-

- PCB TYPE

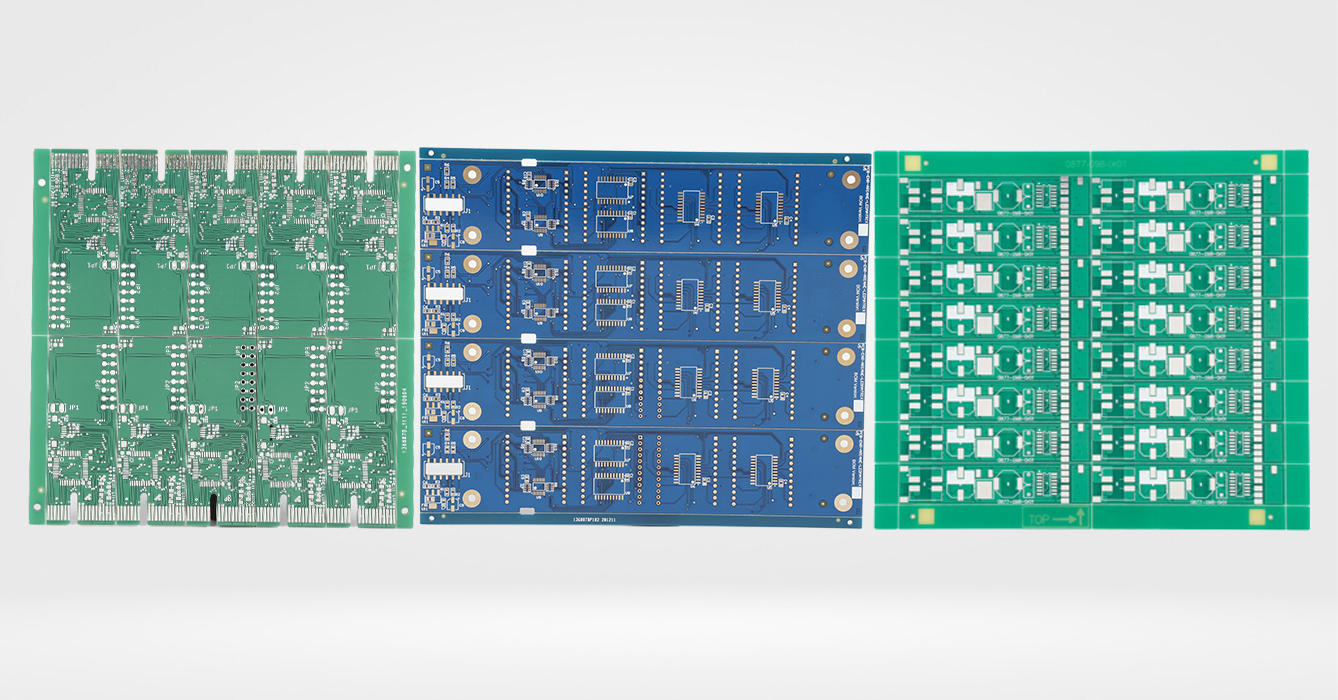

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 15. 2025, 16:45:01

In an era where environmental regulations and corporate sustainability goals drive material innovation, Halogen-Free CEM3 PCB Material Suppliers play a pivotal role in bridging performance demands with eco-conscious manufacturing. Halogen-free CEM3 (Composite Epoxy Material-3) PCB materials eliminate bromine, chlorine, and other halogens—substances historically used as flame retardants but linked to toxic emissions during combustion. As global markets tighten restrictions on hazardous substances (e.g., EU RoHS, China RoHS 2.0), suppliers of these materials have become critical partners for electronics manufacturers seeking compliance without sacrificing functionality. This article examines the role of halogen-free CEM3 PCB material suppliers, their product offerings, quality standards, and the value they bring to industries ranging from consumer electronics to automotive, highlighting how they enable sustainable innovation in printed circuit board production.

Halogen-Free CEM3 PCB Material Suppliers are more than mere vendors; they act as strategic allies in navigating the complex intersection of regulatory compliance, material performance, and sustainability. Their core responsibilities extend beyond manufacturing to include:

Material Innovation: Developing halogen-free formulations that replicate the flame resistance, mechanical strength, and electrical properties of traditional CEM3 while eliminating halogens. This involves researching alternative flame retardants (e.g., phosphorus-based, nitrogen-based compounds) and optimizing resin-glass fiber interactions for consistent performance.

Regulatory Expertise: Staying abreast of global environmental regulations to ensure their materials meet standards such as RoHS, REACH, and UL 94 V-0 (flame resistance). Suppliers provide documentation—including material safety data sheets (MSDS) and compliance certificates—to help manufacturers validate their end products.

Technical Support: Assisting customers with material selection, design integration, and troubleshooting. This includes advising on how halogen-free CEM3 interacts with manufacturing processes (e.g., lamination, etching) and how to optimize PCB designs for the material’s unique properties.

Supply Chain Reliability: Ensuring consistent availability of halogen-free CEM3, even as demand grows. This involves managing raw material sourcing (e.g., halogen-free resins, glass fibers) and scaling production to meet high-volume orders from industries like consumer electronics.

By combining these roles, suppliers enable manufacturers to adopt sustainable materials without disrupting production timelines or compromising product quality.

Top Halogen-Free CEM3 PCB Material Suppliers prioritize formulations that balance sustainability with performance, ensuring their products meet the same rigorous standards as traditional halogenated CEM3:

Historically, halogens (e.g., bromine) provided flame retardancy by releasing radicals that interrupt combustion. Halogen-free CEM3 replaces these with phosphorus, nitrogen, or metal hydroxide-based additives. Reputable suppliers engineer these additives to achieve UL 94 V-0 certification, ensuring the material self-extinguishes quickly and produces minimal smoke—critical for safety in enclosed environments like homes and offices.

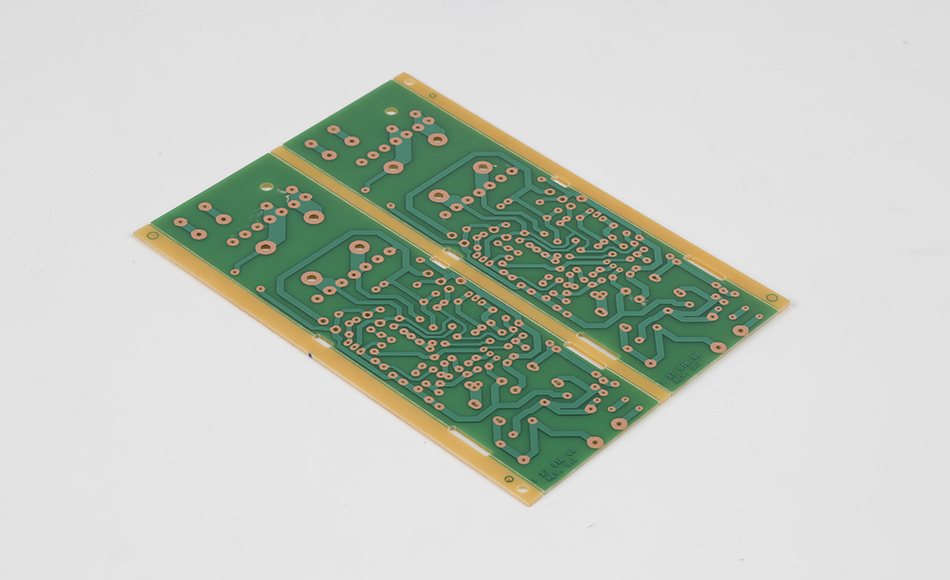

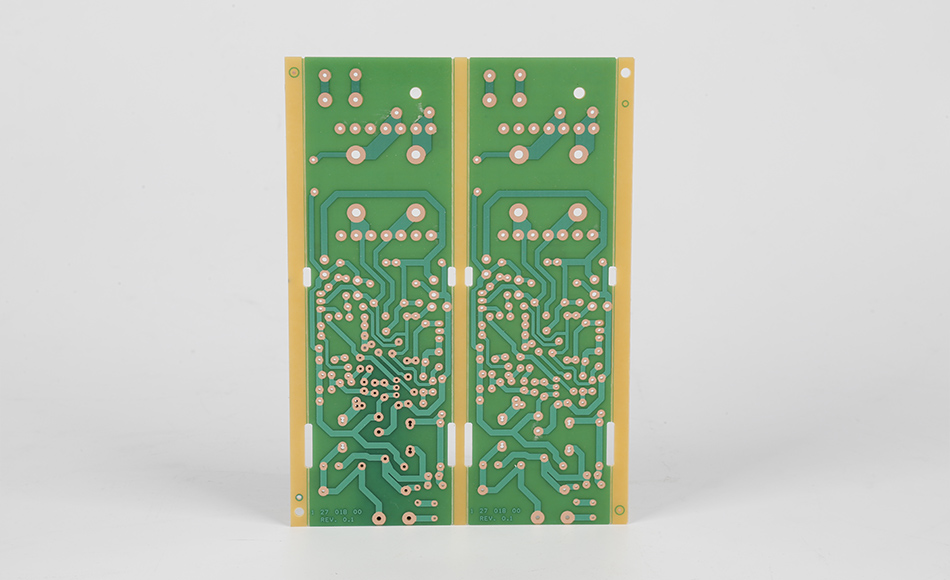

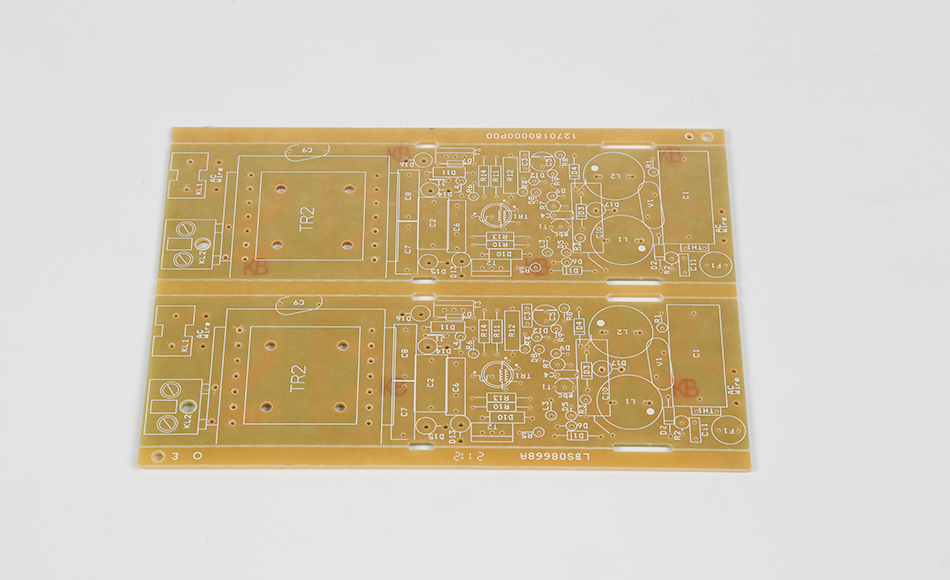

Halogen-free CEM3 retains the hybrid structure of traditional CEM3: a non-woven glass fiber core with woven glass fabric outer layers, bonded by epoxy resin. Suppliers optimize resin chemistry to maintain:

Mechanical Strength: Rigidity sufficient to support component mounting and resist warping during thermal cycling, making it suitable for standard PCB assembly.

Electrical Insulation: Stable dielectric properties (dielectric constant, dissipation factor) for low-to-moderate frequency applications, ensuring signal integrity in devices like home appliances and office equipment.

Thermal Stability: Glass transition temperatures (Tg) comparable to traditional CEM3 (typically 120–130°C), allowing operation in moderate-temperature environments without degradation.

Beyond halogen elimination, leading suppliers focus on cradle-to-gate sustainability. Their materials often feature:

Low Toxicity: Reduced emissions of dioxins and furans during combustion, which are harmful to human health and the environment.

Recyclability: Compatibility with PCB recycling processes, enabling recovery of copper and glass fibers at the end of a product’s lifecycle.

Low Volatile Organic Compounds (VOCs): Resins formulated to release minimal VOCs during curing, supporting cleaner manufacturing environments.

Quality is non-negotiable for Halogen-Free CEM3 PCB Material Suppliers, as even minor variations can impact PCB performance. To maintain consistency, they implement rigorous processes:

Suppliers conduct extensive testing on every batch, including:

Flame Resistance Tests: UL 94 vertical and horizontal burning tests to validate V-0 compliance.

Mechanical Tests: Flexural strength, tensile strength, and impact resistance assessments to ensure the material withstands manufacturing and operational stresses.

Electrical Tests: Dielectric strength, insulation resistance, and signal propagation measurements to confirm electrical performance.

Thermal Tests: Thermal cycling and Tg determination to verify stability under temperature fluctuations.

Adherence to ISO 9001 (quality management) and ISO 14001 (environmental management) standards is common among leading suppliers. These systems ensure consistent production processes, from raw material inspection to final packaging, and minimize environmental impact during manufacturing.

Traceability

Suppliers maintain detailed records of raw material sources, production parameters, and test results for each batch. This traceability allows manufacturers to trace any quality issues back to their origin, facilitating rapid resolution and ensuring compliance with regulatory requirements.

Halogen-Free CEM3 PCB Material Suppliers cater to diverse industries where sustainability, safety, and compliance are priorities:

Smartphones, laptops, and home appliances manufacturers rely on halogen-free CEM3 to meet global RoHS requirements. Suppliers provide materials that support compact designs and low-power circuits, ensuring devices are both eco-friendly and functional. For example, halogen-free CEM3 is used in TV control boards and refrigerator sensors, where flame safety and low toxicity are critical for household use.

As automotive regulations tighten (e.g., EU ELV Directive), suppliers provide halogen-free CEM3 for interior electronics such as infotainment systems, climate controls, and seat sensors. The material’s flame resistance and low smoke emission reduce fire risks in vehicle cabins, while its compliance with automotive standards (e.g., IATF 16949) ensures reliability in harsh operating conditions.

Medical equipment manufacturers require materials that meet strict biocompatibility and safety standards. Halogen-free CEM3, with its low toxicity and compliance with REACH, is used in devices like patient monitors and diagnostic tools. Suppliers often offer specialized grades with enhanced chemical resistance to withstand frequent cleaning with disinfectants.

Factory controllers, sensor modules, and power management systems use halogen-free CEM3 to align with industrial sustainability goals. The material’s durability in dusty, high-vibration environments ensures reliable operation, while its compliance with EU and Asian regulations allows manufacturers to sell globally.

In each industry, suppliers work closely with customers to tailor halogen-free CEM3 formulations to specific application needs, whether enhanced thermal resistance for automotive use or improved dielectric properties for medical devices.

Choosing a Halogen-Free CEM3 PCB Material Supplier requires evaluating factors beyond cost, focusing on long-term partnership potential:

Verify that the supplier’s materials meet all relevant standards (RoHS, REACH, UL 94) and that they provide up-to-date compliance documentation. A supplier with deep regulatory knowledge can help navigate regional differences in requirements, avoiding costly delays in product launches.

Look for suppliers with in-house engineering teams that can assist with material selection, design optimization, and troubleshooting. For example, if a manufacturer encounters delamination during lamination, the supplier should offer guidance on adjusting pressure or temperature parameters.

Assess whether the supplier can scale production to meet demand spikes, especially for high-volume industries like consumer electronics. Short lead times (typically 2–4 weeks for standard orders) are critical for maintaining manufacturing schedules.

Evaluate the supplier’s commitment to environmental responsibility, such as using renewable energy in production, recycling waste, or sourcing raw materials from sustainable suppliers. This aligns with end customers’ growing demand for eco-friendly products.

Request case studies or references from customers in your industry. A supplier with a proven track record in automotive electronics, for example, is more likely to understand the unique demands of that sector than one focused solely on consumer goods.

The landscape for Halogen-Free CEM3 PCB Material Suppliers is evolving, driven by technological advancements and shifting market demands:

Suppliers are developing halogen-free CEM3 with higher Tg (140°C+) and improved thermal conductivity to expand its use in power-dense applications like electric vehicle (EV) chargers and industrial inverters. These formulations compete with halogenated FR4, offering a sustainable alternative for higher-temperature environments.

Research into bio-based epoxy resins—derived from plant oils or agricultural waste—is gaining traction. Suppliers are testing these resins in halogen-free CEM3, reducing reliance on petroleum-based materials and lowering carbon footprints.

Leading suppliers are investing in recycling programs for end-of-life halogen-free CEM3 PCBs, recovering glass fibers and copper for reuse in new materials. This closes the loop on sustainability, appealing to manufacturers with circular economy goals.

Suppliers are using digital tools (e.g., AI-driven material modeling) to accelerate the development of custom halogen-free formulations. This allows for faster turnaround on tailored solutions, such as materials optimized for specific manufacturing processes or application environments.

Halogen-Free CEM3 PCB Material Suppliers are indispensable partners in the electronics industry’s shift toward sustainability. By providing materials that balance regulatory compliance, performance, and environmental safety, they enable manufacturers to produce PCBs that meet global standards without compromising functionality. From consumer electronics to automotive systems, their innovations—including phosphorus-based flame retardants, bio-based resins, and recyclable formulations—are driving the adoption of eco-friendly practices across the supply chain. As regulations tighten and consumer demand for sustainable products grows, the role of these suppliers will only become more critical, ensuring that the electronics industry continues to innovate while minimizing its environmental impact. For manufacturers seeking to navigate the complexities of modern material selection, partnering with a reputable halogen-free CEM3 supplier is a strategic step toward long-term success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB