-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 05. 2025, 12:41:24

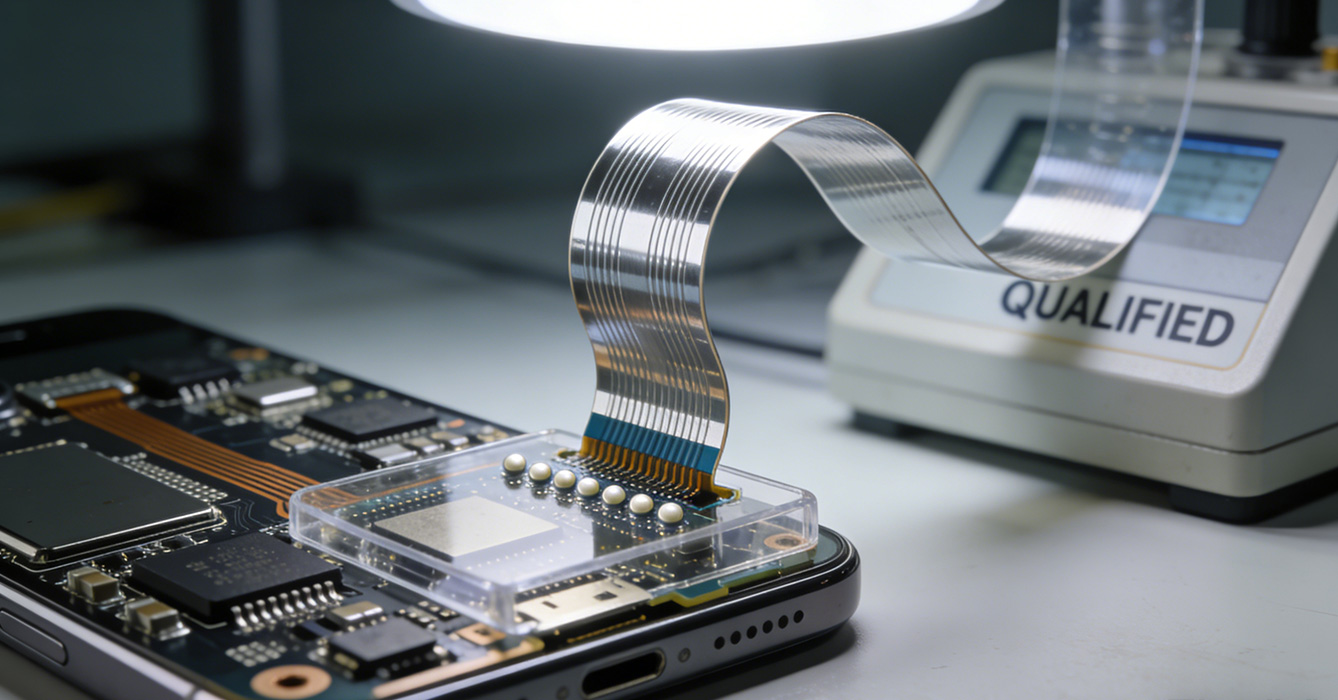

As smartphone design evolves beyond traditional rigid forms toward foldable, rollable, and slider configurations, a Flexible Smartphone FPC Manufacturer has become a core enabler of this morphological innovation. Specializing in flexible printed circuits (FPCs) engineered for the dynamic operating demands of modern smartphones, these manufacturers go beyond basic flexibility—they tailor solutions to balance mechanical adaptability, signal stability, and long-term durability. Unlike generic FPC manufacturers, a Flexible Smartphone FPC Manufacturer deeply understands the unique stressors of flexible mobile devices (e.g., repeated folding, dynamic component movement) and the industry’s pursuit of versatile user experiences. For smartphone brands aiming to differentiate in the competitive market through innovative form factors, partnering with a professional Flexible Smartphone FPC Manufacturer is a pivotal step in turning bold design concepts into reliable, market-ready products.

The competitive edge of a top Flexible Smartphone FPC Manufacturer lies in its ability to adapt flexible FPC technology to support the diverse morphological innovations of smartphones:

- Form-Factor Versatility: Leading manufacturers develop flexible FPCs tailored for various smartphone designs, including foldable (clamshell/foldable), rollable, and slider models. For foldable devices, they optimize FPCs for narrow fold radii and millions of bending cycles; for rollable phones, they create ultra-flexible FPCs that can extend and retract smoothly without signal interruption. This versatility allows brands to explore a wide range of innovative form factors while ensuring core functionality remains intact.

- Dynamic Stress Resilience: Flexible smartphones face continuous mechanical stress from daily use (folding, sliding) and environmental factors (temperature fluctuations). Flexible Smartphone FPC Manufacturers address this by selecting high-flex endurance materials (e.g., enhanced polyimide films) and optimizing circuit routing to reduce stress concentration at fold points. They also integrate reinforcement structures at key connection areas, ensuring FPCs maintain mechanical and electrical stability even under prolonged dynamic stress.

- Integrated Function Compatibility: Modern smartphones require seamless integration of multiple high-performance functions (5G, high-res cameras, wireless charging) into flexible form factors. Manufacturers design flexible FPCs that can accommodate dense component layouts without compromising flexibility, leveraging ultra-fine routing technologies and low-loss materials to ensure stable signal transmission for high-frequency and high-speed applications.

Professional Flexible Smartphone FPC Manufacturers rely on specialized technical capabilities to overcome the unique challenges of flexible mobile device applications:

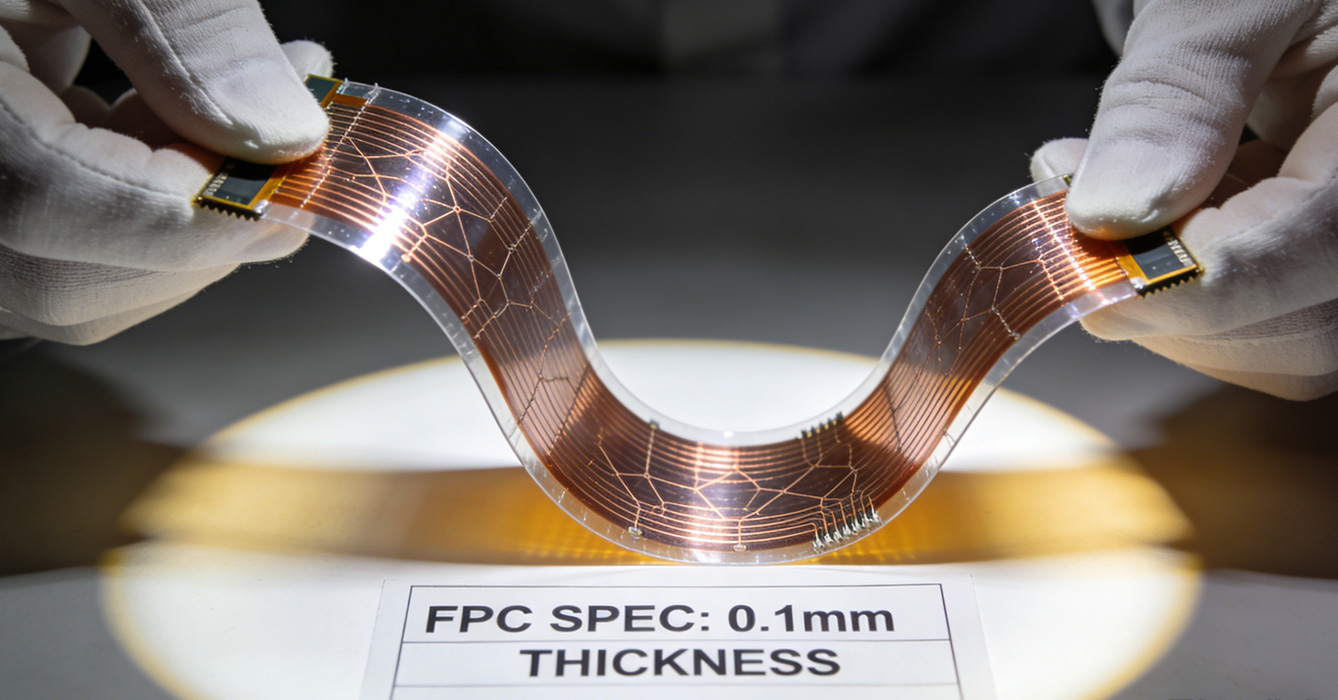

- Flex-Optimized Material Engineering: Beyond standard polyimides, manufacturers collaborate with material suppliers to develop custom flexible substrates with enhanced properties—such as improved tear resistance, thermal stability, and bend endurance. They also optimize adhesive and coverlay materials to ensure compatibility with flexible movements, preventing delamination or material degradation over time.

- Precision Dynamic Routing & Layout: Using advanced EDA (Electronic Design Automation) tools, engineers design FPC layouts that minimize stress during bending and sliding. This includes curved routing at fold areas, staggered component placement to avoid stress concentration, and modular design to separate rigid and flexible segments. These optimizations ensure FPCs can adapt to dynamic movements without damaging circuits or connectors.

- Dynamic Reliability Testing & Validation: Unlike static testing for rigid FPCs, manufacturers implement rigorous dynamic testing protocols to simulate real-world use. Key tests include bend endurance cycling (up to 1 million+ cycles), torsion testing, and thermal-mechanical fatigue testing. These tests validate the FPC’s performance under the repeated dynamic stress typical of flexible smartphones, ensuring long-term reliability.

Flexible Smartphone FPC Manufacturers play a central role in the smartphone innovation ecosystem, collaborating with multiple stakeholders to accelerate technological advancement:

- Brand Co-Design Partnerships: Manufacturers participate in the early design phase of flexible smartphones, providing DFM (Design for Manufacturability) insights specific to flexible FPCs. They work closely with brand engineers to align FPC design with overall device morphology, ensuring that flexibility, functionality, and assembly feasibility are balanced from the conceptual stage.

- Material Supplier Synergy: To push the boundaries of flexible FPC performance, manufacturers collaborate with material suppliers to develop next-generation flexible substrates, adhesives, and conductive materials. This synergy drives innovations such as thinner, more durable substrates and low-loss materials for 5G flexible devices.

- Component Manufacturer Alignment: They coordinate with component suppliers (e.g., display, sensor, battery manufacturers) to ensure flexible FPCs are compatible with the latest miniaturized and flexible components. This alignment enables seamless integration of components into flexible smartphone designs, supporting multi-functional innovation.

Given the dynamic nature of flexible smartphones, Flexible Smartphone FPC Manufacturers adhere to strict quality and compliance standards to ensure product reliability:

- Comprehensive Quality Control: Manufacturers implement full-lifecycle quality control, covering raw material inspection, in-process testing (e.g., circuit continuity, bend stress testing), and final product validation. Advanced inspection technologies, such as 3D AOI (Automated Optical Inspection) and X-ray testing, detect micro-defects (e.g., micro-cracks, poor soldering) that could compromise flexible performance.

- Industry-Specific Compliance: They comply with global smartphone industry standards, including IPC-6012/2221 (for FPC quality), RoHS/REACH (environmental protection), and IATF 16949 (for automotive-grade quality, relevant for high-reliability smartphone components). Additionally, they meet brand-specific quality requirements for flexible devices, such as enhanced bend endurance and signal integrity standards.

In conclusion, a Flexible Smartphone FPC Manufacturer is a key driver of smartphone morphological innovation, enabling the transition from rigid to versatile flexible forms through specialized technical capabilities and ecosystem collaboration. By focusing on flexible material engineering, dynamic reliability, and integrated function compatibility, these manufacturers help brands deliver innovative, durable flexible smartphones that resonate with consumers. As the demand for more versatile and user-centric mobile devices continues to grow, the strategic value of a professional Flexible Smartphone FPC Manufacturer will become increasingly indispensable in the global smartphone industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB