-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 11. 2025, 12:49:11

Battery systems are the core power source for new energy vehicles (NEVs), energy storage systems, portable electronics, and medical devices, where safety is non-negotiable. A professional High Safety Battery FPC Supplier plays a pivotal role in ensuring battery operational safety by engineering flexible printed circuits (FPCs) with specialized protective designs, material selection, and performance optimization. Unlike generic FPC suppliers, these specialized providers focus on addressing battery-specific safety risks—such as overcurrent, overheating, short circuits, and insulation failure—while maintaining the flexibility and integration efficiency required for modern battery packs. For brands developing high-reliability battery products, partnering with a reputable High Safety Battery FPC Supplier is critical to mitigating safety hazards and meeting stringent industry safety standards.

The competitive edge of a top High Safety Battery FPC Supplier lies in its mastery of targeted safety technologies that proactively prevent and mitigate battery system risks:

- Overcurrent & Overheat Protection Design: Battery FPCs must handle high current loads while preventing thermal buildup. Leading suppliers integrate precision current-limiting circuit designs and thermal sensing integration—such as embedding temperature sensor pads directly into FPC layouts—to enable real-time temperature monitoring. They also use high-temperature-resistant conductive materials and widened trace widths to enhance current-carrying capacity and heat dissipation, avoiding overheating-induced insulation degradation or circuit meltdown.

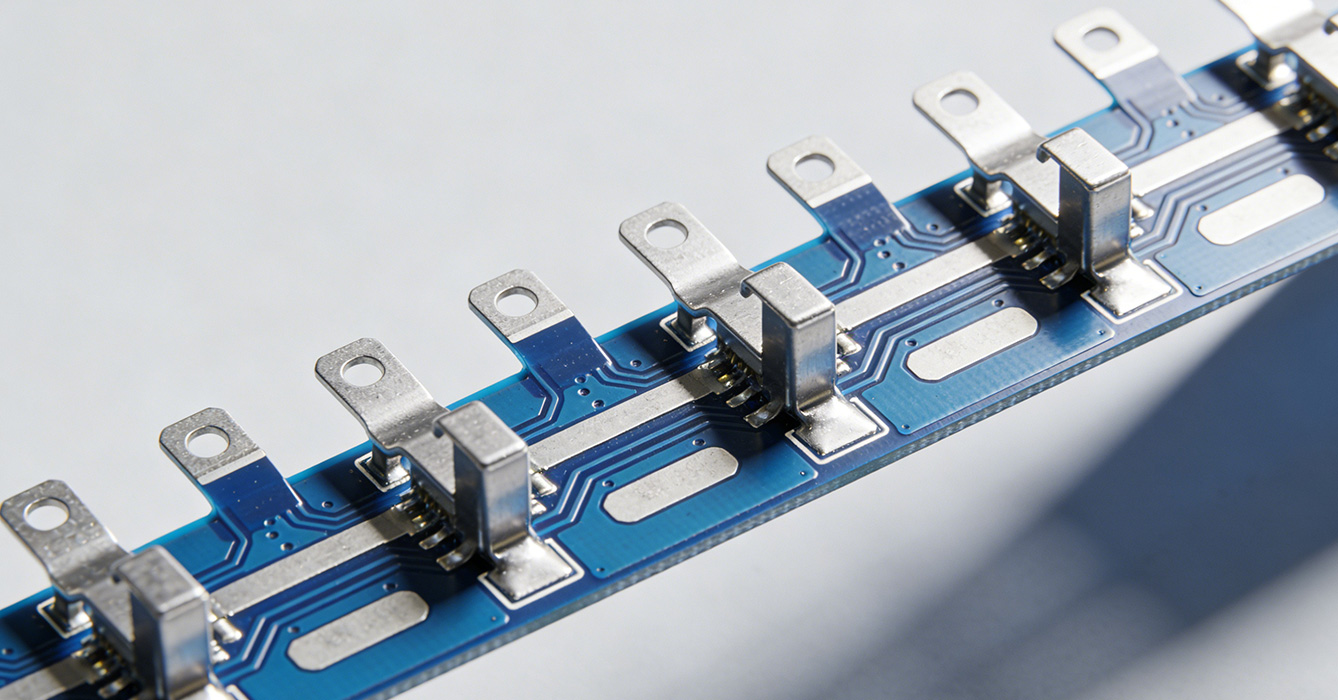

- Enhanced Insulation & Short-Circuit Prevention: Short circuits are a major battery safety hazard, so suppliers prioritize insulation reinforcement. They adopt double-layer insulation coverlays, high-dielectric-strength substrate materials, and sealed edge structures to prevent contact between conductive traces and external metal components. Additionally, they optimize circuit routing to minimize trace overlap and ensure sufficient spacing between high-voltage and low-voltage regions, eliminating potential short-circuit paths.

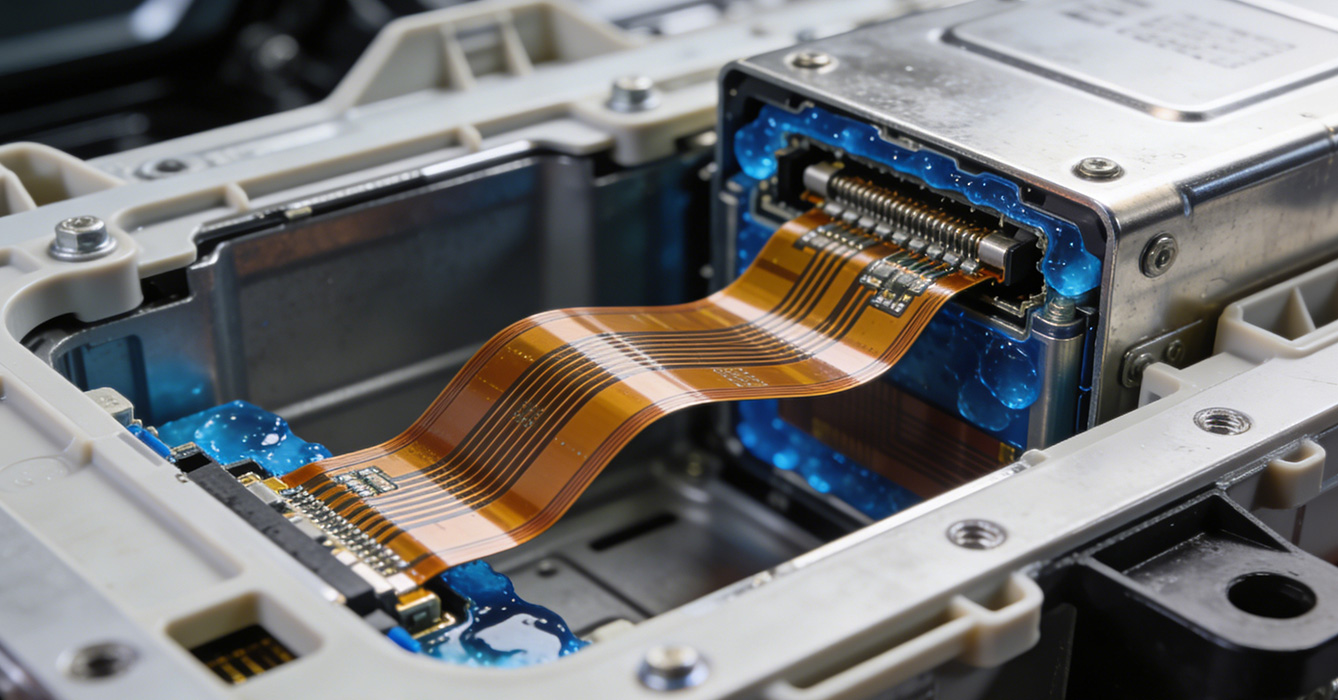

- Mechanical & Vibration Resilience: Battery systems (especially in NEVs and industrial equipment) face constant vibration and mechanical stress. High Safety Battery FPC Suppliers design FPCs with reinforced bend zones, flexible adhesive systems, and anti-fatigue substrates to withstand long-term vibration without circuit breakage or insulation damage. For battery packs with complex structures, they also implement rigid-flex FPC designs to balance flexibility and structural stability, ensuring reliable connections between battery cells and the BMS (Battery Management System).

A professional High Safety Battery FPC Supplier tailors solutions to the unique safety requirements of different battery application scenarios:

- New Energy Vehicle (NEV) Battery FPCs: NEV动力电池 demand FPCs that comply with strict automotive safety standards (IATF 16949). Suppliers develop FPCs with flame-retardant materials, high-voltage insulation (up to 1000V+), and resistance to automotive fluids (oil, coolant). These FPCs integrate with BMS for real-time fault diagnosis, supporting functions such as overcharge protection and thermal runaway prevention—critical for vehicle safety.

- Energy Storage System FPCs: Large-scale energy storage systems (e.g., grid storage, commercial backup power) require FPCs with high-current safety and long-term reliability. Suppliers design modular FPC solutions with centralized current distribution structures, enhanced heat dissipation, and surge protection circuits to handle the high power loads of energy storage batteries. They also use corrosion-resistant materials to adapt to the long-term operational environment of energy storage facilities.

- Portable & Medical Battery FPCs: For portable electronics (smartphones, laptops) and medical devices (portable diagnostic equipment), FPCs must balance safety and miniaturization. Suppliers develop ultra-thin, lightweight FPCs with low-power consumption designs and compact protective circuits. Medical battery FPCs additionally comply with ISO 13485 standards, using biocompatible materials and EMI shielding to avoid interfering with sensitive medical equipment.

To ensure FPCs meet the highest safety standards, High Safety Battery FPC Suppliers implement comprehensive testing and compliance protocols:

- Battery-Specific Safety Testing: Key tests include overcurrent endurance testing, thermal cycling (simulating -40°C to 125°C extremes), insulation resistance testing, and short-circuit simulation. For NEV applications, additional vibration testing and thermal runaway propagation testing validate FPC performance under extreme failure scenarios. These tests ensure FPCs do not become a safety bottleneck in battery systems.

- Global Safety Standard Compliance: Suppliers strictly comply with international standards such as IPC-6012/2221 (FPC quality), RoHS/REACH (environmental protection), IATF 16949 (automotive), and ISO 13485 (medical). They also meet industry-specific safety certifications, such as UL 94 V-0 for flame retardancy and VDE for high-voltage insulation, facilitating clients’ global market access.

High Safety Battery FPC Suppliers act as strategic safety partners, supporting clients through collaborative R&D and end-to-end services:

- Early-Stage Safety Co-Design: Suppliers participate in the early R&D phase of battery systems, working closely with battery and BMS engineers to integrate safety requirements into FPC design. They provide DFM (Design for Manufacturability) insights on safety-focused layout optimization, material selection, and component integration, ensuring the FPC aligns with the overall battery safety strategy.

- Rapid Prototyping & Safety Validation: To accelerate battery product development, suppliers offer rapid prototyping services, delivering functional FPC prototypes for safety testing. They assist clients in conducting preliminary safety validation, identifying potential risks early and iterating on design improvements to enhance safety performance.

- Mass Production Safety Assurance: During mass production, suppliers use AI-driven optical inspection (AOI) and insulation resistance testing to ensure consistent safety quality. They implement full batch traceability systems to track raw material safety certifications and production test data, enabling rapid response to any safety-related issues.

In conclusion, a High Safety Battery FPC Supplier is a critical enabler of safe, reliable battery systems, leveraging specialized safety technologies, scenario-specific adaptation, and rigorous validation to mitigate core battery safety risks. As the demand for high-performance batteries grows across NEVs, energy storage, and portable electronics, the strategic value of partnering with a professional High Safety Battery FPC Supplier will continue to rise. Their ability to balance safety, performance, and integration efficiency makes them indispensable in the pursuit of safer, more sustainable battery technologies.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB