-

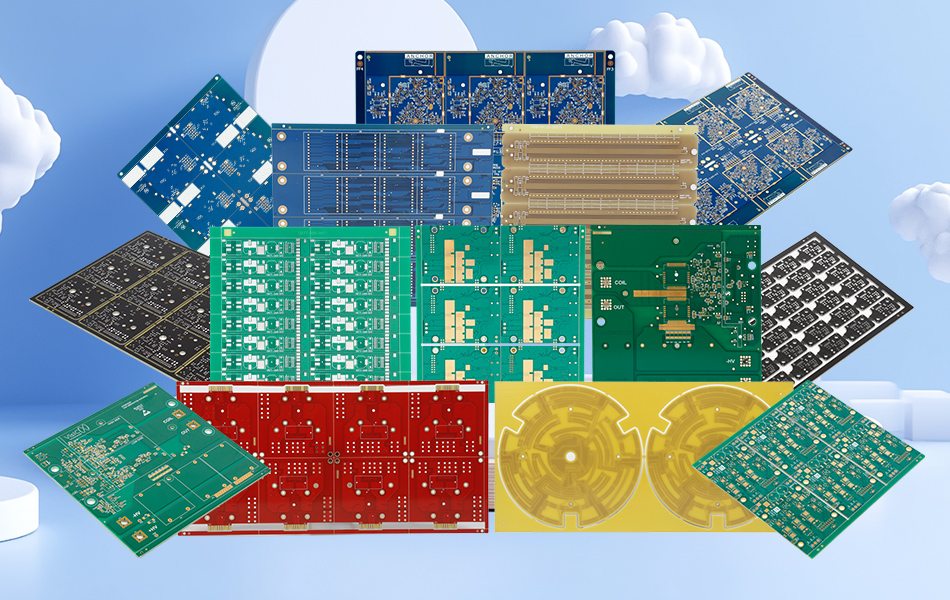

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 30. 2025, 16:21:51

In the evolution of modern lighting technology, LED Lighting FR4 PCB serves as a critical integration platform, bridging the performance needs of light-emitting diodes (LEDs) with the mechanical and electrical requirements of illumination systems. As LED technology advances toward higher efficiency, longer lifespans, and broader applications, FR4 (Flame Retardant 4) printed circuit boards have emerged as the substrate of choice, offering a balance of thermal management, electrical stability, and cost-effectiveness. This article explores the design considerations, performance attributes, application diversity, and manufacturing essentials of LED Lighting FR4 PCB, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

LED Lighting FR4 PCB’s effectiveness stems from its tailored compatibility with LED technology, addressing the unique challenges of illumination systems:

Thermal Stability: The glass-reinforced epoxy matrix of FR4 provides moderate thermal conductivity, facilitating heat dissipation from LEDs—a critical factor in maintaining luminous efficacy and preventing premature degradation. While not as thermally conductive as metal-core PCBs, FR4’s thermal performance suffices for most general lighting applications, where heat generation is balanced with system design.

Electrical Insulation: FR4’s dielectric properties ensure safe isolation between LED drive circuits and conductive components, preventing short circuits in moisture-prone environments common in lighting (e.g., outdoor fixtures, bathroom lighting). Its stable insulation resistance supports consistent current delivery to LEDs, maintaining brightness uniformity.

Mechanical Durability: The rigid structure of FR4 resists vibration, impact, and dimensional changes from temperature cycles, ensuring LED solder joints remain intact in applications ranging from ceiling fixtures to industrial worklights. This durability extends system lifespans, reducing maintenance costs.

Halogen-Free Variants: Increasingly adopted in LED Lighting FR4 PCBs to meet environmental regulations, halogen-free FR4 eliminates hazardous substances while maintaining flame retardancy (UL94 V-0), aligning with eco-friendly lighting trends.

High-Tg Formulations: Specialized FR4 grades with enhanced glass transition temperatures improve thermal resilience for high-power LED arrays, resisting softening under sustained heat in applications like high-bay lighting or stadium illumination.

Effective LED Lighting FR4 PCB design requires balancing thermal, electrical, and mechanical factors to optimize illumination performance:

Trace Layout for Heat Spreading: Copper traces are optimized to distribute heat from LED pads across the PCB surface, reducing hotspots. Wider traces and copper pours connected to LED anode/cathode pads enhance thermal conduction, leveraging FR4’s substrate to dissipate heat passively.

Thermal Vias and Copper Planes: Strategic placement of thermal vias (plated through-holes) connects top-layer LED pads to inner or bottom copper planes, creating additional heat dissipation pathways. These planes act as heat spreaders, reducing thermal resistance between LEDs and the ambient environment.

Solder Mask Selection: Heat-resistant solder masks (e.g., epoxy-based formulations) protect copper traces while withstanding the operating temperatures of LED modules, preventing yellowing or degradation that could affect light output.

Current Distribution: Uniform trace resistance ensures consistent current flow to parallel LED strings, preventing brightness discrepancies. Low-resistance copper cladding minimizes voltage drops, critical for maintaining stable forward voltage across LEDs.

EMI Suppression: Ground planes in multi-layer LED Lighting FR4 PCBs reduce electromagnetic interference (EMI) from LED drivers, preventing noise from affecting sensitive electronics in smart lighting systems (e.g., dimmers, sensors, or IoT connectivity modules).

Dimming Compatibility: PCB layouts accommodate dimming circuits (PWM, TRIAC, or 0-10V) with optimized trace routing, ensuring smooth brightness adjustment without flickering—a key user experience factor in residential and commercial lighting.

LED Lighting FR4 PCB’s versatility enables its use in virtually every lighting category, adapting to varied environmental and performance demands:

Residential and Commercial Fixtures: Ceiling panels, downlights, and track lighting rely on LED Lighting FR4 PCBs for compact design and uniform light distribution. FR4’s rigidity supports slim fixture profiles, while its cost-effectiveness enables mass production for consumer markets.

Architectural Lighting: Cove lighting, wall washers, and accent lighting use FR4 PCBs to integrate LED arrays with decorative form factors, leveraging the substrate’s design flexibility for curved or custom shapes (via scored or flexible FR4 variants).

Street and Area Lighting: LED streetlights and parking lot fixtures utilize LED Lighting FR4 PCBs with weather-resistant coatings, resisting moisture, dust, and temperature extremes. FR4’s durability ensures reliable performance in unprotected outdoor environments.

Industrial and Hazardous Area Lighting: High-bay lights, explosion-proof fixtures, and tunnel lighting depend on FR4’s flame retardancy and mechanical strength, with specialized formulations meeting safety standards for hazardous locations.

Automotive Lighting: Interior ambient lighting, daytime running lights, and brake lights use LED Lighting FR4 PCBs for vibration resistance and thermal stability, integrating with vehicle electrical systems seamlessly.

Horticultural Lighting: Grow lights for indoor farming leverage FR4 PCBs to support high-density LED arrays, with thermal design optimizing heat dissipation to maintain consistent light spectra for plant growth.

Producing reliable LED Lighting FR4 PCBs requires precision processes tailored to illumination system requirements:

Component Placement Optimization: LED pads are positioned to ensure uniform heat distribution, with spacing designed to prevent optical interference (e.g., shadowing) while facilitating efficient soldering during assembly.

Copper Thickness and Finish: Thicker copper layers enhance heat spreading, while surface finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) improve solder joint reliability and resistance to oxidation—critical for LED longevity.

Thermal Mapping: Infrared imaging verifies heat distribution across the PCB, ensuring no localized hotspots exceed LED manufacturer recommendations. This testing validates trace layout and via effectiveness.

Environmental Stress Screening: Samples undergo humidity cycling, temperature shock, and vibration testing to simulate real-world conditions, ensuring the PCB maintains performance in damp, dusty, or high-vibration environments.

Lighting Safety Standards: LED Lighting FR4 PCBs comply with IEC 60598 (lighting fixtures) and UL 8750 (LED equipment), ensuring electrical safety and flame retardancy. Halogen-free variants meet RoHS and REACH requirements, supporting eco-label certifications.

As LED lighting evolves toward smart, sustainable systems, LED Lighting FR4 PCB technology is advancing to meet new demands:

Sensor and Control Integration: FR4 PCBs are increasingly designed to accommodate ambient light sensors, motion detectors, and wireless modules (e.g., Bluetooth, Wi-Fi), enabling smart dimming, color tuning, and connectivity without compromising thermal performance.

Energy Efficiency Enhancements: Low-loss FR4 formulations reduce power consumption in LED driver circuits, aligning with global energy efficiency standards for lighting systems.

Recyclable Materials: Manufacturers are developing FR4 variants with recycled glass fibers and bio-based epoxy resins, reducing the environmental footprint of LED Lighting PCBs while maintaining performance.

Circular Economy Practices: PCB design for disassembly facilitates LED and copper recovery at end-of-life, supporting recycling initiatives in the lighting industry.

High-Density LED Arrays: Advanced FR4 substrates support finer trace spacing and smaller vias, enabling higher LED counts per unit area for applications like high-output floodlights and video walls.

Thermal Enhancement Additives: Ceramic or graphene fillers in FR4 resins improve thermal conductivity, extending FR4’s applicability to mid-power LED systems traditionally reliant on metal-core substrates.

LED Lighting FR4 PCB stands as a foundational technology in modern illumination, balancing performance, cost, and versatility to support the diverse needs of LED lighting systems. Its thermal stability, electrical reliability, and mechanical durability make it ideal for applications ranging from residential fixtures to industrial lighting, while ongoing innovations in materials and design expand its capabilities. As the lighting industry continues to prioritize efficiency, sustainability, and smart functionality, LED Lighting FR4 PCB will remain a critical enabler, bridging LED technology with the practical demands of illumination systems. For engineers and manufacturers, it represents a proven, adaptable platform for creating the next generation of energy-efficient lighting solutions.

Keywords: LED Lighting FR4 PCB, illumination systems, thermal management, FR4 substrate, LED reliability, smart lighting, sustainable lighting, PCB design.

This article provides a comprehensive, technically focused overview of LED Lighting FR4 PCB, emphasizing its role in modern illumination while ensuring originality and alignment with SEO best practices.

Related Articles

FR4 PCB Manufacturer | High Tg & Reliable PCB Material FR4 Solutions

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

FR4 PCB Manufacturer for Prototype and Mass Production

Tg170 FR4 PCB Datasheet PDF: A Detailed Exploration of High-Tg Laminate Specifications

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

HDI Blind/Buried Vias FR4 PCB: High-Density Interconnect Solutions for Advanced Electronics

FR4 PCB Material Specification Sheet: A Comprehensive Technical Guide

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB