-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 12. 2025, 11:30:55

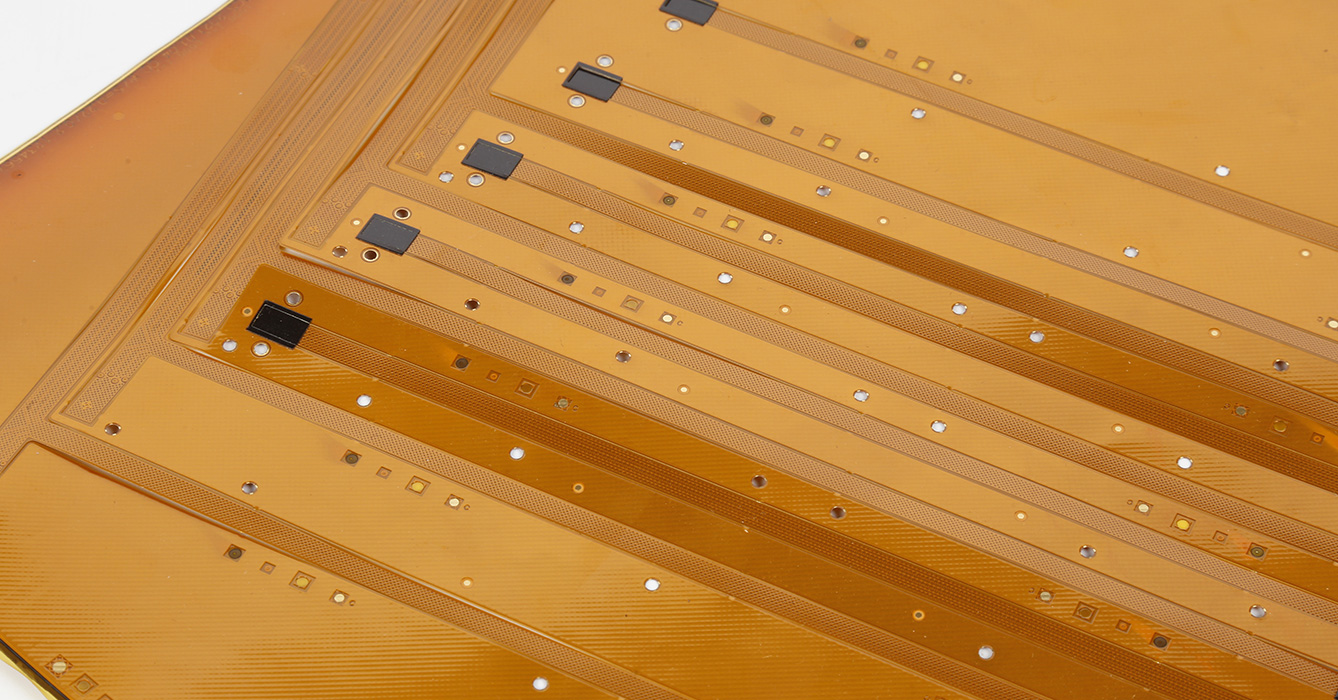

In the global flexible printed circuit (FPC) industry, quality consistency and reliability are the cornerstones of long-term cooperation between suppliers and clients. An ISO 9001 Flexible PCB Supplier distinguishes itself by adhering to the rigorous requirements of the ISO 9001 quality management system, integrating systematic quality control into every link of FPC design, production, and service. Unlike non-certified suppliers that rely on fragmented quality checks, ISO 9001-certified suppliers establish standardized, traceable, and continuously improved quality processes, ensuring that each batch of FPC products meets predefined quality benchmarks. For electronics brands pursuing global market expansion and high-quality product strategies, partnering with an ISO 9001 Flexible PCB Supplier is critical to mitigating quality risks, simplifying compliance audits, and building end-user trust.

The core competitiveness of a top ISO 9001 Flexible PCB Supplier lies in its holistic quality control process built around the ISO 9001 framework, covering the entire lifecycle of FPC products:

- Standardized Raw Material Sourcing & Inspection: ISO 9001 requires strict control over incoming materials to eliminate quality hazards at the source. Certified suppliers establish a qualified supplier evaluation system, conducting rigorous audits of raw material providers (substrates, copper foils, adhesives) to ensure their compliance with quality standards. Incoming materials undergo standardized inspection processes, including material composition verification, electrical performance testing, and environmental adaptability evaluation. All inspection data is recorded and traceable, ensuring full transparency of raw material quality.

- Controlled Production Processes & In-Process Quality Monitoring: ISO 9001 emphasizes the stability and controllability of production processes. Suppliers implement standardized operating procedures (SOPs) for every production link, from circuit design and etching to lamination and cutting. Advanced process monitoring tools—such as AI-driven AOI (Automated Optical Inspection) and real-time production data tracking systems—are used to detect process deviations and defects in real time. Any non-conforming products are flagged, isolated, and analyzed to identify root causes, with corrective actions implemented to prevent recurrence.

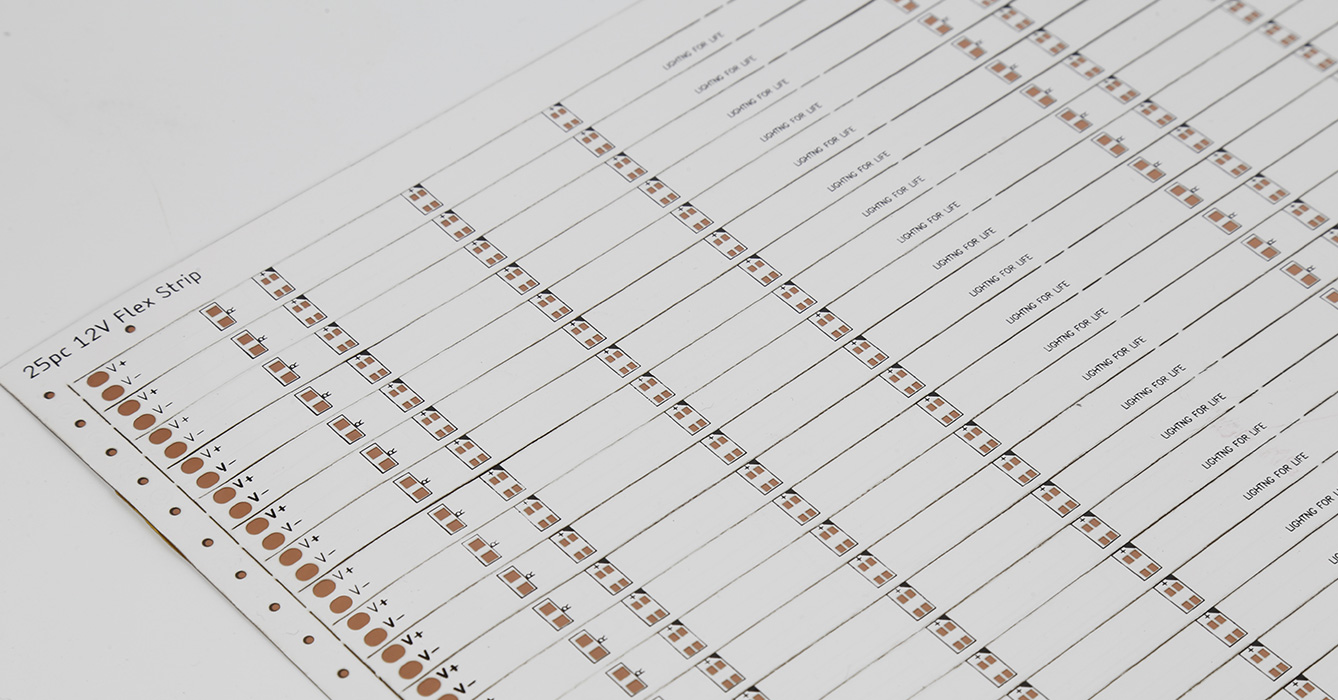

- Strict Finished Product Testing & Delivery Verification: Before delivery, all FPC products undergo comprehensive finished product testing in accordance with ISO 9001-defined criteria. Tests include electrical performance (continuity, insulation resistance), mechanical durability (flex endurance, bend radius), and environmental adaptability (temperature cycling, humidity resistance). Only products that pass all tests are allowed to leave the factory. Additionally, certified suppliers establish a complete delivery verification process, ensuring accurate product identification, proper packaging, and timely documentation (test reports, quality certificates) to support clients’ incoming inspection.

Partnering with an ISO 9001 Flexible PCB Supplier brings multi-dimensional value to clients, enhancing their market competitiveness:

- Risk Mitigation & Quality Consistency: The ISO 9001 system’s emphasis on preventive control and continuous improvement helps reduce the risk of quality failures. Clients can rely on the supplier’s stable quality control processes to ensure consistent performance of FPCs across batches, avoiding production delays and costs caused by non-conforming components.

- Simplified Global Market Compliance: ISO 9001 is an internationally recognized quality standard. Working with a certified supplier simplifies clients’ compliance audits for global markets, as the supplier’s quality management system has already been validated by third-party authorities. This is particularly valuable for clients operating in regulated industries (automotive, medical, aerospace) where strict quality certifications are mandatory.

- Enhanced Supply Chain Transparency & Collaboration: ISO 9001 requires comprehensive documentation and traceability, providing clients with full visibility into the FPC production process. This transparency facilitates effective supply chain management, enabling clients to track product batches, review quality data, and collaborate with suppliers to optimize designs or processes. The supplier’s commitment to continuous improvement also ensures that clients benefit from ongoing quality and efficiency enhancements.

Top ISO 9001 Flexible PCB Suppliers tailor their quality management processes to meet the unique requirements of different industries, while maintaining ISO 9001’s core principles:

- Consumer Electronics: For FPCs used in smartphones, wearables, and tablets, suppliers optimize ISO 9001 processes to focus on miniaturization, light weight, and high flex endurance. Strict control over circuit precision and material consistency ensures FPCs meet the slim form factor and long-term reliability requirements of consumer devices.

- Automotive Electronics: Under the ISO 9001 framework, suppliers integrate automotive-specific quality requirements (aligned with IATF 16949) into their processes. This includes enhanced thermal resistance testing, vibration resistance verification, and strict traceability to meet the safety and durability demands of in-vehicle FPC applications.

- Medical Devices: For medical FPCs (patient monitors, diagnostic equipment), suppliers implement ISO 9001-compliant processes with additional controls for biocompatibility, sterility, and electromagnetic compatibility (EMC). These processes ensure FPCs meet the strict quality and safety standards of the medical industry (ISO 13485).

ISO 9001 is not a static standard, and leading ISO 9001 Flexible PCB Suppliers embrace its focus on continuous improvement to drive long-term quality excellence:

- Quality Data Analysis & Root Cause Improvement: Suppliers regularly analyze quality data (defect rates, customer complaints, process performance) to identify improvement opportunities. Root cause analysis tools (e.g., 5 Whys, Fishbone Diagrams) are used to address underlying issues, with corrective and preventive actions implemented to enhance process stability.

- Employee Training & Competence Development: Under ISO 9001, suppliers invest in ongoing employee training to ensure all staff have the necessary competence to implement quality processes. This includes training on SOPs, quality tools, and industry-specific requirements, fostering a quality-oriented culture across the organization.

- Technology & Process Innovation: Continuous improvement extends to technological innovation. Suppliers leverage ISO 9001’s process management framework to integrate new technologies (e.g., advanced etching, intelligent inspection) into production, enhancing quality while improving efficiency and reducing costs.

In conclusion, an ISO 9001 Flexible PCB Supplier delivers more than just high-quality FPCs—it provides a systematic, traceable, and continuously improving quality assurance system that builds trust and drives mutual success. As global markets increasingly demand consistent, reliable electronic components, the value of partnering with an ISO 9001-certified supplier becomes more prominent. For brands aiming to enhance product quality, simplify compliance, and strengthen supply chain resilience, an ISO 9001 Flexible PCB Supplier is an indispensable strategic partner.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB