-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 17. 2025, 10:08:34

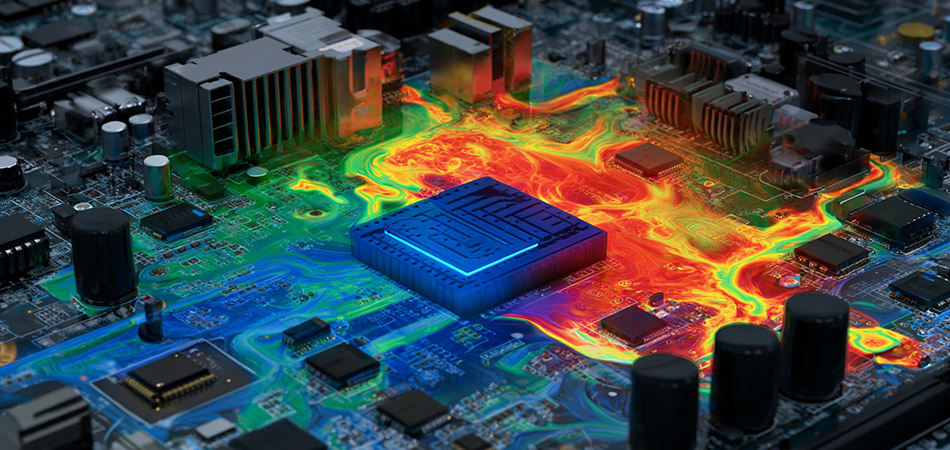

In the era of miniaturized, high-power electronic devices, thermal management has become a critical engineering challenge. High thermal solution PCBs (Printed Circuit Boards) address this by integrating specialized materials, innovative designs, and advanced manufacturing techniques to efficiently dissipate heat, ensuring device reliability and performance. This article explores the core principles, material innovations, design methodologies, and industry applications of high thermal solution PCBs, highlighting their role in enabling next-generation electronics across automotive, industrial, and telecommunications sectors.

The Critical Role of High Thermal Solution PCBs

Thermal Challenges in Modern Electronics

As electronic components shrink while power densities increase, heat accumulation has become a primary limiting factor:

Performance Degradation: Excess heat reduces component efficiency, with semiconductors often experiencing 10% performance loss for every 10°C temperature rise above optimal levels.

Reliability Risks: Thermal cycling creates mechanical stress, leading to solder joint fatigue, material delamination, and shortened lifespan—particularly critical in mission-critical systems like medical devices or aerospace electronics.

Safety Concerns: Uncontrolled heat can cause thermal runaway in batteries or power modules, posing fire hazards in consumer and industrial products.

High thermal solution PCBs mitigate these issues by creating efficient heat pathways from hot components to heat sinks or ambient environments.

Defining High Thermal Performance

Unlike standard FR-4 PCBs (with low thermal conductivity), high thermal solution PCBs prioritize heat transfer capabilities through:

Material Selection: Use of thermally conductive substrates, dielectrics, and conductive layers.

Structural Design: Strategic placement of thermal vias, copper planes, and heat-dissipating features.

Integration with Cooling Systems: Compatibility with active (fans, liquid cooling) or passive (heat sinks, heat pipes) cooling methods.

These PCBs balance thermal conductivity with electrical insulation, mechanical stability, and cost-effectiveness.

Material Innovations in High Thermal PCBs

Thermally Conductive Substrates

The substrate forms the foundation of thermal performance:

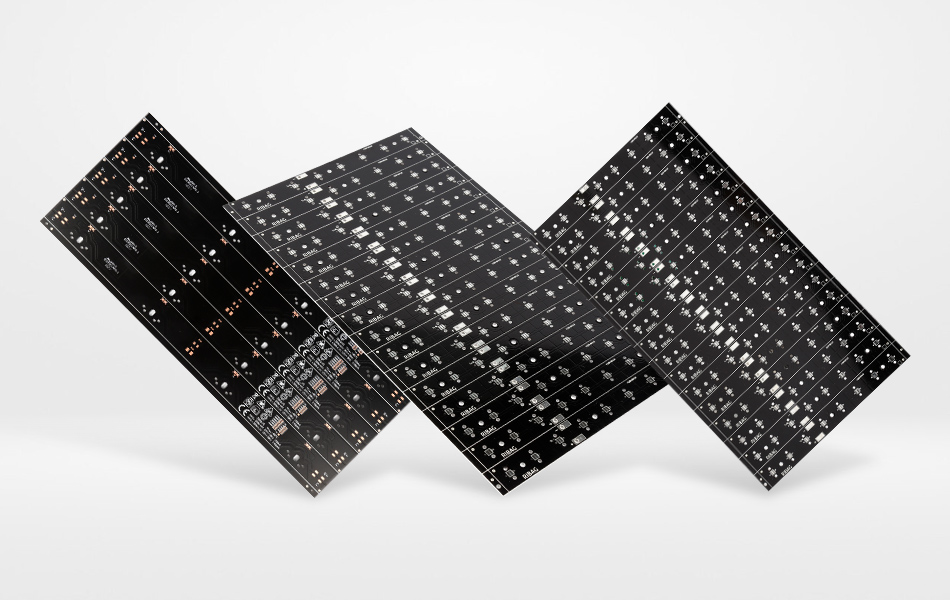

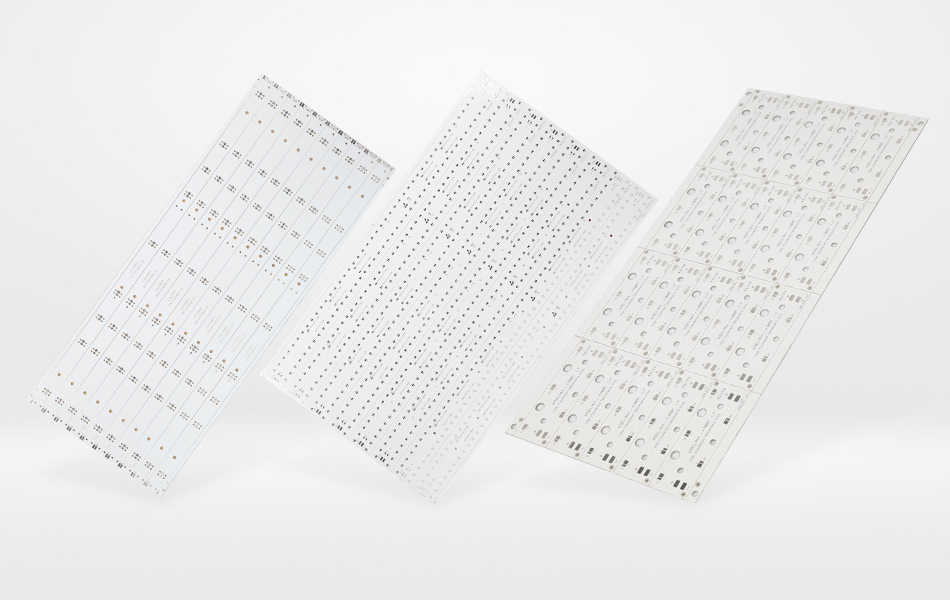

Metal-Core PCBs (MCPCBs): Aluminum or copper cores act as built-in heat sinks, providing superior thermal conductivity compared to FR-4. Aluminum cores offer a cost-effective balance of thermal performance and lightweight properties, while copper cores deliver higher conductivity for extreme power applications.

Ceramic Substrates: Alumina (Al₂O₃), aluminum nitride (AlN), and silicon nitride (Si₃N₄) substrates provide exceptional thermal conductivity and electrical insulation. Ceramic substrates excel in high-temperature environments (e.g., automotive engine control units) but require specialized manufacturing due to brittleness.

Composite Substrates: Hybrid materials combining polymers with ceramic or metal fillers (e.g., epoxy-aluminum nitride composites) bridge the gap between cost and performance, offering improved thermal conductivity over FR-4 without the fragility of pure ceramics.

Advanced Dielectric Layers

The dielectric layer must insulate electrically while enabling heat transfer:

Ceramic-Filled Polymers: Epoxy or polyimide resins loaded with ceramic particles (boron nitride, aluminum oxide) enhance thermal conductivity. These dielectrics maintain flexibility, making them suitable for rigid-flex PCBs in wearable devices.

Thermoplastic Elastomers: High-temperature resistant elastomers with thermal conductive fillers provide shock absorption and heat dissipation, ideal for rugged industrial PCBs subjected to vibration.

Nanocomposite Dielectrics: Graphene or carbon nanotube (CNT) additives create thermal conduction pathways within the dielectric matrix, improving heat transfer without compromising insulation properties.

Conductive Layer Enhancements

Copper layers contribute to both electrical conduction and heat dissipation:

Thick Copper Foil: Increased copper thickness reduces resistive heating and enhances heat spread from high-power components. Heavy copper layers (2–3 oz) are common in power converters and motor drives.

Rolled vs. Electrolytic Copper: Rolled copper, with a smoother surface and consistent grain structure, minimizes thermal resistance at the dielectric-copper interface, improving heat transfer efficiency.

Copper-Infused Heat Spreader Layers: Embedded copper planes or mesh structures within the PCB create lateral heat spread, preventing hotspots in dense component layouts.

Design Strategies for Thermal Optimization

Thermal Pathway Engineering

Efficient heat flow requires deliberate design of thermal pathways:

Thermal Vias: Plated through-holes filled with thermally conductive materials create vertical heat bridges between layers. Strategic placement beneath high-power components (e.g., MOSFETs, LEDs) connects hot copper pads directly to metal cores or heat sinks.

Copper Planes: Large, continuous copper areas act as heat spreaders, distributing heat evenly across the PCB. Pairing power planes with ground planes creates a thermal capacitor effect, absorbing and dissipating transient heat spikes.

Component Placement: Grouping heat-generating components to concentrate heat for efficient dissipation, while isolating temperature-sensitive components (e.g., sensors, ICs) from hot zones.

Layout and Routing Considerations

Thermal performance is influenced by PCB layout:

Short Thermal Paths: Minimizing the distance between heat sources and heat sinks reduces thermal resistance. Direct mounting of components to metal cores or heat sinks via thermal pads enhances this effect.

Avoiding Thermal Bottlenecks: Ensuring wide, unobstructed copper traces from high-power components to thermal vias or heat spreaders. Narrow traces create resistive heating and restrict heat flow.

Symmetrical Design: Balanced copper distribution reduces warpage during thermal cycling, maintaining consistent thermal contact with heat sinks.

Integration with Cooling Systems

High thermal PCBs work synergistically with cooling solutions:

Passive Cooling Integration: Designing PCB surfaces to accept heat sinks via thermal adhesives or mechanical fasteners. Textured or ridged metal cores increase surface area for better heat dissipation.

Active Cooling Compatibility: Incorporating mounting points for fans or liquid cooling manifolds, with thermal vias directing heat to these active systems.

Thermal Interface Materials (TIMs): Using phase-change materials, thermal greases, or pads between PCBs and heat sinks to fill micro-gaps, reducing contact thermal resistance.

Manufacturing Processes for High Thermal PCBs

Advanced Lamination Techniques

Lamination ensures strong bonding between layers while preserving thermal pathways:

Controlled Pressure/Temperature Lamination: Precise control during lamination prevents voids in dielectric layers, which act as thermal insulators. Vacuum lamination removes air bubbles, ensuring uniform contact between copper, dielectric, and substrate layers.

Direct Bonding: Copper is bonded directly to ceramic or metal substrates without adhesives, eliminating the thermal resistance of traditional bonding agents. This technique is critical for high-power semiconductor modules.

Roll-to-Roll Processing: For flexible high thermal PCBs, continuous roll lamination maintains consistent layer thickness and bonding, suitable for high-volume production of wearable tech or flexible displays.

Precision Drilling and Vias Formation

Thermal vias require specialized drilling to maximize heat transfer:

Laser Drilling: Creates small-diameter, high-density thermal vias with minimal damage to surrounding layers, ideal for fine-pitch PCBs in 5G devices.

Mechanical Drilling with Plating: For larger vias, mechanical drilling followed by copper plating ensures electrical and thermal continuity. Filled vias (with epoxy or copper) prevent solder wicking and enhance thermal conductivity.

Micro-Via Stacks: Stacked micro-vias create vertical heat paths through multiple layers, critical for high-density PCBs in data center servers.

Surface Finishes for Thermal Performance

Surface treatments balance solderability, corrosion resistance, and thermal conductivity:

Electroless Nickel Immersion Gold (ENIG): Provides a flat, solderable surface with good thermal stability, suitable for high-temperature applications.

Organic Solderability Preservative (OSP): A thin organic coating that protects copper while maintaining thermal conductivity, ideal for cost-sensitive consumer electronics.

Thermal Spray Coatings: Metal or ceramic coatings applied to substrate surfaces to enhance heat radiation and corrosion resistance in outdoor PCBs.

Industry Applications of High Thermal Solution PCBs

Automotive Electronics

High thermal PCBs are critical in electric vehicles (EVs) and advanced driver-assistance systems (ADAS):

Battery Management Systems (BMS): Monitor and balance battery cells, with thermal PCBs dissipating heat from sensors and power electronics to prevent thermal runaway.

Power Inverters: Convert DC battery power to AC for motors, requiring PCBs that handle high currents and heat generation. Metal-core PCBs with thick copper layers are standard here.

ADAS Sensors: Radar, LiDAR, and camera modules generate heat during operation; high thermal PCBs maintain sensor accuracy by preventing overheating.

Telecommunications and Data Centers

Next-gen communication infrastructure demands thermal efficiency:

5G Base Stations: High-power amplifiers and transceivers in 5G towers generate significant heat; ceramic-substrate PCBs with thermal vias ensure reliable operation in outdoor environments.

Data Center Servers: High-density computing racks use high thermal PCBs to dissipate heat from CPUs and GPUs, reducing reliance on energy-intensive cooling systems.

Satellite Communications: PCBs in satellite payloads must withstand extreme temperature fluctuations; ceramic-metal composite PCBs provide thermal stability in vacuum conditions.

Industrial and Renewable Energy

Industrial environments require robust thermal management:

Motor Drives and Inverters: Control high-power industrial motors, with metal-core PCBs dissipating heat from IGBTs and rectifiers.

Solar Inverters: Convert DC solar power to AC, operating in high-temperature outdoor settings. High thermal PCBs ensure efficiency and longevity.

Industrial Sensors: Monitor temperature, pressure, and vibration in harsh environments; thermal PCBs protect sensitive electronics from ambient heat.

Consumer Electronics

Even compact devices benefit from thermal optimization:

LED Lighting: High-power LEDs generate significant heat; MCPCBs dissipate this heat to maintain brightness and lifespan in residential, commercial, and automotive lighting.

Gaming Consoles and GPUs: High-performance processors in gaming systems rely on high thermal PCBs with copper heat spreaders to prevent throttling during intensive gameplay.

Wearable Devices: Compact, flexible high thermal PCBs manage heat from processors and sensors, ensuring user comfort while maintaining performance.

Challenges and Future Trends in High Thermal PCBs

Current Challenges

Cost vs. Performance: Advanced materials (ceramics, high-purity metals) increase production costs, limiting adoption in cost-sensitive applications.

Manufacturing Complexity: Bonding dissimilar materials (e.g., ceramics and metals) requires specialized processes, increasing production time and complexity.

Design Integration: Balancing thermal, electrical, and mechanical requirements demands multi-physics simulation tools and cross-disciplinary expertise.

Emerging Innovations

2D Material Integration: Graphene and hexagonal boron nitride (hBN) layers offer ultra-high thermal conductivity, enabling thinner, more efficient PCBs for next-gen devices.

Additive Manufacturing: 3D printing of thermal PCBs allows complex geometries, such as internal cooling channels, customized for specific heat loads.

Smart Thermal Management: PCBs integrated with temperature sensors and adaptive cooling control, optimizing heat dissipation in real time based on operating conditions.

Sustainable Materials: Bio-based polymers with thermal conductive fillers reduce environmental impact while maintaining performance, aligning with global sustainability goals.

Conclusion

High thermal solution PCBs are indispensable in modern electronics, enabling the miniaturization and increased power density demanded by today’s technologies. Through material innovations (metal cores, ceramic composites), design strategies (thermal vias, copper planes), and advanced manufacturing, these PCBs efficiently manage heat, ensuring reliability, performance, and safety across industries.

As electronics continue to evolve—with 6G, quantum computing, and next-gen EVs on the horizon—high thermal PCBs will play an even more critical role. Addressing cost challenges, integrating new materials, and advancing manufacturing techniques will drive the next wave of thermal management solutions, ensuring electronics can operate at peak performance while remaining cool, efficient, and sustainable.

For engineers and manufacturers, prioritizing thermal design early in the development cycle—using simulation tools, selecting appropriate materials, and collaborating across disciplines—will be key to unlocking the full potential of high thermal solution PCBs in future technologies.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB