-

- PCB TYPE

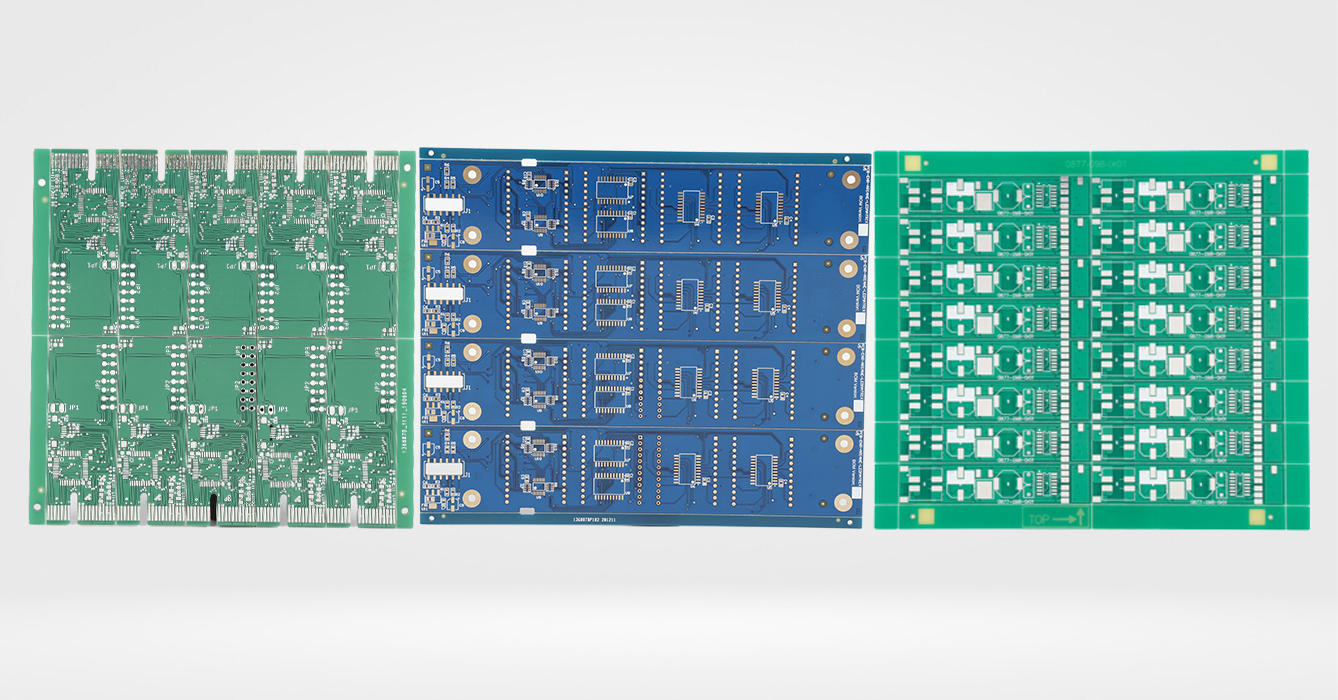

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 16. 2025, 10:25:21

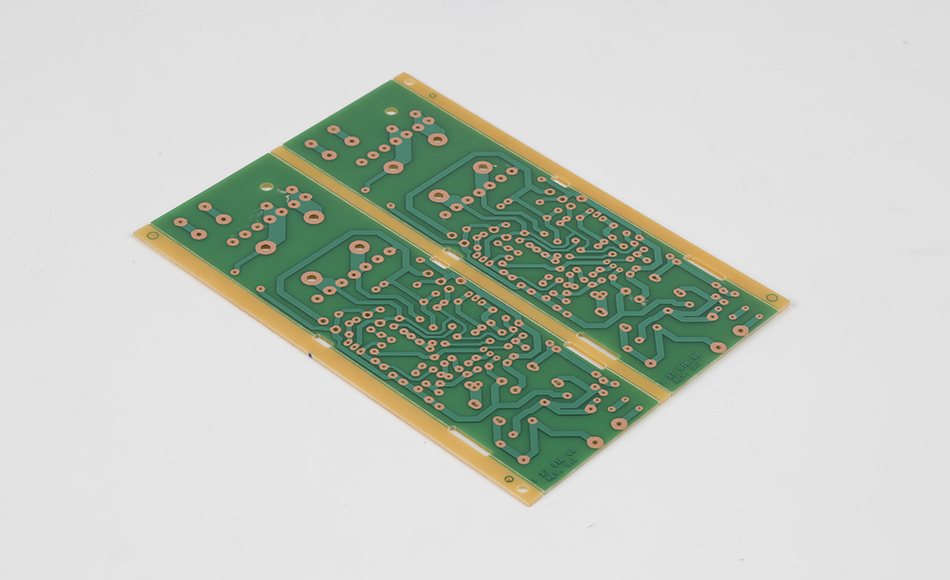

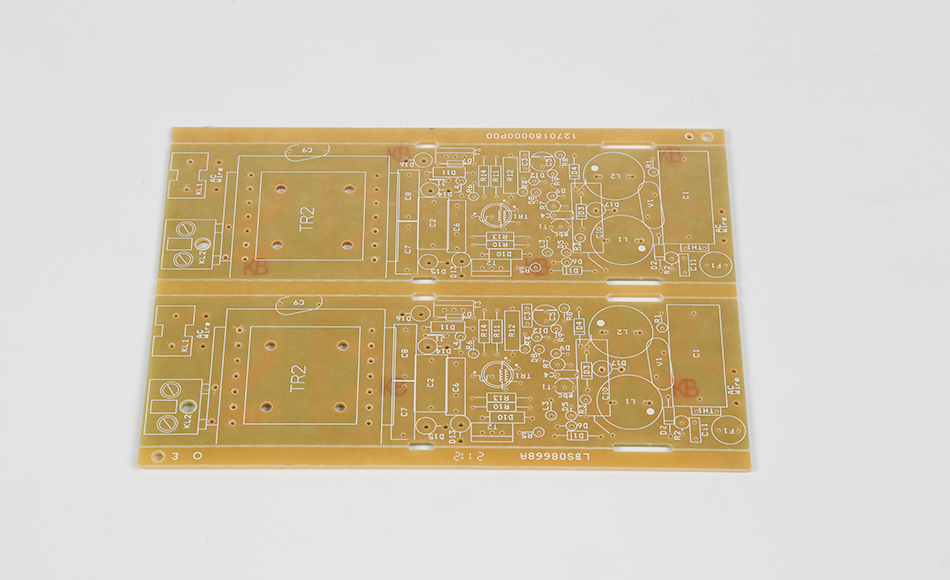

In the global electronics supply chain, ISO 9001 CEM-3 PCB Manufacturer China has emerged as a critical player, combining rigorous quality management with cost-effective production to meet the demands of industries worldwide. CEM-3 (Composite Epoxy Material-3) PCBs, valued for their balanced performance and affordability, require precise manufacturing processes to ensure reliability, and ISO 9001 certification—an international standard for quality management systems—serves as a benchmark for excellence in this field. Chinese manufacturers, leveraging their expertise in mass production, advanced facilities, and adherence to global standards, have become go-to partners for companies seeking high-quality CEM-3 PCBs at competitive prices. This article examines the role of ISO 9001-certified CEM-3 PCB manufacturers in China, their quality management practices, advantages for global clients, and impact on industries ranging from consumer electronics to automotive, highlighting how they bridge quality and cost in the global market.

ISO 9001 certification is more than a credential for ISO 9001 CEM-3 PCB Manufacturer China; it is a framework that ensures consistent quality, process efficiency, and customer satisfaction. For CEM-3 PCBs—materials balancing mechanical strength, electrical insulation, and flame resistance—this certification is particularly critical, as even minor defects can compromise performance in end-use applications.

ISO 9001 requires manufacturers to implement:

Documented Quality Processes: From raw material inspection to final testing, every step in CEM-3 PCB production is standardized and recorded, ensuring traceability and reproducibility.

Continuous Improvement: Regular audits and corrective actions identify inefficiencies, driving ongoing enhancements in manufacturing techniques, material selection, and quality control.

Customer Focus: Manufacturers must align processes with customer requirements, whether for specific flame resistance standards (e.g., UL94 V-0) or custom design specifications.

For CEM-3 PCBs, which are used in safety-critical applications like home appliances and automotive electronics, this structured approach minimizes the risk of failures, ensuring compliance with global regulations and building trust with international clients.

Chinese manufacturers have established themselves as leaders in ISO 9001-certified CEM-3 PCB production through a combination of industrial expertise, infrastructure, and strategic advantages:

China’s electronics manufacturing hubs—such as the Pearl River Delta and Yangtze River Delta—benefit from economies of scale. Concentrated supply chains for raw materials (epoxy resins, glass fibers, copper foil) reduce logistics costs, while large-scale production facilities lower per-unit manufacturing expenses. This efficiency allows ISO 9001 CEM-3 PCB manufacturers in China to offer competitive pricing without sacrificing quality, a key advantage for global clients seeking cost-effective solutions.

Investments in state-of-the-art equipment—including automated lamination lines, laser drilling machines, and AI-driven optical inspection systems—enable precise production of CEM-3 PCBs. These technologies ensure consistent layer alignment, clean drilling, and accurate trace etching, critical for maintaining the material’s electrical and mechanical properties. ISO 9001 certification ensures these processes are standardized and monitored, further enhancing quality.

Chinese manufacturers have deep experience in optimizing CEM-3 materials for diverse applications. They work closely with resin suppliers to develop formulations that balance flame resistance, thermal stability, and cost, tailoring PCBs for specific industries (e.g., high-temperature variants for automotive interiors or halogen-free options for eco-conscious consumer electronics). This expertise, combined with ISO 9001’s focus on process control, ensures CEM-3 PCBs meet exacting standards.

ISO 9001 CEM-3 PCB manufacturers in China prioritize compliance with international regulations, including RoHS (restriction of hazardous substances), REACH (chemical safety), and UL (safety standards). They maintain detailed documentation to validate material safety and performance, simplifying the import process for clients in Europe, North America, and beyond. This commitment to compliance reduces barriers for global companies sourcing PCBs from China.

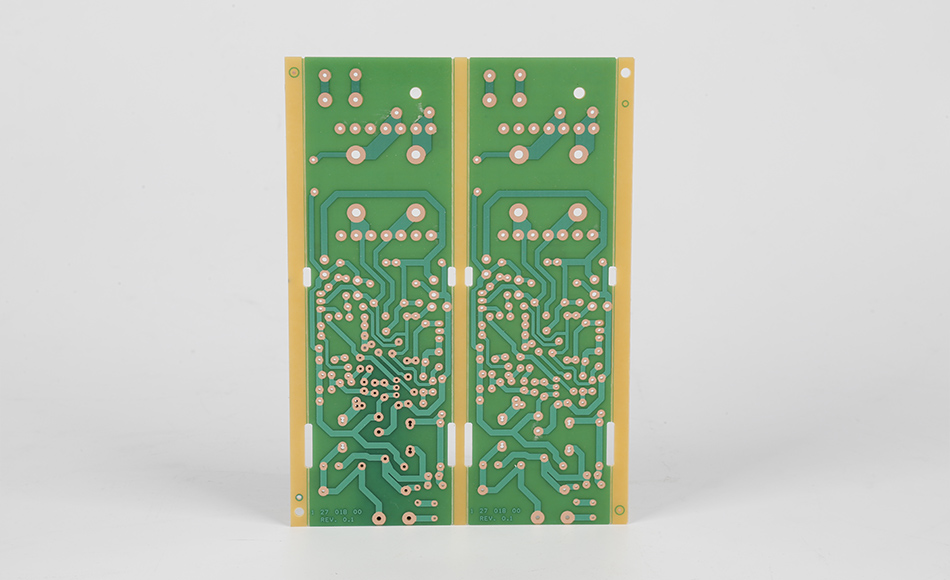

ISO 9001-certified manufacturers in China implement robust quality control measures throughout CEM-3 PCB production, ensuring consistency from raw materials to finished products:

Incoming materials—epoxy resins, glass fibers, and copper foil—undergo rigorous testing to verify purity, adhesion properties, and flame resistance. Only materials meeting predefined specifications (aligned with ISO 9001 requirements) are approved for production, preventing defects downstream.

Key production stages, such as lamination, drilling, and etching, include real-time inspections:

Lamination: Sensors monitor temperature and pressure to ensure proper curing of epoxy resins, critical for maintaining CEM-3’s mechanical strength.

Drilling: Automated systems check hole size and alignment to prevent short circuits or poor component fit.

Etching: Optical inspection tools verify trace width and spacing, ensuring electrical performance meets design requirements.

Finished CEM-3 PCBs undergo comprehensive testing, including:

Electrical Tests: Continuity checks and insulation resistance measurements validate signal integrity.

Mechanical Tests: Flexural strength and impact resistance assessments ensure durability.

Flame Resistance Tests: UL94 V-0 certification is verified to confirm safety in end-use environments.

These tests, documented under ISO 9001 guidelines, provide clients with traceable evidence of quality.

Global clients benefit from collaborating with ISO 9001-certified CEM-3 PCB manufacturers in China through a unique combination of quality, cost, and flexibility:

ISO 9001 ensures standardized processes, reducing variability in CEM-3 PCB performance. Meanwhile, China’s manufacturing efficiency translates to lower costs compared to Western counterparts, making high-quality PCBs accessible for high-volume applications like consumer electronics.

Manufacturers offer tailored solutions, adapting CEM-3 PCB designs to meet specific requirements—whether multi-layer configurations for compact devices or specialized surface finishes for harsh environments. ISO 9001’s focus on customer satisfaction ensures these customizations are delivered without compromising quality.

China’s streamlined supply chains and large-scale production capacity enable quick lead times, even for custom orders. This agility is critical for industries with tight product launch schedules, such as smartphone or home appliance manufacturers.

As client demand grows, ISO 9001 CEM-3 PCB manufacturers in China can scale production efficiently, leveraging their infrastructure to increase output without sacrificing quality. This scalability supports long-term partnerships, from prototyping to mass production.

ISO 9001-certified CEM-3 PCBs from China support diverse industries, each benefiting from the combination of quality and affordability:

Smartphones, televisions, and home appliances rely on CEM-3 PCBs for their control circuits. Manufacturers in China deliver high-volume orders meeting strict RoHS compliance, ensuring these devices are safe and eco-friendly.

In-vehicle systems, such as infotainment units and climate controls, use CEM-3 PCBs for their flame resistance and durability. ISO 9001 certification ensures compliance with automotive standards (e.g., IATF 16949), critical for reliability in vehicle environments.

Factory sensors and basic control modules use CEM-3 PCBs for their mechanical stability. Chinese manufacturers provide ruggedized variants capable of withstanding dust, moisture, and vibration, backed by ISO 9001’s quality guarantees.

Low-risk medical equipment, such as blood pressure monitors, uses CEM-3 PCBs for their biocompatibility and reliability. ISO 9001-certified manufacturers ensure these PCBs meet strict cleanliness and safety standards.

As global demand for sustainable, high-quality electronics grows, ISO 9001 CEM-3 PCB manufacturers in China are adapting to new trends:

Manufacturers are integrating recycled glass fibers and bio-based epoxy resins into CEM-3 formulations, reducing environmental impact. ISO 9001’s focus on process improvement supports these initiatives, ensuring sustainable practices do not compromise quality.

AI and IoT technologies are being deployed to enhance quality control, with real-time data analytics optimizing production parameters and predicting defects. This digital transformation aligns with ISO 9001’s emphasis on efficiency and continuous improvement.

Research into high-temperature CEM-3 (with glass transition temperatures above 140°C) and halogen-free formulations is expanding the material’s application scope, enabling its use in more demanding environments while maintaining ISO 9001 quality standards.

ISO 9001 CEM-3 PCB Manufacturer China plays a pivotal role in the global electronics ecosystem, offering a compelling blend of quality, cost efficiency, and regulatory compliance. By adhering to ISO 9001 standards, these manufacturers ensure consistent performance of CEM-3 PCBs, a material valued for its balanced properties in countless applications. Their expertise in material optimization, advanced manufacturing infrastructure, and commitment to continuous improvement make them trusted partners for industries worldwide. As sustainability and smart manufacturing become increasingly important, Chinese manufacturers are poised to lead innovation in CEM-3 PCB production, reinforcing their position as global leaders in quality and affordability. For companies seeking reliable, cost-effective PCB solutions, partnering with an ISO 9001-certified CEM-3 manufacturer in China remains a strategic choice.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB