-

- PCB TYPE

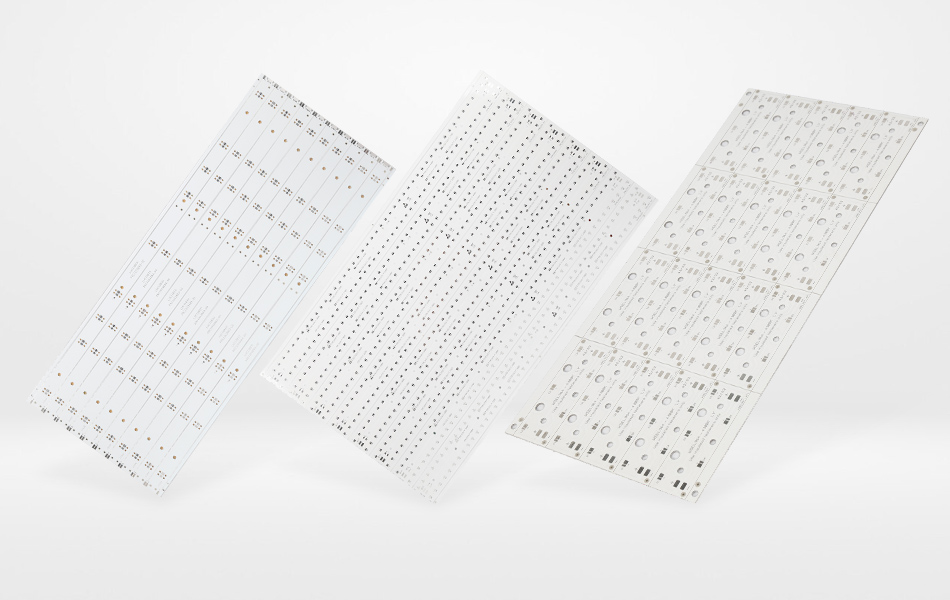

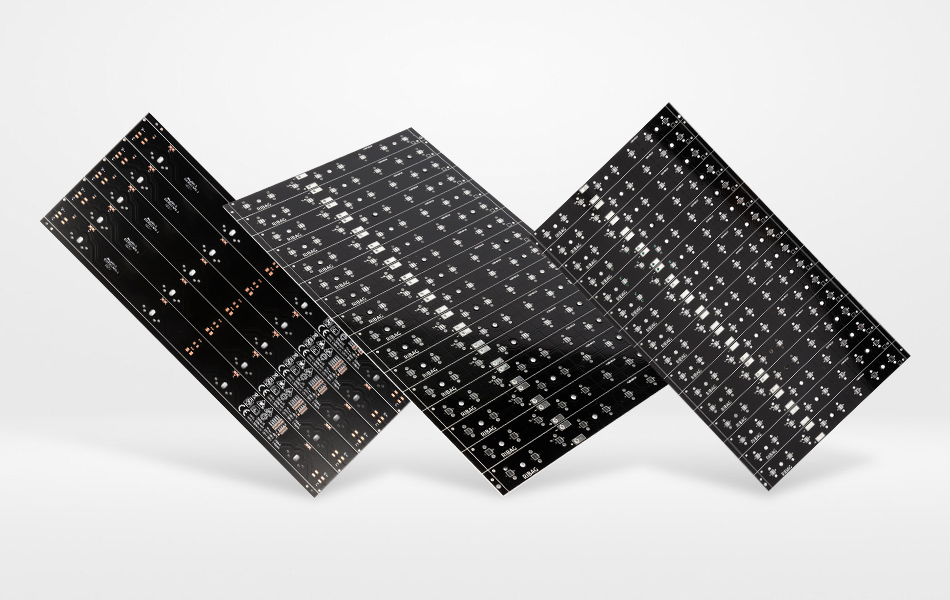

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 30. 2025, 11:33:11

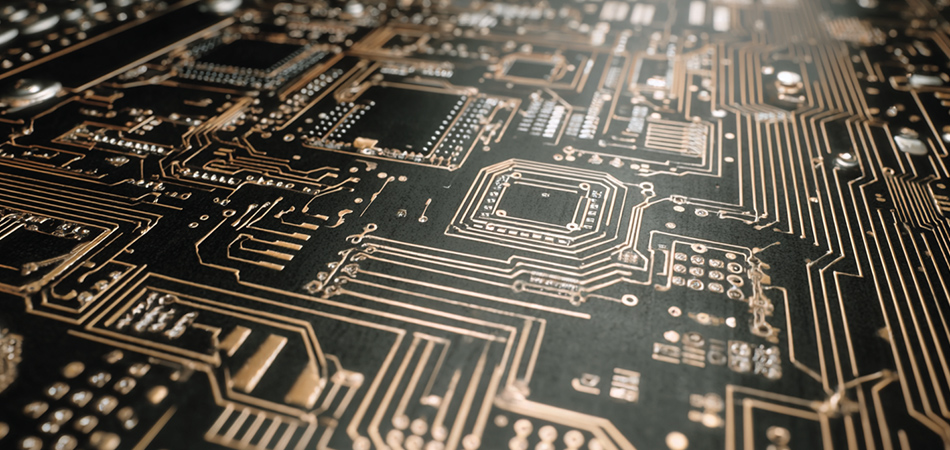

The Glow of Progress: When Light Meets Engineering

Dusk falls, and along the city streets, a soft, even glow replaces the harsh flicker of traditional lamps. These modern LED lights—crisp, efficient, and long - lasting—owe their reliability to an unassuming hero: the aluminum substrate. Nestled beneath the radiant diodes, this unpretentious layer of metal serves as both the backbone and cooling system for LED lighting, transforming how we illuminate our world.

Aluminum substrates are the unsung architects of light, blending thermal efficiency with mechanical resilience. Imagine a bustling metropolis at night: every streetlight, every shopfront display, every subtle architectural accent relies on a thin sheet of aluminum to manage the heat that threatens to dim the brilliance of LEDs. It’s a tale of materials science meeting artistic illumination, where each component plays a role in crafting both functionality and ambiance.

The Threefold Symphony of Structure

The Conductive Canvas: Copper’s Luminous Pathways

At the surface, a network of copper traces weaves like a glowing map, guiding electricity to each LED chip. These intricate pathways, etched with precision, are the veins of the lighting system, carrying energy with minimal loss. The copper layer lies like a thin, shimmering skin, its thickness adapted to the intensity of the light—thicker where currents surge through high - power arrays, delicate where subtle glows suffice.

The Insulating Embrace: Dielectric’s Dual Role

Beneath the copper, a dielectric layer acts as both guardian and guide. Like a thermal bridge, it separates the conductive copper from the aluminum base while allowing heat to flow freely. Composed of polymers infused with ceramic particles, this layer is a marvel of balance: it prevents electrical short - circuits yet conducts heat like a silent river, channeling warmth away from the light - emitting diodes.

The Aluminum Core: Nature’s Coolant

The aluminum substrate itself is the heart of this thermal ecosystem. Picture a block of aluminum, lightweight yet robust, its atomic structure designed by nature to dissipate heat. When an LED chip ignites, sending photons into the world, the aluminum substrate acts like a vast, efficient radiator. It captures the residual heat, spreading it across its surface and releasing it into the air, ensuring the LED remains at a temperature where it can shine brightly for years.

Thermal Management: The Art of Keeping Cool

In the world of LED lighting, heat is both a byproduct and a villain. Left unchecked, it causes LEDs to fade, their colors shifting and their lifespan shortening. The aluminum substrate steps in as a masterful cooler, its thermal conductivity creating a seamless escape route for heat.

Imagine a high - power LED array in a stadium floodlight: each diode is a tiny sun, generating warmth as it produces light. The aluminum substrate beneath acts like a network of invisible rivers, carrying that heat away from the diodes. Thermal vias—like vertical tunnels—pierce the layers, allowing heat to travel from the copper traces down to the aluminum base, where it dissipates into the fixture’s heat sink. This silent process ensures the floodlight can bathe a sports field in consistent light for thousands of hours, never dimming under the pressure of continuous use.

Designing for Light and Life

The Geometry of Glow: Layouts that Breathe

Designers approach aluminum substrates like painters, considering every curve and connection. LEDs are placed not just for brightness but for thermal harmony. Clusters of diodes are spaced to prevent overheating, their positions calculated to create even light distribution while allowing the aluminum to work its cooling magic.

In a modern office building, the ceiling lights must provide consistent illumination without overheating. The aluminum substrate here is a thin, unobtrusive layer, its surface etched with copper traces that form a grid beneath the LEDs. Each via is a tiny chimney, drawing heat down to the aluminum, which in turn is nestled within the light fixture’s frame, releasing warmth gently into the room without causing discomfort.

Weathering the Elements: Substrates in the Wild

Outdoor lighting presents unique challenges. Rain, snow, and UV rays test the mettle of every component. Aluminum substrates rise to the occasion, their alloys chosen for corrosion resistance. Anodized coatings add a protective skin, like a suit of armor, while the dielectric layer remains steadfast against moisture.

Consider a coastal town’s pier lights: battered by saltwater spray and harsh sunlight, these fixtures rely on aluminum substrates to endure. The aluminum here is a 3000 - series alloy, its manganese content defending against corrosion. The substrate’s design includes extra thermal vias, ensuring that even in the humid air, heat does not accumulate, and the LEDs continue to guide ships safely to shore, night after night.

Manufacturing: Where Precision Meets Poetry

Lamination: Bonding Layers with Care

The creation of an aluminum substrate is a process of precision. Layers of copper, dielectric, and aluminum are pressed together under heat and pressure, like a delicate sandwich. The dielectric, often a prepreg infused with resin, melts slightly under pressure, forming a bond that is both strong and thermally conductive. This is no haphazard assembly; each millimeter must be uniform, each layer aligned with the precision of a watchmaker.

Etching: Sculpting Conductive Pathways

Using photolithography, the copper layer is transformed from a solid sheet into a complex network of traces. It’s a process akin to carving a masterpiece: a photosensitive resist is applied, exposed to light through a stencil, and the unprotected copper is etched away. The result is a maze of conductive paths, each trace width calculated to carry current without overheating, each curve designed for both functionality and resilience.

Testing: Ensuring the Light Lasts

Before an aluminum substrate can illuminate the world, it undergoes rigorous testing. Thermal imaging cameras capture heat patterns, ensuring no hotspots threaten the LEDs. Vibration tests simulate the rough ride of a truck carrying streetlights, while humidity chambers mimic tropical downpours. Only when the substrate proves its ability to withstand these trials does it earn the right to carry the glow of LEDs into the world.

Invisible in Use, Indispensable in Impact

Urban Landscapes: Lighting the City’s Soul

Walk through a modern city at night, and you’re surrounded by the work of aluminum substrates. The sleek streetlights that line boulevards, the dynamic façade lighting of skyscrapers, even the subtle glow of crosswalk signals—all rely on these unassuming metal layers. They enable architects to dream in light, creating structures that come alive after dark, their aluminum substrates working silently to keep the illumination steady and energy efficient.

Indoor Sanctuaries: Light that Feels Like Home

In our homes and offices, aluminum substrates enable lighting that mimics natural sunlight or creates cozy atmospheres. A kitchen’s under - cabinet lights, a library’s reading lamps, a yoga studio’s ambient glow—each depends on an aluminum substrate to stay cool and consistent. Here, the substrate’s role is to disappear, allowing the light to take center stage, enhancing daily life without drawing attention to its own engineering.

Beyond the Ordinary: Specialty Illumination

Aluminum substrates also shine in specialized applications. In greenhouses, they support LED grow lights that mimic the sun, their thermal efficiency ensuring plants receive consistent light without heat stress. In medical facilities, they enable sterile, bright lighting that aids surgeons, their durability standing up to frequent sterilization. Even in automotive headlights, where vibration and temperature swings are extreme, aluminum substrates keep the road ahead brightly lit.

The Future: Where Light Meets Innovation

As LED technology evolves, so too do aluminum substrates. Imagine micro - LED arrays so dense they create seamless displays, their aluminum substrates adapted to manage heat at a microscopic level. Or consider outdoor lights that harvest energy from the sun, their substrates designed to double as both cooling systems and lightweight frames.

The next generation of aluminum substrates may incorporate nano - materials, their thermal conductivity enhanced by tiny particles of graphene or boron nitride. They might be 3D - printed to create intricate internal channels for heat dissipation, or coated with self - healing polymers that repair minor damage from environmental stress.

In this future, aluminum substrates will continue to be the silent partners of light, their presence felt in the consistency of the glow, the longevity of the fixtures, and the efficiency of the systems. They will remain invisible to the eye but indispensable to the experience, proving that sometimes, the most important innovations are those that work hardest to stay out of the limelight.

Epilogue: The Quiet Power of Light

The story of LED lighting is not just about diodes and electricity; it’s about the materials that make consistent, efficient light possible. Aluminum substrates are the bridge between technology and experience, between engineering and art. They turn the science of heat management into the art of illumination, allowing us to light our world with clarity, sustainability, and beauty.

The next time you walk under a streetlight, switch on a desk lamp, or marvel at a building’s illuminated facade, take a moment to appreciate the silent work happening beneath the surface. There, an aluminum substrate is doing its part, ensuring that the light remains bright, the diodes stay cool, and the world stays brilliantly lit—one unassuming layer of metal at a time.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB