-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 04. 2026, 16:55:08

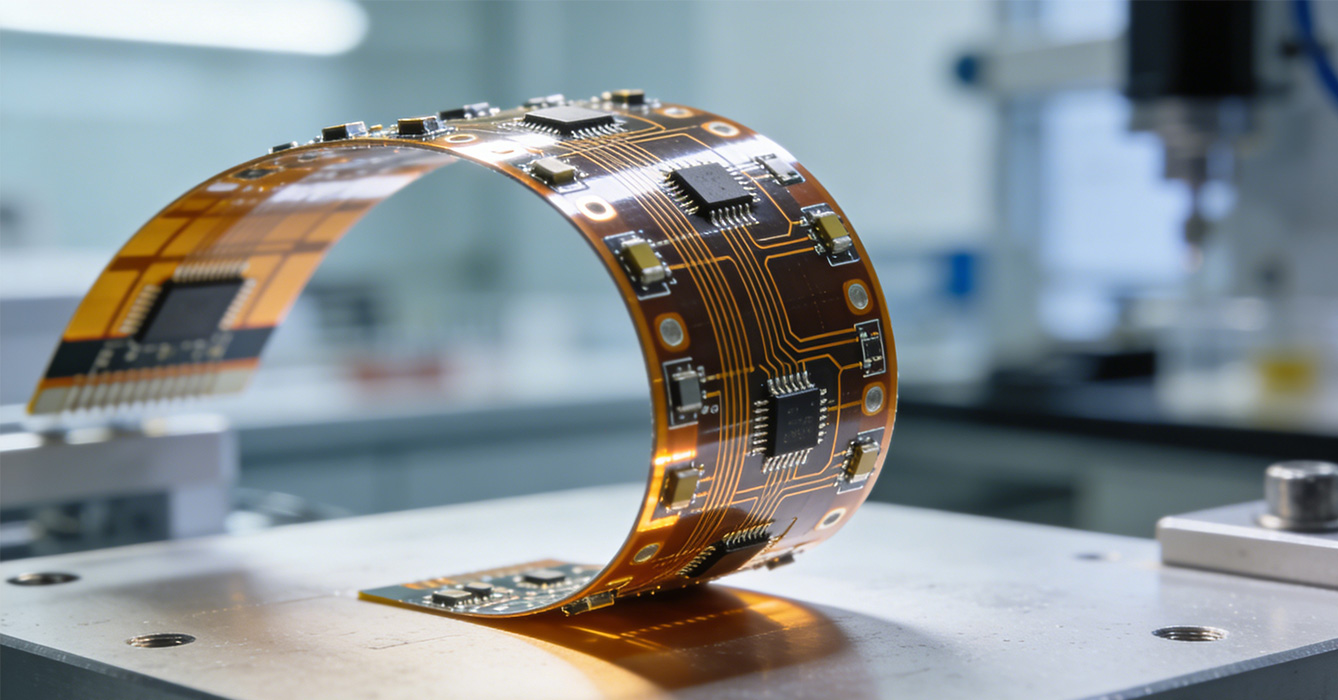

In the realm of advanced electronics, where performance margins are narrow and operational reliability is non-negotiable, High Precision Flexible Circuit Assembly has emerged as a foundational technology. This specialized assembly process combines the inherent flexibility of flexible circuits with ultra-precise manufacturing techniques, delivering interconnect solutions that meet the stringent requirements of mission-critical applications. From life-saving medical devices to high-performance aerospace systems, High Precision Flexible Circuit Assembly ensures that electronic components integrate seamlessly, transmit signals accurately, and withstand extreme operating conditions. As industries demand increasingly miniaturized, high-density, and reliable electronic systems, the role of this assembly technology in driving innovation and ensuring operational safety has become irreplaceable.

The reliability of High Precision Flexible Circuit Assembly stems from three interconnected technical pillars that work in synergy to achieve exceptional precision. Firstly, advanced material compatibility and handling are paramount. High-precision assembly relies on high-performance substrates such as polyimide and liquid crystal polymer (LCP), which offer superior thermal stability and dimensional consistency. Specialized handling techniques prevent material deformation during assembly, ensuring that the flexible circuit maintains its structural integrity and electrical performance—critical for applications where even minor deviations can lead to system failure.

Secondly, precision assembly processes are the backbone of this technology. Techniques such as adhesiveless polyimide lamination eliminate delamination risks, while advanced surface mount technology (SMT) enables the placement of miniaturized components with extreme accuracy. Laser precision drilling and excising further enhance assembly precision, allowing for high-density interconnects that support complex electronic functions without compromising flexibility. These processes are often integrated into automated production workflows, reducing human error and ensuring consistent quality across large-scale production runs.

Thirdly, rigorous quality inspection and validation systems safeguard assembly precision. Automated optical inspection (AOI) and advanced testing protocols monitor every stage of the assembly process, detecting minute defects such as misalignments or solder joint inconsistencies. Compliance with industry-specific standards—including ISO 13485 for medical applications and AS 9100 for aerospace—ensures that High Precision Flexible Circuit Assembly meets the strict reliability requirements of mission-critical sectors.

High Precision Flexible Circuit Assembly has become indispensable in industries where failure is not an option, enabling innovations in life-saving and high-performance systems. In the medical device sector, it plays a vital role in advanced bioelectronic systems, such as conformal wound monitoring and treatment devices. These systems require ultra-precise assembly of sensor arrays and drug-delivery components on flexible substrates, ensuring biocompatibility, reliable signal transmission, and accurate localized treatment—capabilities that directly impact patient outcomes.

In the aerospace and defense industry, High Precision Flexible Circuit Assembly supports components operating in extreme environments, from cryogenic temperatures to high levels of radiation. Assembled flexible circuits are used in satellite communication systems, aircraft avionics, and space exploration equipment, where their lightweight design, high reliability, and resistance to harsh conditions contribute to fuel efficiency and mission success. The ability to withstand repeated vibration and temperature fluctuations makes these assemblies ideal for critical aerospace applications.

The high-end consumer electronics sector also benefits from this technology, particularly in foldable devices and advanced wearable tech. High Precision Flexible Circuit Assembly ensures that the flexible circuits in foldable device hinges can withstand hundreds of thousands of bending cycles while maintaining stable signal transmission. In wearable health monitors, it enables the integration of miniaturized sensors and wireless communication modules, delivering accurate health data without compromising user comfort.

Choosing the right partner for High Precision Flexible Circuit Assembly is critical to ensuring system reliability. Firstly, evaluate the partner’s technical expertise in material handling and precision processes. Look for experience with advanced substrates and assembly techniques, as well as a proven track record in mission-critical industries. Case studies and client testimonials from medical or aerospace sectors can provide valuable insights into their capabilities.

Secondly, verify their quality management system and compliance credentials. A reliable partner should hold relevant industry certifications and implement rigorous inspection and testing protocols. Their ability to provide full traceability of materials and assembly processes is essential for applications where accountability and reliability are paramount.

Finally, assess their collaborative engineering capabilities. High Precision Flexible Circuit Assembly often requires close collaboration between the assembly partner and the client’s design team. A partner that offers design-for-manufacturability advice can optimize the flexible circuit design, ensuring that it is both technically feasible and cost-effective to assemble—critical for accelerating time-to-market without compromising quality.

As technology evolves, High Precision Flexible Circuit Assembly is embracing digitalization and sustainability to meet emerging industry demands. Digital twin technology is being integrated into assembly processes, allowing for virtual testing and optimization before physical production—reducing development time and improving reliability. AI-driven quality control systems are also enhancing defect detection capabilities, further提升 assembly precision.

Sustainability is another growing focus, with manufacturers adopting eco-friendly materials and energy-efficient assembly processes. The development of recyclable substrates and lead-free assembly techniques aligns with global environmental goals, making High Precision Flexible Circuit Assembly more sustainable without compromising performance. These trends are poised to expand the application of this technology into new sectors while maintaining its core value of reliability.

In conclusion, High Precision Flexible Circuit Assembly is a critical enabler of reliability in mission-critical electronic systems, supporting innovations in medical, aerospace, and consumer electronics. Its technical pillars of advanced material handling, precision processes, and rigorous quality control ensure that electronic components perform consistently in the most demanding environments. By selecting a partner with strong technical expertise, robust quality systems, and collaborative capabilities, businesses can leverage this technology to create high-performance, reliable products. As digitalization and sustainability trends deepen, High Precision Flexible Circuit Assembly will continue to evolve, playing an even more vital role in shaping the future of advanced electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB