-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 26. 2025, 12:46:21

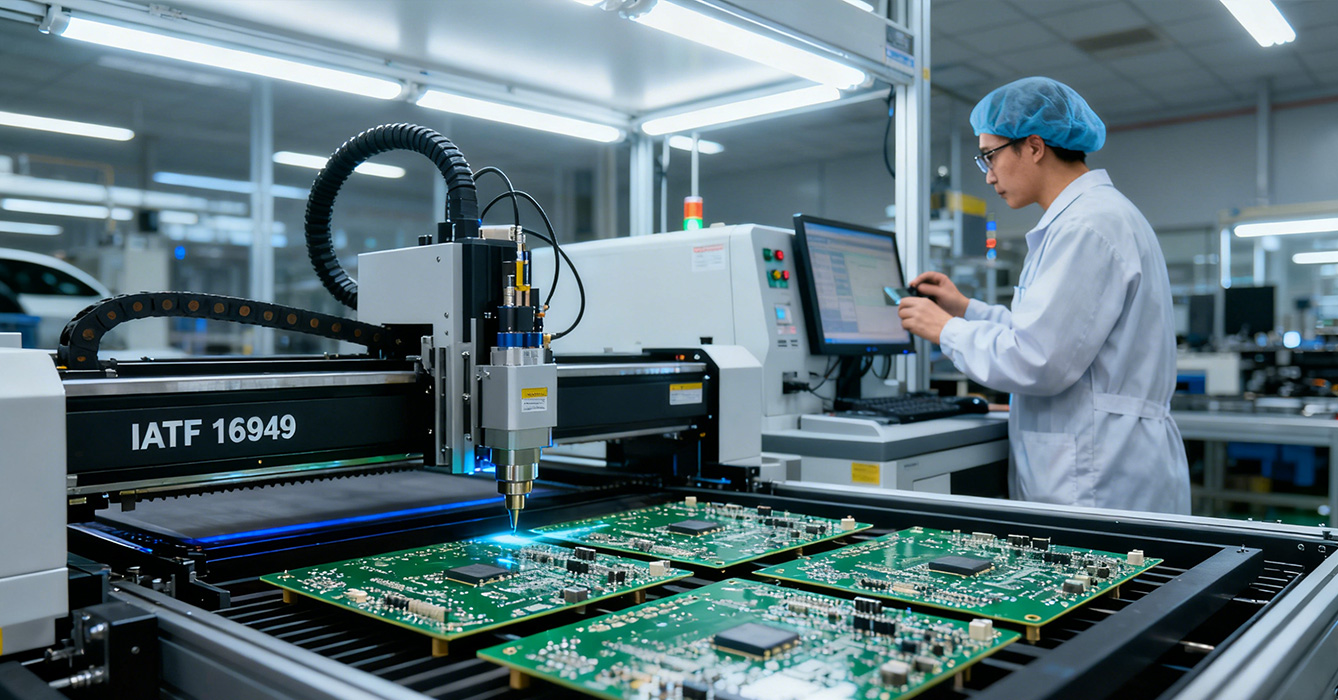

In the demanding landscape of automotive electronics, where safety, durability, and performance are non-negotiable, the IATF 16949 Sinkpad Automotive PCB has emerged as a critical component. Designed to meet the rigorous quality management requirements of the automotive industry, this specialized PCB combines the integrated thermal management of sinkpad technology with the strict compliance framework of IATF 16949. It addresses the unique challenges of vehicle electronics—extreme temperature fluctuations, vibration, and high power density—delivering a solution that ensures long-term reliability in critical systems from powertrains to advanced driver assistance systems (ADAS). For automakers and tier suppliers, this PCB is more than a component; it’s a foundational element of safe, efficient, and compliant automotive electronics.

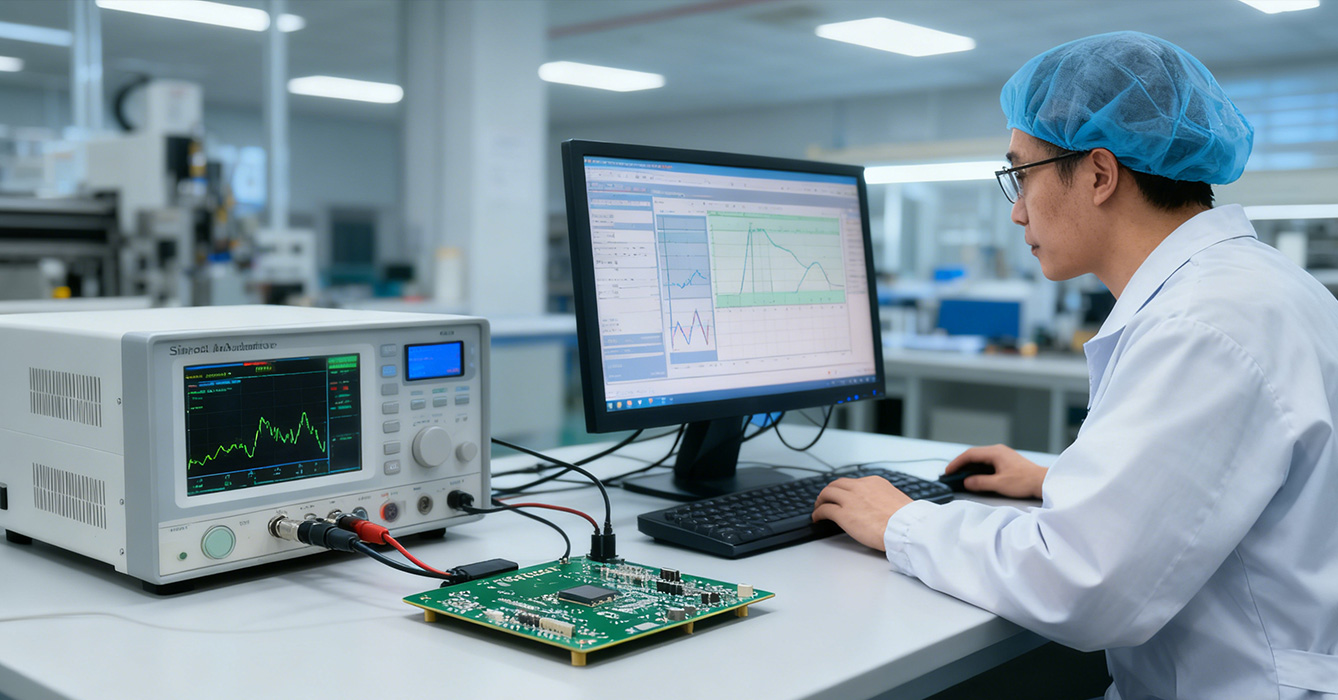

At the core of the IATF 16949 Sinkpad Automotive PCB is adherence to the IATF 16949 standard, a globally recognized framework for quality management in the automotive sector. This compliance is not merely a certification but a commitment to consistent, defect-free production and continuous improvement. Unlike general-purpose PCBs, these automotive-grade sinkpad PCBs undergo rigorous process controls, from raw material sourcing to final assembly, to meet the standard’s strict requirements. This includes traceability of all components, advanced failure mode and effects analysis (FMEA), and regular audits to ensure ongoing compliance. For automakers, this translates to reduced risk of component failure, minimized warranty claims, and alignment with global automotive quality expectations—critical in an industry where safety and reputation are paramount.

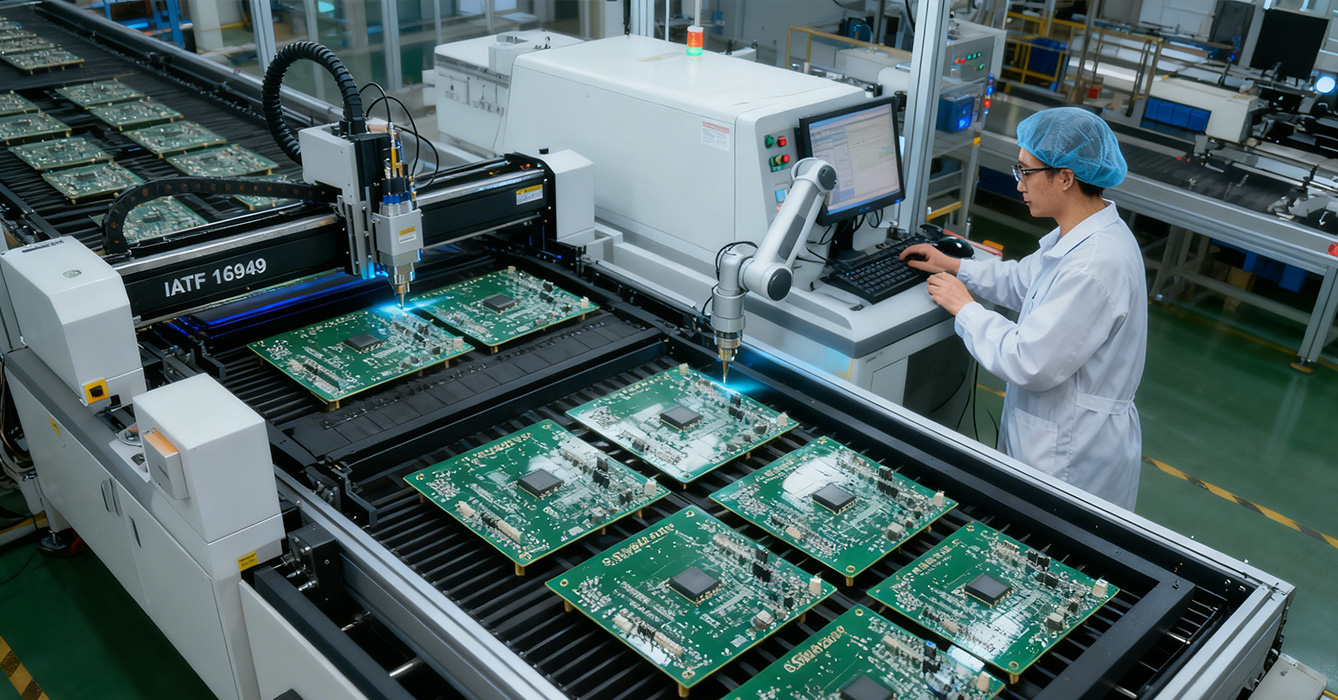

Automotive electronics operate in some of the harshest environments, with components exposed to temperature swings from -40°C to 150°C, constant vibration, and high electrical loads. Sinkpad technology addresses these challenges by integrating dedicated thermal management structures directly into the PCB. Unlike traditional PCBs that rely on external heat sinks, the sinkpad design creates a direct thermal path from high-power components—such as power semiconductors, LED drivers, and battery management system (BMS) modules—to the PCB substrate. This integrated approach eliminates hotspots, reduces thermal resistance, and ensures uniform heat distribution, preventing component degradation and extending service life. For critical automotive systems like electric vehicle (EV) powertrains or ADAS sensors, this thermal resilience is essential to maintaining performance and safety under extreme operating conditions.

Automotive applications impose unique demands that generic PCBs cannot meet, making the IATF 16949 Sinkpad Automotive PCB a necessity:

Reliability Under Stress: Vehicles endure years of vibration, temperature cycling, and mechanical shock. The sinkpad PCB’s reinforced structure and thermal stability resist warpage and solder joint failure, ensuring consistent performance over the vehicle’s lifetime.

Power Density Support: Modern vehicles, particularly EVs, require high-power electronics in compact spaces. The sinkpad’s integrated thermal management enables higher power density without compromising reliability, supporting the miniaturization of critical systems like on-board chargers (OBCs) and traction inverters.

Safety Compliance: Automotive electronics play a direct role in vehicle safety, from ABS systems to ADAS. IATF 16949 compliance ensures that the PCB meets strict safety standards, reducing the risk of electrical failures that could compromise driver and passenger safety.

The versatility and reliability of the IATF 16949 Sinkpad Automotive PCB make it indispensable across key automotive electronics systems:

Electric Vehicle (EV) Powertrains: Powers traction inverters and OBCs, managing the high heat generated by SiC and GaN semiconductors while ensuring efficient power transfer.

Battery Management Systems (BMS): Monitors and balances battery cell temperatures, preventing thermal runaway and extending battery lifespan in EVs and hybrids.

Advanced Driver Assistance Systems (ADAS): Supports sensors, cameras, and radar modules with stable thermal and electrical performance, ensuring accurate data collection for features like adaptive cruise control and lane-keeping assist.

Interior & Exterior Lighting: Powers high-power LED headlights, taillights, and ambient lighting systems, withstanding under-hood and cabin temperature fluctuations.

As automotive technology evolves toward electrification, autonomy, and connectivity, the demand for high-performance, compliant PCBs will only grow. The IATF 16949 Sinkpad Automotive PCB is well-positioned to meet this demand, combining proven thermal management with a quality framework that scales with industry advancements. Future innovations will likely focus on enhancing thermal efficiency to support higher-power EV systems, integrating smarter diagnostic features for predictive maintenance, and aligning with emerging sustainability standards for automotive manufacturing. For automakers and suppliers, investing in this specialized PCB is a strategic choice that ensures compliance, enhances reliability, and supports the development of next-generation vehicles.

In summary, the IATF 16949 Sinkpad Automotive PCB represents the gold standard for automotive electronics, uniting IATF 16949’s quality rigor with sinkpad technology’s thermal resilience. It addresses the unique challenges of vehicle environments, delivering a component that is safe, durable, and efficient. As the automotive industry continues its shift toward electrification and autonomy, this PCB will remain a critical enabler of innovation, ensuring that vehicles are not just smarter, but also more reliable and compliant.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB