-

- PCB TYPE

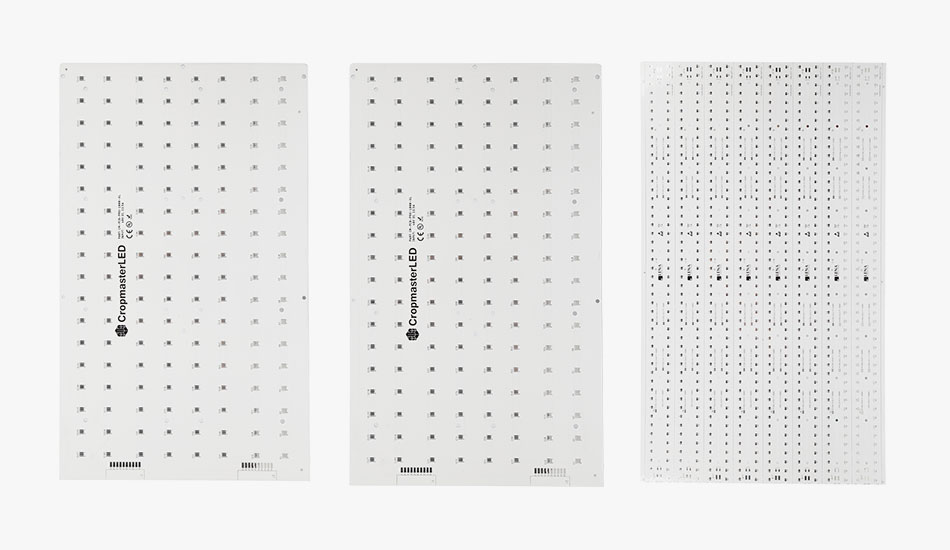

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 07. 2025, 11:03:58

In an era defined by environmental consciousness and strict regulatory demands, the electronics industry is undergoing a profound shift toward sustainable materials. Halogen Free Metal Clad Laminates (HF-MCLs) have emerged as a pivotal innovation, combining the thermal and mechanical advantages of metal-based printed circuit boards (PCBs) with the ecological benefits of halogen-free formulations. This article explores the technical nuances, applications, and industry significance of HF-MCLs, sheddin light on their role in driving eco-friendly advancements in electronics manufacturing.

Metal Substrate: A base layer of aluminum or copper, providing thermal conductivity and mechanical support, similar to traditional metal-core PCBs.

Halogen-Free Dielectric Layer: A thermally conductive insulating layer formulated without halogenated flame retardants, often using alternative materials like metal hydroxides, phosphorus-based compounds, or silicon-based polymers.

Copper Foil Layer: The top layer, where conductive traces and components are integrated, ensuring electrical functionality.

The absence of halogens addresses environmental and health concerns related to toxic emissions during manufacturing, recycling, or combustion, while maintaining the high-performance attributes of metal-clad structures.

Metal Substrate

Aluminum: Preferred for its lightweight, cost-effectiveness, and moderate thermal conductivity (≈200 W/m·K), suitable for general-purpose applications like LED lighting and consumer electronics.

Copper: Offers superior thermal conductivity (≈400 W/m·K) for high-power scenarios, though its higher cost and weight limit use in niche applications like aerospace and industrial electronics.

Halogen-Free Dielectric Layer

Thermal Performance: High thermal conductivity to enable efficient heat transfer from components to the metal substrate.

Electrical Insulation: Dielectric strength to prevent arcing or short circuits, often achieved through ceramic-filled polymers or nanocomposite materials.

Flame Retardancy: Halogen-free flame retardants (HFFRs), such as magnesium hydroxide or ammonium polyphosphate, which release water or form char layers to suppress fires without emitting toxic halogens.

Copper Foil Layer

Engineered for trace precision and signal integrity, the copper foil in HF-MCLs supports fine-pitch routing and high-current applications, complementing the thermal and mechanical benefits of the underlying layers.

Environmental Compliance

Regulatory Adherence: HF-MCLs meet strict international standards like RoHS, REACH, and IEC 61249-2-21, which restrict halogen use in electronics. This compliance is critical for products sold in the EU, North America, and other regions with aggressive sustainability goals.

Reduced Toxicity: Eliminating halogenated flame retardants prevents the release of dioxins and furans—highly toxic compounds linked to environmental pollution and health risks—during manufacturing, use, or disposal.

Enhanced Thermal Management

Efficient Heat Dissipation: The metal substrate in HF-MCLs dissipates heat up to 100x more effectively than organic substrates like FR-4, making them ideal for high-power components such as MOSFETs, IGBTs, and high-brightness LEDs.

Thermal Stability: Halogen-free dielectric materials maintain structural integrity across wide temperature ranges (-40°C to 150°C+), reducing the risk of delamination or thermal stress.

Mechanical Robustness

Vibration and Impact Resistance: The metal core provides mechanical rigidity, making HF-MCLs suitable for rugged environments in automotive, industrial, and aerospace applications.

Component Support: Heavy components (e.g., heat sinks, connectors) can be securely mounted without compromising board integrity, thanks to the laminate’s robust foundation.

Electrical Performance

Signal Integrity: Low dielectric loss in modern HF-MCL formulations supports high-frequency applications (e.g., 5G antennas, radar systems) by minimizing signal degradation.

Design Flexibility: Multi-layer HF-MCLs enable complex layouts with buried vias and blind holes, accommodating advanced PCB architectures without sacrificing thermal or electrical performance.

Cost-Effective Sustainability

Simplified Compliance: Avoidance of halogen-specific waste disposal fees and certification complexities.

Extended Lifespan: Improved thermal and mechanical reliability reduces component replacement and maintenance needs.

Consumer Electronics

High-Power Devices: Laptops, gaming consoles, and smartphones with energy-dense batteries or fast-charging systems rely on HF-MCLs to manage heat in compact form factors.

E-Waste Reduction: Halogen-free materials facilitate easier recycling, aligning with circular economy goals for consumer tech manufacturers.

Automotive Electronics

EV/HEV Systems: Inverters, battery management systems (BMS), and electric motor controllers in electric vehicles require HF-MCLs for thermal efficiency and compliance with automotive sustainability standards (e.g., ELV Directive).

ADAS and Lighting: Advanced driver assistance systems and LED headlights use HF-MCLs to balance heat dissipation, mechanical stability, and eco-friendliness.

Industrial and Renewable Energy

Solar Inverters and Wind Turbines: HF-MCLs withstand the harsh conditions of industrial environments while meeting RoHS compliance for renewable energy infrastructure.

Factory Automation: Robotics and control systems benefit from the laminates’ resistance to vibration and thermal cycling.

Medical Devices

Implantable Electronics and Diagnostics: HF-MCLs’ biocompatibility (when paired with non-toxic materials) and thermal stability make them suitable for medical devices, where halogen-free compliance is increasingly required for regulatory approval.

Aerospace and Defense

Avionics and Satellite Systems: HF-MCLs meet stringent military standards (e.g., MIL-P-55110) for non-toxic emissions during combustion, critical for aircraft and space applications.

Radar and Communication Equipment: High-frequency performance and ruggedness support advanced defense electronics.

Design Considerations for HF-MCLs

Material Selection

Dielectric Compatibility: Ensure the halogen-free dielectric layer’s coefficient of thermal expansion (CTE) matches the metal substrate and copper foil to prevent delamination. For example, aluminum (CTE: 23 ppm/°C) pairs well with polymers like cyanate ester (CTE: 18–22 ppm/°C).

Thermal Conductivity vs. Insulation: Higher thermal conductivity in the dielectric (e.g., 1–5 W/m·K) improves heat transfer but may require thicker layers for adequate voltage isolation in high-power designs.

Thermal Design Strategies

Thermal Vias: Plated-through holes connecting the copper layer to the metal substrate enhance heat dissipation. Strategic placement near hotspots (e.g., power transistors) is critical.

Heat Sink Integration: Direct bonding of heat sinks to the metal substrate via thermal interface materials (TIMs) further boosts cooling efficiency in extreme applications.

Manufacturing Compatibility

Lamination Pressures: Halogen-free dielectric materials may require higher lamination pressures (10–15 psi vs. 5–8 psi for traditional materials) to ensure proper adhesion, impacting PCB fabrication workflows.

Drilling and Plating: Harder metal substrates (e.g., copper) may necessitate diamond-tipped drills and specialized plating processes to avoid burrs or voids in vias.

Environmental Testing

Flame Retardancy Certification: Verify compliance with UL 94 V-0 or IEC 60695 standards using halogen-free test methods, which focus on smoke density and toxic gas emission levels.

Humidity and Chemical Resistance: Assess how the laminate performs in humid environments (e.g., 85°C/85% RH testing) to prevent dielectric breakdown or metal corrosion.

Cost Pressures

Material Innovation: Manufacturers are developing hybrid laminates (e.g., aluminum-copper composites) to balance performance and cost, reducing reliance on pure copper in non-critical applications.

Economies of Scale: Growing demand for HF-MCLs in automotive and consumer electronics is driving down per-unit costs through mass production.

Performance Trade-offs

Thermal Conductivity Gap: Halogen-free dielectrics often have slightly lower thermal conductivity than halogenated counterparts. Nanofillers (e.g., boron nitride, graphene) are being explored to bridge this gap without compromising flame retardancy.

Processing Complexity: Halogen-free resins may have shorter pot lives or higher curing temperatures, requiring adjustments in PCB manufacturing schedules.

Global Regulatory Variability

Regional Standards: Ensure compliance with evolving regulations, such as California’s Proposition 65 or China’s SJ/T 11364, which may impose stricter limits on specific HFFR components.

Sustainable Materials Innovation

Bio-Based Dielectrics: Researchers are developing halogen-free dielectrics from renewable sources, such as plant-based epoxies or lignin-derived polymers, to further reduce carbon footprints.

Recyclable Metal Substrates: Aluminum and copper are already highly recyclable; future HF-MCLs may incorporate quick-disconnect adhesives or dissolvable dielectrics to simplify metal recovery.

Miniaturization and High-Density Integration

Thin-Film Technologies: Sub-100μm metal substrates and ultra-thin dielectrics (e.g., 25μm) are enabling HF-MCLs for flexible PCBs in wearables and medical devices.

3D Integration: Stacked HF-MCLs with through-silicon vias (TSVs) are being tested for advanced packaging in AI chips and high-performance computing (HPC).

Global Adoption of Halogen-Free Standards

Legislative Drivers: The EU’s New Legislative Framework (NLF) for chemicals and the U.S. EPA’s Safer Choice program are accelerating the phase-out of halogenated materials, creating a $2.3 billion market for HF-MCLs by 2028 (CAGR: 7.8%, according to MarketsandMarkets).

Consumer Demand: Eco-conscious consumers are increasingly prioritizing halogen-free electronics, pushing OEMs to adopt HF-MCLs in flagship products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB