-

- PCB TYPE

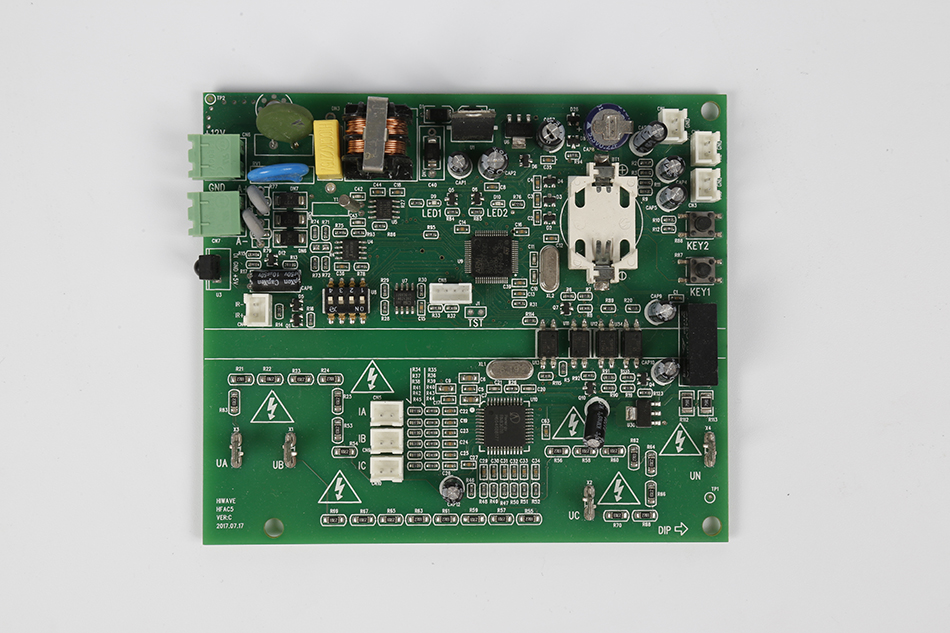

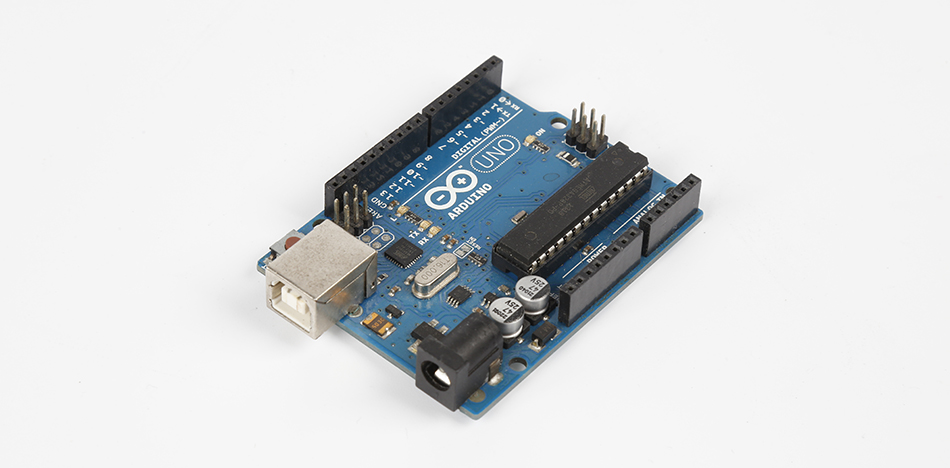

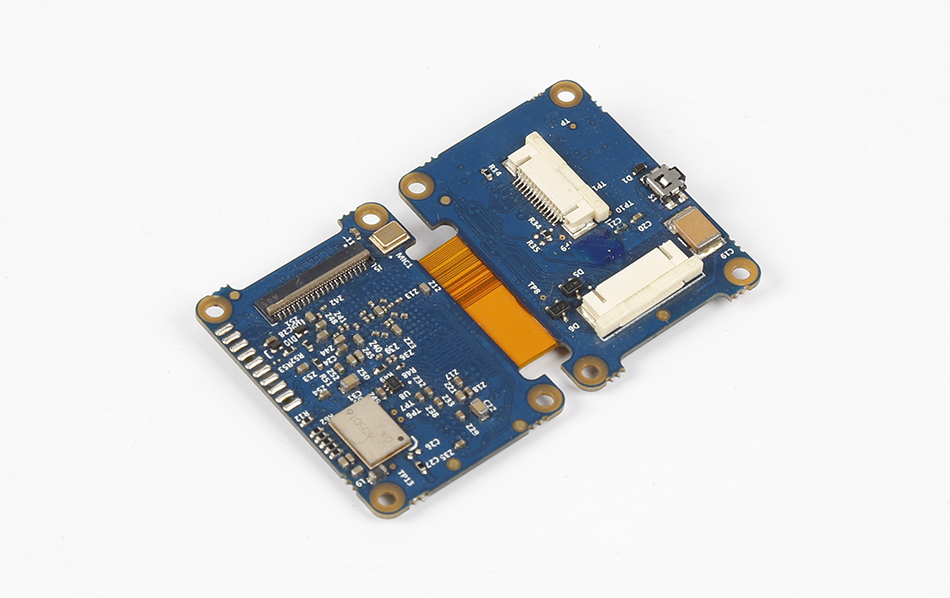

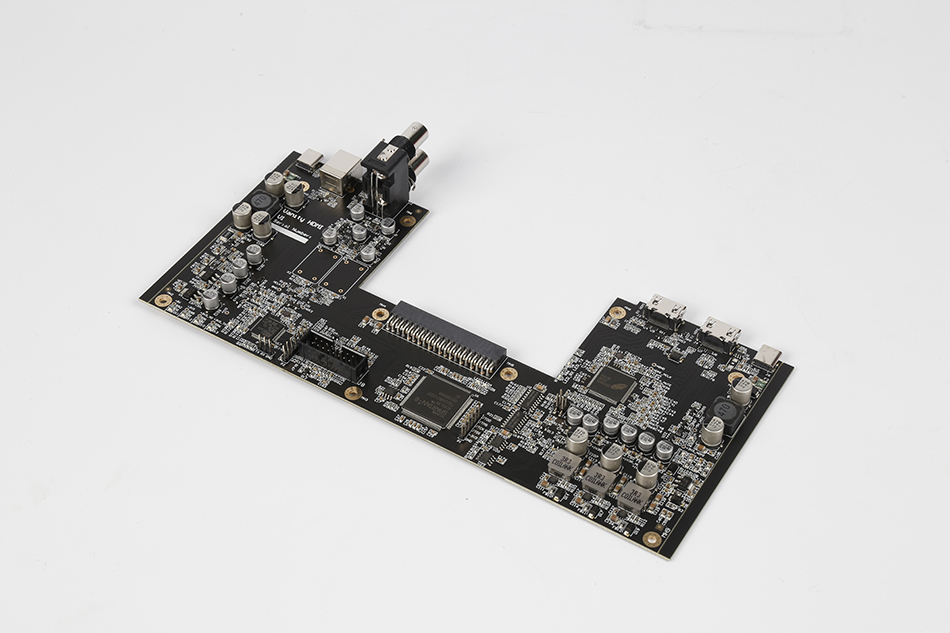

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 04. 2025, 10:49:45

Full-Service Turnkey PCB Assembly represents a comprehensive, end-to-end solution that simplifies electronics manufacturing by integrating every stage of PCB production—from design validation and component sourcing to assembly, testing, and final delivery. Unlike traditional PCB assembly services that require clients to manage fragmented processes (e.g., sourcing parts, coordinating with multiple vendors), turnkey solutions place full responsibility in the hands of a single provider. This approach is a game-changer for businesses of all sizes, from startups with limited engineering resources to multinational corporations seeking to optimize efficiency. By offering a “one-stop shop” experience, full-service turnkey PCB assembly reduces lead times, minimizes supply chain risks, and ensures alignment with industry standards—all while letting clients focus on core innovation rather than production logistics.

The value of turnkey solutions lies in their holistic coverage of the production lifecycle, with each phase designed to seamlessly integrate with the next:

Turnkey providers start with proactive design collaboration, reviewing client schematics and PCB layouts to ensure manufacturability. Engineers offer insights to optimize component placement, reduce material waste, and address potential bottlenecks (e.g., signal interference, thermal issues) before production begins. This early engagement eliminates costly reworks and ensures the design aligns with both technical requirements and production capabilities.

A key differentiator of turnkey assembly is full component sourcing responsibility. Providers leverage established relationships with global suppliers to secure high-quality parts at competitive prices, while managing inventory, verifying component authenticity, and mitigating shortages through dual-sourcing strategies. This eliminates the burden of component procurement for clients and reduces risks associated with counterfeit parts or supply chain disruptions.

Turnkey services handle all assembly needs, from surface-mount technology (SMT) for miniaturized components to through-hole technology (THT) for high-power applications. Advanced capabilities—such as BGA, QFP, and micro-assembly—are seamlessly integrated, with automated pick-and-place machines and precision reflow soldering ensuring consistency. Hybrid assembly (combining SMT and THT) is also supported to meet diverse design requirements.

Quality is embedded throughout the turnkey process, with multi-layered testing protocols:

- Solder paste inspection (SPI) and automated optical inspection (AOI) catch surface defects during assembly.

- In-circuit testing (ICT) and functional testing validate electrical performance against specifications.

- X-ray inspection verifies hidden connections (e.g., BGA solder joints) for mission-critical applications.

All processes adhere to standards like IPC-A-610, ISO 9001, and industry-specific certifications (e.g., ISO 13485 for medical devices).

Post-assembly, turnkey providers handle cleaning (to remove flux residues), conformal coating (for environmental protection), and packaging. They also manage logistics—including domestic and international shipping, customs clearance, and just-in-time (JIT) delivery—to ensure on-time arrival at the client’s facility or end destination.

Full-service turnkey PCB assembly adapts to the unique needs of various sectors, delivering tailored value:

For resource-constrained businesses, turnkey solutions eliminate the need to build in-house supply chains or hire specialized production teams. This accelerates time-to-market and reduces upfront investment, letting startups focus on product development and market penetration.

Medical electronics demand strict compliance and traceability. Turnkey providers manage documentation (e.g., material certificates, test reports) and adhere to ISO 13485 and FDA requirements, ensuring assemblies meet sterility, reliability, and biocompatibility standards.

Industrial devices require ruggedized assemblies that withstand harsh conditions. Turnkey services integrate conformal coating, vibration-resistant mounting, and thermal management, while managing the sourcing of industrial-grade components to ensure long-term durability.

Fast-paced consumer tech markets benefit from turnkey’s streamlined production, enabling rapid scaling from prototype to mass production. Providers handle high-volume assembly efficiently, while optimizing costs to meet price-sensitive market demands.

The evolution of turnkey solutions is shaped by digital transformation and industry demands:

- Digital Collaboration Platforms: Cloud-based tools let clients track production in real time, share design updates, and access test data remotely, enhancing transparency.

- Customization at Scale: Advanced automation enables personalized assemblies (e.g., niche industrial sensors) without sacrificing high-volume efficiency.

- Sustainable Manufacturing: Turnkey providers are adopting eco-friendly practices—such as lead-free solders, recyclable packaging, and energy-efficient production lines—to align with client ESG goals.

Full-Service Turnkey PCB Assembly redefines electronics manufacturing by offering a seamless, risk-mitigated path from design to delivery. Its holistic approach simplifies complex processes, reduces time-to-market, and ensures consistent quality—making it an invaluable strategic partner for businesses across industries. As electronics grow more complex and supply chains more dynamic, turnkey solutions will remain a cornerstone of efficient, innovative production, empowering clients to focus on what they do best: creating cutting-edge products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB