-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 07. 2025, 10:22:26

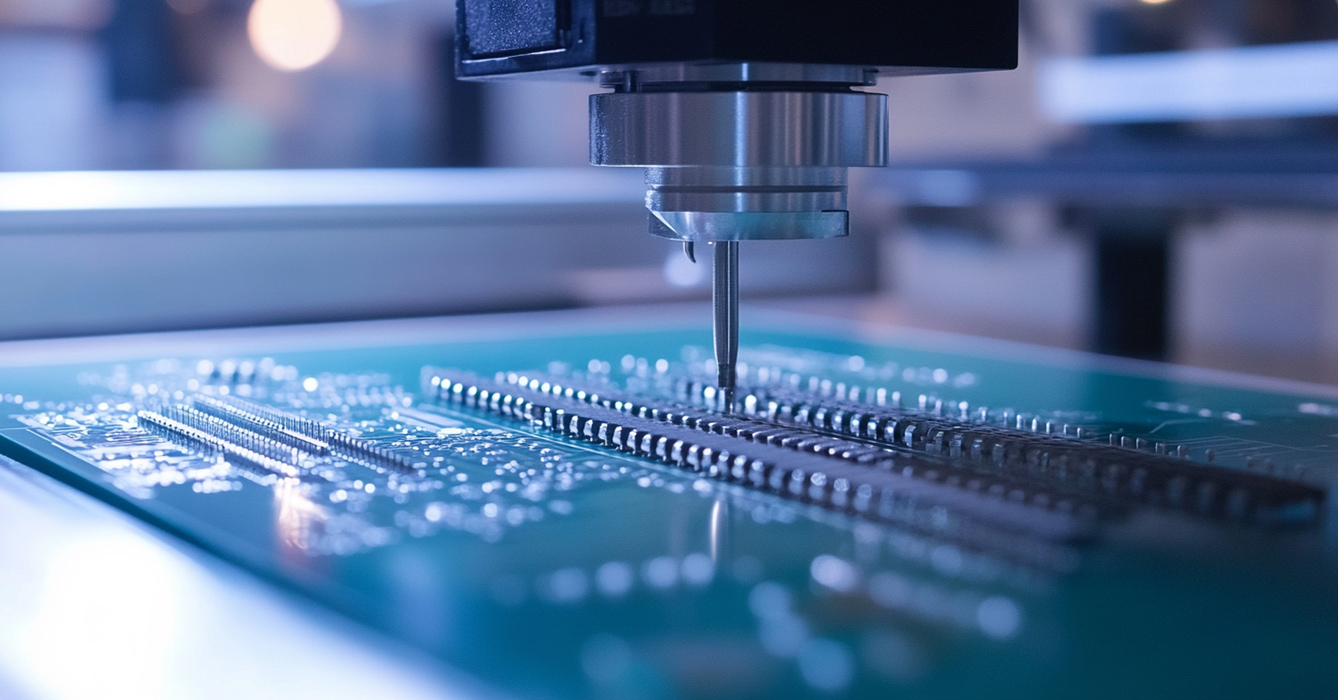

A High-Precision SMT Stencils Maker plays a pivotal role in modern electronics manufacturing, as the quality of surface-mount technology (SMT) stencils directly impacts solder paste transfer efficiency, component placement accuracy, and final product reliability. Unlike standard stencil providers, high-precision makers specialize in crafting custom stencils tailored to the demands of dense PCB designs, miniaturized components, and high-volume production—catering to industries from consumer electronics to aerospace. These stencils act as the critical bridge between PCB design and assembly, ensuring precise deposition of solder paste onto PCB pads to form robust, consistent solder joints. As electronics grow more complex (with ultra-fine-pitch components and HDI PCBs), the expertise of a high-precision SMT stencils maker becomes indispensable for mitigating defects, reducing rework, and optimizing production yields. This article explores the core capabilities, quality standards, industry applications, and emerging trends defining top-tier high-precision SMT stencil manufacturers.

Top-tier makers distinguish themselves through advanced technical capabilities that balance precision, customization, and durability:

High-precision makers leverage two primary fabrication methods, selected based on design requirements:

- Laser-Cut Stencils: Ideal for fine-pitch components (down to 0.3mm pitch), laser cutting uses fiber lasers to create ultra-precise apertures with clean edges, minimizing solder bridging and ensuring uniform paste release.

- Electroformed Stencils: Used for micro-components (e.g., 01005 resistors) and HDI PCBs, electroforming deposits nickel onto a precision master to create apertures with sub-micron accuracy and smooth sidewalls, enhancing paste transfer for delicate designs.

Both processes are supported by CAD/CAM integration, where stencil designs are directly synced with PCB layouts to eliminate translation errors.

A key strength of high-precision makers is optimizing aperture geometry for specific components and solder paste types. Engineers adjust aperture size, shape (e.g., rounded corners, stepped apertures), and spacing to address challenges like tombstoning (for small passives) or insufficient solder (for BGA pads). This customization ensures consistent paste volume—critical for components with varying pad sizes on the same PCB.

High-precision stencils are crafted from high-grade materials like stainless steel (304 or 420 series) for rigidity and corrosion resistance. Makers also offer surface treatments:

- Nano-Coatings: Reduce solder paste adhesion, extending stencil lifespan and reducing cleaning frequency.

- Electropolishing: Smooths aperture edges to prevent paste buildup and improve release efficiency.

These enhancements ensure stencils withstand high-volume production (tens of thousands of prints) without compromising precision.

Reliable high-precision SMT stencils makers adhere to strict quality control protocols to deliver defect-free products:

- Aperture Metrology: Use optical measurement systems (e.g., 3D laser scanners) to verify aperture dimensions, ensuring compliance with IPC-7525 (the industry standard for stencil design).

- Visual Inspection: Automated optical inspection (AOI) detects surface defects like burrs, scratches, or uneven coating, while cross-sectional analysis validates aperture wall quality.

- Traceability: Maintain detailed records of material batches, fabrication parameters, and inspection results—critical for industries like medical and aerospace with strict regulatory requirements.

High-precision stencils are tailored to the unique needs of diverse sectors:

Smartphones, laptops, and wearables rely on high-precision stencils to assemble dense PCBs with miniaturized components (e.g., microprocessors, RF modules). Stencils ensure consistent solder joints for thin, lightweight devices that demand both performance and durability.

EVs and ADAS systems require stencils that support high-temperature solder pastes and ruggedized components. High-precision makers design stencils for PCB assemblies in engine control units (ECUs) and sensor modules, where reliability under extreme vibration and temperature fluctuations is non-negotiable.

Medical devices (e.g., diagnostic scanners) and aerospace electronics (e.g., avionics) use electroformed stencils for micro-components and mission-critical PCBs. High-precision apertures ensure zero-defect assembly, as failures could have life-threatening consequences.

The industry is evolving to meet the demands of next-generation electronics:

- AI-Driven Design Optimization: Machine learning algorithms analyze past production data to recommend aperture adjustments, reducing trial-and-error and accelerating time-to-market.

- Sustainable Manufacturing: Makers are adopting eco-friendly practices, such as recycling stencil materials and using water-based cleaning agents, to align with global sustainability goals.

- Miniaturization Support: As components shrink to sub-millimeter sizes (e.g., microLEDs), makers are developing stencils with apertures as small as 50 microns, supported by advanced electroforming and laser technology.

A High-Precision SMT Stencils Maker is more than a supplier—it’s a strategic partner in electronics manufacturing, enabling the assembly of complex, reliable products across industries. By combining advanced fabrication technologies, custom design expertise, and rigorous quality control, these makers address the critical gap between PCB design and production efficiency. As electronics continue to miniaturize and demand higher performance, the role of high-precision SMT stencil makers will only grow, solidifying their position as indispensable enablers of innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB