-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 01. 2025, 10:00:13

With the rapid evolution of electronic devices toward ultra-compact sizes, high-frequency operation, and multi-functional integration, the demand for high density interconnect (HDI) flexible printed circuits (FPCs) has become increasingly prominent. A professional High Density Interconnect FPC Producer serves as a core innovator in this field, specializing in the R&D and production of HDI FPCs that feature ultra-fine traces, micro vias, and advanced cross-layer interconnect structures. Unlike conventional FPC producers, these specialized providers possess in-depth expertise in resolving signal integrity issues, optimizing interconnect density, and adapting to diverse high-end application requirements. For brands engaged in 5G communications, autonomous driving, and precision medical devices, partnering with a reputable High Density Interconnect FPC Producer is crucial to realizing product innovation and maintaining market competitiveness.

The competitive edge of a High Density Interconnect FPC Producer lies in its specialized technical capabilities, which cover the entire lifecycle of HDI FPC development and production:

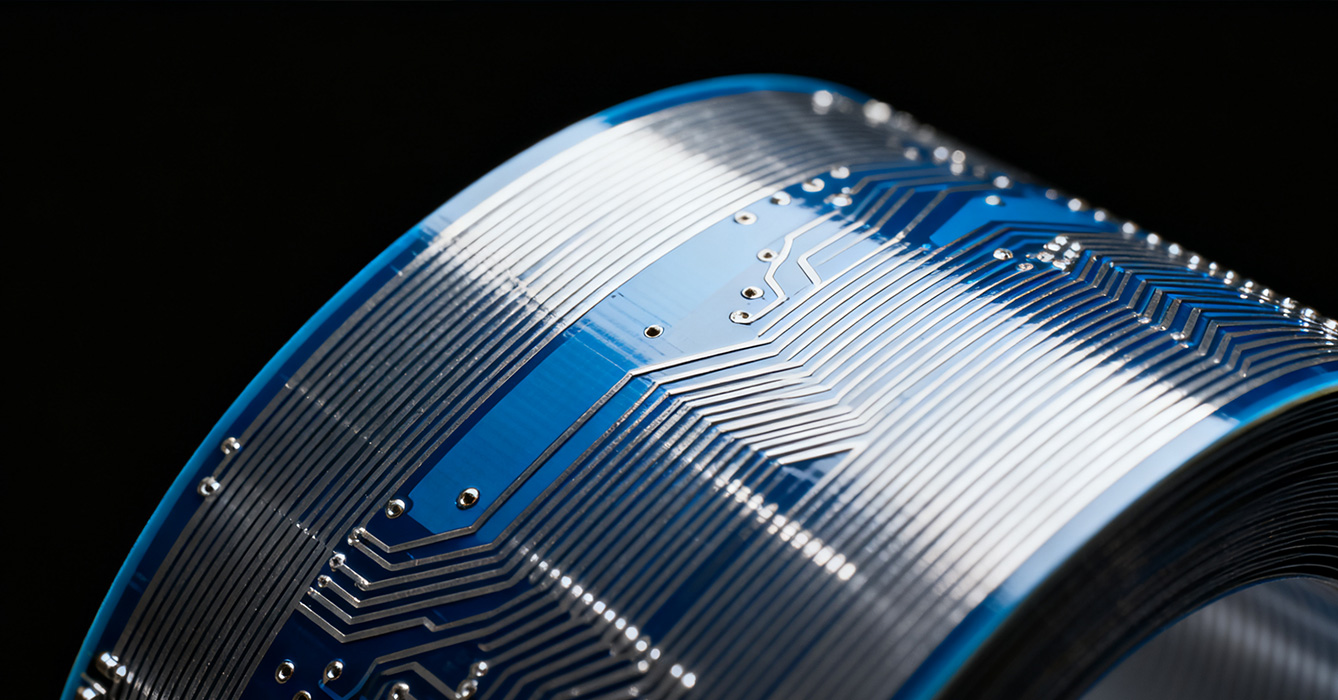

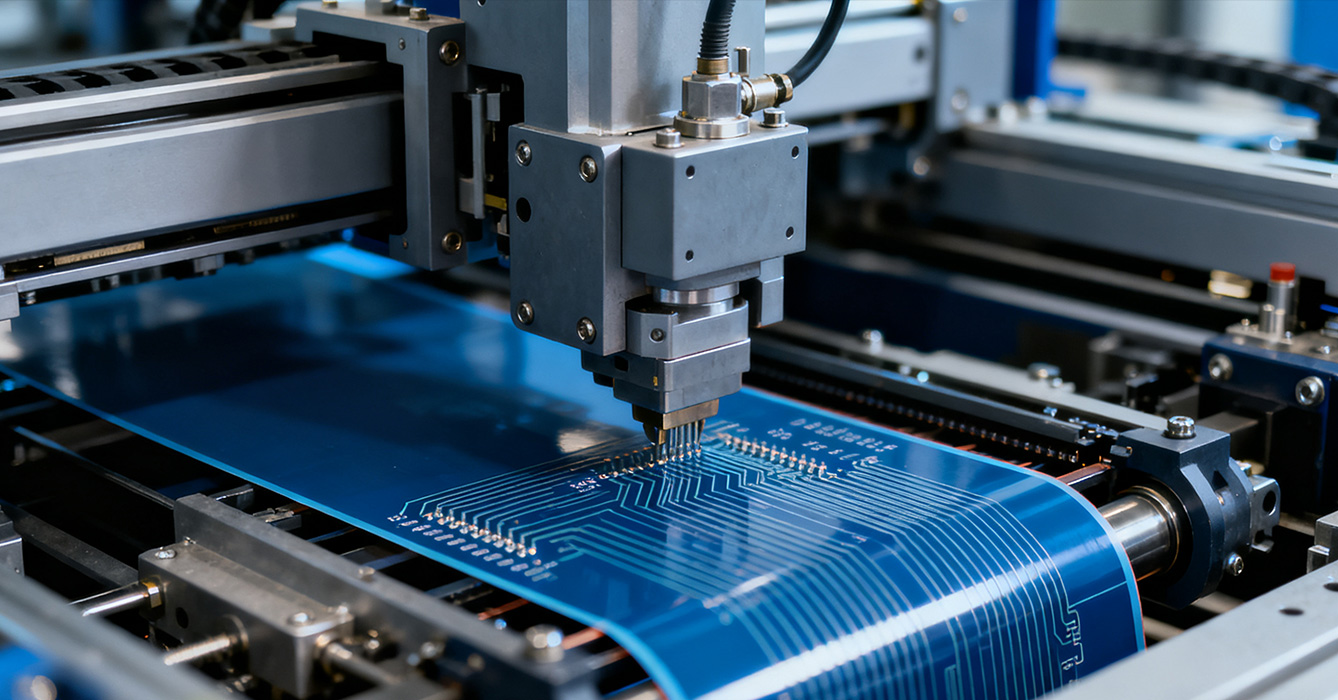

- Advanced Interconnect Technology Mastery: Top producers excel in core HDI interconnect technologies, including micro blind/buried via fabrication, stacked via formation, and sequential lamination. These technologies enable the creation of dense cross-layer connections with via diameters far smaller than those of standard FPCs, significantly increasing interconnect density and reducing circuit footprint. Advanced processes such as laser drilling with sub-micron precision and plasma desmearing ensure the reliability of micro vias, laying a solid foundation for high-performance signal transmission.

- Multi-Layer HDI Stackup Customization: A skilled High Density Interconnect FPC Producer does not limit itself to fixed layer counts but offers customized multi-layer stackup solutions (ranging from 2-layer to 8-layer and above) based on application needs. By strategically arranging power, ground, and signal layers, they minimize electromagnetic interference (EMI) and crosstalk in high-density circuits. This customization capability allows HDI FPCs to adapt to different performance requirements, from low-power wearables to high-power automotive electronic systems.

- High-Frequency Signal Integrity Optimization: For high-end electronic devices operating at GHz frequencies (e.g., 5G millimeter-wave modules, ADAS radar systems), signal integrity is critical. Leading producers leverage professional electromagnetic simulation tools to optimize circuit layouts and select low-loss dielectric materials (e.g., high-frequency polyimides with low Dk/Df values). These measures effectively reduce signal attenuation and delay, ensuring stable and efficient data transmission even in high-frequency scenarios.

- Strict Quality Assurance for HDI Reliability: HDI FPCs with complex interconnect structures have higher quality requirements. Producers implement a full-process quality control system, including X-ray inspection for via internal integrity, automated optical inspection (AOI) for ultra-fine trace defects, and environmental reliability tests (thermal cycling, humidity testing, flexing tests). They also comply with international standards such as IPC-6012/2221 and industry-specific certifications, ensuring consistent quality across all production batches.

The advanced interconnect solutions provided by High Density Interconnect FPC Producers address key pain points in modern electronic design, making them irreplaceable in high-end sectors:

1. Enabling Ultra-High Integration of Miniaturized Devices: As devices such as smart wearables, miniaturized medical implants, and portable 5G terminals become increasingly compact, standard FPCs cannot meet the demand for integrating dozens of components and thousands of interconnects. HDI FPCs from specialized producers, with their high-density interconnects and compact stackups, enable more functions to be integrated into a limited space, driving the trend of device miniaturization and light weight.

2. Supporting High-Speed Data Transmission in Next-Generation Electronics: 5G communication, autonomous driving, and VR/AR technologies require ultra-high-speed data transmission. The advanced interconnect technologies and signal integrity optimization capabilities of High Density Interconnect FPC Producers ensure that HDI FPCs can transmit high-frequency signals with minimal loss, providing a reliable hardware foundation for these cutting-edge technologies. This is a capability that conventional FPC producers cannot match.

3. Adapting to Complex Mechanical and Environmental Requirements: Unlike rigid HDI PCBs, HDI FPCs maintain excellent flexibility, allowing them to adapt to curved, folded, or dynamically moving application scenarios (e.g., foldable smartphone hinges, robotic joints). Producers optimize material selection and layer structure design to balance interconnect density and mechanical flexibility, ensuring that HDI FPCs can withstand repeated bending and harsh environmental conditions (extreme temperatures, vibration, moisture) without performance degradation.

4. Reducing Total Manufacturing Costs for High-End Products: Although HDI FPC production requires advanced technologies, professional producers can optimize the manufacturing process to reduce costs. By increasing interconnect density, they reduce the number of required FPCs and assembly steps, simplifying the overall production process of end devices. Additionally, the high reliability of HDI FPCs reduces product failure rates and warranty costs, optimizing the total cost of ownership for customers.

High Density Interconnect FPC Producers focus on high-end electronic sectors that demand high interconnect density and performance:

- 5G & High-End Consumer Electronics: Supplies HDI FPCs for 5G smartphones, millimeter-wave modules, premium VR/AR headsets, and foldable devices. These HDI FPCs enable the integration of multiple high-frequency modules and sensors, supporting advanced features such as 5G full-band connectivity, high-resolution displays, and multi-modal sensing.

- Automotive Autonomous Driving & EV Systems: Provides HDI FPCs for ADAS domain controllers, lidar/radar systems, EV battery management systems (BMS), and in-vehicle infotainment systems. These FPCs withstand extreme automotive environments (temperature ranges of -40°C to 150°C, vibration) while ensuring high-speed signal transmission between critical components, enhancing driving safety and EV performance.

- Precision Medical Devices: Delivers miniaturized HDI FPCs for implantable pacemakers, minimally invasive surgical robots, and portable diagnostic equipment. The high-density interconnects support precise sensor data transmission and control signal delivery, while biocompatible materials and strict sterility control ensure patient safety and device reliability.

- Aerospace & Industrial IoT: Manufactures high-reliability HDI FPCs for aerospace avionics, satellite communication systems, and industrial IoT edge computing devices. These FPCs feature lightweight designs, radiation resistance, and high signal integrity, meeting the strict requirements of aerospace and industrial environments for component reliability and performance.

In conclusion, a High Density Interconnect FPC Producer is a key driver of innovation in the high-end electronics industry, providing advanced interconnect solutions that bridge the gap between design concepts and practical applications. By mastering core HDI technologies, offering customized stackup solutions, and ensuring strict quality control, these producers deliver HDI FPCs that meet the ultra-high integration, high-frequency, and flexibility requirements of modern electronic devices. As the electronics industry continues to advance toward intelligence and miniaturization, the role of High Density Interconnect FPC Producers will become increasingly important. For brands seeking to lead in high-end markets, partnering with a reputable High Density Interconnect FPC Producer is a strategic investment in product innovation and long-term competitiveness.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB