-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 10. 2025, 13:41:27

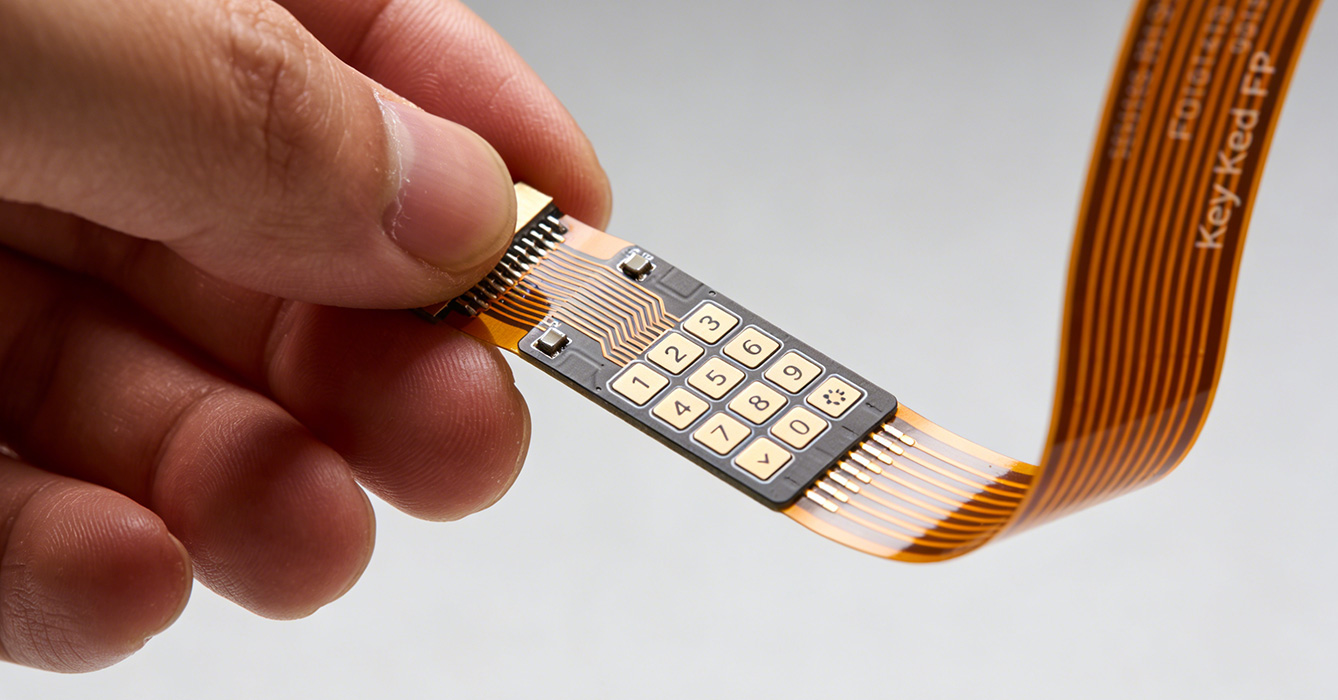

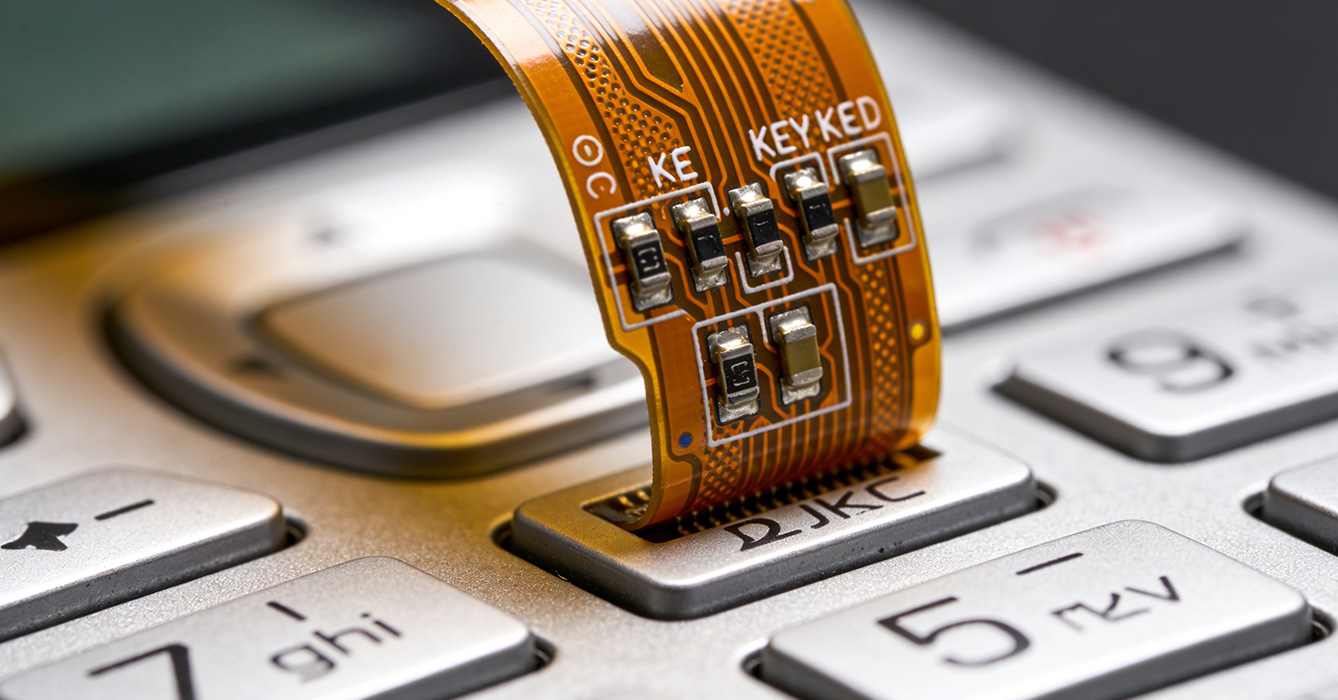

Keypads serve as the vital human-machine interface (HMI) across industrial control systems, automotive dashboards, medical devices, and consumer electronics, requiring flexible printed circuits (FPCs) that combine consistent performance, mechanical resilience, and seamless integration. A professional KeyPads FPC Manufacturer distinguishes itself through end-to-end manufacturing expertise and scenario-driven reliability engineering, going beyond basic component production to deliver FPC solutions tailored to the unique operating demands of diverse keypad applications. Unlike generic FPC producers, specialized KeyPads FPC Manufacturers deeply understand the mechanical and environmental stresses on keypad circuits, ensuring their products withstand repeated usage cycles and harsh conditions. For brands developing high-reliability keypads, partnering with a reputable KeyPads FPC Manufacturer is essential to safeguarding product performance and end-user trust.

The core competitiveness of a top KeyPads FPC Manufacturer lies in its integrated manufacturing capabilities, which ensure consistent quality and performance throughout the production lifecycle:

- Application-Matched Material Selection & Validation: Manufacturers prioritize material sourcing tailored to keypad use cases, selecting substrates, conductive materials, and adhesives based on factors such as flex endurance, temperature resistance, and chemical compatibility. For industrial keypads, this means corrosion-resistant copper foils and rugged polyimide substrates; for automotive applications, heat-resistant materials compliant with automotive-grade standards; and for medical devices, biocompatible and disinfectant-resistant films. All materials undergo rigorous pre-production validation to ensure they meet performance benchmarks.

- Precision Fabrication Processes: Leveraging advanced manufacturing technologies—such as laser etching for ultra-fine circuit patterns, automated lamination for consistent layer bonding, and precision stamping for accurate contact formation—manufacturers ensure keypad FPCs meet tight dimensional tolerances. These processes minimize human error, ensuring uniform circuit resistance and contact reliability across high-volume production runs. For complex keypad designs (e.g., multi-layered or rigid-flex structures), specialized molding and assembly techniques ensure structural integrity.

- Automated Quality Inspection Throughout Production: Integrating AI-driven optical inspection (AOI), X-ray testing, and contact resistance measurement into the production line, manufacturers detect micro-defects (e.g., trace breaks, poor solder joints) in real time. Automated inspection ensures 100% coverage of critical features, avoiding faulty components from entering the next production stage and maintaining consistent quality across batches.

KeyPads FPC Manufacturers excel in engineering solutions that withstand the specific stresses of different keypad applications, ensuring long-term reliability:

- Industrial Keypad FPC Solutions: Industrial keypads face dust, vibration, chemical exposure, and extreme temperature fluctuations. Manufacturers engineer ruggedized FPCs with sealed edge structures, reinforced contact points, and EMI shielding. They also implement stress-relief circuit designs to withstand the mechanical impact of heavy-duty usage, ensuring reliable signal transmission in factory, mining, or construction environments.

- Automotive Keypad FPC Solutions: In-vehicle keypads (steering wheel controls, infotainment systems) must endure temperature extremes (-40°C to 85°C), vibration, and UV radiation. KeyPads FPC Manufacturers produce automotive-grade FPCs compliant with IATF 16949 standards, using flame-retardant and heat-resistant materials. They also optimize circuit routing to minimize signal loss and ensure electromagnetic compatibility (EMC) with other vehicle electronics.

- Medical Keypad FPC Solutions: Medical device keypads require sterile, easy-to-disinfect designs and precise signal transmission. Manufacturers use medical-grade, biocompatible materials and sealed FPC structures to prevent contamination. They also implement strict quality control to ensure compliance with ISO 13485 standards, critical for applications such as patient monitors and diagnostic equipment.

- Consumer Electronics Keypad FPC Solutions: For smartphones, gaming controllers, and remote controls, manufacturers balance slim form factors with durability. They produce ultra-thin FPCs with compact contact layouts, integrating backlight circuits where needed. These FPCs are engineered to withstand daily usage cycles, including repeated presses and minor impacts, while maintaining low power consumption.

Leading KeyPads FPC Manufacturers act as strategic partners, providing comprehensive support to streamline customers’ product development and production processes:

- Fast Prototyping & Design Optimization: To accelerate product development, manufacturers offer rapid prototyping services, delivering functional FPC prototypes within short lead times. Their engineering teams collaborate with customers to optimize designs for manufacturability (DFM), reducing production costs and avoiding potential issues during mass production.

- Scalable Mass Production Capacity: With flexible production lines and global manufacturing facilities, manufacturers can scale production from small batches to high-volume runs seamlessly. They maintain strict production scheduling to meet customers’ delivery deadlines, supporting timely product launches and market expansion.

- Global Supply Chain & Traceability: Establishing a reliable global supply chain for raw materials, manufacturers ensure consistent material availability even during market fluctuations. They also implement full batch traceability systems, tracking every production stage from material sourcing to delivery, enabling quick resolution of any quality issues and ensuring compliance with global regulations.

To meet the strict requirements of diverse industries, KeyPads FPC Manufacturers adhere to rigorous quality standards and regulatory compliance:

- Comprehensive Compliance with Global Standards: Manufacturers comply with international standards such as IPC-6012/2221 (FPC quality), RoHS/REACH (environmental protection), IATF 16949 (automotive), and ISO 13485 (medical). This ensures their FPC solutions can be integrated into products for global markets, avoiding regulatory barriers.

- Rigorous Reliability Testing: All keypad FPCs undergo targeted testing, including flex endurance cycling (simulating millions of presses), thermal cycling, humidity aging, salt spray testing, and signal integrity analysis. These tests validate performance under real-world conditions, ensuring the FPCs meet the lifespan and reliability expectations of each application.

In conclusion, a KeyPads FPC Manufacturer is a critical partner in developing reliable, high-performance keypad interfaces, leveraging end-to-end manufacturing expertise, scenario-driven reliability engineering, and customer-centric support. By balancing precision production, scalability, and compliance, these manufacturers empower brands to deliver keypads that excel in diverse operating environments. As HMI technology continues to evolve, the role of KeyPads FPC Manufacturers in ensuring keypad durability, performance, and manufacturability will remain indispensable for brands aiming to succeed in competitive global markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB