-

- PCB TYPE

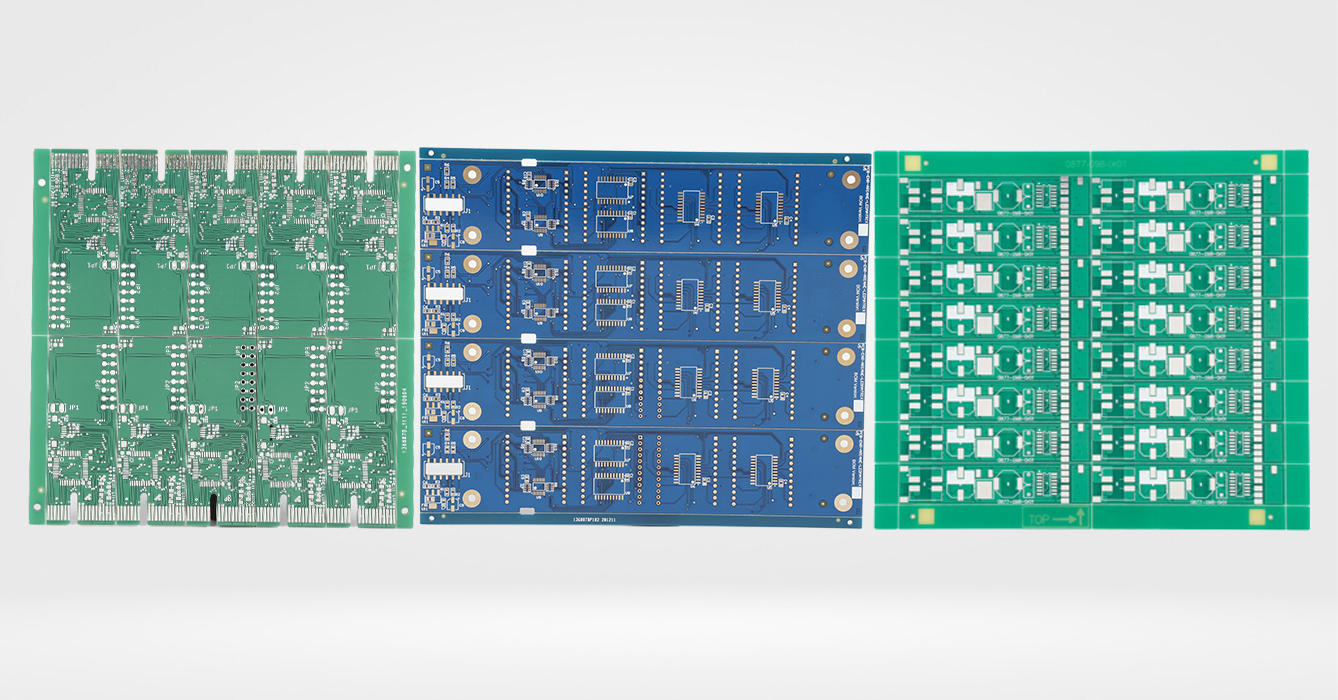

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 16. 2025, 11:40:56

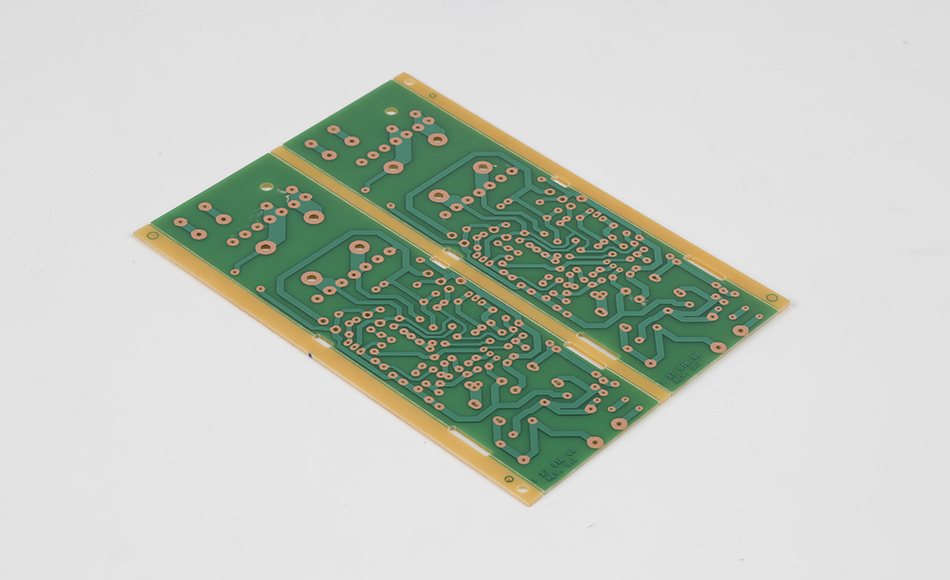

In the fast-paced world of electronics manufacturing, High Volume CEM3 PCB Manufacturing Service stands as a cornerstone for meeting the demands of mass-produced devices. CEM3 (Composite Epoxy Material-3) PCBs, with their balanced blend of performance, affordability, and reliability, are ideal for high-volume applications—from household appliances to consumer electronics—where consistency and cost-efficiency are paramount. High volume manufacturing services specialize in producing tens of thousands to millions of CEM3 PCBs, leveraging advanced automation, streamlined processes, and rigorous quality control to deliver uniform results at scale. This article explores the intricacies of high volume CEM3 PCB manufacturing, including production strategies, quality assurance measures, technological innovations, and the industries that rely on these services, highlighting how they bridge scalability and precision in modern electronics.

CEM3 PCBs are uniquely suited for high volume production, thanks to their material properties and manufacturing compatibility:

CEM3’s hybrid structure—non-woven glass core with woven glass outer layers—balances performance and raw material costs. In high volume manufacturing, these savings multiply: the non-woven core reduces resin usage, while standardized production processes minimize waste. For example, a manufacturer producing 100,000 CEM3 PCBs for microwave ovens can achieve significant per-unit cost reductions compared to using FR4, without sacrificing the flame resistance or electrical insulation required for the application.

CEM3’s material composition simplifies high volume production. Its non-woven glass core absorbs epoxy resin evenly, reducing lamination time, while its surface smoothness ensures consistent copper etching. Unlike FR4, which requires tighter process controls for woven glass alignment, CEM3’s forgiving structure allows for faster throughput on automated lines, making it ideal for mass production.

High volume electronics—such as TVs, printers, and basic sensors—operate in moderate environments, where CEM3’s properties (temperature range of -30°C to 105°C, UL94 V-0 flame resistance) are perfectly matched. These devices do not require the extreme performance of FR4 or specialized substrates, making CEM3 the most cost-effective choice for high volume runs.

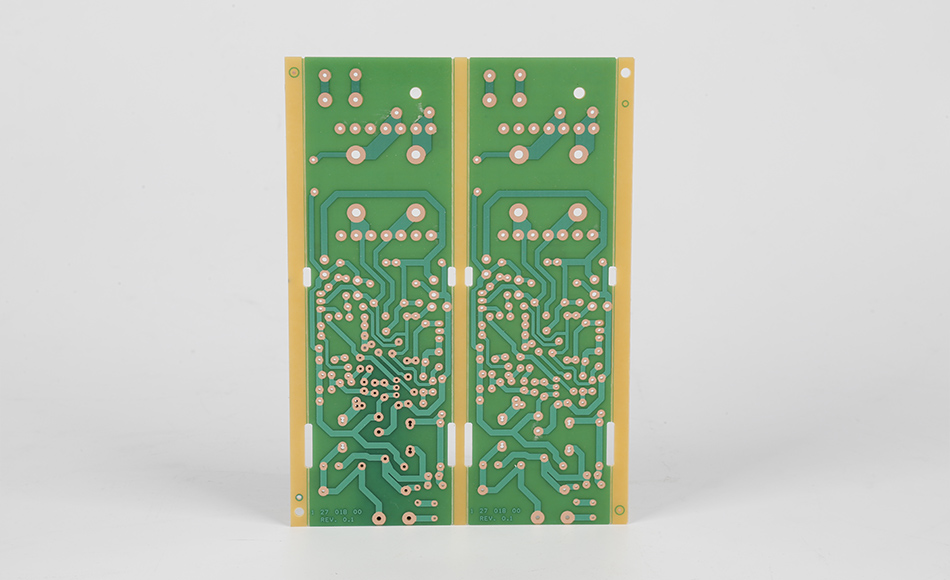

High volume CEM3 PCB manufacturing services rely on specialized strategies to ensure efficiency, consistency, and scalability:

Automation is the backbone of high volume manufacturing, with robotics and AI-driven systems handling:

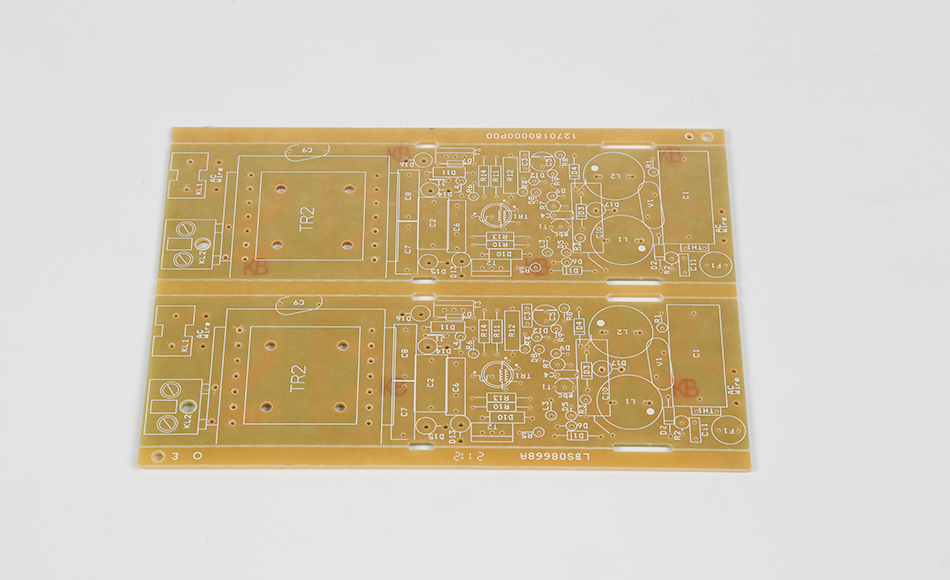

Prepreg Cutting and Stacking: Machines precisely cut non-woven glass mats and woven fabric layers, stacking them with copper foil to ensure uniform thickness and alignment. This reduces human error and speeds up production.

Lamination: Automated presses with real-time temperature and pressure monitoring cure epoxy resins consistently, preventing delamination and ensuring mechanical strength across thousands of units.

Drilling and Routing: Computer numerical control (CNC) drilling machines create vias and mounting holes with micron-level precision, ensuring compatibility with standard components.

Etching and Surface Finishing: Automated etching lines apply and remove photoresist, creating circuit traces with consistent width and spacing. Surface finishes like HASL are applied uniformly to ensure solderability.

These automated processes reduce cycle times from days to hours, enabling manufacturers to meet tight deadlines for high volume orders.

High volume CEM3 PCB services thrive on standardization. By using modular designs—common panel sizes, trace configurations, and component footprints—manufacturers minimize setup times and maximize production efficiency. For example, a service producing PCBs for multiple smartphone models might use a standard panel size with adjustable trace layouts, allowing quick reconfiguration between orders without overhauling the entire production line.

To support high volume production, manufacturers maintain robust supply chains for raw materials:

Just-in-Time (JIT) Delivery: Epoxy resins, glass fibers, and copper foil are delivered in bulk, reducing inventory costs while ensuring materials are fresh and meet quality standards.

Dual Sourcing: Critical materials are sourced from multiple suppliers to mitigate shortages, ensuring production continuity even if one supplier faces delays.

Material Testing: Incoming materials undergo batch testing to verify consistency, preventing defects that could affect thousands of PCBs downstream.

Maintaining quality across millions of units is a defining challenge of high volume CEM3 PCB manufacturing. Services address this through:

SPC uses real-time data to monitor production parameters—such as lamination temperature, etching time, and drill depth—ensuring they stay within predefined tolerances. If deviations occur, the system alerts operators, preventing defective units from being produced. For example, SPC might detect a slight increase in etching time, prompting adjustments to avoid over-etching and trace damage.

AOI (Automated Optical Inspection): Cameras and AI algorithms inspect every PCB for defects—missing traces, short circuits, or solder mask misalignment—at speeds of up to 100 units per minute.

X-Ray Inspection: For multi-layer CEM3 PCBs, X-ray systems check for internal defects like delamination or via misalignment, which are invisible to optical inspection.

Electrical Testing: Flying probe testers verify continuity and insulation resistance across all traces, ensuring each PCB meets electrical specifications.

These systems eliminate human error in inspection, ensuring that even a single defective unit in 10,000 is caught before shipping.

Each batch of high volume CEM3 PCBs is assigned a unique identifier, linking it to raw material lots, production parameters, and test results. This traceability allows manufacturers to quickly isolate and address issues if defects are found post-delivery. For example, if a batch of PCBs fails in field testing, the manufacturer can review SPC data and material records to identify the root cause—whether a resin batch with low adhesion or a lamination press calibration error.

High volume CEM3 PCB services support industries where mass production and cost efficiency are critical:

Home Appliances: Refrigerators, washing machines, and microwaves use CEM3 PCBs for control panels and sensor interfaces. High volume services produce millions of these PCBs annually, ensuring consistent performance and compliance with safety standards.

Audio and Video Devices: TVs, speakers, and streaming devices rely on CEM3 PCBs for signal processing. High volume manufacturing keeps costs low, making these devices accessible to global markets.

Printers and Scanners: These devices require PCBs with stable mechanical and electrical properties to handle continuous operation. High volume services produce PCBs in bulk, ensuring compatibility with standard components like stepper motors and sensors.

Copiers: CEM3 PCBs in copiers manage paper transport, toner application, and data processing. High volume production ensures these PCBs are affordable and reliable for office environments.

Interior Systems: Infotainment units, climate controls, and seat sensors use CEM3 PCBs. High volume services produce these in quantities matching vehicle production runs (often 100,000+ units per model), ensuring consistency across entire vehicle fleets.

Environmental Sensors: Temperature, humidity, and motion sensors deployed in smart buildings or factories use CEM3 PCBs. High volume manufacturing makes these sensors cost-effective for large-scale deployment.

Advancements in technology are reshaping high volume CEM3 PCB services, enhancing efficiency and expanding capabilities:

Machine learning algorithms analyze production data to predict equipment failures—such as worn drill bits or malfunctioning AOI cameras—allowing maintenance before breakdowns disrupt production. This reduces downtime, critical for meeting high volume deadlines.

High volume services are adopting eco-friendly practices:

Energy-Efficient Equipment: Lamination presses and etching lines use variable-speed motors and heat recovery systems to reduce energy consumption.

Waste Reduction: Scrap materials (e.g., excess copper, unused resin) are recycled, and water used in etching is treated and reused.

Low-VOC Resins: Epoxy resins with low volatile organic compound emissions reduce environmental impact and improve workplace safety.

High-Mix, High-Volume (HMLV) Flexibility

Modern services combine high volume production with the ability to handle multiple product variants simultaneously. Using flexible automation and quick-change tooling, they can switch between PCB designs in minutes, catering to industries with diverse product lines (e.g., consumer electronics).

High Volume CEM3 PCB Manufacturing Service is a linchpin of modern electronics, enabling the mass production of reliable, cost-effective PCBs for countless devices. By leveraging automation, standardization, and rigorous quality control, these services deliver consistency across millions of units, meeting the demands of industries from consumer electronics to automotive. As technology advances, innovations like AI-driven inspection and sustainable manufacturing are making high volume CEM3 production more efficient and eco-friendly, ensuring it remains a vital part of the global electronics supply chain. For manufacturers seeking to scale production without sacrificing quality, high volume CEM3 PCB services offer a proven, pragmatic solution.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB