-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 11. 2025, 12:52:17

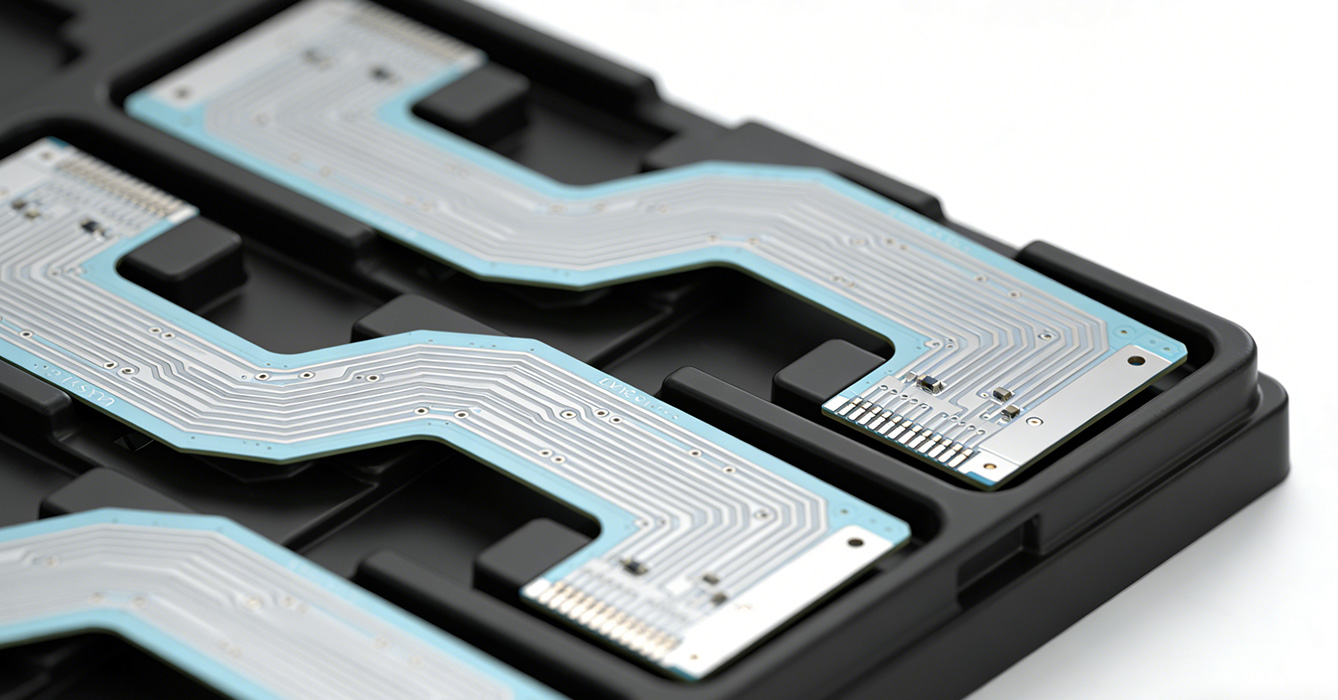

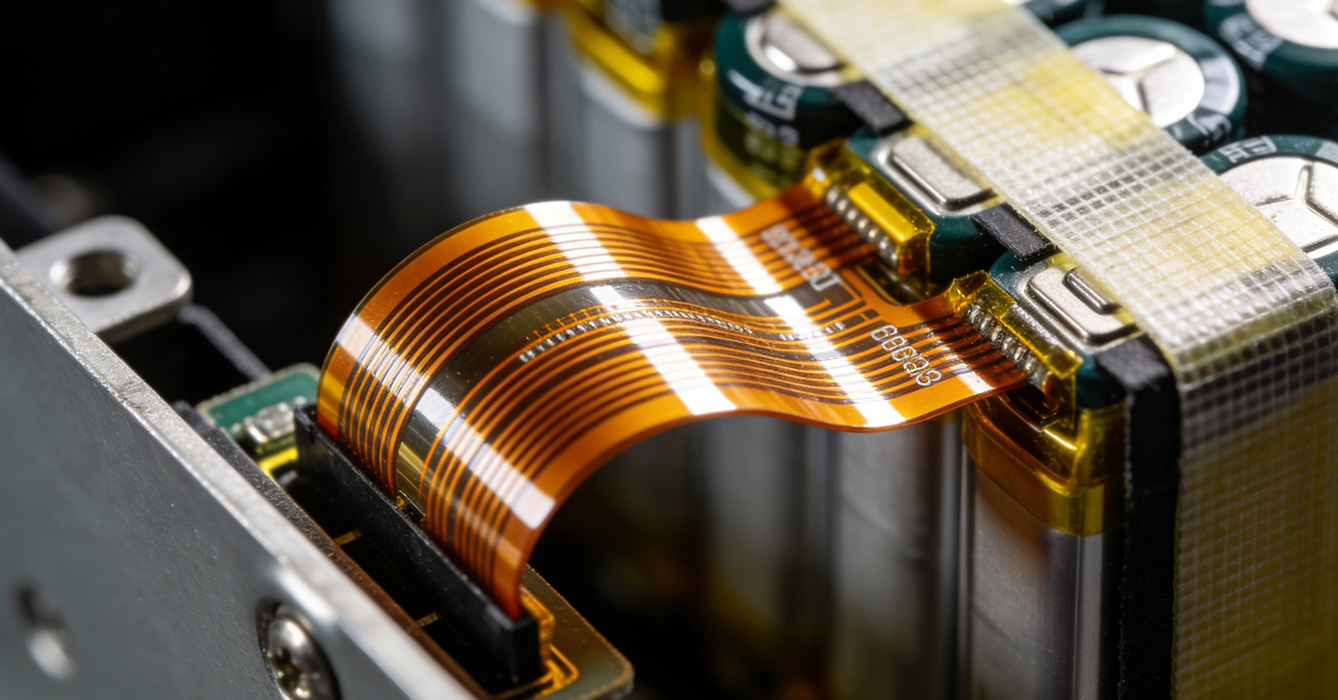

Lithium batteries have become the dominant power source for electric vehicles (EVs), energy storage systems, portable electronics, and renewable energy integration, thanks to their high energy density, long cycle life, and lightweight advantages. A professional Lithium Battery FPC Manufacturer plays a crucial role in unlocking the full performance potential of lithium battery systems by engineering flexible printed circuits (FPCs) tailored to the unique electrochemical and operational characteristics of lithium batteries. Unlike generic battery FPC suppliers, these specialized manufacturers focus on addressing lithium battery-specific challenges—such as stable current transmission during high-rate charging/discharging, compatibility with lithium battery chemistry, and long-term reliability under cyclic load conditions. For brands developing high-performance lithium battery products, partnering with a reputable Lithium Battery FPC Manufacturer is essential to ensuring system efficiency, durability, and market competitiveness.

The core competitiveness of a top Lithium Battery FPC Manufacturer lies in its ability to design FPCs that align with the unique operational demands of lithium battery systems:

- High-Rate Charge/Discharge Compatibility: Lithium batteries (especially EV and energy storage variants) require FPCs capable of handling high current loads during rapid charging and peak discharge. Manufacturers optimize circuit trace designs with widened paths and high-conductivity copper foils to minimize resistance and heat generation. They also integrate low-inductance layouts to avoid voltage drops and ensure stable power delivery, which is critical for maintaining lithium battery performance and lifespan.

- Chemical & Thermal Compatibility: Lithium battery electrolytes and operational thermal cycles pose unique material challenges. Leading manufacturers select lithium-compatible substrate materials and adhesives that resist electrolyte corrosion and maintain structural integrity across the lithium battery’s operating temperature range (-20°C to 60°C, or wider for extreme applications). This prevents material degradation that could lead to short circuits or performance loss.

- Cell-Level Integration Precision: Lithium battery packs consist of numerous individual cells requiring precise connection. Lithium Battery FPC Manufacturers design FPCs with ultra-precise pad positioning to match lithium battery cell terminals, enabling seamless integration and uniform current distribution across cells. This precision reduces cell imbalance, a key factor in extending lithium battery pack life and preventing premature failure.

Specialized manufacturing processes are critical to producing FPCs that meet the stringent requirements of lithium battery systems:

- Precision Etching & Lamination Technologies: Manufacturers use advanced laser etching and semi-additive processes to achieve ultra-fine circuit lines (sub-20μm) and tight tolerances, essential for compact lithium battery packs. Automated lamination processes ensure consistent bonding of substrate and coverlay materials, preventing delamination during repeated charge-discharge cycles and thermal expansion/contraction.

- Cleanroom Production Environments: Lithium battery FPCs are highly sensitive to contamination, which can cause internal short circuits. Reputable manufacturers produce FPCs in Class 1000/10000 cleanrooms, minimizing dust, moisture, and particulate contamination. This strict environmental control ensures the FPCs do not introduce reliability risks to lithium battery systems.

- Modular & Scalable Production: To accommodate the diverse size requirements of lithium battery packs (from small portable batteries to large EV/energy storage packs), manufacturers adopt modular production lines. This allows for flexible customization of FPC sizes and configurations, while maintaining consistent quality across both small-batch and high-volume production runs.

Lithium Battery FPC Manufacturers prioritize reliability engineering to ensure FPCs perform consistently throughout the lithium battery’s lifespan:

- Charge-Discharge Cycle Testing: FPCs undergo accelerated charge-discharge cycle testing to simulate years of lithium battery operation. This testing validates circuit stability, material durability, and contact reliability, ensuring the FPCs do not degrade or fail during the lithium battery’s typical 1000+ cycle lifespan.

- Aging & Environmental Stress Testing: Additional tests include high-temperature aging, humidity cycling, and vibration testing to replicate real-world operating conditions. For EV applications, FPCs are also tested for resistance to automotive fluids and mechanical stress from vehicle movement, ensuring long-term reliability in harsh environments.

- Thermal Management Integration: To prevent thermal buildup in high-power lithium battery systems, manufacturers design FPCs with integrated thermal vias or heat-dissipating layers. These features enhance heat transfer from the FPC to the battery pack’s cooling system, protecting both the FPC and the lithium battery cells from overheating-induced damage.

Leading Lithium Battery FPC Manufacturers act as strategic partners, supporting the development of advanced lithium battery technologies:

- Early-Stage Co-Development with Battery Makers: Manufacturers participate in the early R&D phase of next-gen lithium batteries (e.g., solid-state lithium batteries, high-nickel batteries), collaborating with battery engineers to design FPCs that adapt to new cell structures and performance requirements. This ensures FPCs do not limit the potential of innovative lithium battery technologies.

- Customized Solutions for Emerging Applications: For emerging lithium battery applications—such as solid-state EV batteries, portable medical lithium devices, and grid-scale energy storage—manufacturers develop specialized FPC solutions. These include FPCs compatible with solid electrolyte materials, ultra-miniaturized designs for portable devices, and high-voltage resistant FPCs for large-scale energy storage systems.

- Compliance & Certification Support: Manufacturers ensure FPCs comply with lithium battery industry standards, such as IEC 62133 (lithium battery safety), IATF 16949 (automotive), and ISO 13485 (medical). They provide comprehensive compliance documentation to support clients’ lithium battery product certifications, facilitating global market access.

In conclusion, a Lithium Battery FPC Manufacturer is a critical enabler of high-performance lithium battery systems, leveraging lithium-specific design, advanced manufacturing, and lifecycle reliability engineering. As the demand for high-energy-density, long-lasting lithium batteries grows across EVs, energy storage, and portable electronics, the strategic value of partnering with a specialized Lithium Battery FPC Manufacturer will continue to rise. Their ability to tailor FPC solutions to the unique needs of lithium batteries makes them indispensable in advancing sustainable and efficient energy storage technologies.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB