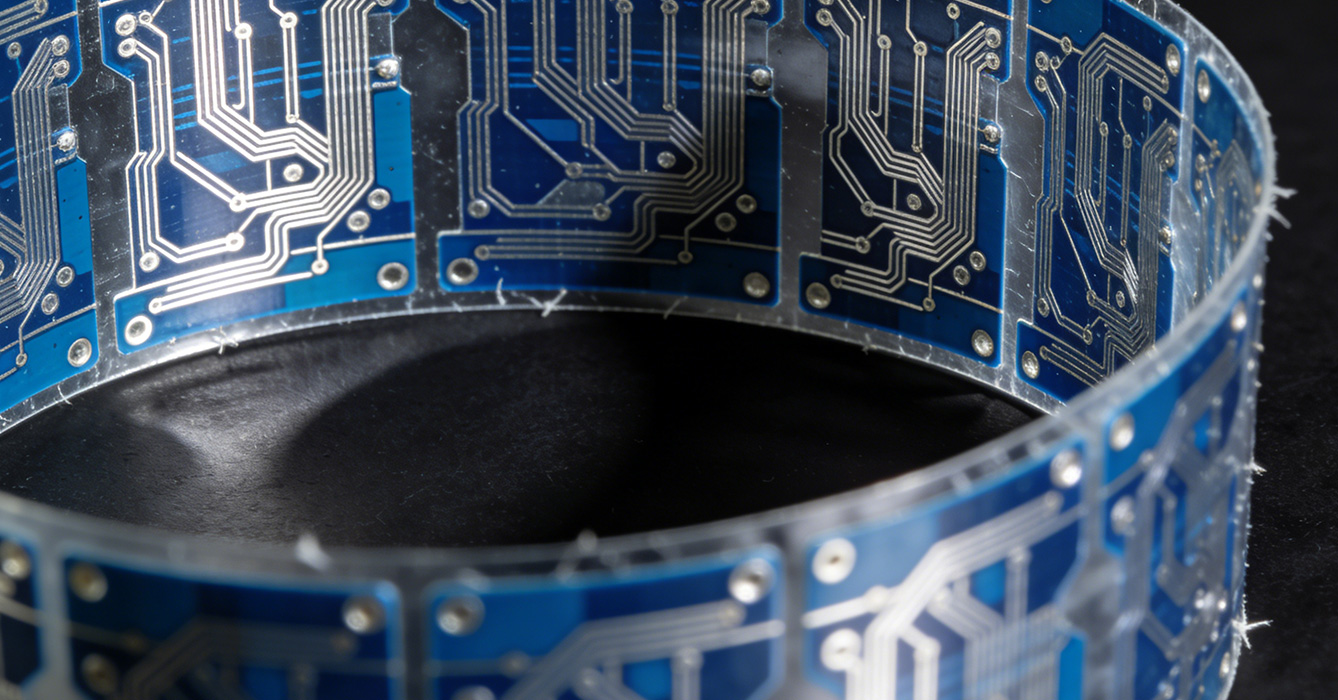

Beyond the dual-wheel drive, flexible PCB is accelerating its penetration into emerging high-value fields, opening up new growth spaces for the electronics industry:

- AR/VR Devices: Supporting Immersive Experience Upgrade: AR/VR devices require compact, lightweight, and high-performance circuit solutions to achieve portability and immersive display. Flexible PCB’s ability to adapt to complex 3D structures allows it to be integrated into the curved surfaces of head-mounted displays, connecting micro-displays, motion sensors, and wireless communication modules. Its low signal attenuation characteristics ensure real-time transmission of high-definition image and motion data, laying a technical foundation for the popularization of AR/VR technology in gaming, education, and industrial training.

- Industrial Control: Enhancing Reliability in Harsh Environments: In industrial control systems such as intelligent manufacturing sensors and industrial robots, flexible PCB is designed to withstand extreme temperatures, humidity, and chemical corrosion. Its flexible nature enables integration into narrow and irregular spaces of industrial equipment, providing stable electrical connections for real-time data collection and control signal transmission. This reliability ensures the continuous operation of industrial systems, improving production efficiency and reducing maintenance costs.

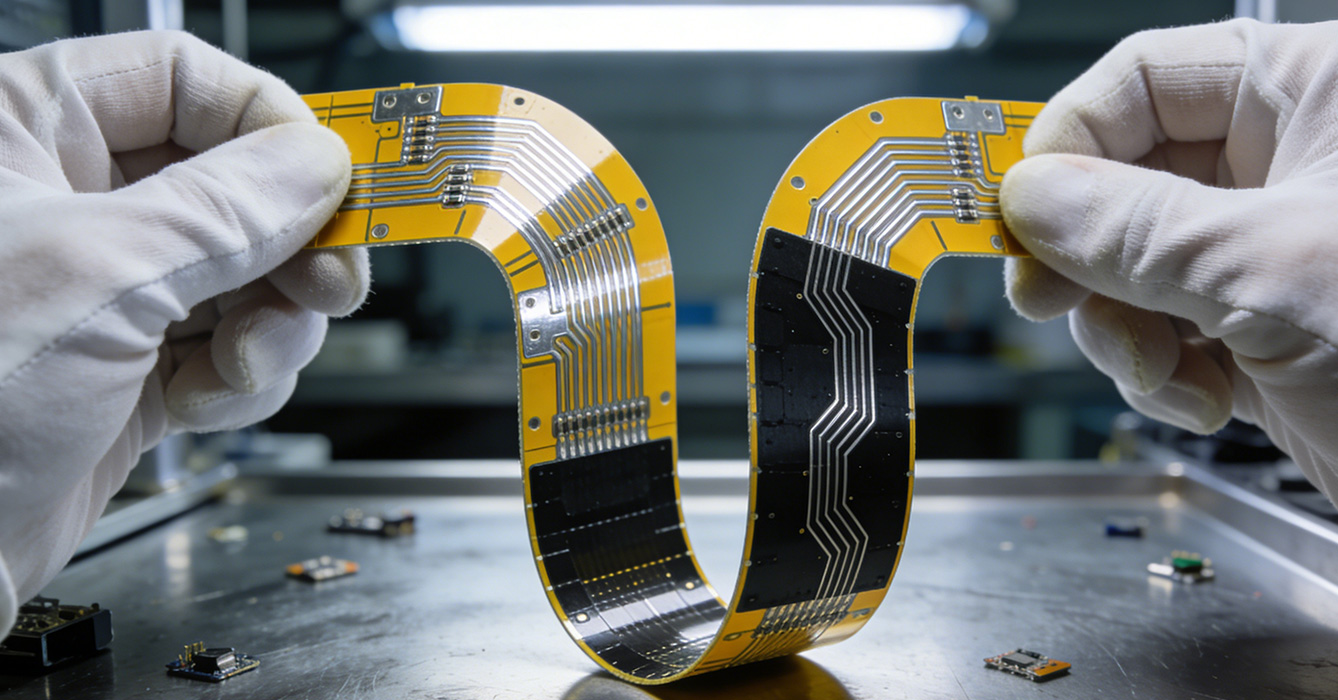

The sustainable development of flexible PCB relies on continuous technological innovation and the evolution of the industrial ecosystem, focusing on high-performance materials and integrated service models:

- High-Performance Material Application: To meet the requirements of high-frequency and high-speed transmission in 5G and automotive radar applications, flexible PCB is increasingly adopting advanced materials such as liquid crystal polymer (LCP) and modified polyimide (MPI). These materials offer excellent dielectric properties and thermal stability, reducing signal loss and ensuring stable performance in high-frequency environments. The development and localization of these high-end materials are also becoming key focuses of the industry, promoting the independent development of the flexible PCB industrial chain.

- Integrated Service Model Innovation: To enhance customer stickiness and improve production efficiency, many flexible PCB manufacturers are extending their service scope to provide one-stop solutions integrating FPC design, manufacturing, and SMT (Surface Mount Technology) assembly. This model reduces the number of cooperative links for downstream manufacturers, shortens product development cycles, and promotes the modularization and integration of electronic products.

The future development of flexible PCB will focus on intelligence integration and sustainable manufacturing to adapt to the evolving needs of the electronic industry:

- Intelligent Manufacturing Upgrade: The integration of AI and big data into flexible PCB production processes will enable real-time monitoring and prediction of manufacturing defects, improving production yield and reducing costs. Automated production lines based on machine vision will further enhance the precision and efficiency of flexible PCB manufacturing.

- Sustainable & Eco-Friendly Development: Driven by global environmental protection requirements, the industry will accelerate the development and application of recyclable flexible PCB materials and low-pollution manufacturing processes. This will reduce the environmental impact of electronic waste and align with the sustainable development goals of the global electronics industry.

- Wider Application Expansion: With technological advancements, flexible PCB will further penetrate into aerospace, medical devices, and smart textiles, expanding its application boundaries and creating new market demands. Its role in enabling lightweight, miniaturized, and intelligent electronic products will become increasingly prominent.

In conclusion, flexible PCB is witnessing a new era of dual-wheel growth and cross-sector expansion, becoming a key driver of innovation in the global electronics industry. Its unique advantages in adaptability, reliability, and integration support the development of consumer electronics, automotive electronics, and emerging fields such as AR/VR. As technology continues to advance and the industrial ecosystem matures, flexible PCB will play an even more vital role in shaping the future of the electronic industry, promoting the upgrading of products and the transformation of the industrial chain.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB