-

- PCB TYPE

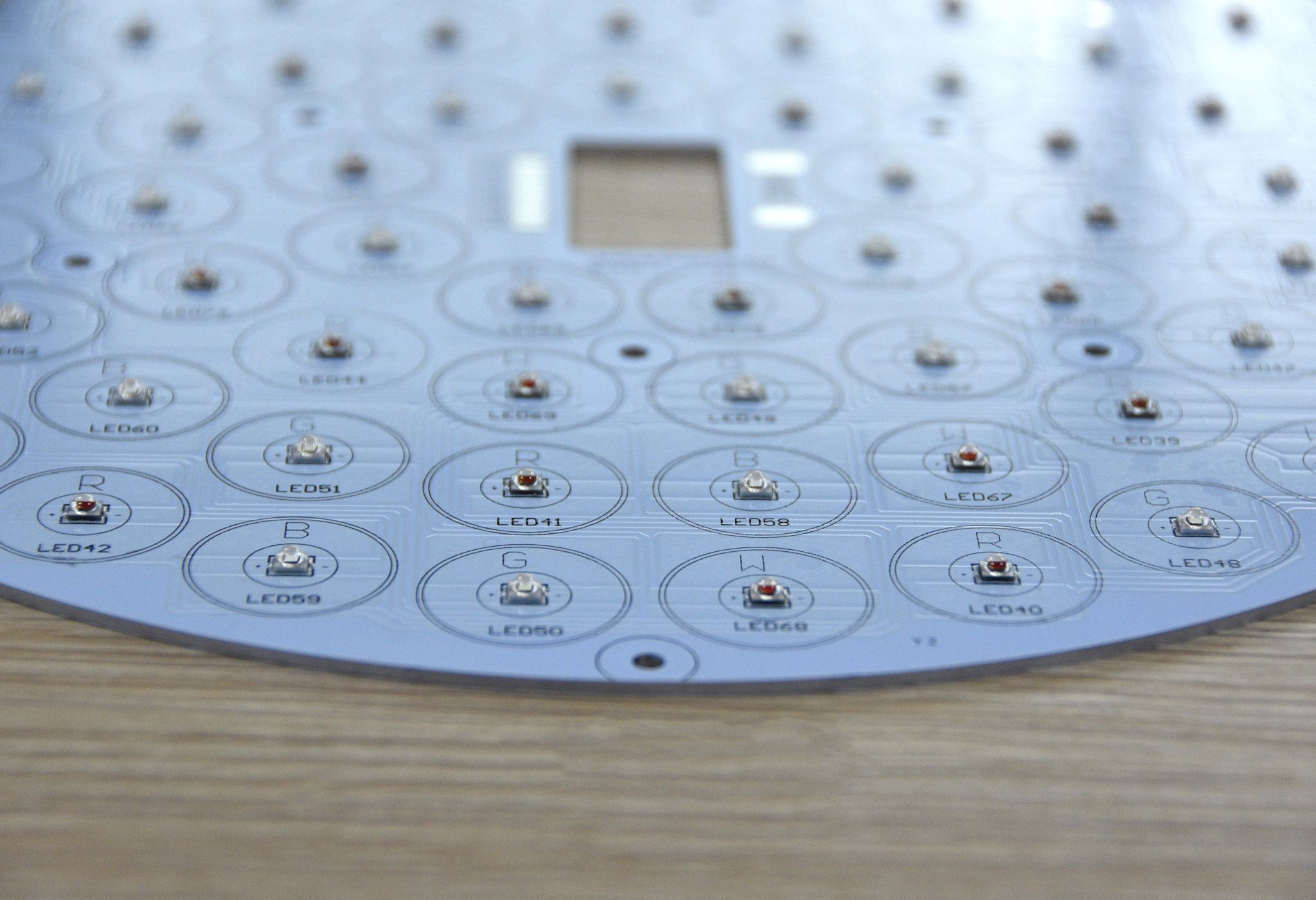

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 30. 2025, 08:52:31

In today's fast-paced world, the demand for electronic devices is skyrocketing. As a result, manufacturers are continually seeking ways to speed up production without compromising quality. One solution that has emerged is the high-speed Surface Mount Technology (SMT) assembly process. This article will guide you through the intricacies of this process, shedding light on why it's become a game-changer in the electronics manufacturing industry.

High-speed SMT assembly refers to the process of mounting electronic components onto a printed circuit board (PCB) at an accelerated pace. This method leverages advanced machinery and technology to place components with incredible precision and speed, enhancing production efficiency and reducing turnaround time.

Solder Paste Application: The process begins with the application of solder paste onto the PCB using a stencil. This paste acts as an adhesive to hold components in place temporarily and as a conduit to create electrical connections.

Component Placement: High-speed pick-and-place machines then position components onto the solder-pasted areas of the PCB. These machines can handle thousands of components per hour, drastically speeding up the assembly process.

Reflow Soldering: Once components are placed, the PCB undergoes reflow soldering. The board is heated, melting the solder paste and permanently affixing the components to the board.

Inspection and Quality Control: Finally, the assembled boards go through a series of inspections to ensure that all components are correctly placed and functioning as intended. Automated Optical Inspection (AOI) systems are commonly used for this purpose.

The high-speed SMT assembly process offers several advantages that make it an attractive choice for manufacturers:

One of the primary benefits of high-speed SMT assembly is its ability to significantly increase production speed. Advanced machinery can place components much faster than manual assembly, allowing manufacturers to meet tight deadlines and high demand.

Modern SMT machines are equipped with cutting-edge technology that ensures components are placed with incredible precision. This accuracy minimizes errors and defects, resulting in higher-quality products.

By automating much of the assembly process, high-speed SMT reduces the need for manual labor. This not only lowers labor costs but also minimizes human error, further enhancing product quality.

High-speed SMT assembly lines are highly adaptable, allowing manufacturers to quickly adjust to changes in product design or volume. This flexibility is crucial in an industry where innovation and demand are constantly evolving.

Technology plays a pivotal role in the high-speed SMT assembly process. From sophisticated software to state-of-the-art machinery, technology ensures that every aspect of the process is optimized for speed and accuracy.

At the heart of the high-speed SMT process are pick-and-place machines. These machines use precision robotics to position components onto PCBs with exceptional speed and accuracy. Advanced models can handle a wide variety of component sizes and shapes, further enhancing their versatility.

Reflow ovens are another critical component of the SMT process. These ovens heat the entire PCB to a controlled temperature, ensuring that solder paste melts evenly and components are securely attached. Modern reflow ovens come with programmable settings, allowing manufacturers to fine-tune the process for different products.

To maintain high-quality standards, inspection systems are used to verify that components are correctly placed and soldered. Automated Optical Inspection (AOI) systems use cameras and sensors to detect any discrepancies, allowing for quick corrections and reducing the risk of defective products reaching consumers.

Despite its many advantages, high-speed SMT assembly does present some challenges:

As electronic devices become more compact, the components themselves are also shrinking. Handling these tiny components requires even greater precision and advanced technology, which can increase costs.

Modern PCBs often feature complex designs that can be challenging to assemble quickly. Manufacturers must invest in advanced machinery and skilled technicians to navigate these complexities efficiently.

The initial investment in high-speed SMT equipment can be significant. However, for many manufacturers, the long-term benefits in terms of speed, accuracy, and reduced labor costs outweigh the upfront expenses.

The future of SMT assembly looks promising, with several trends on the horizon that could further revolutionize the process:

AI and machine learning are poised to play a significant role in the future of SMT assembly. These technologies can optimize production processes, predict maintenance needs, and enhance quality control, making the assembly process even more efficient.

The development of new materials with enhanced properties could lead to even faster and more reliable assembly processes. Conductive adhesives and advanced solder pastes are just a few examples of materials that could transform the industry.

As Industry 4.0 technologies become more prevalent, SMT assembly lines will likely become more interconnected. This integration will allow for real-time monitoring and data analysis, further enhancing efficiency and product quality.

The high-speed SMT assembly process has revolutionized the electronics manufacturing industry, offering unmatched speed, precision, and flexibility. By leveraging advanced technology and addressing the challenges of component miniaturization and complex designs, manufacturers can continue to meet the growing demand for electronic devices. As new trends and technologies emerge, the future of SMT assembly looks brighter than ever, promising even greater efficiencies and possibilities.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB