-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 16. 2025, 11:47:06

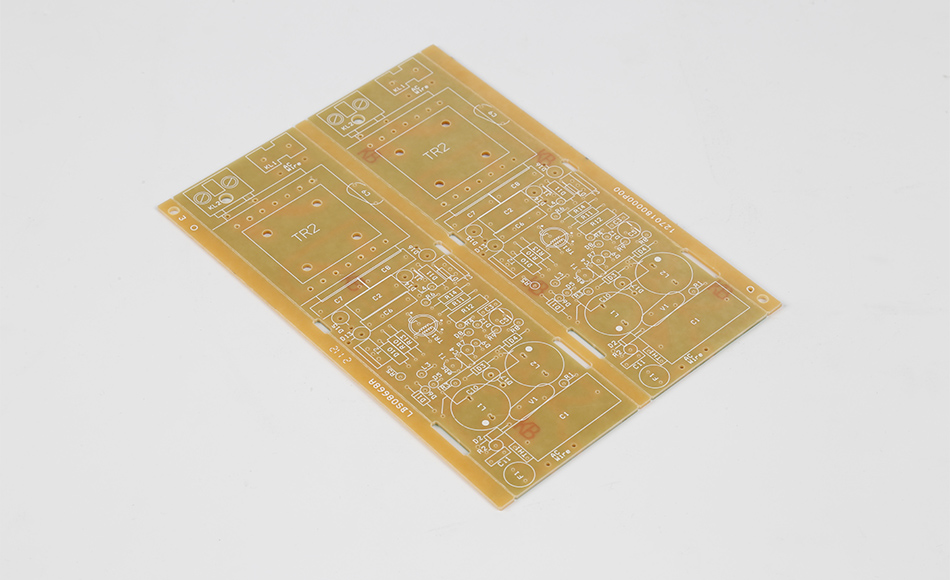

A CEM-3 PCB Manufacturer plays a pivotal role in the electronics supply chain, specializing in the production of printed circuit boards using Composite Epoxy Material-3 (CEM-3). Unlike manufacturers focused solely on high-volume or niche materials, CEM-3 PCB manufacturers excel in balancing versatility, quality, and cost-effectiveness, catering to a broad spectrum of industries from consumer electronics to industrial automation. CEM-3, with its hybrid structure of non-woven glass fiber core and woven glass fabric layers bonded by epoxy resin, offers a unique set of properties that make it ideal for applications requiring moderate mechanical strength, stable electrical performance, and flame resistance—without the premium price tag of high-performance alternatives like FR4. This article delves into the expertise, production processes, quality standards, and client-centric approaches that define a reputable CEM-3 PCB manufacturer, highlighting their role in enabling innovation across diverse electronic devices.

A CEM-3 PCB Manufacturer brings specialized knowledge to every stage of production, ensuring that CEM-3’s inherent advantages are maximized for each client’s unique needs:

Understanding the nuances of CEM-3 composition is foundational. Manufacturers leverage expertise in epoxy resin chemistry and glass fiber properties to optimize the material’s performance:

Resin Selection: Choosing epoxy formulations with the right viscosity and curing characteristics to ensure proper adhesion to glass fibers and copper foil, critical for preventing delamination.

Fiber Integration: Balancing the ratio of non-woven core to woven outer layers to achieve desired rigidity and flexibility, tailoring the substrate for applications like rigid control boards or slightly flexible sensor interfaces.

Flame Retardancy: Incorporating additives (e.g., phosphorus-based compounds) to meet UL94 V-0 standards without compromising electrical insulation, a key requirement for consumer and industrial electronics.

This material expertise allows manufacturers to adapt CEM-3 to specific environments, such as high-humidity industrial settings or temperature-fluctuating automotive cabins.

CEM-3’s hybrid structure demands specialized manufacturing processes, and skilled manufacturers refine these to ensure consistency:

Impregnation Control: Precisely saturating non-woven glass mats with resin to avoid uneven distribution, which can lead to weak spots or electrical inconsistencies.

Lamination Precision: Controlling heat and pressure to cure the epoxy matrix without damaging the glass fibers, ensuring the substrate maintains dimensional stability across temperature cycles.

Surface Preparation: Treating the copper-clad surface to enhance solderability, a critical step for reliable component mounting in end devices.

These processes are fine-tuned through years of experience, allowing manufacturers to produce CEM-3 PCBs that perform consistently across batches.

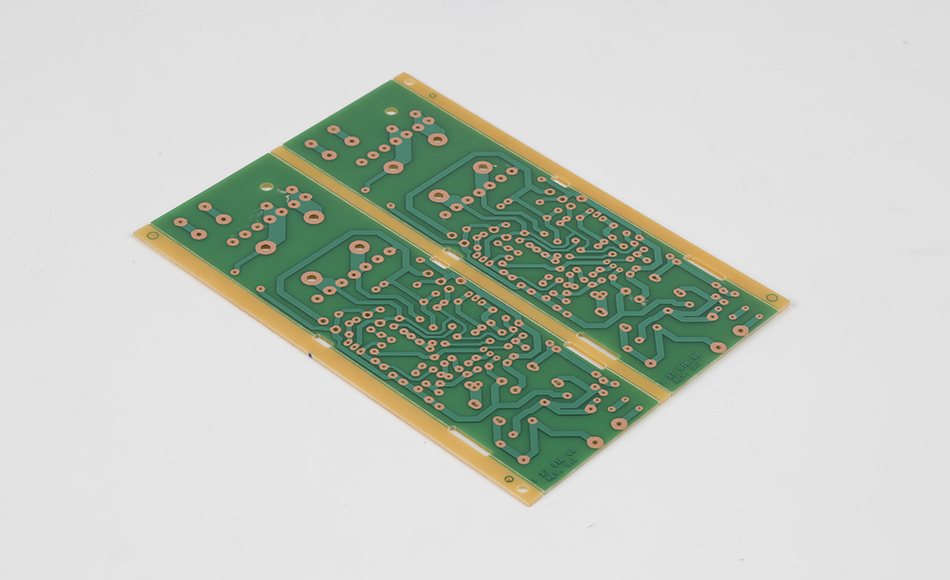

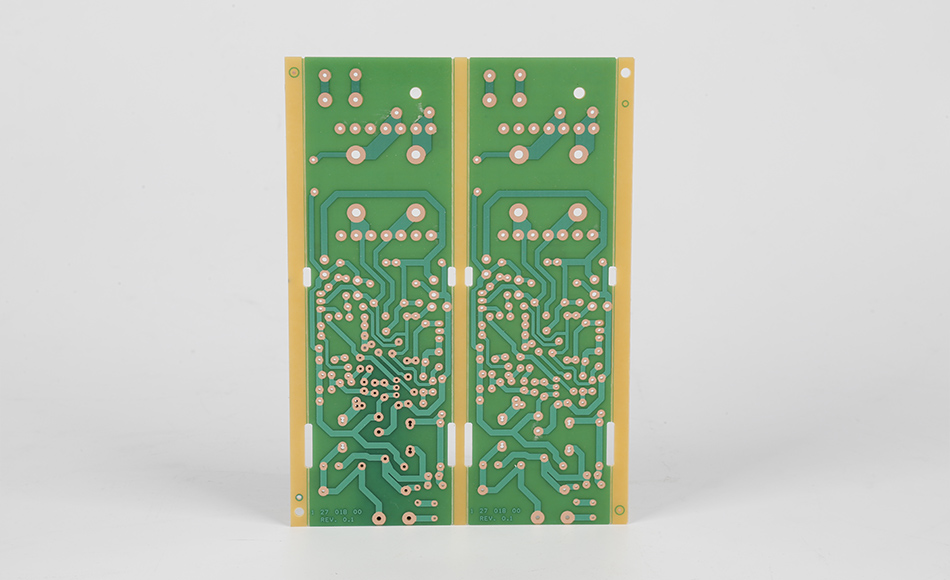

A versatile CEM-3 PCB Manufacturer offers a range of production capabilities to meet diverse client requirements, from low-volume prototypes to medium-scale production runs:

Manufacturers support clients through the entire product lifecycle:

Rapid Prototyping: Using automated cutting and small-batch lamination to produce a few dozen CEM-3 PCBs for design validation, allowing clients to test form, fit, and function before scaling up.

Medium-Volume Production: Leveraging semi-automated lines to produce thousands of units, ideal for pre-market launches or niche industrial devices where high-volume mass production isn’t yet justified.

Customization Flexibility: Adapting layer counts (typically 1–4 layers for CEM-3), trace widths, and hole sizes to match client designs, whether for simple LED driver boards or more complex sensor arrays.

This scalability makes CEM-3 manufacturers valuable partners for startups and established companies alike, supporting both innovation and market expansion.

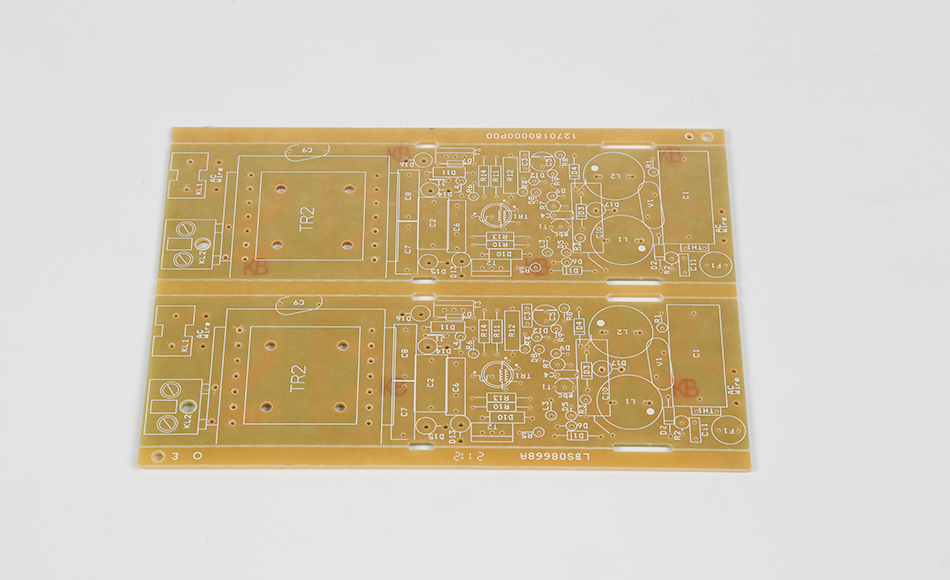

CEM-3 PCB manufacturers accommodate a wide range of design specifications:

Standard Formats: Producing PCBs in common sizes (e.g., 100x150mm) with standard component footprints for off-the-shelf applications like home appliance control panels.

Custom Geometries: Fabricating non-rectangular boards or those with cutouts for space-constrained devices, such as wearable health monitors or compact industrial sensors.

Specialized Surface Finishes: Offering options like OSP (Organic Solderability Preservative) for lead-free assembly or ENIG (Electroless Nickel Immersion Gold) for high-reliability connections in medical devices.

This flexibility ensures that CEM-3 PCBs integrate seamlessly into clients’ existing designs and manufacturing workflows.

Reputable CEM-3 PCB Manufacturers prioritize quality and compliance, ensuring their products meet global standards and client specifications:

Adherence to recognized standards is non-negotiable:

ISO 9001: Implementing quality management systems to ensure consistent processes, from raw material inspection to final testing.

UL Certification: Validating flame resistance (UL94 V-0) and electrical safety to meet regulatory requirements for consumer and industrial electronics.

RoHS Compliance: Ensuring CEM-3 PCBs are free of hazardous substances (e.g., lead, cadmium) to align with global environmental regulations.

These certifications provide clients with confidence that the PCBs will perform reliably and meet market access requirements.

Manufacturers conduct comprehensive testing to verify CEM-3 PCB performance:

Electrical Testing: Checking continuity, insulation resistance, and dielectric strength to ensure signal integrity and prevent short circuits.

Mechanical Testing: Assessing flexural strength and impact resistance to validate durability in handling and operation.

Environmental Testing: Subjecting PCBs to temperature cycling (-30°C to 105°C) and humidity exposure (85% RH) to simulate real-world conditions, ensuring they withstand environmental stress.

Testing data is documented and shared with clients, providing transparency and supporting product qualification.

CEM-3 PCB Manufacturers cater to diverse sectors, each benefiting from CEM-3’s balanced properties:

Home Appliances: Refrigerators, microwaves, and air conditioners use CEM-3 PCBs for their control systems. Manufacturers produce PCBs that balance cost and reliability, ensuring these devices operate safely in household environments.

Personal Electronics: Low-power devices like remote controls, portable speakers, and digital clocks rely on CEM-3 for its electrical insulation and lightweight properties. Manufacturers tailor PCBs to fit compact designs with minimal component density.

Sensor Networks: CEM-3 PCBs power temperature, pressure, and motion sensors in factories, where their resistance to dust and moderate vibration is valuable. Manufacturers produce ruggedized variants with thicker copper traces for industrial environments.

Basic Control Systems: Simple relay controllers and motor drives use CEM-3 PCBs for their cost-effectiveness. Manufacturers ensure these PCBs can handle the moderate current levels and temperature fluctuations common in industrial settings.

Interior Components: Infotainment systems, seat adjusters, and lighting controls use CEM-3 PCBs, which perform reliably in the temperature range of vehicle cabins. Manufacturers produce PCBs that resist automotive fluids (e.g., cleaning agents) and meet strict safety standards.

Non-Critical Sensors: Parking sensors and cabin air quality monitors leverage CEM-3’s affordability and stability, with manufacturers ensuring compatibility with automotive assembly processes.

Low-Risk Equipment: Blood pressure monitors, thermometers, and nebulizers use CEM-3 PCBs for their biocompatibility and cost-effectiveness. Manufacturers adhere to strict cleanliness standards to prevent contamination.

Top CEM-3 PCB Manufacturers differentiate themselves through collaborative partnerships with clients:

Manufacturers offer engineering assistance to optimize designs for CEM-3:

DFM (Design for Manufacturability) Feedback: Advising clients on trace spacing, hole sizes, and layer stackups to ensure designs are compatible with CEM-3’s manufacturing constraints, reducing production delays and costs.

Material Selection Guidance: Recommending CEM-3 variants (e.g., halogen-free for eco-conscious clients) based on application requirements, such as operating temperature or flame resistance needs.

Manufacturers provide visibility into raw material sourcing and production timelines, helping clients plan inventory and meet launch deadlines. This includes sharing information on material lead times, batch testing results, and production schedules.

Even after shipment, manufacturers offer support:

Technical Troubleshooting: Assisting clients with assembly issues, such as solderability problems, by analyzing PCB samples and suggesting process adjustments.

Rework Services: Providing limited rework for minor defects, helping clients avoid scrapping entire batches and minimizing waste.

CEM-3 PCB Manufacturers are adapting to emerging trends to remain competitive:

Manufacturers are adopting eco-friendly measures, such as using recycled glass fibers and bio-based epoxy resins, to reduce the environmental impact of CEM-3 production. This aligns with client demands for sustainable supply chains and global efforts to reduce electronics waste.

Investing in AI-driven inspection and robotics to enhance precision and reduce cycle times, even for medium-volume production. This allows manufacturers to offer faster turnaround without compromising quality.

Developing CEM-3 formulations with higher glass transition temperatures (Tg) and improved thermal conductivity to expand their use into more demanding applications, such as light industrial power supplies, while retaining cost advantages over FR4.

A CEM-3 PCB Manufacturer is more than a producer; they are a strategic partner in electronics development, leveraging expertise in material science, process engineering, and client collaboration to deliver reliable, cost-effective PCBs. By focusing on CEM-3’s unique balance of properties, these manufacturers enable innovation across industries, from consumer electronics to industrial automation. Their commitment to quality, compliance, and flexibility ensures that CEM-3 remains a vital material in the electronics ecosystem, meeting the diverse needs of modern devices. For clients seeking a pragmatic solution that balances performance and cost, partnering with a reputable CEM-3 PCB manufacturer is a decision that drives both innovation and market success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB