-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 26. 2025, 12:47:34

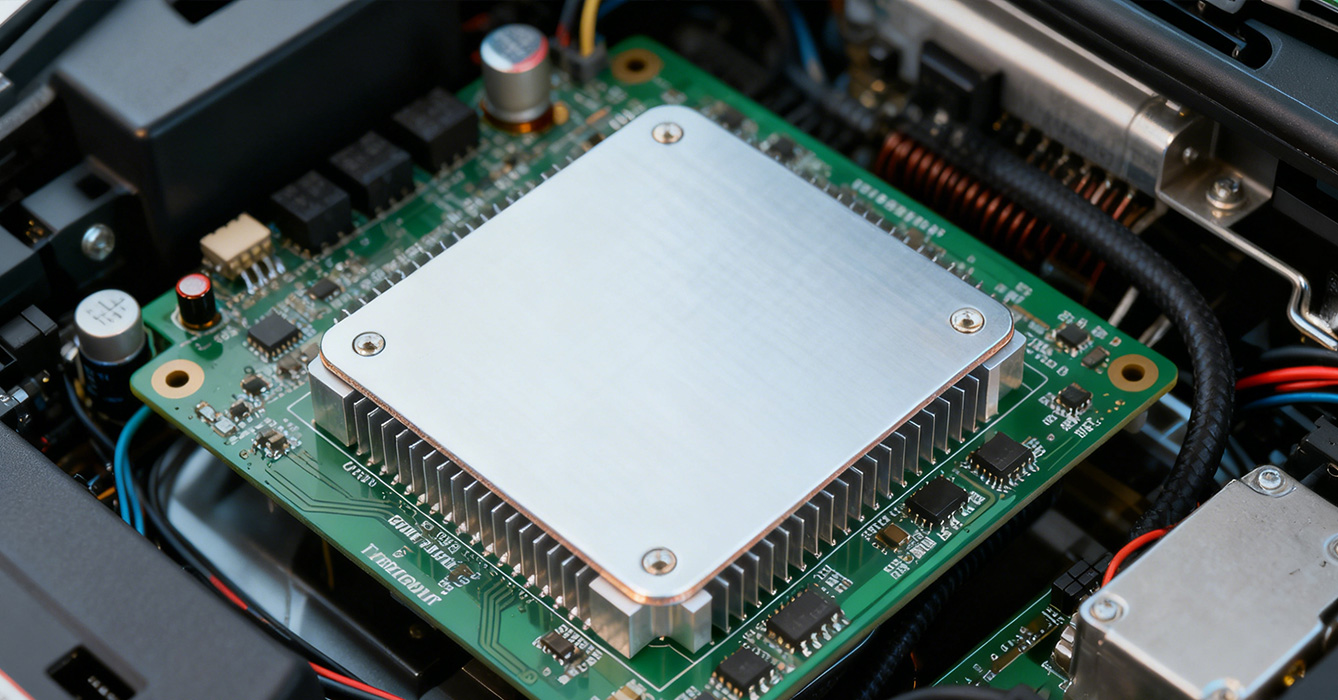

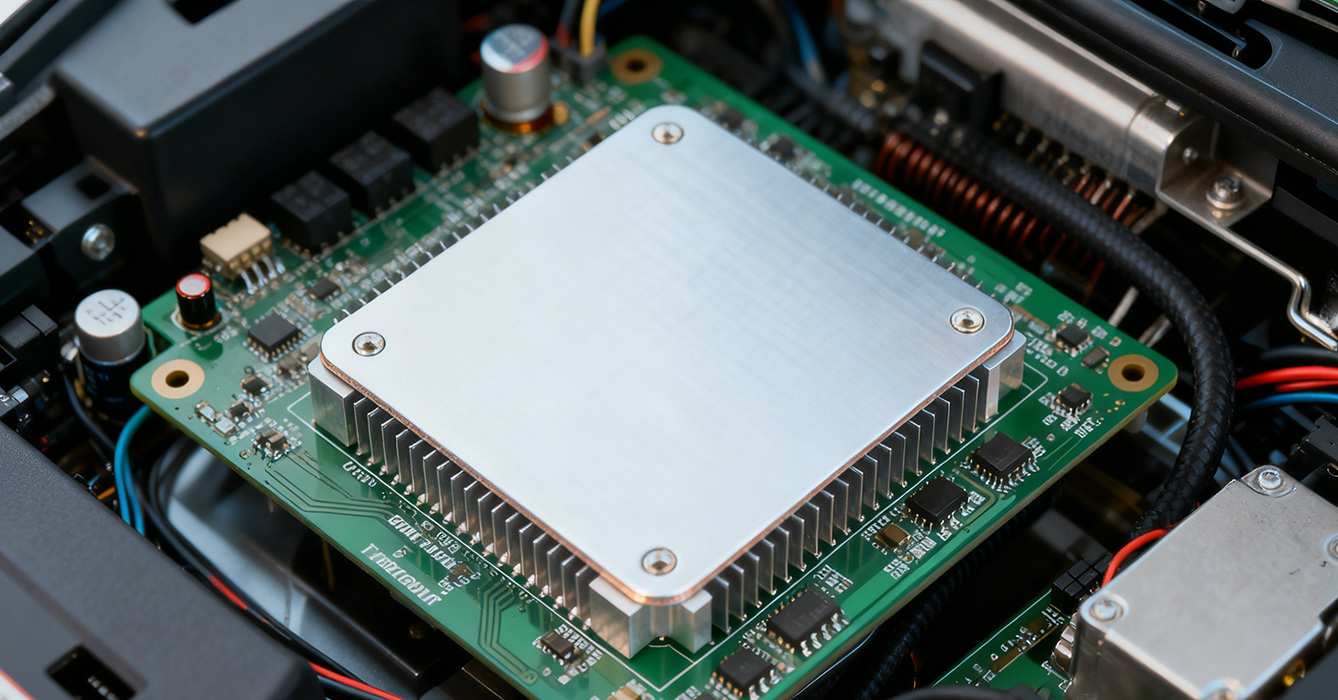

In the harsh operating conditions of modern automobiles—where under-hood temperatures can soar, and electronic systems face continuous thermal stress—High Temperature Sinkpad Auto PCB has become an indispensable component. Designed specifically to thrive in extreme heat, this specialized PCB merges the integrated thermal management of sinkpad technology with high-temperature-resistant materials and construction. It addresses the critical challenge of maintaining reliability in automotive electronics exposed to sustained high temperatures, from electric vehicle (EV) powertrains to engine control units (ECUs). For automakers and tier suppliers, this PCB delivers the thermal resilience needed to ensure safety, performance, and longevity in the most demanding vehicle systems.

Automotive electronics operate in environments far more extreme than consumer or industrial applications. Under-hood components, in particular, face temperature ranges that can exceed 150°C for extended periods, while even cabin electronics must withstand thermal cycling between freezing cold and intense heat. Generic PCBs often fail under such stress—solder joints crack, substrates degrade, and thermal management systems become ineffective. High Temperature Sinkpad Auto PCB is engineered to overcome these limitations, with materials and design optimized to resist thermal aging, warpage, and electrical breakdown at elevated temperatures. This resilience is not just a performance feature; it’s a safety imperative, as electronic failures in critical systems like EV batteries or ADAS can have catastrophic consequences.

At the heart of High Temperature Sinkpad Auto PCB is an advanced sinkpad design tailored for extreme heat. Unlike standard sinkpad PCBs, this automotive-grade solution uses high-thermal-conductivity substrates and reinforced sink structures that maintain efficiency even at temperatures above 180°C. The sinkpad acts as a dedicated thermal channel, drawing heat directly from high-power components—such as SiC/GaN semiconductors, power regulators, and LED drivers—away from sensitive circuits. This integrated approach eliminates the need for bulky external heat sinks, which can fail or become inefficient in extreme heat, while ensuring uniform heat distribution across the PCB. By preventing hotspots and reducing thermal resistance, the sinkpad design extends component lifespan and maintains consistent performance, even in the most heat-prone areas of a vehicle.

What sets this specialized PCB apart is its focus on thermal durability and automotive-specific demands:

Heat-Resistant Materials: Constructed with high-temperature substrates (such as polyimide or ceramic-filled composites) and solder materials rated for continuous exposure to 150°C+ temperatures, resisting degradation and maintaining structural integrity over time.

Reinforced Mechanical Stability: The sinkpad structure and substrate are engineered to resist warpage and mechanical stress caused by thermal cycling, ensuring solder joints remain intact and components stay properly aligned.

Optimized Thermal Pathways: Sinkpad regions are strategically placed to target high-heat components, with thermal vias and copper layers designed to maximize heat dissipation without compromising electrical performance.

Automotive-Grade Reliability: Tested to meet strict automotive standards for thermal shock, vibration, and long-term durability, ensuring compliance with industry requirements for vehicle electronics.

High Temperature Sinkpad Auto PCB is essential for vehicle systems that operate in the most extreme thermal environments:

EV Powertrains & On-Board Chargers (OBCs): Manages the intense heat generated by high-power semiconductors in traction inverters and OBCs, ensuring efficient power transfer and preventing overheating-related failures.

Engine Control Units (ECUs): Withstands the extreme heat of under-hood installations, maintaining precise control over engine performance, emissions, and fuel efficiency.

Battery Management Systems (BMS): Monitors and regulates battery cell temperatures in EVs and hybrids, preventing thermal runaway even during fast charging or high-load operation.

High-Power Lighting: Powers LED headlights, fog lights, and auxiliary lighting systems mounted in heat-prone areas, ensuring consistent brightness and reliability.

As automakers push toward electrification and higher power densities, the thermal demands on vehicle electronics continue to grow. EVs, in particular, require PCBs that can handle the heat generated by high-voltage batteries and power electronics, while autonomous vehicles rely on ADAS systems that must perform flawlessly in all thermal conditions. High Temperature Sinkpad Auto PCB enables this innovation by providing a reliable foundation for heat-critical systems, allowing engineers to design more compact, efficient, and powerful automotive electronics. For suppliers, this PCB represents a competitive advantage, offering a solution that addresses a key pain point in modern vehicle design—thermal reliability.

In conclusion, High Temperature Sinkpad Auto PCB is a specialized solution that meets the unique thermal challenges of automotive electronics. By combining advanced sinkpad technology with high-temperature-resistant materials, it delivers the resilience needed to thrive in extreme vehicle environments. From EV powertrains to under-hood ECUs, this PCB ensures safety, performance, and longevity, making it a critical component for the next generation of automobiles. As the automotive industry continues to evolve, the demand for high-temperature-resistant PCBs will only increase—solidifying the role of High Temperature Sinkpad Auto PCB as a cornerstone of automotive electronic design.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB