-

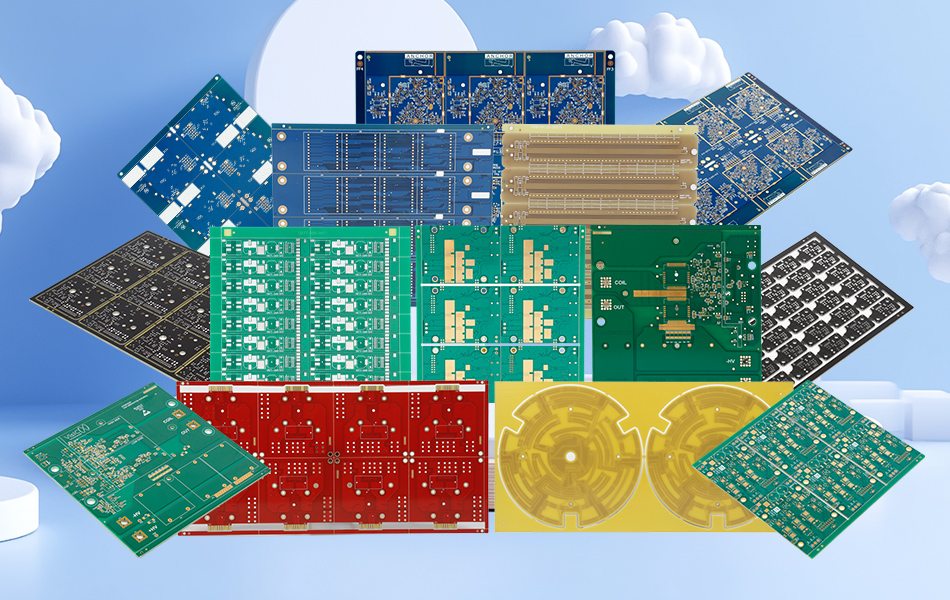

- PCB TYPE

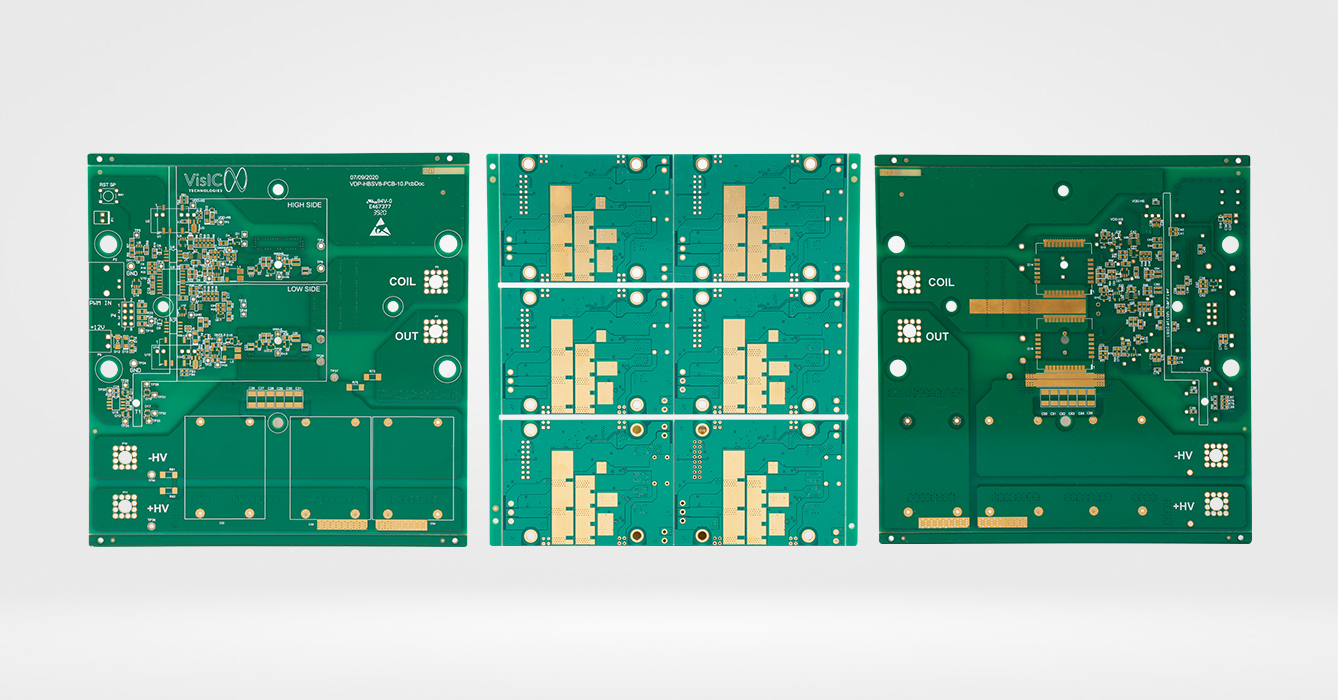

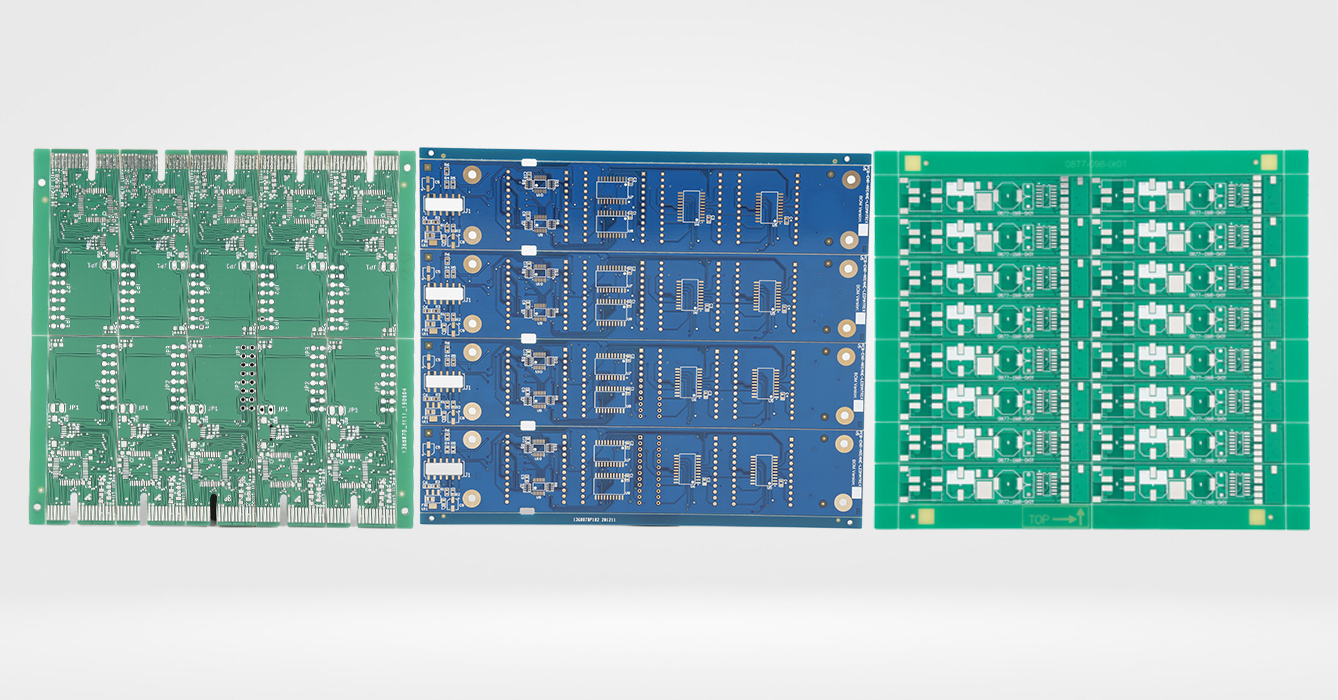

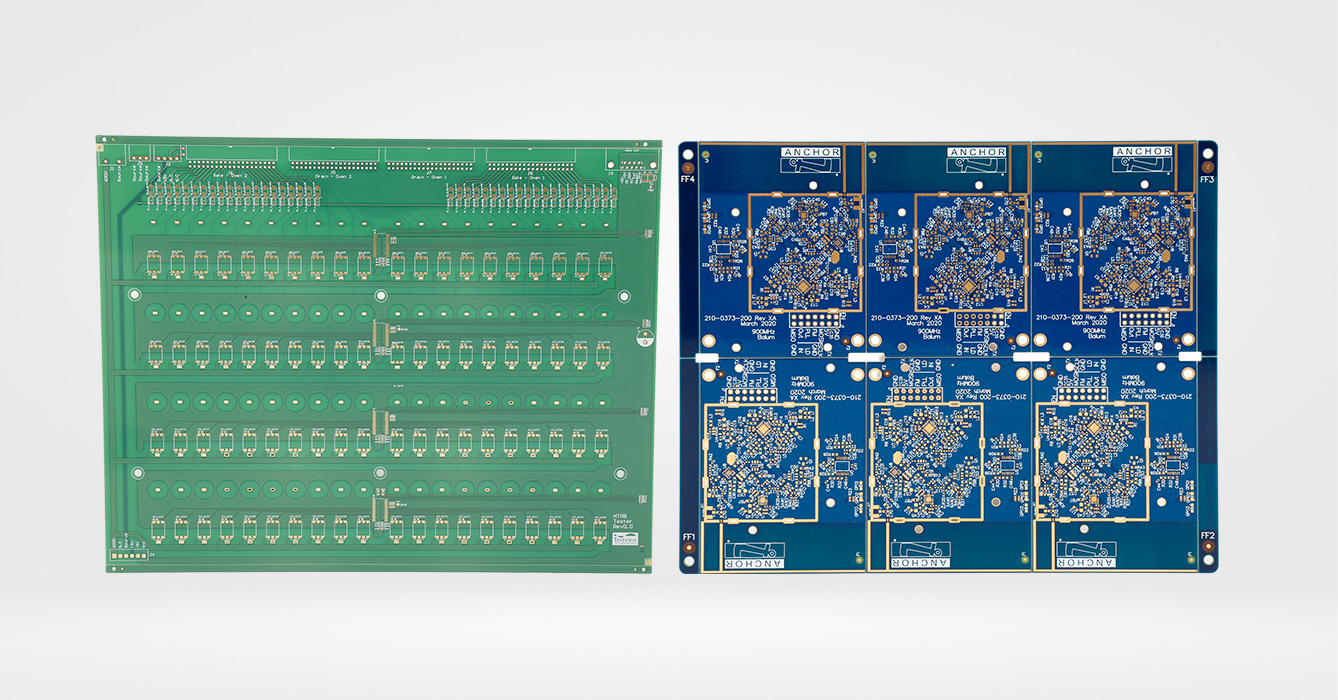

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 30. 2025, 16:14:31

In the rapidly evolving landscape of solid-state lighting, High Brightness LED FR4 PCB serves as a critical integration platform, bridging the performance demands of high-output LEDs with the practical advantages of FR4 substrate technology. Designed to manage the unique challenges of intense illumination—including heat dissipation, mechanical stability, and long-term reliability—these specialized PCBs enable applications ranging from industrial floodlights to architectural lighting. This article explores the design principles, material optimizations, performance attributes, application ecosystems, and manufacturing considerations of High Brightness LED FR4 PCB, ensuring industry 专业性 (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Design Fundamentals: Adapting FR4 for High Brightness LEDs

High Brightness LED FR4 PCB requires deliberate engineering to address the dual demands of intense light output and thermal management, leveraging FR4’s inherent strengths while mitigating its limitations:

Structural Optimizations for Thermal Performance

Enhanced Copper Distribution: Unlike standard PCBs, high brightness LED designs incorporate strategically thickened copper traces and expanded copper planes. These features act as passive heat spreaders, distributing thermal energy from high-output LEDs across the FR4 substrate to reduce hotspots—a critical factor in preventing premature light degradation (lumen depreciation).

Thermally Conductive Dielectric Layers: Advanced FR4 formulations for high brightness applications integrate ceramic fillers or modified epoxy resins to improve thermal conductivity within the substrate. This modification reduces thermal resistance between the LED junction and the PCB, enhancing heat transfer without compromising electrical insulation.

Strategic Vias and Heat Paths: Plated through-holes (PTHs) and thermal vias create vertical heat conduction pathways, channeling heat from the LED mounting pad through the FR4 layers to external heat sinks or cooling structures. This multi-dimensional heat management ensures consistent performance under sustained high-power operation.

These design elements transform standard FR4 into a substrate capable of supporting the thermal demands of high brightness LEDs, balancing cost-effectiveness with functional performance.

Material Synergy: FR4 Substrates and High Brightness LED Compatibility

The performance of High Brightness LED FR4 PCB hinges on the compatibility between FR4 material properties and the operational characteristics of high-output LEDs:

FR4 Material Traits Supporting High Brightness Operation

Thermal Stability: FR4 substrates used in high brightness LED systems are selected for their stable glass transition temperature (Tg), ensuring the material retains rigidity and dimensional stability under the elevated temperatures generated by intense illumination. This prevents warping that could disrupt LED alignment or solder joint integrity.

Mechanical Rigidity: The woven glass fiber reinforcement in FR4 provides structural support for heavy LED arrays and external heat sinks, resisting mechanical stress from thermal expansion and vibration—common in outdoor or industrial lighting environments.

Electrical Insulation and Signal Integrity: FR4’s robust dielectric properties maintain insulation between power traces and heat sinks, while low dissipation factor ensures stable current regulation for consistent LED brightness. This is critical for preventing flicker or uneven illumination in large-scale lighting systems.

Material Modifications for Enhanced Performance

Halogen-Free Formulations: Many high brightness LED FR4 PCBs utilize halogen-free epoxy resins to meet environmental regulations, reducing toxic emissions during manufacturing and end-of-life disposal while maintaining flame retardancy (UL94 V-0) for safety in enclosed lighting fixtures.

Corrosion-Resistant Copper Cladding: High-purity, anti-tarnish copper layers ensure low contact resistance at LED solder joints, preventing voltage drops that could reduce brightness or cause premature failure in high-current circuits.

Key Performance Attributes of High Brightness LED FR4 PCB

High Brightness LED FR4 PCBs deliver a unique set of performance benefits tailored to the demands of intense illumination systems:

Thermal Management Efficiency

Heat Spreading Capability: The combination of optimized copper layouts and thermally enhanced FR4 enables effective heat distribution, keeping LED junction temperatures within safe operating ranges. This directly extends LED lifespan, as excessive heat is the primary cause of lumen depreciation in high brightness devices.

Passive Cooling Support: FR4’s rigidity allows integration with heat-dissipating features like extended copper tabs or heat sink mounting provisions, enabling passive cooling strategies that reduce reliance on active fans—ideal for dust-prone industrial or outdoor environments.

Illumination Consistency and Reliability

Uniform Current Distribution: Precision-etched copper traces ensure consistent current delivery to each LED in an array, preventing brightness variations that compromise lighting quality in applications like sports stadiums or warehouse illumination.

Environmental Resilience: FR4’s resistance to moisture, UV radiation, and chemical exposure—enhanced by conformal coatings or specialized surface finishes—ensures reliable operation in harsh conditions, from coastal salt spray to industrial fumes.

Design Flexibility for Scalability

Customizable Layouts: FR4’s compatibility with standard PCB manufacturing processes allows for flexible design of LED arrays, from compact high-density modules to large-format panels, supporting scalability across lighting applications (e.g., from streetlights to airport runways).

Integration with Control Systems: High brightness LED FR4 PCBs easily accommodate embedded drivers, dimming circuits, and sensor interfaces, enabling smart lighting features like daylight harvesting or motion activation without requiring separate control boards.

Application Ecosystems for High Brightness LED FR4 PCB

High Brightness LED FR4 PCBs enable illumination solutions across diverse sectors requiring intense, reliable light output:

Outdoor and Infrastructure Lighting

Street and Highway Lighting: Large-format FR4 PCBs support high brightness LED arrays for roadway illumination, leveraging thermal management features to withstand extreme temperature fluctuations and weather exposure while maintaining long lifespans (reducing maintenance costs).

Architectural and Landscape Lighting: Custom-shaped FR4 substrates accommodate curved or irregular LED arrangements, enabling dramatic lighting effects on buildings, bridges, and public spaces while ensuring uniform brightness distribution.

Industrial and Commercial Illumination

Warehouse and Factory Lighting: High ceiling installations use high brightness LED FR4 PCBs to deliver intense, energy-efficient illumination over large areas, with robust thermal design ensuring reliability in 24/7 operating environments.

Sports and Venue Lighting: Stadiums and arenas rely on these PCBs to power LED arrays that meet broadcast-quality brightness standards, with low-light depreciation ensuring consistent performance during extended events.

Specialized High-Intensity Applications

Agricultural Lighting: Controlled-environment farming systems use high brightness LED FR4 PCBs to deliver specific light spectra for crop growth, with FR4’s thermal stability ensuring consistent performance in humid greenhouse conditions.

Emergency and Safety Lighting: Critical illumination systems (e.g., airport runways, marine navigation lights) utilize these PCBs for their reliability, with redundant current paths and robust construction ensuring operation during power fluctuations or environmental stress.

Manufacturing and Quality Assurance for High Brightness LED FR4 PCB

The production of High Brightness LED FR4 PCBs involves specialized processes to ensure thermal performance and reliability:

Precision Manufacturing Techniques

Controlled Lamination: FR4 cores, prepreg layers, and copper foils are bonded under precise temperature and pressure conditions to eliminate voids in the dielectric layer, minimizing thermal resistance between copper traces and the substrate.

Thermal Via Formation: Laser-drilled thermal vias with high copper plating thickness create efficient vertical heat paths, connecting LED pads to internal or external heat-dissipating layers without compromising structural integrity.

Surface Finishing for Thermal Conductivity: ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) finishes are applied to enhance solder joint reliability at LED mounting sites, ensuring low thermal resistance and long-term conductivity.

Rigorous Quality Validation

Thermal Imaging Testing: Infrared thermography maps heat distribution across the PCB under simulated operating conditions, verifying that hotspots remain within safe limits for LED longevity.

Thermal Cycling and Humidity Testing: Samples undergo repeated temperature cycles and high-humidity exposure to simulate years of outdoor operation, ensuring no delamination or solder joint failure that could reduce brightness.

Electrical Performance Verification: Continuity testing and current distribution analysis confirm uniform power delivery to all LEDs, preventing brightness inconsistencies in final lighting systems.

Advantages Over Alternative Substrates

High Brightness LED FR4 PCBs offer distinct benefits compared to metal-core PCBs (MCPCBs) or ceramic substrates in specific applications:

Cost-Effectiveness for Large-Scale Applications

Lower Material and Production Costs: FR4’s mature manufacturing processes and widespread availability reduce costs compared to ceramic or MCPCBs, making it ideal for large-area lighting systems where material expense is a critical factor.

Scalability: FR4 PCBs support larger panel sizes than many alternative substrates, enabling seamless integration of extensive LED arrays without the need for multiple interconnected boards.

Design Versatility

Compatibility with Complex Layouts: FR4’s suitability for multi-layer designs allows integration of power regulation, dimming circuits, and sensor interfaces within the same PCB, reducing system complexity and assembly costs.

Ease of Customization: Standard PCB fabrication techniques enable rapid prototyping and design iterations for custom lighting geometries, supporting unique architectural or industrial illumination requirements.

Balanced Performance for Moderate Heat Loads

Optimal for Mid-Range Brightness Needs: While MCPCBs excel in extreme high-heat scenarios, High Brightness LED FR4 PCBs provide sufficient thermal management for most industrial and outdoor lighting applications, offering a better performance-to-cost ratio for moderate heat loads.

Future Trends in High Brightness LED FR4 PCB Technology

As high brightness LED technology advances, FR4 PCB solutions are evolving to meet emerging demands:

Material Innovations

Nano-Reinforced FR4 Substrates: Integration of graphene or ceramic nanoparticles into epoxy resins is enhancing thermal conductivity of FR4 substrates, expanding their suitability for higher brightness applications previously limited to metal-core substrates.

Sustainable Formulations: Development of bio-based epoxy resins and recycled glass fiber content reduces the environmental impact of High Brightness LED FR4 PCBs, aligning with global sustainability goals in lighting manufacturing.

Design and Manufacturing Advancements

AI-Optimized Thermal Layouts: Machine learning algorithms are being used to optimize copper distribution and via placement, maximizing heat dissipation in compact designs while minimizing material usage.

Additive Manufacturing Integration: 3D printing techniques are enabling the creation of custom heat-dissipating structures on FR4 PCBs, such as internal cooling channels or conformal heat sinks, enhancing thermal performance in space-constrained fixtures.

Application Expansion

Human-Centric Lighting Systems: High Brightness LED FR4 PCBs are supporting tunable white light systems for commercial and residential spaces, with FR4’s electrical stability enabling precise control of color temperature and brightness.

UV-C Disinfection Lighting: Modified FR4 substrates with UV-resistant materials are being used in high brightness UV-C LED systems, leveraging FR4’s mechanical stability for reliable operation in healthcare and sanitization applications.

Conclusion

High Brightness LED FR4 PCB represents a specialized, cost-effective solution for intense illumination systems, balancing thermal management, mechanical reliability, and design flexibility. By optimizing FR4’s inherent properties—thermal stability, mechanical rigidity, and electrical insulation—engineers have created a platform capable of supporting the demands of high-output LEDs in applications from outdoor lighting to industrial illumination. While alternative substrates dominate extreme heat scenarios, High Brightness LED FR4 PCBs remain the preferred choice for moderate to high brightness applications requiring scalability, customization, and cost efficiency. As material innovations enhance thermal conductivity and sustainability, their role in advancing solid-state lighting technology will continue to grow, illuminating the path for energy-efficient, high-performance illumination systems.

Keywords: High Brightness LED FR4 PCB, LED illumination systems, thermal management, FR4 substrate, industrial lighting, outdoor lighting, PCB manufacturing, halogen-free PCB.

This article provides a comprehensive, technically rigorous overview of High Brightness LED FR4 PCB, emphasizing its engineering solutions, application diversity, and future potential while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB