-

- PCB TYPE

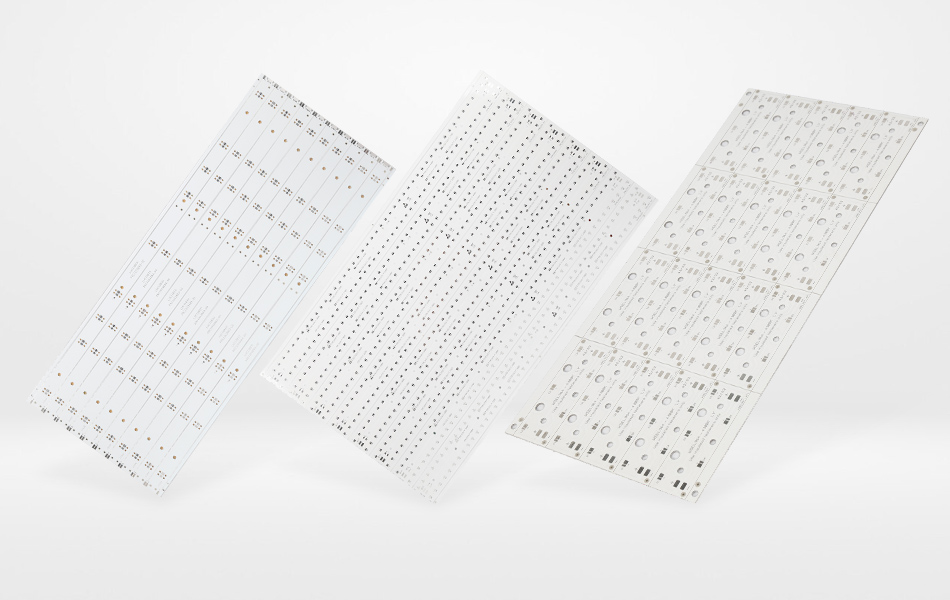

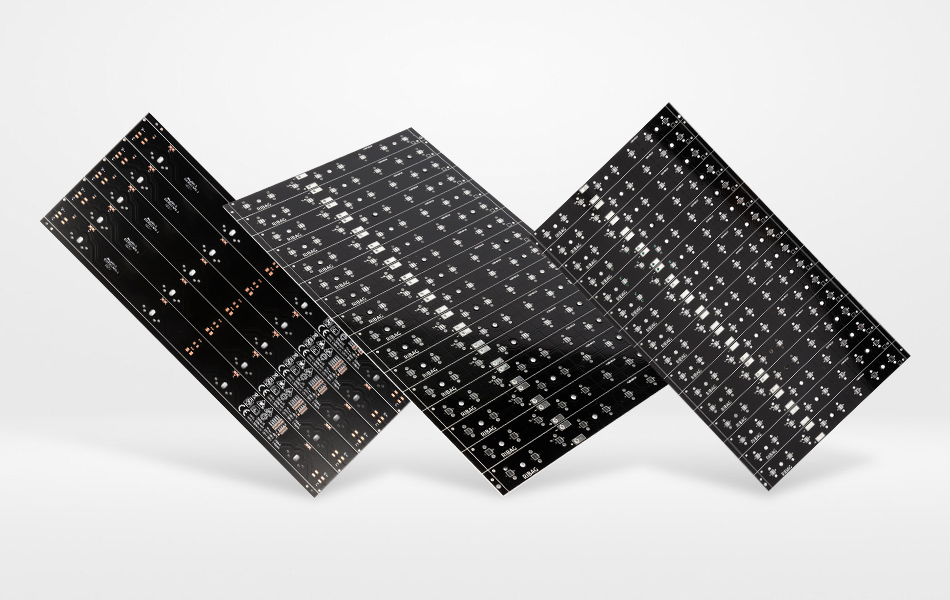

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 30. 2025, 11:18:10

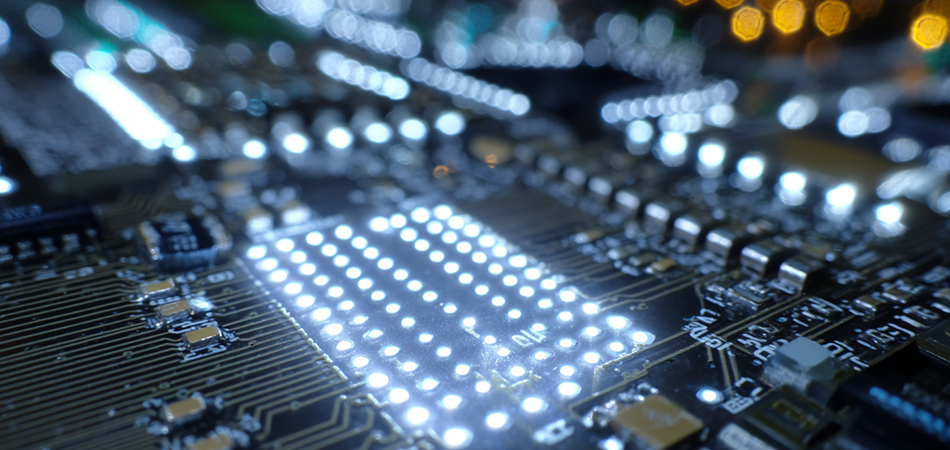

In the rapidly evolving landscape of lighting technology, High Power Light-Emitting Diode (LED) systems have emerged as the standard for energy efficiency and longevity. Central to the performance of these systems is the Aluminum Printed Circuit Board (PCB), which plays a pivotal role in managing the heat generated by high-power LEDs. This article delves into the critical role of aluminum PCBs in high-power LED applications, exploring their technical specifications, design considerations, manufacturing processes, industry applications, and future trends. As the demand for sustainable, high-performance lighting continues to grow, understanding the synergy between high-power LEDs and aluminum PCBs is essential for advancing efficient lighting solutions across various sectors.

The Critical Role of Aluminum PCBs in High-Power LED Systems

Thermal Management as a Core Requirement

High-power LEDs (typically defined as those with power ratings exceeding 1W per chip) generate significant heat during operation. Excessive heat can lead to:

Lumens Depreciation: Reduced light output over time.

Color Shifting: Changes in the LED's color temperature.

Premature Failure: Shortened lifespan due to thermal stress on components.

Aluminum PCBs address these challenges through their exceptional thermal conductivity, effectively transferring heat away from LED chips to the environment. This thermal management is critical for maintaining LED performance, ensuring consistent illumination, and maximizing operational life.

Synergy Between LEDs and Aluminum PCBs

The marriage of high-power LEDs with aluminum PCBs creates a symbiotic relationship:

LED Efficiency: Aluminum PCBs enable LEDs to operate at lower temperatures, enhancing their luminous efficacy and reducing energy consumption.

Design Flexibility: The mechanical robustness of aluminum PCBs supports diverse lighting form factors, from slim fixtures to complex architectural designs.

Reliability: By minimizing thermal stress, aluminum PCBs contribute to the long-term reliability of LED systems, reducing maintenance costs and environmental waste.

Key Performance Metrics for High-Power LED Aluminum PCBs

Thermal Conductivity: The ability of the PCB to transfer heat, primarily determined by the aluminum substrate and dielectric layer.

Thermal Resistance (Rth): The measure of how effectively heat is dissipated from the LED to the environment, with lower values indicating better performance.

Mechanical Strength: Resistance to vibrations, shocks, and temperature fluctuations, essential for outdoor and industrial applications.

Electrical Insulation: Ensuring safe operation and preventing short-circuits between the LED circuitry and aluminum substrate.

Technical Foundations of High-Power LED Aluminum PCBs

Layered Structure Optimization for LED Applications

Copper Circuit Layer

Thickness Considerations: High-power LED applications often require thicker copper foils (e.g., 2oz or 3oz) to handle higher currents and reduce trace resistance.

Circuit Design: Wide traces and ground planes to minimize voltage drops and facilitate heat spreading from LED chips.

Thermally Conductive Dielectric Layer

Material Selection: Ceramics-filled polymers or advanced composites with high thermal conductivity (≥1.5 W/m·K) to bridge the gap between the copper layer and aluminum substrate.

Thickness Balancing: A thinner dielectric layer reduces thermal resistance but must maintain adequate electrical insulation (typically ≥500V breakdown voltage).

Aluminum Substrate

Alloy Selection: Grades like 1050, 3003, or 5052 are preferred for their thermal conductivity and formability:

1050 Series: High purity (99.5% Al) for optimal thermal transfer.

3003 Series: Improved corrosion resistance for outdoor applications.

5052 Series: Higher mechanical strength for rugged environments.

Thickness Optimization: Balancing thermal performance with mechanical requirements, typically ranging from 0.8mm to 3.0mm.

Thermal Management Strategies

Heat Dissipation Pathways

Direct Heat Transfer: From LED chips through the copper layer and dielectric to the aluminum substrate.

Thermal Vias: Plated through-holes that conduct heat from the top copper layer to the aluminum substrate, enhancing vertical heat transfer.

Heat Sink Integration: Aluminum PCBs can be designed to interface directly with external heat sinks, further augmenting heat dissipation.

Thermal Simulation and Modeling

Finite Element Analysis (FEA): Used to predict temperature distributions and optimize PCB design for minimal thermal gradients.

Thermal Imaging: Post-manufacturing testing to verify heat dissipation performance under actual operating conditions.

Electrical and Mechanical Considerations

Electrical Design

Voltage Clearance: Ensuring sufficient spacing between high-voltage traces and the aluminum substrate to prevent arcing.

Grounding Schemes: Robust grounding networks to minimize electrical noise and ensure stable LED operation.

Mechanical Design

Vibration Resistance: Critical for outdoor lighting and transportation applications, requiring secure component mounting and board rigidity.

Thermal Expansion Matching: Selecting materials with compatible coefficients of thermal expansion (CTE) to avoid delamination between layers.

Design Considerations for High-Power LED Aluminum PCBs

LED Layout and Thermal Via Placement

Component Placement Strategies

Heat Source Grouping: Clustering high-power LEDs to facilitate 集中 heat dissipation through dedicated thermal pathways.

Thermal Spacing: Ensuring adequate distance between LEDs to prevent mutual heating and hotspots.

Thermal Via Optimization

Via Density and Distribution: Strategic placement of vias beneath and around LED chips to maximize heat transfer to the aluminum substrate.

Via Filling: Using thermally conductive materials (e.g., silver epoxy) to fill vias, enhancing their thermal performance.

Copper Pour and Trace Design

Ground Plane Design

Large Copper Areas: Serving as heat spreaders to distribute heat from LED chips across the PCB.

Thermal Stitching: Connecting multiple ground planes with thermal vias to create a unified heat dissipation network.

Trace Width and Thickness

Current-Carrying Capacity: Calculating trace dimensions to handle LED operating currents without excessive heating.

Heat Dissipation Through Traces: Designing traces to act as additional heat paths, especially for high-power LED arrays.

Environmental and Mechanical Factors

Outdoor and Harsh Environment Considerations

Corrosion Resistance: Selecting aluminum alloys and surface finishes (e.g., anodizing) for outdoor lighting applications.

Weatherproofing: Designing PCBs to withstand humidity, temperature fluctuations, and UV exposure.

Mechanical Robustness

Board Stiffness: Choosing appropriate aluminum thickness and reinforcing structures for vibration-prone environments (e.g., automotive lighting).

Mounting Features: Integrating mechanical fastener holes and slots for secure installation in lighting fixtures.

Manufacturing Processes for High-Power LED Aluminum PCBs

Material Preparation and Lamination

Aluminum Substrate Pretreatment

Surface Cleaning: Removing oils, oxides, and contaminants to ensure strong adhesion of the dielectric layer.

Chromate-Free Conversion Coatings: Applying zirconium or titanium-based treatments for environmental compliance and improved adhesion.

Dielectric Lamination

Prepreg Selection: Thermally conductive prepregs with high glass transition temperature (Tg) to withstand LED operating temperatures.

Vacuum Lamination: Ensuring void-free bonding between the copper foil, dielectric, and aluminum substrate under controlled heat (150-200°C) and pressure (5-10 MPa).

Circuit Patterning and Via Formation

Photolithography and Etching

High-Resolution Imaging: Using laser direct imaging (LDI) for precise trace definition, especially for high-density LED arrays.

Eco-Friendly Etchants: Ammonium persulfate or ferric chloride solutions for copper patterning, aligning with environmental standards.

Precision Drilling and Via Plating

Diamond-Coated Drill Bits: For accurate hole placement and minimal burr formation in aluminum substrates.

Electroless Copper Plating: For via walls to establish electrical connections and enhance thermal conductivity.

Thermal Via Filling: Optional step using conductive materials to improve heat transfer through vias.

5.3 Surface Finishing and Quality Control

LED-Compatible Surface Finishes

Lead-Free Solder Finishes: Tin-based alloys (e.g., Sn-Ag-Cu) for reliable solder joints and LED attachment.

Electroless Nickel Immersion Gold (ENIG): Provides a smooth, oxidation-resistant surface for fine-pitch LED packages.

Silver Plating: Optional for high-reliability applications, offering excellent thermal and electrical conductivity.

Rigorous Quality Assurance

Thermal Resistance Testing: Using standardized methods (e.g., JEDEC JESD51) to measure Rth from LED to aluminum substrate.

Lumen Maintenance Testing: Accelerated aging tests to verify long-term performance under continuous operation.

Environmental Testing: Temperature cycling, humidity, and vibration tests to ensure reliability in target applications.

Industry Applications of High-Power LED Aluminum PCBs

Outdoor Lighting: Illuminating Public Spaces

Street Lighting

Energy Efficiency: Aluminum PCBs enable high-power LED streetlights to achieve up to 80% energy savings compared to traditional lighting technologies.

Long Lifespan: Reduced thermal stress on LEDs extends fixture life to 50,000 hours or more, minimizing maintenance costs.

Smart Lighting Integration: Aluminum PCBs support the integration of sensors and controls for adaptive lighting systems.

Area and Landscape Lighting

Architectural Lighting: High-power LED aluminum PCBs facilitate complex lighting designs for buildings, monuments, and public spaces.

Outdoor Display Lighting: Vibrant, energy-efficient lighting for billboards, signs, and digital displays.

Commercial and Industrial Lighting: Functionality Meets Efficiency

High-Bay and Low-Bay Lighting

Industrial Facilities: Aluminum PCBs power high-power LED fixtures in warehouses, factories, and manufacturing plants, providing bright, uniform illumination.

Retail Spaces: Energy-efficient lighting solutions that enhance product visibility while reducing energy consumption.

Refrigeration and Cold Storage Lighting

Thermal Management in Low Temperatures: Aluminum PCBs ensure consistent LED performance in cold environments, critical for food storage and logistics.

Automotive Lighting: Reliability in Demanding Environments

Headlights and Taillights

High-Power LED Arrays: Aluminum PCBs support the high brightness and reliability required for automotive lighting, including adaptive driving beams and daytime running lights.

Vibration and Temperature Resistance: Withstanding the harsh conditions of vehicle operation, from engine compartment heat to road vibrations.

Interior Lighting

Customizable Lighting Solutions: Aluminum PCBs enable slim, flexible lighting designs for vehicle interiors, including ambient lighting and display backlighting.

Specialty Lighting Applications

Horticultural Lighting

High-Power LED Grow Lights: Aluminum PCBs dissipate heat from LEDs optimized for plant growth, ensuring consistent light output and energy efficiency.

UV and IR Lighting: Aluminum PCBs for specialized applications like water purification, curing, and thermal imaging.

Medical and Healthcare Lighting

Surgical and Examination Lighting: High-power LED systems with aluminum PCBs provide bright, shadow-free illumination while maintaining low heat output.

Challenges and Solutions in High-Power LED Aluminum PCB Design

Thermal Management at High Power Densities

Challenge: As LED power densities increase, managing heat becomes more complex, requiring advanced thermal solutions.

Solution: Nano-composite dielectrics with enhanced thermal conductivity, advanced heat sink designs, and improved thermal via technologies.

Cost Optimization for Mass Production

Challenge: Aluminum PCBs can be more expensive than traditional FR-4 PCBs, impacting the cost-effectiveness of LED lighting systems.

Solution: Economies of scale, process optimization, and material innovation to reduce manufacturing costs while maintaining performance.

Design for Long-Term Reliability

Challenge: Ensuring LED systems maintain performance over extended periods, especially in outdoor and harsh environments.

Solution: Rigorous testing protocols, robust material selection, and hermetic sealing techniques for PCBs in exposed applications.

Compatibility with Emerging LED Technologies

Challenge: Adapting aluminum PCB designs to accommodate new LED packages and technologies, such as flip-chip and COB (Chip-on-Board) LEDs.

Solution: Flexible PCB design approaches, collaborative development with LED manufacturers, and advanced simulation tools.

Future Trends in High-Power LED Aluminum PCB Technology

Advanced Material Innovations

Nano-Enhanced Dielectrics: Incorporating graphene, boron nitride, or carbon nanotubes to significantly improve thermal conductivity.

Biodegradable and Sustainable Materials: Development of eco-friendly dielectrics and recycled aluminum substrates for greener manufacturing.

Metal Matrix Composites: Combining aluminum with ceramic fillers to create substrates with tailored thermal and mechanical properties for specific LED applications.

Manufacturing Process Improvements

Additive Manufacturing (3D Printing): Enabling rapid prototyping and customized aluminum PCB designs for high-power LED applications.

Laser Processing: Precision laser drilling and etching for microvias and fine-line traces in high-density LED arrays.

Automated Optical Inspection (AOI): AI-driven quality control systems to ensure consistent manufacturing of high-reliability PCBs.

Integration with Smart Lighting Systems

IoT-Enabled Aluminum PCBs: Incorporating sensors, controllers, and connectivity modules directly onto the PCB for smart lighting functionality.

Wireless Power Transfer: Integration of wireless charging technologies for LED fixtures, enabled by optimized aluminum PCB designs.

Miniaturization and High-Density Integration

Micro-LED and Mini-LED Technologies: Aluminum PCBs designed for next-generation LED arrays with smaller chip sizes and higher pixel densities.

3D Packaging: Stacked LED and driver configurations on aluminum PCBs to create ultra-compact, high-performance lighting modules.

Circular Economy Initiatives

Design for Recycling: Aluminum PCBs designed for easy disassembly and material recovery at end-of-life.

Closed-Loop Manufacturing: Recycling aluminum and copper from used PCBs for new production, reducing environmental impact.

Conclusion

High-power LED aluminum PCBs are at the heart of the modern lighting revolution, enabling energy-efficient, reliable, and versatile lighting solutions across diverse industries. From streetlights to automotive applications and specialty lighting, these PCBs play a crucial role in managing heat, enhancing LED performance, and driving sustainable lighting innovation. As technology advances, the integration of advanced materials, manufacturing processes, and smart lighting systems will further optimize the performance and cost-effectiveness of high-power LED aluminum PCBs. By addressing challenges in thermal management, cost, and reliability, while embracing emerging trends, aluminum PCBs will continue to illuminate the path toward a more energy-efficient and sustainable future in lighting technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB