-

- PCB TYPE

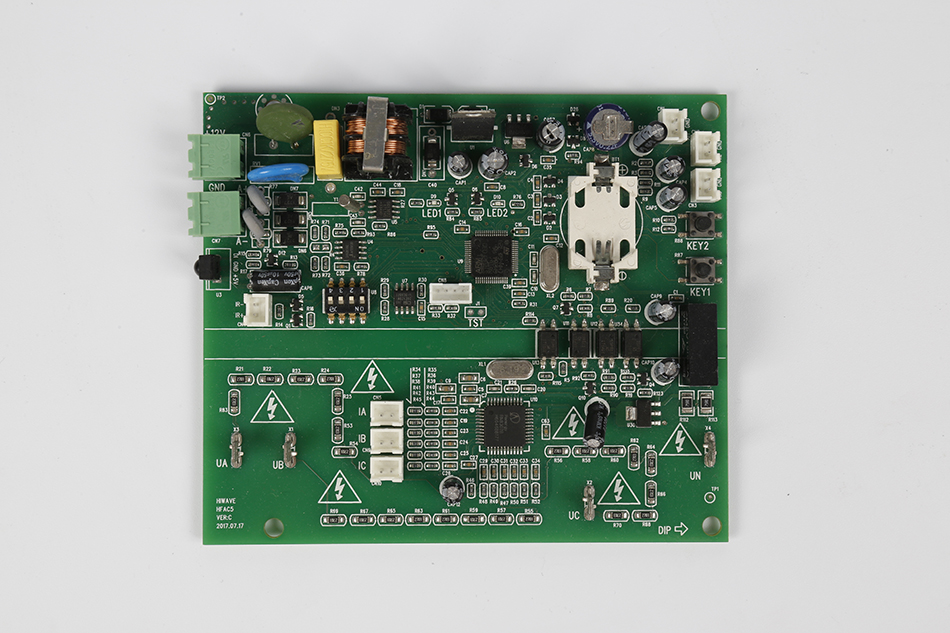

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 28. 2025, 13:40:54

In the world of electronics, the demand for smaller, faster, and more efficient devices is ever-growing. One technology that has risen to meet these demands is High-Density Interconnect (HDI) circuit boards. These advanced PCBs (Printed Circuit Boards) are crucial for modern electronics, enabling more complex circuitry in smaller spaces. A significant component of HDI technology is the use of blind vias. In this article, we’ll explore HDI blind vias PCB assembly, its advantages, and why it's essential for cutting-edge electronics.

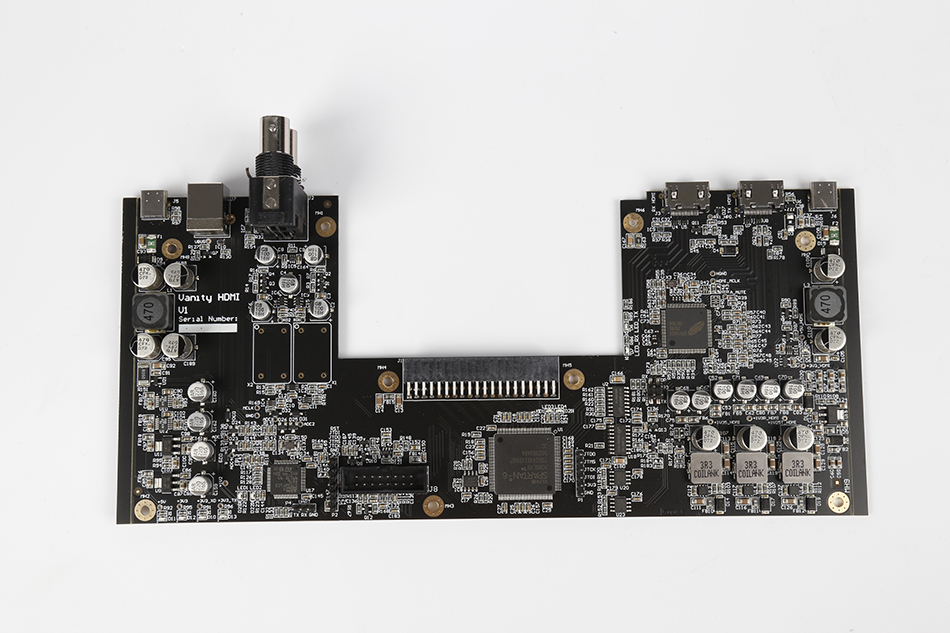

HDI circuit boards are a type of PCB that uses a higher number of interconnects per unit area than traditional boards. This allows for more components to be placed on the board, which is critical for miniaturization in electronics like smartphones, tablets, and laptops. HDI boards are characterized by their finer lines and spaces, smaller vias, and more precise pads.

Blind vias are a type of via that connects the outer layer of a PCB to one or more inner layers but does not go through the entire board. This feature allows designers to maximize the surface area of the board by freeing up space that would otherwise be occupied by through-hole vias. This is particularly beneficial in HDI designs, where space is at a premium.

One of the most significant benefits of using HDI blind vias is the efficient use of space. By connecting only specific layers, blind vias eliminate the need for unnecessary drilling through the entire board, allowing for more components to be placed without compromising functionality.

HDI technology, combined with blind vias, can enhance the electrical performance of the PCB. The shorter connections reduce the inductance and capacitance, leading to faster signal transmission and less power loss. This is crucial for high-speed applications where performance cannot be compromised.

The use of blind vias increases design flexibility by allowing connections between layers without affecting the entire stack. Designers have more freedom to create complex, multi-layered boards that can accommodate advanced features and functionality.

The assembly of HDI blind vias PCBs involves several precise and intricate steps. Each stage is critical in ensuring the functionality and reliability of the final product.

The first step in the assembly process is designing the PCB layout. This involves planning the placement of components, tracing electrical pathways, and determining via locations. The design phase must consider the specific requirements of HDI technology, such as the number of layers and the arrangement of blind vias.

Choosing the right materials is crucial for HDI PCBs. The materials must support high-density designs and withstand the thermal and mechanical stresses of manufacturing and operation. Common materials include high-performance laminates and copper foils.

Drilling the blind vias is one of the most critical steps in HDI PCB assembly. Precision drilling equipment is used to create vias that are only partially through the board. After drilling, the vias are plated to ensure a reliable electrical connection between the layers.

Once the vias are drilled and plated, the individual layers of the PCB are stacked and laminated together. This process must be done carefully to ensure alignment and adhesion between layers, which is essential for the board's integrity and performance.

The final stages of the assembly process involve thorough inspection and testing. Each PCB is inspected for defects and tested to ensure it meets the required electrical specifications. This step is crucial to guarantee the board's reliability in its intended application.

HDI blind vias PCBs are used in a wide range of applications across various industries. Their ability to support complex, high-density designs makes them ideal for the following sectors:

Consumer Electronics: Smartphones, tablets, and wearable devices all benefit from the compact and efficient design of HDI boards.

Automotive: Advanced electronic systems in modern vehicles, such as infotainment and navigation systems, rely on HDI PCBs for their functionality.

Medical Devices: Portable medical equipment and diagnostic tools use HDI technology to ensure reliability and performance.

Telecommunications: Network equipment and communication devices require the high-speed capabilities offered by HDI PCBs.

HDI blind vias PCB assembly is a cornerstone of modern electronics design, enabling the creation of smaller, faster, and more powerful devices. By understanding the benefits and assembly process of HDI technology, manufacturers can produce advanced PCBs that meet the demands of today’s cutting-edge applications. As technology continues to evolve, HDI circuit boards will remain a critical component in the development of next-generation electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB