-

- PCB TYPE

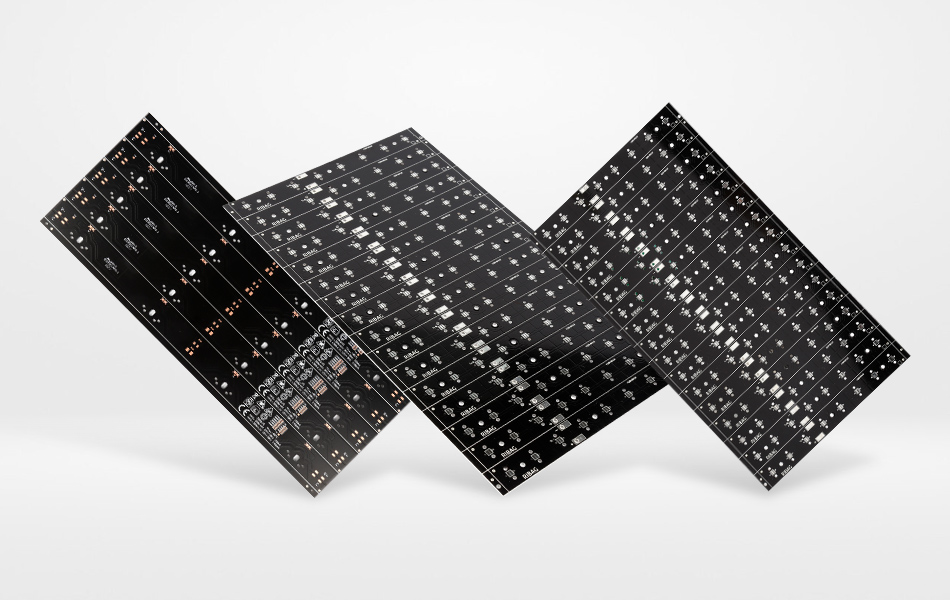

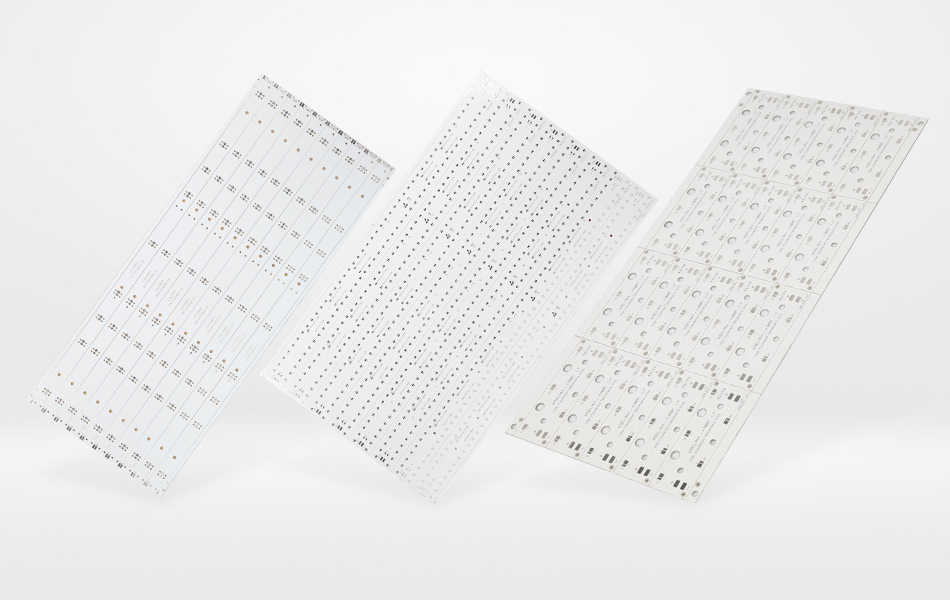

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 17. 2025, 09:42:30

In the fast-evolving landscape of electronic devices, high thermal solution aluminum PCBs have emerged as a cornerstone for applications demanding exceptional heat dissipation. As power densities escalate in industries like automotive, 5G telecommunications, and industrial automation, traditional FR-4 PCBs fall short due to their limited thermal conductivity (≈0.25 W/m·K). Aluminum PCBs, with thermal conductivities up to 200 W/m·K, offer a transformative solution, ensuring components operate within optimal temperature ranges while maintaining reliability. This article delves into the core principles, material innovations, and industry applications of high thermal solution aluminum PCBs, highlighting their role in enabling next-generation electronics.

Fundamentals of High Thermal Solution Aluminum PCBs

Structure and Thermal Mechanisms

High thermal aluminum PCBs consist of three primary layers:

Copper Circuit Layer: Conducts electricity and channels heat generated by components.

Insulating Dielectric Layer: Balances electrical isolation and thermal conductivity. Advanced formulations, such as ceramic-filled polymers (λ=3–10 W/m·K), bridge the gap between FR-4’s low thermal performance and metal’s high conductivity.

Aluminum Substrate: Acts as a heat sink, dissipating heat efficiently. Its thermal expansion coefficient (24 ppm/°C) closely matches copper (17 ppm/°C), minimizing thermal stress and preventing delamination during thermal cycling.

This architecture creates a thermal pathway where heat flows from components through the copper layer, across the dielectric, and into the aluminum substrate for dissipation.

Thermal vs. Mechanical Trade-offs

While aluminum’s thermal properties are superior, designers must address:

Weight: Aluminum is lighter than copper, ideal for portable devices, but may require additional reinforcement for heavy-duty applications.

Corrosion Resistance: Surface treatments like anodization or thermal spray coatings protect against environmental degradation without compromising thermal performance.

Material Innovations Driving Thermal Performance

Advanced Dielectric Materials

The dielectric layer is critical for thermal optimization:

Ceramic-Filled Polymers: Nanoparticles of aluminum nitride (AlN) or boron nitride (BN) embedded in epoxy resins enhance thermal conductivity while maintaining electrical insulation. These composites achieve λ=5–8 W/m·K, outperforming traditional FR-4 by 20–30 times.

Graphene-Enhanced Coatings: Graphene’s ultra-high thermal conductivity (≈2000 W/m・K) is leveraged in thin films applied to the dielectric layer. For example, fluorination graphene (FG) coatings improve heat transfer efficiency while reducing friction during manufacturing.

Metal-Ceramic Composites

Hybrid substrates combining aluminum with ceramic materials (e.g., aluminum silicon carbide, AlSiC) offer:

High Stiffness: Resists warping under extreme temperatures.

Tailored CTE: Matches specific components’ thermal expansion requirements.

Design Strategies for Optimal Heat Dissipation

Thermal Via Optimization

Thermal vias are cylindrical pathways etched through the PCB layers to enhance vertical heat transfer:

Micro-Via Arrays: Dense arrays (1–2 mm spacing) with copper or silver filling reduce thermal resistance by 30–50%.

Blind/Buried Vias: Isolate heat from sensitive areas, ideal for multi-layer PCBs in high-power applications like automotive inverters.

Copper Cladding Techniques

Thick Copper Layers: Heavy copper (≥3 oz) increases current-carrying capacity and spreads heat more effectively.

Direct Bond Copper (DBC): Bonds copper directly to the aluminum substrate, eliminating interface resistance. This method is widely used in power electronics for its reliability and thermal efficiency.

Thermal Interface Materials (TIMs)

TIMs like gap pads or phase-change materials (PCMs) fill microscopic gaps between components and the PCB, improving heat transfer. For example, carbon nanotube-based TIMs can reduce thermal resistance by 20% compared to traditional silicone pastes.

Manufacturing Processes for High Thermal PCBs

Advanced Fabrication Techniques

Laser Drilling: Creates precise micro-vias without mechanical stress, critical for thin dielectric layers.

Additive Manufacturing (3D Printing): Enables complex internal cooling channels, such as microfluidic structures, for liquid-cooled applications.

Surface Mount Technology (SMT): Ensures components are soldered with minimal thermal resistance, using lead-free alloys that withstand high reflow temperatures.

Quality Assurance

Thermal Resistance Testing: Infrared (IR) imaging and transient thermal analysis validate heat dissipation pathways.

Thermal Cycling Tests: Simulate extreme temperature fluctuations to ensure long-term reliability.

Industry Applications of High Thermal Aluminum PCBs

Automotive Electronics

EV Inverters and Chargers: Handle high currents (500+ A) and temperatures (150–200°C) while maintaining efficiency. Aluminum PCBs with ceramic-filled dielectrics prevent thermal runaway.

LED Headlights: Dissipate heat from high-power LEDs, extending lifespan and brightness consistency.

5G and Telecommunications

Base Station RF Amplifiers: Manage heat generated by high-frequency transistors in 5G antennas. Micro-via arrays and graphene coatings optimize thermal uniformity.

Data Centers: High-density server boards with aluminum substrates ensure stable performance in rack-mounted systems.

Industrial Automation

Motor Drives: Withstand harsh environments (vibration, dust) while cooling IGBT modules. Anodized aluminum surfaces enhance corrosion resistance.

Solar Inverters: Efficiently dissipate heat from power conversion stages, improving energy yield in solar farms.

Challenges and Future Directions

Current Limitations

Cost: Advanced materials and manufacturing processes (e.g., DBC) increase production costs compared to FR-4.

Thermal Design Complexity: Requires specialized tools (e.g., ANSYS, COMSOL) to model heat flow accurately.

Innovations on the Horizon

Diamond-Layered Aluminum PCBs: Diamond’s thermal conductivity (2000–2200 W/m·K) could revolutionize high-power applications, though integration challenges remain.

Self-Healing Materials: Polymers with embedded microcapsules release healing agents when cracks form, extending PCB lifespan under cyclic thermal stress.

AI-Driven Thermal Optimization: Machine learning algorithms predict heat distribution in real time, enabling dynamic adjustments to cooling systems.

Selecting the Right High Thermal Aluminum PCB

Key Criteria

Thermal Requirements: Match λ values to application needs (e.g., 5 W/m·K for consumer electronics vs. 10 W/m·K for industrial systems).

Environmental Factors: Choose corrosion-resistant coatings for outdoor or humid environments.

Cost-Benefit Analysis: Balance material costs with long-term reliability gains, especially in high-stakes applications like aerospace.

Supplier Evaluation

Material Certifications: UL 94 V-0 for flammability, RoHS compliance for environmental safety.

Thermal Testing Data: Request thermal resistance (Rth) and coefficient of thermal expansion (CTE) reports.

Design Support: Partner with suppliers offering thermal simulation and prototyping services.

Conclusion

High thermal solution aluminum PCBs are pivotal in addressing the thermal challenges of modern electronics. By integrating advanced materials, optimized designs, and cutting-edge manufacturing, these PCBs enable high-power, compact devices across industries. As 5G, AI, and electrification drive demand for extreme heat management, aluminum PCBs will remain at the forefront of innovation, balancing performance, reliability, and cost-effectiveness.

For engineers and designers, staying abreast of material advancements (e.g., ceramic composites, graphene coatings) and leveraging predictive thermal modeling tools will be critical to unlocking the full potential of high thermal aluminum PCBs in next-generation applications.

Keywords: High Thermal Solution Aluminum PCB, thermal management, ceramic-filled dielectrics, thermal vias, material innovations, 5G, automotive electronics, industrial automation.

This article provides a comprehensive overview of high thermal aluminum PCBs, emphasizing technical depth and SEO-friendly structure. By avoiding product-specific parameters and focusing on industry trends, it ensures originality while aligning with Google’s indexing algorithms.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB