-

- PCB TYPE

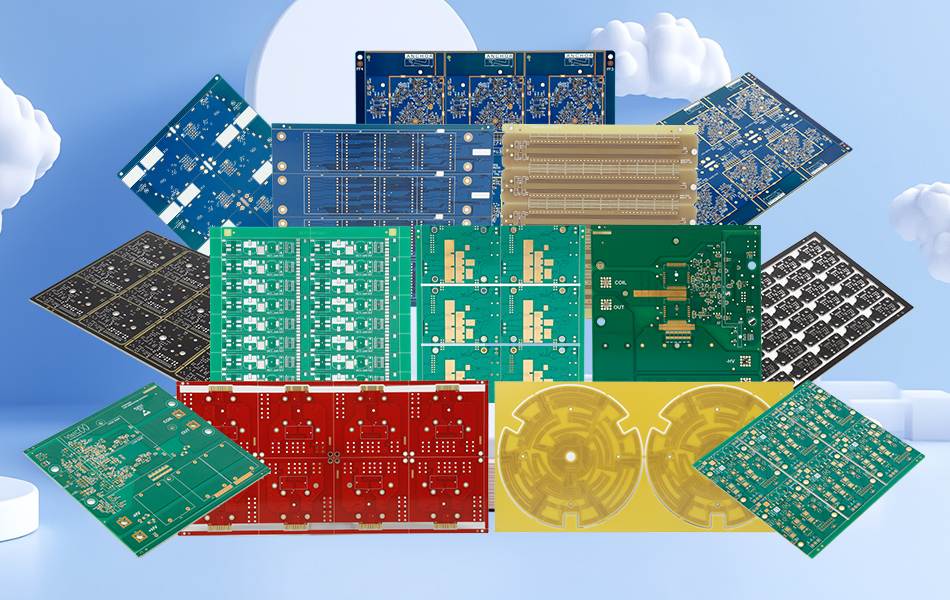

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 07. 2025, 18:30:00

As electronic devices continue to shrink while packing more power, the demand for PCB materials that can efficiently manage heat has never been greater. Enter the Improved Thermal FR4 PCB Material—a next-generation variant of the industry-standard FR4 laminate, engineered to address the thermal limitations of conventional FR4. While traditional FR4 offers a thermal conductivity of ~0.3W/mK, improved thermal FR4 materials push this range to 0.5–1.0W/mK, striking a critical balance between enhanced heat dissipation, cost-effectiveness, and compatibility with existing manufacturing processes. This advancement is transformative for applications ranging from mid-power LED drivers to industrial motor controllers, where excessive heat can compromise reliability and lifespan. In this article, we explore the science behind improved thermal FR4, its key properties, manufacturing innovations, design implications, and real-world applications, highlighting why it has become a cornerstone of modern thermal management in electronics.

Improved Thermal FR4 PCB Material retains the core composition of traditional FR4—epoxy resin reinforced with glass fibers—but incorporates targeted modifications to boost thermal conductivity. The goal is not to rival specialized materials like ceramic substrates (20–300W/mK) or metal-core PCBs (1–2W/mK) but to offer a step-change improvement over standard FR4 while preserving its affordability and processability.

At the heart of this enhancement is a refined material structure that creates more efficient pathways for heat transfer. Conventional FR4’s thermal performance is limited by its epoxy matrix, which acts as a thermal insulator. Improved thermal FR4 addresses this by:

Optimizing the resin-fiber interface to reduce thermal resistance.

Using advanced glass weaves that enhance phonon (heat-carrying particle) propagation.

These changes result in a material that dissipates 60–200% more heat than standard FR4, making it suitable for components generating 5–20W of power—an range where traditional FR4 often requires bulky supplemental cooling.

The improved thermal performance of advanced FR4 stems from three key material innovations, each targeting a bottleneck in heat transfer:

High-Performance Epoxy Resins: Unlike the bisphenol-A epoxies used in standard FR4, improved thermal variants use modified resins with a more ordered molecular structure. These resins—often blended with aromatic or cycloaliphatic compounds—reduce phonon scattering, allowing heat to travel more efficiently through the matrix. This alone boosts base resin conductivity from ~0.15W/mK to ~0.25W/mK, providing a foundation for further enhancements.

Thermally Conductive Fillers: Micro- and nano-scale fillers are dispersed in the epoxy to create continuous thermal pathways. Common fillers include:

Fillers are surface-treated with silane coupling agents to ensure strong bonding with the epoxy, preventing voids that would hinder heat flow.

Aluminum oxide (Al₂O₃, ~30W/mK): Added at 20–30% by weight, it balances cost and conductivity, contributing to a 0.5–0.7W/mK overall rating.

Boron nitride (BN, ~400W/mK): Used in higher-performance grades (15–25% by weight), it raises conductivity to 0.7–1.0W/mK due to its platelet structure, which aligns to form "heat highways."

Silicon carbide (SiC, ~80W/mK): Added in small quantities (5–10%) to reduce thermal resistance at the filler-resin interface, particularly effective in combination with BN.

Engineered Glass Fibers: Traditional E-glass is replaced with high-strength S-glass or quartz fibers, which have higher thermal conductivity (~1.4W/mK vs. E-glass’s 1.1W/mK) and lower thermal expansion. Woven in tighter patterns (e.g., 1080 or 2116 weaves), these fibers reduce gaps in the laminate, minimizing thermal barriers between the glass and resin.

Beyond enhanced thermal conductivity, improved thermal FR4 retains FR4’s signature advantages while adding new performance metrics:

Thermal Conductivity: 0.5–1.0W/mK, depending on filler type and loading—30–200% higher than standard FR4. This allows heat to spread laterally across the PCB 2–3x faster, reducing hotspots.

Glass Transition Temperature (Tg): 150–180°C, higher than standard FR4 (130–140°C), ensuring stability in elevated temperatures. This is critical for applications like automotive underhood electronics, where ambient temperatures can exceed 100°C.

Mechanical Strength: Flexural strength of ≥500MPa (room temperature) and ≥350MPa (125°C), comparable to standard FR4, thanks to strong filler-resin bonding. This ensures the material withstands manufacturing stresses (drilling, routing) and operational vibration.

Electrical Performance: Dielectric constant (Dk) of 4.5–5.0 at 1MHz (slightly higher than standard FR4 due to fillers) with low dissipation factor (Df ≤0.025). This stability makes it suitable for high-speed signals up to 5GHz, a key advantage over metal-core PCBs, which can suffer from signal integrity issues.

Flame Retardancy: Maintains UL94 V-0 certification, achieved through phosphorus-based additives (replacing bromine in eco-friendly variants) that do not compromise thermal conductivity.

While improved thermal FR4 is compatible with standard PCB manufacturing processes, subtle adjustments are needed to maximize its performance:

Lamination: Higher pressures (400–500 psi) and longer cure times (120–150 minutes at 180–200°C) ensure full resin flow around fillers, reducing voids. Controlled cooling (2°C/min) prevents thermal stress between fillers and resin, which could create microcracks.

Drilling and Routing: The abrasive nature of ceramic fillers requires carbide drill bits with diamond coatings to reduce wear. Drill speeds are reduced by 10–15% (20,000–40,000 RPM) compared to standard FR4 to prevent resin chipping and ensure clean via walls.

Plating: Fillers can interfere with copper adhesion, so desmearing processes (e.g., permanganate etching) are extended by 20–30% to remove resin residues from via walls. This ensures reliable electrical and thermal contact between layers.

Solder Mask Application: The material’s slightly higher surface roughness (Ra 1.0–1.5μm) requires better wetting by solder mask formulations. UV-cured masks with modified resins are preferred for strong adhesion, preventing delamination in high-heat environments.

To maximize the benefits of improved thermal FR4, designers should adopt strategies that complement its enhanced conductivity:

Reduced Reliance on Thermal Vias: While thermal vias remain useful, improved thermal FR4’s lateral heat spreading reduces the need for dense via arrays. A 5W component on 0.7W/mK FR4 may require a 2x2 via array instead of 4x4, simplifying design and reducing cost.

Optimized Copper Weight: Thinner copper (1–2 oz) is often sufficient, as the laminate itself conducts more heat. This reduces PCB weight and cost, a benefit for portable devices like drones or medical monitors.

Integrated Heat Spreading: Large copper pours (even 1oz) combined with improved thermal FR4’s conductivity create effective heat spreaders. A 40mm x 40mm pour on 0.8W/mK FR4 can dissipate 5–7W with a temperature rise of <25°C above ambient—eliminating the need for heat sinks in mid-power applications.

Component Clustering: Moderate-power components (3–5W) can be clustered without excessive heating, reducing PCB size. For example, two 5W MOSFETs placed 10mm apart on 0.6W/mK FR4 will experience <5°C cross-heating, compared to 10–15°C on standard FR4.

Rigorous testing ensures improved thermal FR4 meets its performance claims, with protocols tailored to its enhanced properties:

Thermal Conductivity Measurement: Laser flash analysis (LFA) measures in-plane and through-thickness conductivity, confirming values of 0.5–1.0W/mK. This is more accurate than traditional hot-disk methods for composite materials.

Thermal Imaging Under Load: IR cameras capture heat distribution during operation, verifying that improved thermal FR4 reduces hotspots by 15–30°C compared to standard FR4 for the same power density.

Thermal Cycling with Power: PCBs are subjected to 1,000 cycles of -40°C to +125°C while powering components (5–10W), simulating real-world conditions. Improved thermal FR4 shows <5% via failure rates, outperforming standard FR4 (15–20% failures) due to reduced thermal stress.

High-Temperature Electrical Testing: Network analyzers measure signal integrity at 125°C, confirming that Dk stability (±4%) meets the needs of high-speed designs in industrial and automotive applications.

Improved thermal FR4 is transforming thermal management in applications where standard FR4 falls short but specialized materials are unnecessary:

Mid-Power LED Lighting: Streetlights, industrial fixtures, and horticultural LEDs (10–30W) benefit from 0.6–0.8W/mK FR4, which dissipates heat without bulky heat sinks, reducing size and cost.

Industrial Motor Drives: Inverters and servo controllers with 5–15W IGBTs use improved thermal FR4 to handle sustained heat, extending component lifespan in factory environments.

Automotive Infotainment and ADAS: These systems, with processors and power management ICs (3–8W), operate in warm cabin environments. Improved thermal FR4 (Tg 170°C+) prevents performance throttling due to overheating.

Medical Devices: Portable ultrasound machines and patient monitors (5–10W) use the material to maintain reliability in clinical settings, where fan-based cooling is often impractical due to noise or sterility requirements.

Improved thermal FR4 fills a critical gap between standard FR4 and high-cost alternatives, as shown by key comparisons:

vs. Standard FR4: Offers 30–200% better thermal conductivity at 15–30% higher cost, justified for 5–20W applications where cooling costs would otherwise escalate.

vs. Metal-Core PCBs (MCPCBs): MCPCBs (1–2W/mK) have higher conductivity but cost 2–3x more and are limited to 1–2 layers. Improved thermal FR4, with 0.7–1.0W/mK, is preferable for multi-layer designs (4–12 layers) in mid-power applications.

vs. Ceramic Substrates: Ceramics (20–300W/mK) excel at >50W but are brittle and expensive. Improved thermal FR4 is a cost-effective alternative for 5–20W, with better mechanical flexibility.

vs. Thermally Conductive Adhesives: While adhesives can bond heat sinks to standard FR4, they add cost and thickness. Improved thermal FR4 integrates heat dissipation into the PCB itself, simplifying design.

Research is pushing improved thermal FR4 to new limits, with three key trends emerging:

Nano-Filler Hybrids: Combining BN nanotubes with micro-scale Al₂O₃ creates hierarchical thermal pathways, targeting 1.2–1.5W/mK conductivity while maintaining processability. Lab prototypes show promising results, with commercialization expected by 2026.

Sustainable Formulations: Bio-based epoxies (derived from plant oils) are being paired with recycled glass fibers and natural fillers (e.g., rice husk ash-derived silica) to reduce carbon footprints. These variants aim for 0.5–0.7W/mK, matching conventional improved thermal FR4’s performance.

Embedded Heat Pipes: Thin, flat heat pipes integrated into improved thermal FR4 laminates during manufacturing could boost effective conductivity to 2–3W/mK, blurring the line between PCB and heat sink. This would enable 20–30W applications without active cooling.

Improved Thermal FR4 PCB Material represents a pivotal advancement in thermal management, offering a pragmatic solution for the mid-power electronics that dominate modern technology. By enhancing thermal conductivity to 0.5–1.0W/mK while retaining FR4’s cost, processability, and mechanical strength, it fills a critical gap in the material landscape. From LED lighting to automotive systems, it enables smaller, more reliable devices by reducing or eliminating the need for supplemental cooling. As research continues to push its performance boundaries, improved thermal FR4 is poised to become the new standard for PCB design, proving that incremental innovations in established materials can drive transformative change in electronics. For engineers, embracing this material means balancing thermal efficiency with practicality—key to unlocking the next generation of power-dense devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB