-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 05. 2025, 12:39:28

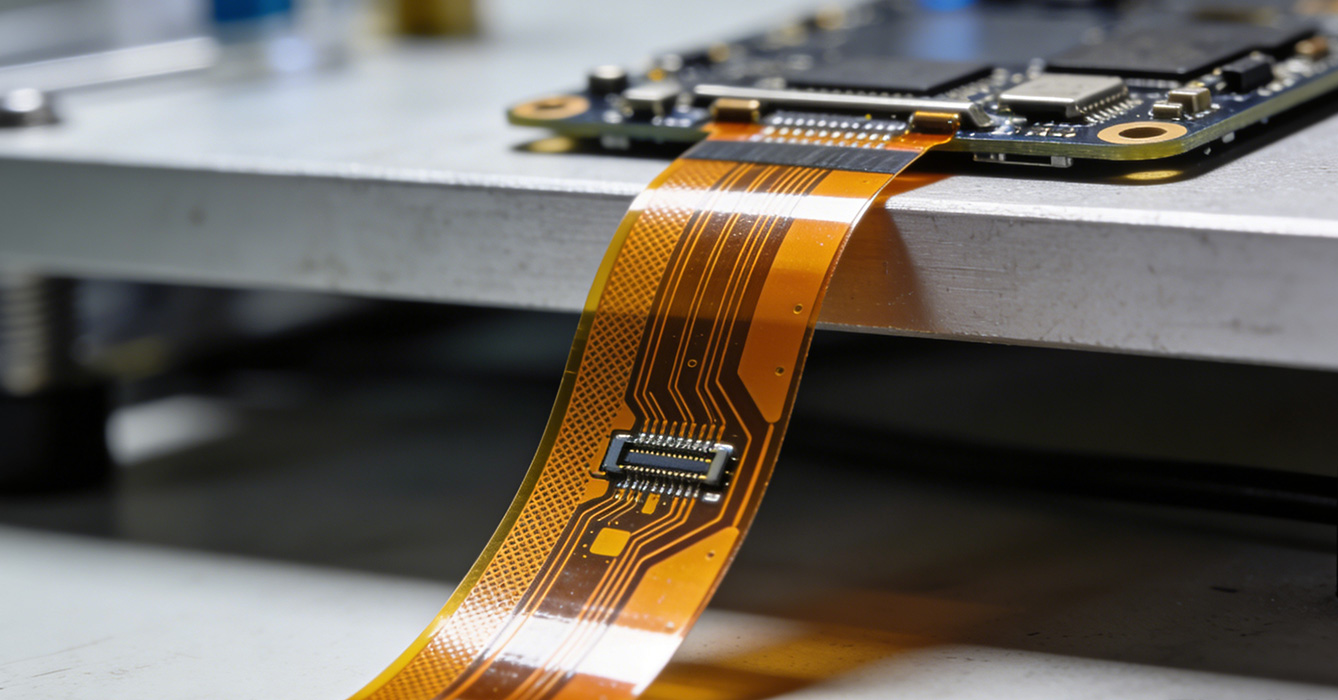

In the fiercely competitive smartphone market, where slim form factors, multi-functional integration, and user experience innovation are core battlegrounds, an Ultra-Thin Smartphone FPC Supplier has evolved from a component provider to a critical strategic collaborator. Specializing in ultra-thin flexible printed circuits (FPCs) tailored for the unique demands of modern smartphones, these suppliers go beyond basic manufacturing—they co-innovate with smartphone brands to solve design bottlenecks, optimize performance, and accelerate product launch cycles. Unlike general FPC suppliers, an Ultra-Thin Smartphone FPC Supplier deeply understands the smartphone industry’s fast iteration rhythm and strict quality standards, focusing on the synergy between ultra-thin design, functional integration, and long-term reliability. For brands striving to lead in the premium and foldable smartphone segments, partnering with such a supplier is a decisive factor in translating innovative concepts into market-winning products.

The core value of a top Ultra-Thin Smartphone FPC Supplier lies in its ability to integrate into the smartphone brand’s innovation chain through in-depth collaboration:

- Early-Stage Design Co-Creation: Leading suppliers participate in the smartphone’s conceptual design phase, providing professional DFM (Design for Manufacturability) insights tailored to ultra-thin FPCs. They collaborate with brand engineers to optimize component layout, FPC routing, and stackup design, ensuring that the ultra-thin FPC can fit within the narrow space of slim smartphone bodies while supporting all high-performance functions (e.g., 5G, high-resolution cameras, fast charging). This early collaboration avoids design rework and shortens development cycles.

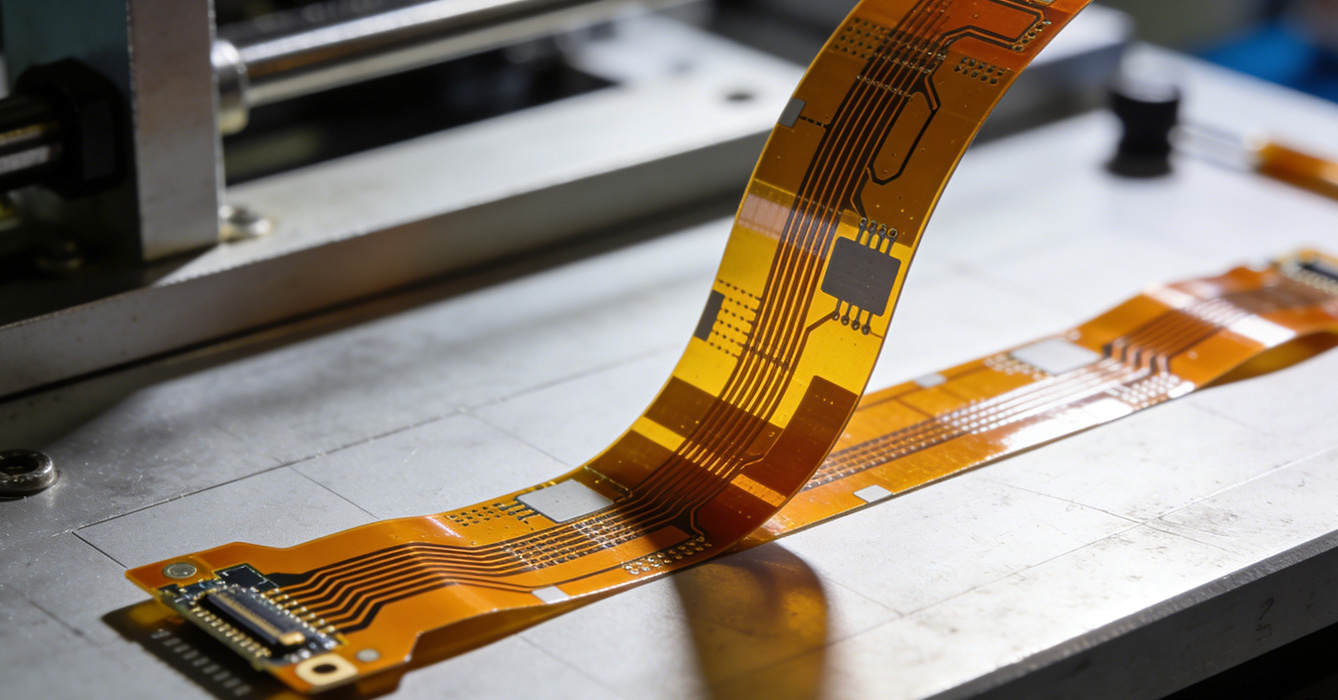

- Rapid Prototyping & Iteration Support: Given the smartphone industry’s 6–12 month product iteration cycle, Ultra-Thin Smartphone FPC Suppliers offer high-efficiency rapid prototyping services. Leveraging digital design tools and flexible production lines, they can deliver functional ultra-thin FPC prototypes within 3–7 days, enabling brands to quickly verify design feasibility and iterate on performance improvements. This rapid response capability is critical for brands to seize market opportunities.

- Seamless Mass Production Transition: After prototype validation, suppliers ensure a smooth transition to mass production by leveraging mature production processes and strict quality control systems. They adapt to the high-volume demands of smartphone manufacturing (millions of units per model) while maintaining consistent quality of ultra-thin FPCs. Additionally, they provide flexible production capacity adjustment to match the brand’s market launch rhythm and inventory management needs.

Leading Ultra-Thin Smartphone FPC Suppliers drive product advancement through continuous technological innovation, focusing on material, process, and design breakthroughs:

- High-Performance Material Synergy: To balance ultra-thinness and reliability, suppliers collaborate with material manufacturers to develop custom substrate materials—such as high-strength, low-loss polyimides with enhanced flex endurance and thermal stability. These materials address the core pain points of ultra-thin FPCs, such as structural fragility and signal loss under high-frequency operation, while adapting to the thermal stress generated by fast charging and high-performance chips.

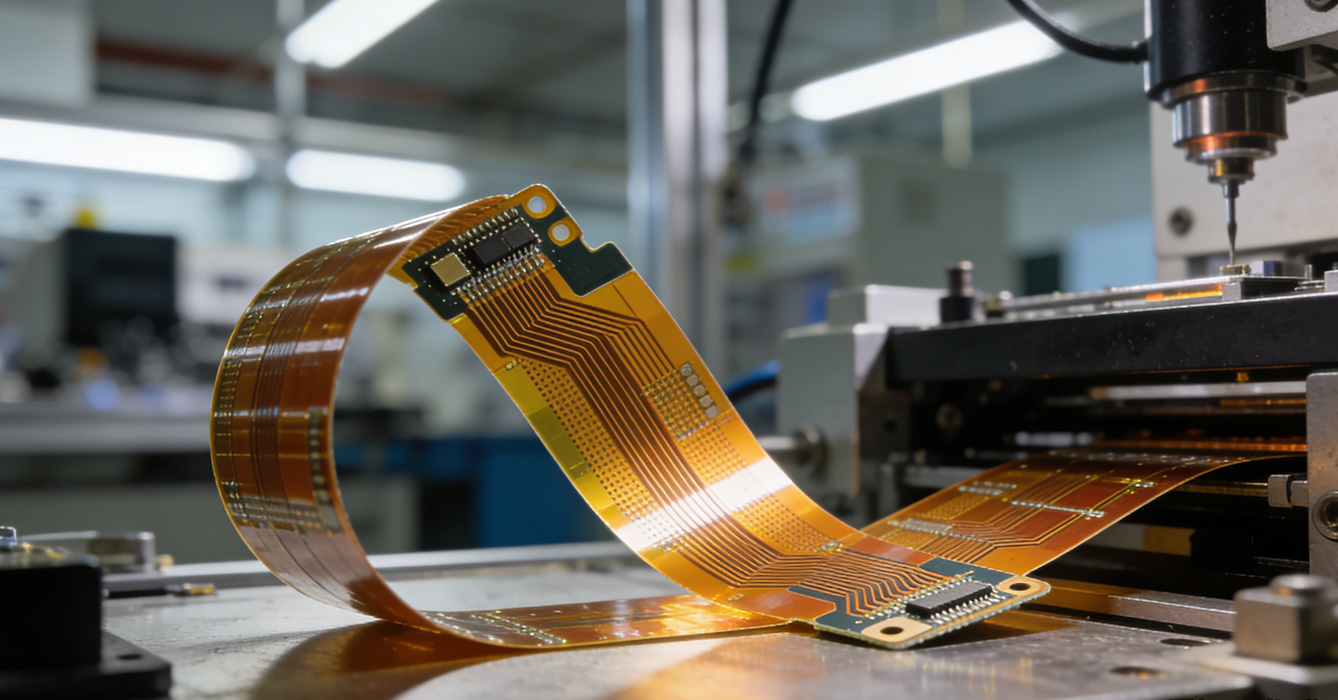

- Modular & Integrated FPC Design: Suppliers innovate modular FPC solutions, integrating multiple functions (e.g., display driver, sensor connection, charging circuit) into a single ultra-thin FPC. This modular design reduces the number of FPC components in the smartphone, saving space and simplifying assembly. For foldable smartphones, they develop integrated hinge FPC modules with optimized fold-area structures, supporting millions of bending cycles without performance degradation.

- Smart Manufacturing & Precision Control: Advanced suppliers adopt smart manufacturing technologies, such as digital twin simulation and AI-driven process monitoring, to optimize ultra-thin FPC production. They use high-precision laser processing equipment to achieve ultra-fine circuit patterns (below 30μm line width/space) and implement 3D AOI (Automated Optical Inspection) systems to detect micro-defects (e.g., micro-cracks, uneven lamination) that are invisible to traditional inspection methods.

Ultra-Thin Smartphone FPC Suppliers adhere to rigorous quality and compliance standards to ensure product reliability and brand reputation:

- Comprehensive Quality Control System: Suppliers implement a full-lifecycle quality control process, covering raw material incoming inspection, in-process testing, and final product validation. Key tests include flex endurance testing (simulating daily use and foldable scenarios), thermal cycling testing (adapting to extreme temperature changes), and signal integrity testing (ensuring stable 5G and high-speed data transmission). Strict batch traceability systems track every production link, enabling rapid defect localization and resolution.

- Industry-Specific Compliance Certification: To meet global smartphone market requirements, suppliers comply with strict industry standards and certifications, such as IPC-6012/2221 (for FPC quality), RoHS/REACH (for environmental protection), and ISO 9001 (for quality management). For premium brands, they also meet additional custom quality standards, such as enhanced reliability testing for flagship models.

Forward-looking Ultra-Thin Smartphone FPC Suppliers proactively adapt to emerging industry trends, laying the groundwork for next-gen smartphone innovation:

- Foldable & Rollable Display Evolution: Suppliers are developing ultra-thin FPCs with higher flex endurance and smaller fold radii to support the next generation of foldable and rollable smartphones. They optimize material selection and fold-area design to reduce FPC thickness further while enhancing durability.

- AIoT & Multi-Sensor Integration: As smartphones become the core of the IoT ecosystem, suppliers are innovating ultra-thin FPCs that support seamless integration of multiple sensors (e.g., biometric, environmental, motion sensors). These FPCs ensure stable signal transmission between sensors and the mainboard, enabling advanced features such as intelligent health monitoring and context-aware services.

- Green & Sustainable Manufacturing: In response to global sustainability trends, suppliers are adopting eco-friendly materials and energy-efficient production processes. They develop recyclable ultra-thin FPC substrates and reduce waste generation during manufacturing, helping smartphone brands achieve their carbon neutrality goals.

In conclusion, an Ultra-Thin Smartphone FPC Supplier is a key enabler of smartphone innovation, driving progress through strategic collaboration, technological innovation, and strict quality control. By integrating into the brand’s innovation chain, co-creating solutions, and adapting to future trends, these suppliers help brands gain a competitive edge in the fast-paced mobile market. As smartphones continue to evolve toward slimmer, more flexible, and more intelligent forms, the strategic value of a professional Ultra-Thin Smartphone FPC Supplier will become increasingly prominent.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB