-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 10. 2025, 13:39:50

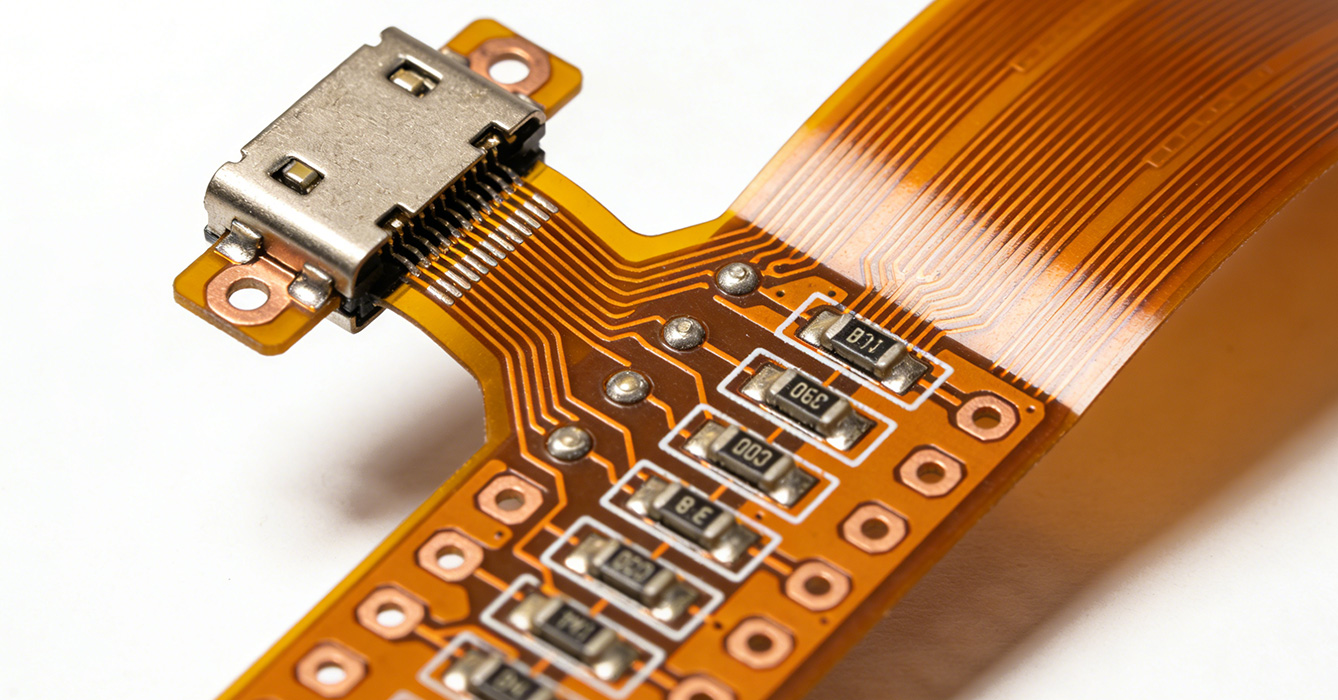

In the era of diversified electronic products, keypads—as critical human-machine interaction (HMI) components—are increasingly required to adapt to unique form factors, functional demands, and operating environments. A professional Custom Keypad FPC Design Service stands out as a key enabler for brands seeking differentiated keypad solutions, bridging the gap between conceptual design and practical implementation. Unlike standardized FPC offerings, this tailored service focuses on understanding client-specific requirements, integrating application-driven design strategies, and optimizing flexible printed circuits (FPCs) for keypad performance, compatibility, and user experience. For enterprises developing specialized keypads for industrial control, automotive, medical, or consumer electronics, leveraging a reliable Custom Keypad FPC Design Service is essential to translating innovation into market-competitive products.

The primary advantage of a Custom Keypad FPC Design Service lies in its ability to address the non-standard requirements that standardized solutions cannot fulfill, delivering targeted value for diverse use cases:

- Form Factor Adaptation for Compact/Irregular Designs: Many innovative devices (e.g., wearable controllers, custom industrial panels) feature non-traditional, compact, or irregular keypad layouts. The design service optimizes FPC size, shape, and layer structure to fit tightly constrained spaces, using ultra-thin substrates and precision routing to integrate contacts, traces, and connectors without compromising functionality. This ensures the FPC seamlessly matches the keypad’s unique physical design.

- Functional Integration Tailored to Usage Scenarios: Different keypads demand specific functional integrations—such as backlight circuits for low-light environments, anti-static protection for industrial settings, or low-power designs for battery-operated devices. The custom design service integrates these functions into the FPC layout, optimizing circuit topology to balance performance and energy efficiency. For example, medical keypad FPCs may include integrated shielding for electromagnetic interference (EMI) to avoid disrupting sensitive diagnostic equipment.

- Tactile Feedback Optimization for User Experience: Tactile response is a critical user experience factor for keypads. The design service collaborates with clients to match FPC design with tactile dome specifications, adjusting substrate stiffness, contact point placement, and trace routing to ensure consistent, responsive feedback across all keys. This customization ensures the keypad feels intuitive and reliable for end-users.

A professional Custom Keypad FPC Design Service delivers a seamless, end-to-end process to guide clients through every stage of FPC development:

- Requirements Discovery & Feasibility Analysis: The service begins with in-depth consultation to understand the client’s keypad application (environment, usage frequency, functional goals), device constraints (size, power, assembly requirements), and quality standards. Engineers conduct feasibility analysis to evaluate technical risks, material compatibility, and manufacturing viability, providing DFM (Design for Manufacturability) insights to avoid costly rework later.

- Conceptual Design & Simulation: Using advanced EDA (Electronic Design Automation) tools, engineers create preliminary FPC designs, including circuit layout, trace routing, component placement, and material selection. They perform simulation tests—such as signal integrity analysis, mechanical stress simulation, and thermal analysis—to validate design performance and identify potential issues (e.g., crosstalk, stress concentration) before prototyping.

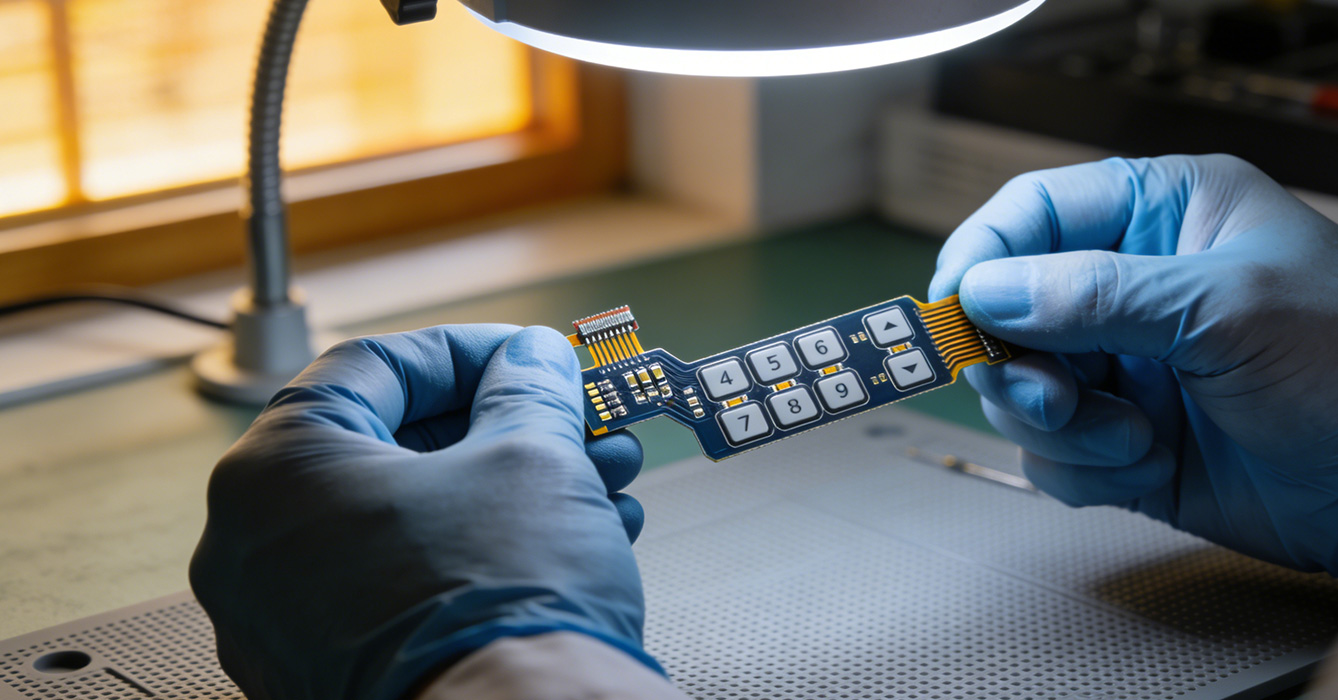

- Prototype Development & Iteration: Based on the validated design, the service produces functional FPC prototypes for physical testing. Clients can evaluate the prototype’s fit, function, and tactile performance, providing feedback for iterative improvements. The design team adjusts the layout, materials, or structure as needed, ensuring the final design meets all requirements.

- Design Validation & Documentation: The final custom design undergoes rigorous validation testing (e.g., contact resistance, flex endurance, environmental compatibility) to confirm performance. The service provides comprehensive documentation—including design schematics, material specifications, assembly guidelines, and test reports—to support the client’s mass production and quality control processes.

A top-tier Custom Keypad FPC Design Service tailors solutions to the unique challenges of different industries, ensuring designs align with sector-specific standards and operating conditions:

- Industrial Keypad Design: For industrial control panels exposed to dust, vibration, and chemical agents, the design focuses on ruggedization—integrating sealed edge structures, anti-corrosion materials, and reinforced contact points. The FPC layout is optimized for EMI shielding to prevent interference from industrial machinery, ensuring reliable signal transmission in harsh factory or mining environments.

- Automotive Keypad Design: In-car keypads (steering wheel controls, infotainment systems) require designs that withstand temperature extremes (-40°C to 85°C), vibration, and UV radiation. The service adheres to IATF 16949 standards, selecting heat-resistant, flame-retardant materials and optimizing circuit routing to minimize signal loss. Designs also consider EMC (Electromagnetic Compatibility) to avoid disrupting vehicle electronics.

- Medical Keypad Design: Medical device keypads (patient monitors, diagnostic equipment) demand sterile, easy-to-disinfect designs. The custom service uses biocompatible, chemical-resistant materials (medical-grade polyimides) and sealed FPC structures to prevent contamination. Designs prioritize precise signal transmission for critical operations and comply with ISO 13485 standards.

- Consumer Electronics Keypad Design: For smartphones, gaming controllers, or remote controls, the focus is on slim form factors, low-power consumption, and aesthetic integration. The service designs ultra-thin FPCs with compact contact layouts, integrating backlight circuits and touch sensors where needed. Designs also balance flexibility with durability to support daily usage cycles.

A leading Custom Keypad FPC Design Service acts as a strategic partner, supporting clients’ long-term innovation goals through collaborative engagement:

- Early-Stage Co-Creation: The service joins clients’ product development teams in the early stages, contributing FPC expertise to shape keypad concepts. This collaborative approach ensures the FPC design is aligned with the overall product vision, avoiding design conflicts and accelerating time-to-market.

- Technology Scouting & Future-Proofing: Design engineers stay updated on emerging materials and technologies (e.g., flexible conductive inks, advanced shielding solutions) to incorporate into custom designs. They help clients future-proof their keypads by integrating scalable designs that can adapt to future functional upgrades.

- Post-Design Support: Beyond finalizing the design, the service provides ongoing support during mass production, including troubleshooting manufacturing issues, optimizing production processes, and validating batch quality. This ensures the custom FPC design is consistently implemented at scale.

In conclusion, a Custom Keypad FPC Design Service is a critical enabler of keypad innovation, delivering tailored solutions that address the unique form factor, functional, and environmental requirements of diverse applications. By leveraging an end-to-end design process, scenario-driven optimization, and collaborative partnership, this service empowers brands to create differentiated, high-performance keypads that stand out in competitive markets. As HMI innovation continues to drive electronic product differentiation, the strategic value of partnering with a professional Custom Keypad FPC Design Service will only grow for enterprises aiming to deliver user-centric, innovative devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB