-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 12. 2025, 11:33:00

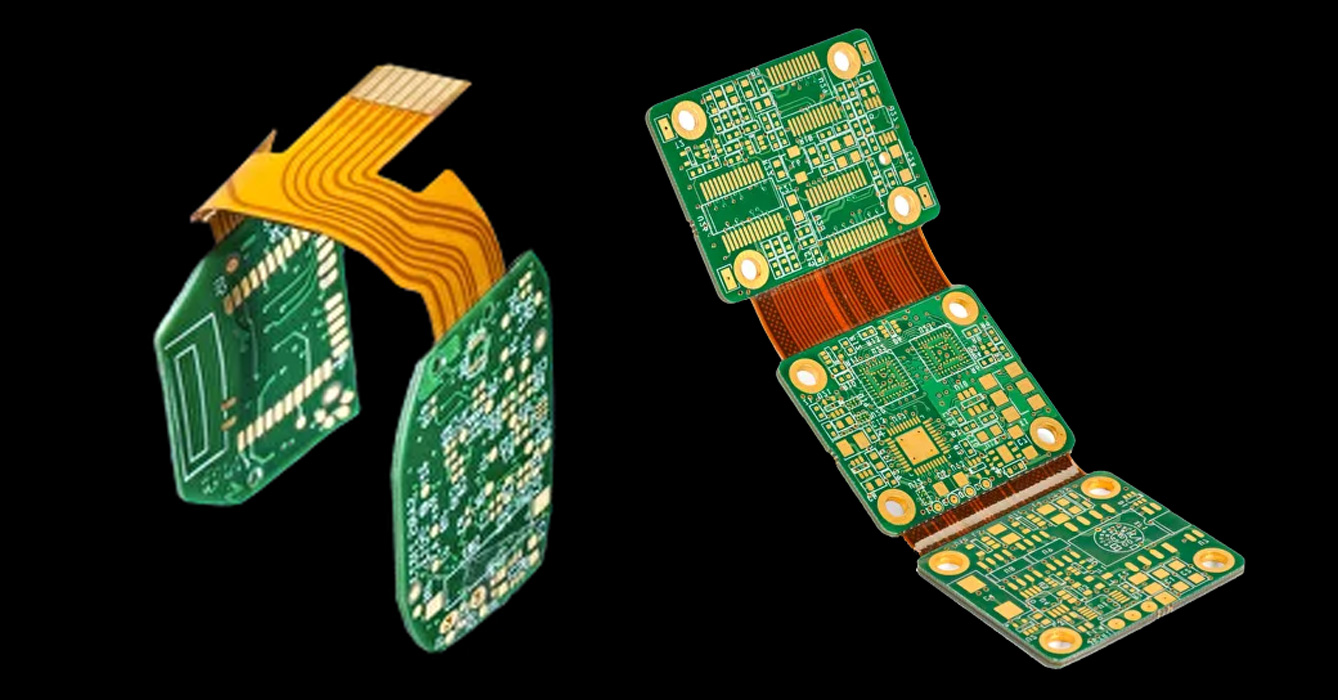

In the fast-paced electronics industry, product iteration cycles are shrinking, and market demands for rapid prototyping and small-batch production are escalating. A professional Quick Turn Flexible PCB Supplier plays a pivotal role in shortening clients’ product development and launch cycles by delivering high-quality flexible printed circuits (FPCs) with accelerated lead times. Unlike traditional FPC suppliers bound by rigid production schedules, quick-turn specialists leverage agile manufacturing systems, streamlined processes, and responsive supply chains to meet urgent order requirements—from rapid prototyping to small-to-medium batch production. For electronics brands aiming to seize market opportunities, validate new designs quickly, or address emergency production needs, partnering with a reliable Quick Turn Flexible PCB Supplier is a strategic enabler of competitive advantage.

The competitive edge of a top Quick Turn Flexible PCB Supplier lies in its integrated agile capabilities, which ensure speed without compromising quality:

- Streamlined Design-to-Production Workflow: Quick-turn suppliers optimize the entire workflow by eliminating redundant approval processes and adopting parallel engineering. They use advanced EDA (Electronic Design Automation) tools with pre-built FPC design templates and DFM (Design for Manufacturability) checklists to quickly validate design feasibility. Engineers collaborate with clients in real time to resolve design issues, ensuring seamless transition from design finalization to production initiation—cutting down design iteration time by 30% or more.

- Intelligent & Flexible Manufacturing Lines: To handle rapid order changes and short lead times, suppliers deploy modular, intelligent production lines. These lines feature automated equipment (laser etching, rapid lamination machines) that can be quickly reconfigured for different FPC specifications. AI-driven quality inspection tools (real-time AOI, automated electrical testing) enable fast defect detection without slowing down production, ensuring high-quality output even at accelerated speeds.

- Strategic Material Inventory & Supply Chain Collaboration: Leading suppliers maintain strategic inventories of core raw materials (high-performance substrates, conductive foils, adhesives) commonly used in diverse FPC applications. They also establish long-term partnerships with material suppliers, ensuring priority access to materials for urgent orders. This proactive material management eliminates delays caused by material procurement, a key bottleneck in traditional FPC production.

Quick Turn Flexible PCB Suppliers excel in rapid prototyping and small-batch production, addressing the critical needs of product development phases:

- Fast Prototyping for Design Validation: For electronics brands in the R&D stage, suppliers deliver functional FPC prototypes in as little as 24–48 hours. This rapid turnaround allows clients to quickly validate design concepts, test FPC compatibility with other components, and iterate on design improvements. The prototypes maintain the same material and process standards as mass-produced FPCs, ensuring accurate performance testing results.

- Small-Batch Production for Market Testing: After prototype validation, quick-turn suppliers support small-batch production (typically 100–5,000 units) to enable clients to conduct market testing and pilot launches. They maintain consistent quality across small batches, using the same intelligent production lines as mass production, while offering flexible order adjustments to accommodate feedback from initial market responses.

- Seamless Scaling to Mass Production: A key advantage of professional quick-turn suppliers is their ability to seamlessly scale from small-batch to mass production. Clients avoid the hassle of switching suppliers during production scaling, as the supplier’s modular production lines and quality systems ensure consistent performance and lead times even as order volumes increase.

Top Quick Turn Flexible PCB Suppliers tailor their rapid response capabilities to meet the unique urgent requirements of different industries:

- Consumer Electronics: For fast-changing consumer electronics (smartphones, wearables, AR/VR devices), suppliers support rapid iteration of FPC designs to match new product features. They handle urgent orders for seasonal product launches (e.g., holiday gadgets) and ensure quick replacement of FPCs for product upgrades, helping brands stay ahead in the competitive consumer market.

- Medical Devices: Medical device manufacturers often require quick-turn FPCs for emergency medical equipment (e.g., portable diagnostic tools during public health events) or clinical trial devices. Suppliers comply with ISO 13485 standards while accelerating production, ensuring FPCs meet strict medical safety requirements without compromising delivery speed.

- Automotive Electronics: For automotive prototype development and emergency parts replacement, suppliers deliver automotive-grade FPCs (aligned with IATF 16949) with quick turnaround. They handle urgent orders for in-vehicle electronic system upgrades and prototype testing, supporting automakers’ rapid innovation in electric and intelligent vehicles.

A common misconception is that quick delivery sacrifices quality, but top Quick Turn Flexible PCB Suppliers integrate rigorous quality control into every rapid production环节:

- Real-Time Quality Monitoring: Intelligent production lines are equipped with in-line inspection tools that detect defects in real time, eliminating the need for post-production rework (a major delay factor). Automated electrical testing ensures FPC performance meets specifications before delivery.

- Standardized Quick-Turn Quality Processes: Suppliers establish standardized quality protocols specifically for quick-turn orders, including pre-production material verification, process parameter locking, and final product sampling inspection. These protocols ensure consistent quality across all urgent orders.

- Traceability & Documentation: Even for rapid orders, suppliers maintain full traceability of raw materials and production processes. They provide comprehensive quality documentation (test reports, material certificates) with each order, supporting clients’ compliance and quality audits.

In conclusion, a Quick Turn Flexible PCB Supplier is a critical partner for electronics brands navigating fast-paced market changes. By leveraging agile manufacturing systems, streamlined workflows, and responsive supply chains, they deliver high-quality FPCs in accelerated lead times, supporting rapid design validation, market testing, and product launches. As the electronics industry continues to prioritize speed and innovation, the strategic value of partnering with a professional Quick Turn Flexible PCB Supplier will only grow—enabling brands to turn ideas into market-ready products faster than ever before.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB