-

- PCB TYPE

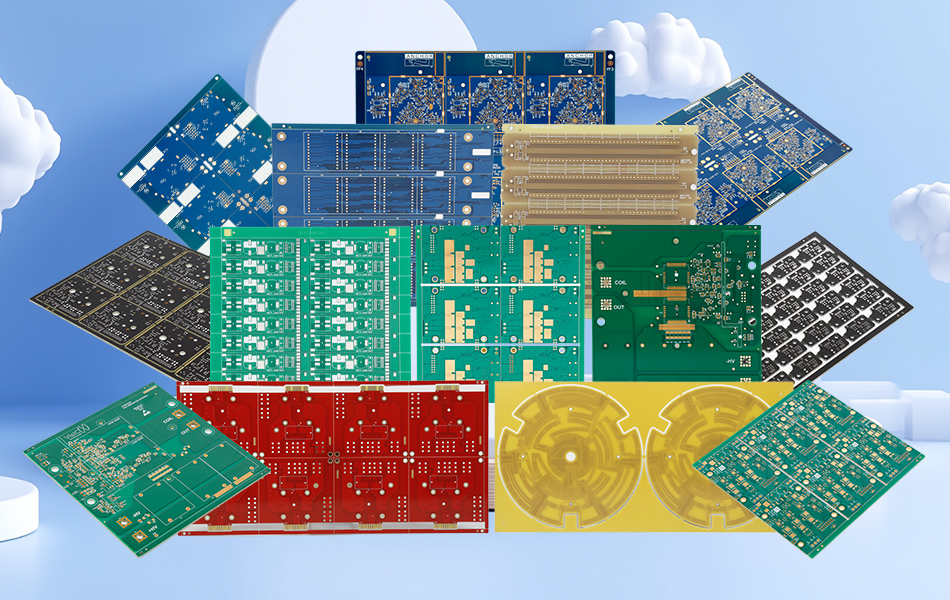

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 26. 2025, 10:37:32

In the foundational landscape of electronic manufacturing, high quality FR4 printed circuit boards (PCBs) stand as the backbone of countless electronic systems, offering a balanced combination of electrical insulation, mechanical stability, and cost-effectiveness. Derived from glass-reinforced epoxy laminate, FR4 has become the industry standard for general-purpose and specialized electronics, supporting applications from consumer devices to industrial control systems. Unlike metal-core or ceramic PCBs optimized for extreme thermal conditions, high quality FR4 PCBs excel in versatility, reliably meeting the demands of low to medium power electronics while ensuring signal integrity and structural durability. This article explores the material composition, performance attributes, industry applications, and manufacturing standards of high quality FR4 PCBs, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

Material Composition and Structural Design of High Quality FR4 PCBs

High quality FR4 PCBs are engineered from a composite material system, with each component contributing to its overall performance and reliability:

Core Material Architecture

Glass Fiber Reinforcement: The structural foundation of FR4 is a woven glass fiber cloth, selected for its mechanical strength, dimensional stability, and resistance to thermal expansion. This reinforcement prevents warping and flexing, ensuring the PCB maintains its shape under temperature fluctuations and mechanical stress—critical for consistent component alignment and solder joint integrity.

Epoxy Resin Matrix: The glass fiber cloth is impregnated with a high-grade epoxy resin, which binds the fibers together and forms the insulating base material. In high quality FR4, the resin is formulated for low moisture absorption, high dielectric strength, and flame resistance (typically meeting UL94 V0 standards), enhancing reliability in humid or high-temperature environments.

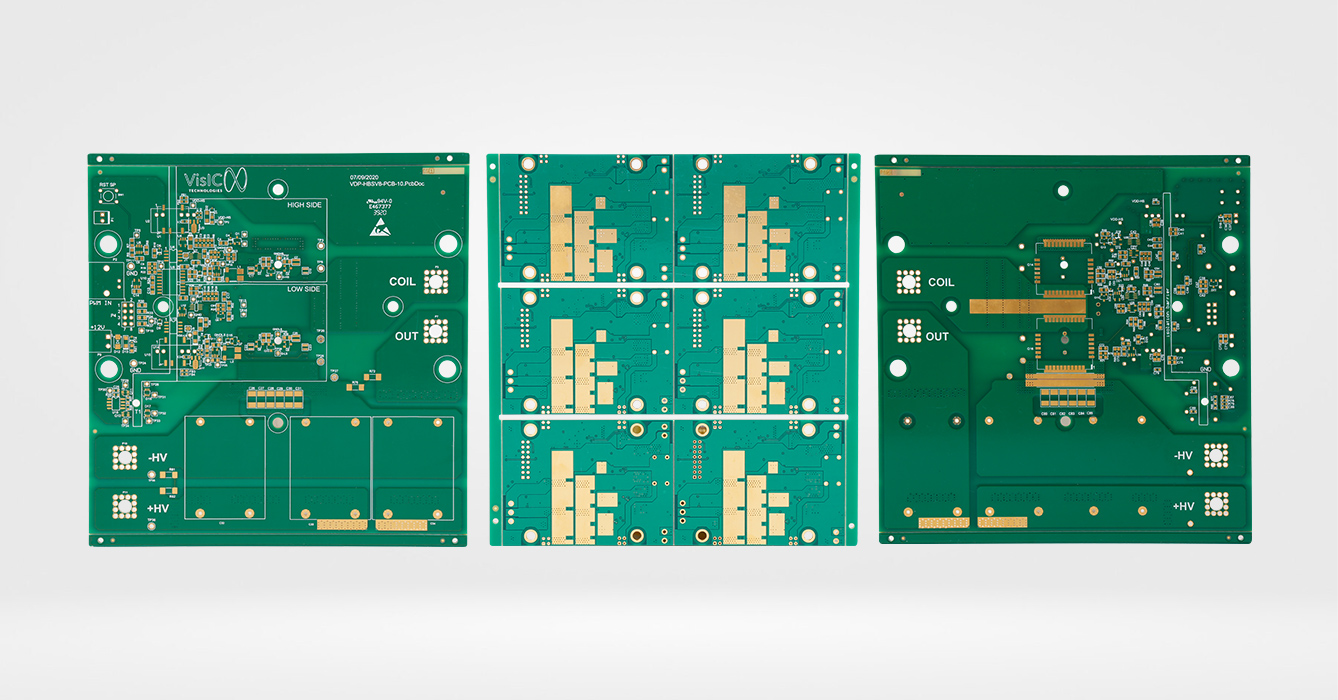

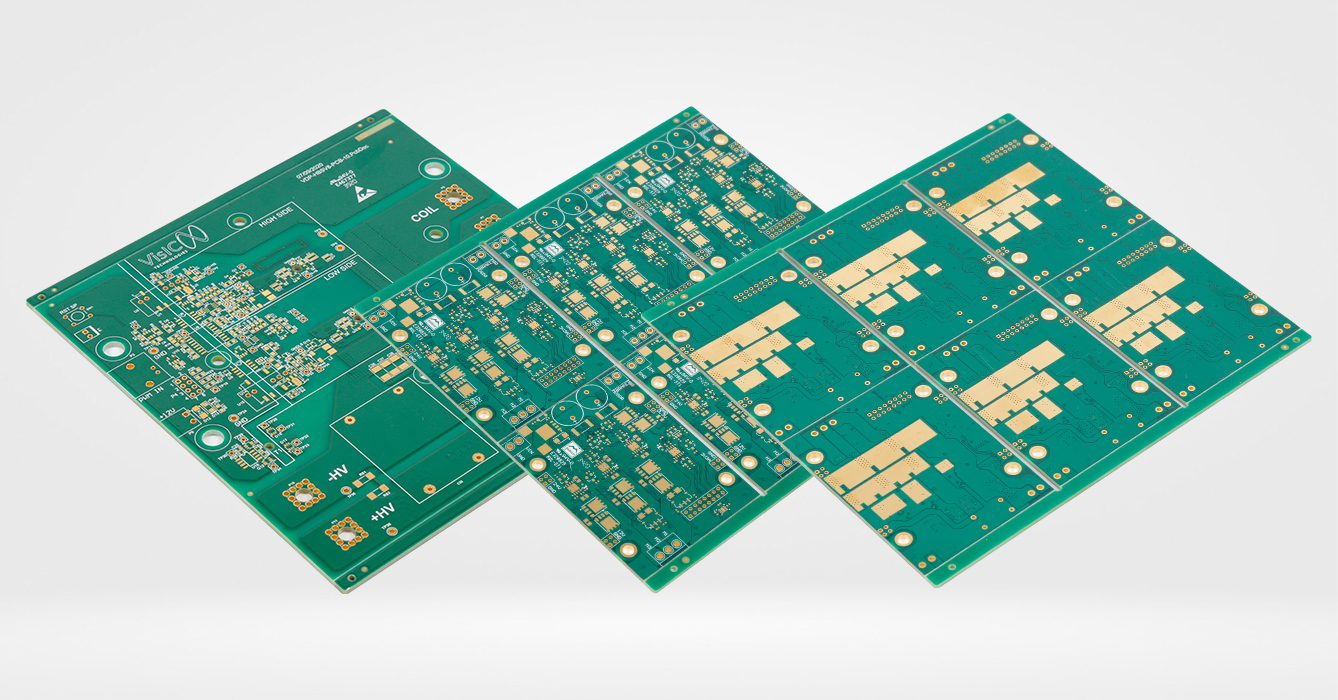

Copper Foil Layer: A thin layer of high-purity copper is bonded to one or both sides of the FR4 substrate (single-sided, double-sided, or multi-layer configurations). The copper forms conductive pathways for electrical signals, with uniform thickness and surface smoothness ensuring low resistance and reliable solderability. In multi-layer PCBs, additional FR4 layers and copper foils are laminated together with dielectric prepreg materials to create complex circuit architectures.

This composite structure creates a robust insulating-conductive system, where the glass-epoxy core provides electrical insulation and mechanical support, while the copper layers enable signal transmission—balancing functionality and cost for widespread adoption.

Key Material Properties

Electrical Insulation: High quality FR4 exhibits excellent dielectric strength, preventing current leakage between conductive traces and ensuring safe operation in low to medium voltage applications. Its stable dielectric constant (Dk) minimizes signal distortion, making it suitable for digital and analog circuits alike.

Mechanical Durability: The glass fiber reinforcement endows FR4 with high tensile strength and impact resistance, withstands handling during assembly and operational stress in devices ranging from handheld gadgets to industrial machinery.

Thermal Stability: While not designed for extreme heat dissipation like aluminum PCBs, high quality FR4 maintains structural and electrical integrity across typical operating temperatures, resisting degradation from prolonged exposure to moderate heat in enclosed electronics.

Performance Advantages of High Quality FR4 PCBs

High quality FR4 PCBs offer a suite of benefits that make them the preferred choice for diverse electronic applications:

Versatility Across Applications

Broad Compatibility: FR4 PCBs support a wide range of components, from surface-mount devices (SMDs) to through-hole connectors, making them adaptable to consumer electronics, automotive systems, and industrial controls. Their compatibility with standard manufacturing processes (e.g., reflow soldering, wave soldering) simplifies production and reduces costs.

Design Flexibility: High quality FR4 can be fabricated into single-sided, double-sided, or multi-layer configurations, with advanced variants supporting high-density interconnects (HDIs) for compact devices. This flexibility enables complex circuit designs without sacrificing reliability.

Cost-Effectiveness and Reliability

Balanced Performance-to-Cost Ratio: Compared to specialized materials like ceramic or metal-core PCBs, FR4 offers a more affordable solution for applications where extreme thermal management is unnecessary. This makes it ideal for high-volume production in consumer electronics and IoT devices.

Long-Term Stability: High quality FR4 formulations resist moisture absorption, chemical degradation, and thermal aging, ensuring consistent performance over extended service lives—critical for applications like medical devices and infrastructure electronics with multi-decade lifespans.

Signal Integrity and Electrical Performance

Low Signal Loss: The stable dielectric properties of high quality FR4 minimize signal attenuation and crosstalk, supporting reliable data transmission in digital circuits, analog sensors, and communication modules. This makes it suitable for applications up to moderate frequencies, such as USB interfaces and Ethernet connections.

Customizable Conductivity: By varying copper thickness and trace design, FR4 PCBs can be optimized for low resistance in power distribution circuits or precise impedance control in signal pathways, adapting to specific electrical requirements.

Industry Applications of High Quality FR4 PCBs

High quality FR4 PCBs are integral to countless electronic systems across sectors, where their balance of performance and cost drives innovation:

Consumer Electronics

Portable Devices: Smartphones, tablets, laptops, and wearables rely on compact FR4 PCBs to house processors, memory modules, and connectivity components. Their lightweight design and signal integrity support the high-speed data transmission required for modern user experiences.

Home Appliances: Refrigerators, washing machines, and smart home devices use FR4 PCBs in control panels and sensor interfaces, where reliability and cost-effectiveness are prioritized over extreme thermal management.

Automotive Electronics

In-Car Infotainment and Controls: FR4 PCBs power infotainment systems, dashboard displays, and climate controls, where they withstand moderate temperatures and vibration while ensuring reliable operation of low-power electronics.

Lighting and Comfort Systems: Interior LED lighting, seat adjustment controls, and safety sensors (e.g., airbag triggers) use FR4 PCBs for their balance of electrical performance and mechanical durability in cabin environments.

Industrial and Medical Electronics

Industrial Control Systems: Programmable logic controllers (PLCs), sensor modules, and low-power motor drives utilize FR4 PCBs for their stability in factory environments, supporting data collection and automation without the need for extreme heat dissipation.

Medical Devices: Diagnostic equipment, patient monitors, and portable medical tools rely on high quality FR4 PCBs for their electrical insulation, biocompatibility (with appropriate coatings), and reliability in sensitive healthcare applications.

Communication and IoT

Networking Hardware: Routers, switches, and modems use FR4 PCBs for their signal integrity in data transmission, supporting wired and wireless connectivity in home and office networks.

IoT Devices: Smart sensors, wearable trackers, and environmental monitors leverage FR4 PCBs for their compact design, low cost, and reliable performance in low-power, battery-operated systems.

Manufacturing and Quality Assurance for High Quality FR4 PCBs

The production of high quality FR4 PCBs involves precision processes and rigorous testing to ensure consistency and reliability:

Advanced Manufacturing Techniques

Controlled Lamination: In multi-layer PCBs, FR4 cores and copper layers are bonded with prepreg materials under precise temperature and pressure, eliminating voids and ensuring strong interlayer adhesion—critical for preventing delamination and maintaining signal integrity.

High-Accuracy Etching: Chemical or laser etching removes excess copper to create circuit traces, with automated systems ensuring tight tolerances for high-density designs. This precision reduces variability and ensures consistent performance across production batches.

Surface Finish Application: Protective coatings such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative) are applied to enhance solderability, corrosion resistance, and shelf life, tailored to assembly requirements.

Quality Validation Protocols

Electrical Testing: Each PCB undergoes continuity checks, insulation resistance testing, and impedance verification to ensure no short circuits, open circuits, or signal degradation.

Mechanical and Environmental Testing: Samples are subjected to thermal cycling, humidity exposure, and flex testing to validate durability under operational conditions, ensuring they meet industry standards for reliability.

Visual and Dimensional Inspection: Automated optical inspection (AOI) systems detect defects such as trace damage, solder mask misalignment, or foreign material, ensuring only high quality boards proceed to assembly.

Future Trends in High Quality FR4 PCB Development

FR4 PCB technology continues to evolve, driven by demands for higher performance, sustainability, and miniaturization:

Material Innovations

High-Temperature FR4 Variants: Development of FR4 formulations with improved heat resistance extends their applicability to warmer environments, such as underhood automotive systems and industrial equipment with moderate power densities.

Eco-Friendly Materials: Manufacturers are integrating recycled glass fibers and bio-based epoxy resins to reduce environmental impact, aligning with global sustainability initiatives and circular economy goals.

Design Advancements

High-Density Interconnects (HDIs): Advanced FR4 PCBs with micro-vias and fine-pitch traces enable more compact designs for portable electronics and IoT devices, increasing functionality without increasing size.

Embedded Components: Integration of passive components (resistors, capacitors) within FR4 layers reduces board size and improves signal integrity, supporting miniaturization in consumer and medical devices.

Specialized Coatings and Treatments

Enhanced Environmental Resistance: New solder masks and conformal coatings improve FR4’s resistance to moisture, chemicals, and UV exposure, expanding its use in outdoor IoT devices and industrial applications.

Thermal Management Additions: While not replacing metal-core PCBs, FR4 with thermally conductive additives or embedded heat spreaders is being developed to enhance heat dissipation for medium-power components, bridging the gap between standard FR4 and specialized substrates.

Conclusion

High quality FR4 printed circuit boards remain indispensable in modern electronics, offering a unique combination of versatility, reliability, and cost-effectiveness that supports innovation across consumer, automotive, industrial, and medical sectors. Their glass-reinforced epoxy architecture balances electrical insulation, mechanical stability, and signal integrity, making them the foundation of countless low to medium power electronic systems. As material science and manufacturing techniques advance, FR4 PCBs continue to evolve, adapting to demands for miniaturization, sustainability, and enhanced performance. Whether powering a smartphone, a medical monitor, or an industrial sensor, high quality FR4 PCBs deliver the consistent, reliable performance that forms the backbone of today’s connected world.

Keywords: high quality FR4 PCB, printed circuit board, electronic manufacturing, FR4 material, consumer electronics, industrial control, PCB reliability, signal integrity.

This article provides a comprehensive, technically rigorous overview of high quality FR4 printed circuit boards, emphasizing their material properties, applications, and future trends while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB