-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 18. 2025, 16:21:42

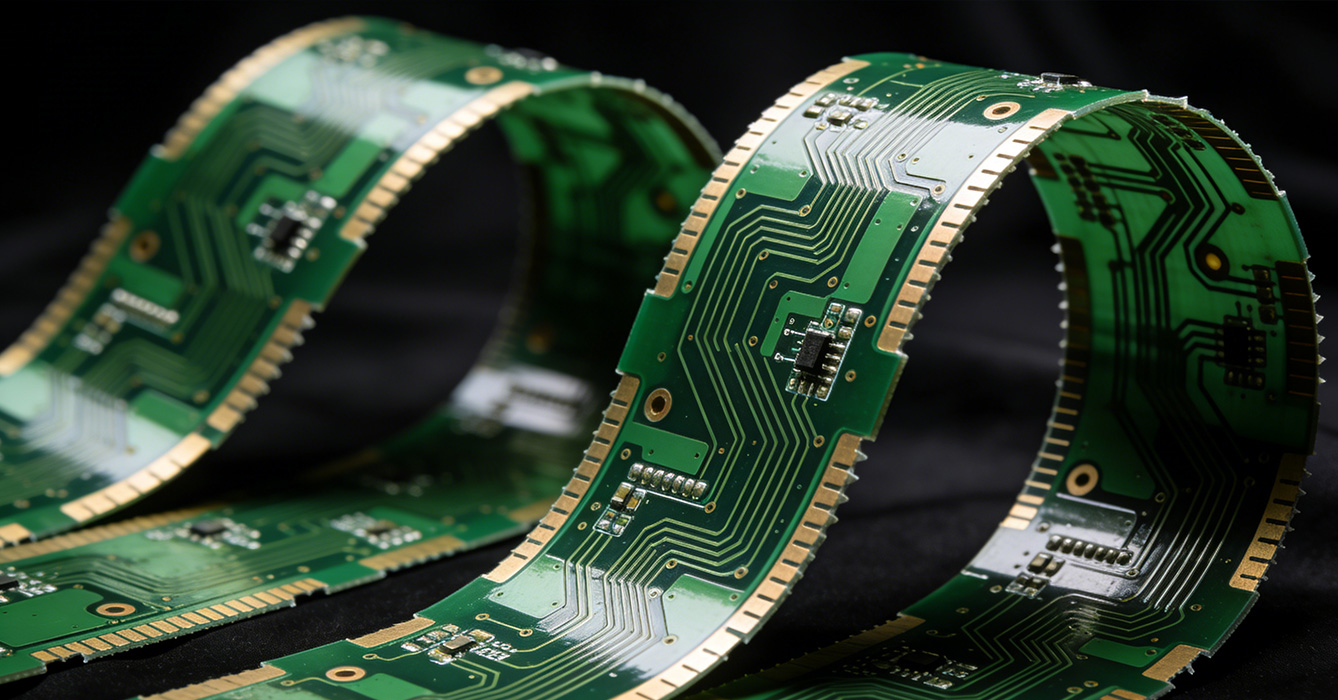

As global environmental regulations tighten and the electronics industry embraces sustainable development, RoHS Certified Flexible PCB Board has become a mandatory requirement for manufacturers targeting international markets. RoHS (Restriction of Hazardous Substances) certification ensures that flexible PCB boards are free from or contain minimal levels of hazardous materials such as lead, cadmium, and mercury, aligning with global green manufacturing standards. Unlike non-certified flexible PCBs, RoHS Certified Flexible PCB Board not only reduces environmental impact but also unlocks access to key markets including the European Union, North America, and Southeast Asia. For electronics manufacturers, adopting RoHS-compliant flexible PCB solutions is no longer just a regulatory obligation but a strategic move to enhance brand credibility and expand global reach.

Achieving RoHS certification for flexible PCB boards requires rigorous control over materials and manufacturing processes, addressing the core restrictions of hazardous substances:

- Hazardous Substance Restriction & Material Substitution: RoHS directives strictly limit the use of six key hazardous substances, with updated RoHS 2.0 extending restrictions to ten substances including phthalates. RoHS Certified Flexible PCB Board replaces traditional lead-based solders with lead-free alternatives such as tin-silver-copper (SAC) alloys. Substrates and adhesives are also optimized—halogen-free polyimide (PI) substrates replace brominated flame-retardant materials, and low-VOC (volatile organic compound) inks are adopted for circuit printing. These material substitutions ensure compliance while maintaining the flexible PCB’s mechanical and electrical performance.

- Process Optimization for Contamination Prevention: Manufacturing processes are redesigned to avoid cross-contamination. Dedicated production lines are established for RoHS-compliant products, separating them from non-compliant production to prevent lead or mercury residue transfer. Advanced soldering technologies such as laser soldering with nitrogen protection reduce the need for flux, minimizing hazardous emissions and residues. Post-production cleaning processes use environmentally friendly solvents, eliminating the use of ozone-depleting substances.

Sustained RoHS compliance for flexible PCB boards relies on comprehensive supply chain management, covering raw material sourcing to final product testing:

- Supplier Qualification & Material Auditing: Manufacturers of RoHS Certified Flexible PCB Board implement strict supplier qualification criteria, requiring raw material suppliers to provide RoHS compliance declarations and third-party test reports. Regular on-site audits of upstream suppliers ensure that substrates, copper foils, and solders consistently meet RoHS limits. This upstream control prevents non-compliant materials from entering the production process.

- End-to-End Testing & Documentation: Rigorous testing protocols are applied throughout production. X-ray fluorescence (XRF) screening is used for rapid detection of hazardous substances in raw materials and semi-finished products, with inductively coupled plasma optical emission spectrometry (ICP-OES) for precise chemical analysis. Comprehensive technical documentation is maintained, including bill of materials (BOM), material safety data sheets (MSDS), and test reports, to support certification audits and market access verification.

RoHS certification is a key enabler for flexible PCB boards to enter global high-value markets, addressing regional regulatory requirements:

- EU & International Market Entry: RoHS compliance is mandatory for electronic products sold in the EU, with non-compliant products facing import bans and penalties. RoHS Certified Flexible PCB Board also meets equivalent standards in other regions, such as China RoHS, Korea RoHS, and California’s Proposition 65. This cross-regional compliance simplifies market access for electronics manufacturers, supporting the global distribution of products such as consumer electronics, automotive components, and medical devices.

- Competitive Advantage & Brand Credibility: In an increasingly eco-conscious market, RoHS certification enhances brand reputation by demonstrating a commitment to environmental responsibility. Manufacturers using RoHS Certified Flexible PCB Board are more likely to secure partnerships with global brands prioritizing sustainability. Additionally, compliance reduces the risk of regulatory fines and product recalls, ensuring business continuity in dynamic international markets.

The development of RoHS Certified Flexible PCB Board is evolving toward stricter compliance standards and enhanced environmental sustainability:

- Adaptation to Evolving Regulatory Standards: As RoHS directives continue to expand (e.g., adding new restricted substances), manufacturers are investing in R&D to develop next-generation compliant materials. This includes bio-based polyimide substrates and recyclable conductive layers, further reducing the environmental footprint of flexible PCB boards.

- Intelligent Compliance Monitoring: AI-powered testing and monitoring systems are being integrated into production processes, enabling real-time detection of hazardous substance risks. This improves testing efficiency, reduces costs, and ensures consistent compliance across large-scale production runs.

- Synergy with Circular Economy Goals: RoHS Certified Flexible PCB Board is increasingly designed for recyclability, supporting the circular economy in the electronics industry. Advanced disassembly technologies and material recovery processes are being developed to maximize the reuse of compliant materials, reducing electronic waste and resource consumption.

In conclusion, RoHS Certified Flexible PCB Board is a critical component for electronics manufacturers navigating global environmental regulations and sustainable development goals. Its compliance-focused design, supported by rigorous material substitution, supply chain management, and testing protocols, enables market access and enhances competitive advantage. As regulatory standards tighten and sustainability becomes a core business imperative, the role of RoHS Certified Flexible PCB Board will continue to grow, driving innovation in green electronics manufacturing and supporting a more sustainable global supply chain.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB