-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 12. 2025, 11:35:05

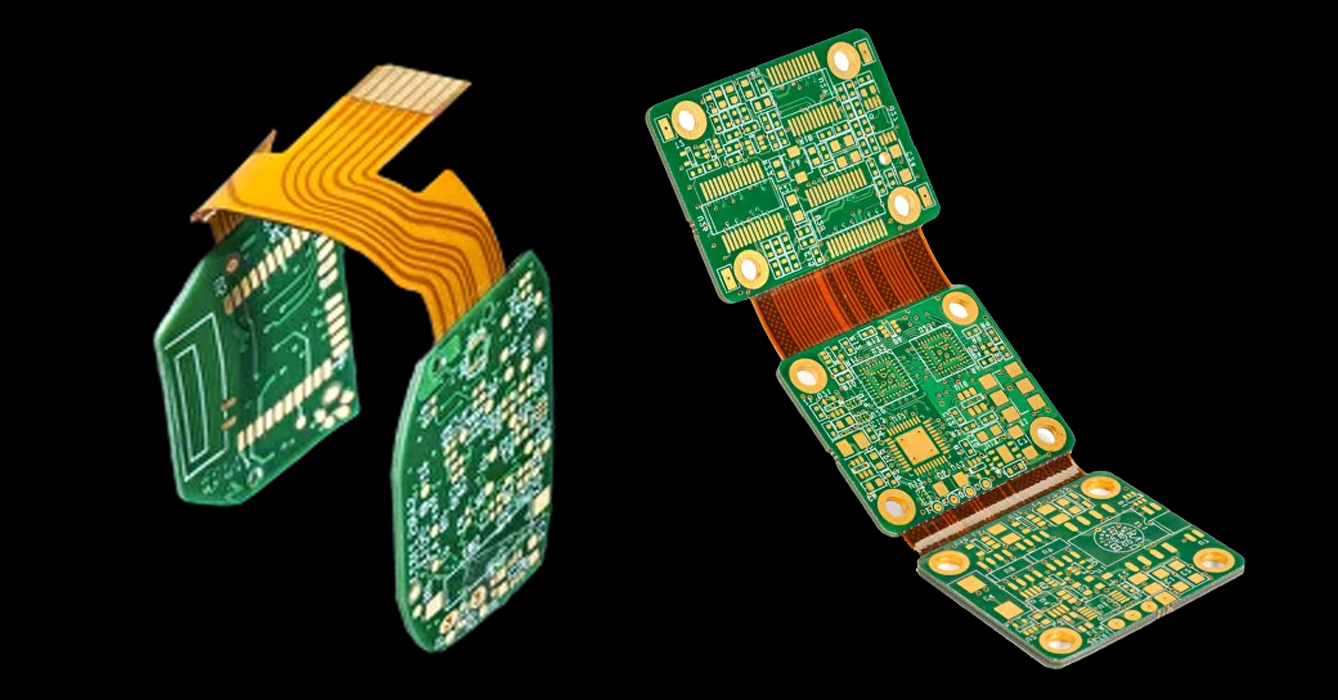

As the electronics industry marches toward intelligence, miniaturization, and flexibility, flexible PCB (Flexible Printed Circuit) has evolved from a supporting component to a core enabler of technological innovation. Its unique advantages—flexibility, lightweight, high integration density, and adaptability to irregular form factors—make it an indispensable foundation for integrating emerging technologies such as AIoT (Artificial Intelligence of Things), flexible electronics, and advanced semiconductor packaging. Unlike traditional rigid PCBs, flexible PCB breaks through the physical constraints of electronic device design, enabling the development of innovative products ranging from wearable smart devices to flexible displays and intelligent automotive systems. For electronics manufacturers pursuing technological differentiation, mastering the application and innovation potential of flexible PCB is key to seizing the opportunities of the new technological revolution.

Flexible PCB serves as a critical bridge for the integration of multiple emerging technologies, driving the upgrading of electronic products and the expansion of application scenarios:

- Integration with AIoT Ecosystem: In the AIoT era, a large number of distributed sensors and intelligent terminals require compact, low-power, and reliable connection solutions. Flexible PCB, with its ultra-thin and lightweight characteristics, enables seamless integration of sensors, microcontrollers, and wireless communication modules. It supports stable data transmission and power supply in small-sized intelligent devices (such as smart sensors, wearable health monitors), laying the foundation for the interconnection of everything in the AIoT ecosystem.

- Synergy with Flexible Electronics Technology: The combination of flexible PCB and flexible electronics (such as flexible OLEDs, flexible solar cells) has spawned a new generation of flexible electronic products. Flexible PCB provides a flexible circuit carrier for these devices, realizing the integration of display, energy supply, and control functions on a single flexible substrate. For example, flexible foldable smartphones rely on high-performance flexible PCB to achieve stable signal transmission between folded screen modules, ensuring smooth user experience.

- Adaptation to Advanced Semiconductor Packaging: With the development of semiconductor technology toward high integration and miniaturization, advanced packaging technologies such as Chip-on-Flex (COF) and Chip-in-Flex (CIF) have become mainstream. Flexible PCB, as the core carrier of these packaging technologies, enables direct integration of chips on flexible substrates, reducing the size of electronic components and improving signal transmission efficiency. This adaptation is crucial for the development of high-performance microelectronic devices such as ultra-thin tablets and miniature medical sensors.

The continuous evolution of materials and processes is the key to improving the performance of flexible PCB and adapting to emerging application requirements:

- High-Performance Material Innovation: To meet the demands of harsh application environments (such as high temperature, high humidity, and strong corrosion), the industry is developing new flexible substrate materials with higher thermal stability and chemical resistance, such as modified polyimide and liquid crystal polymer (LCP). LCP-based flexible PCB, in particular, has excellent high-frequency signal transmission performance, making it an ideal choice for 5G/6G communication devices and automotive radar systems.

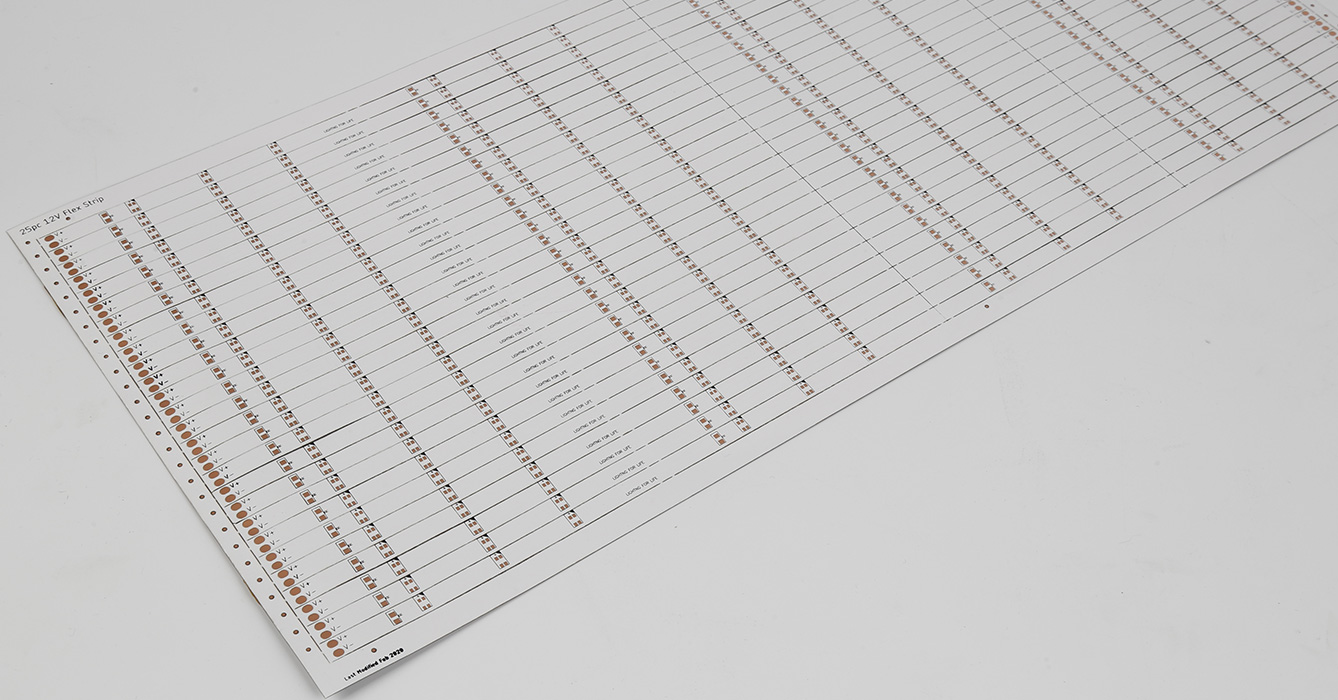

- Precision Manufacturing Process Upgrade: The adoption of advanced manufacturing processes such as laser direct imaging (LDI) and semi-additive process (SAP) has improved the circuit precision and integration density of flexible PCB. LDI technology enables the production of ultra-fine circuit lines (below 10μm), while SAP reduces material waste and improves the reliability of circuit connections. These process upgrades support the miniaturization and high-performance development of flexible PCB.

- Multi-Functional Coating Technology: The application of multi-functional coatings (such as anti-static, anti-corrosion, and hydrophobic coatings) enhances the environmental adaptability of flexible PCB. For example, anti-static coatings prevent electrostatic damage to sensitive electronic components in flexible PCB, while hydrophobic coatings ensure the normal operation of flexible PCB in humid environments such as marine and medical devices.

Flexible PCB has developed targeted solutions for the emerging needs of different industries, promoting industrial upgrading:

- Wearable & Consumer Electronics: In wearable devices (smartwatches, fitness bracelets), flexible PCB is designed into ultra-thin and bendable structures to fit the curved surface of the human body. It integrates sensor circuits, power management circuits, and wireless communication circuits, realizing multi-functional integration while ensuring comfort. In consumer electronics such as foldable laptops, flexible PCB enables the folding function of the device through high-flex endurance design.

- Intelligent Automotive Electronics: With the development of electric vehicles and autonomous driving, the demand for flexible PCB in automotive electronics is increasing. It is used in in-vehicle displays, steering wheel control modules, and battery management systems (BMS), providing high-reliability circuit connections that can withstand vehicle vibration, high temperature, and electromagnetic interference. Flexible PCB also helps to reduce the weight of automotive electronic systems, improving energy efficiency.

- Advanced Medical Devices: In advanced medical devices (such as minimally invasive surgical instruments, implantable pacemakers), flexible PCB is used to realize ultra-miniaturization and high reliability of the device. It can be designed into complex shapes to fit the internal structure of the human body, and uses biocompatible materials to ensure safety. The stable signal transmission performance of flexible PCB is crucial for the accurate operation of medical devices.

The future development of flexible PCB focuses on breaking through technical bottlenecks and building a more comprehensive innovation ecosystem:

- Stretchable PCB Technology: R&D of stretchable PCB with elastic characteristics is underway, which can adapt to dynamic deformation scenarios such as smart clothing and soft robots. This technology relies on new stretchable conductive materials and structural designs, opening up new application fields for flexible electronics.

- Green & Sustainable Development: The industry is accelerating the development of environmentally friendly flexible PCB, using recyclable materials and low-pollution production processes. This not only meets global environmental protection requirements but also aligns with the sustainable development strategies of electronics manufacturers.

- Standardization & Industrial Collaboration: Establishing unified technical standards for flexible PCB is crucial for promoting industry development. Cross-industry collaboration between flexible PCB manufacturers, semiconductor companies, and end-device manufacturers will accelerate the iteration of technologies and the popularization of applications.

In conclusion, flexible PCB is at the core of the integration of emerging electronic technologies, driving the innovation and upgrading of electronics industry. Its application boundaries are constantly expanding with the evolution of materials, processes, and application scenarios. As the demand for intelligent, flexible, and miniaturized electronic products grows, the strategic value of flexible PCB will become increasingly prominent. For enterprises aiming to lead technological innovation, in-depth exploration of the potential of flexible PCB and active layout of related R&D will be the key to gaining competitive advantages in the future market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB