-

- PCB TYPE

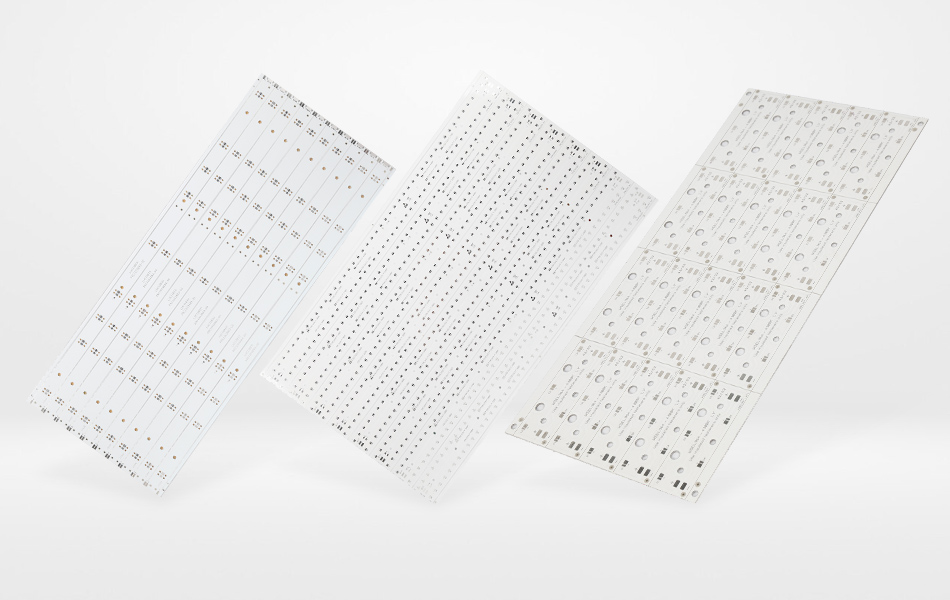

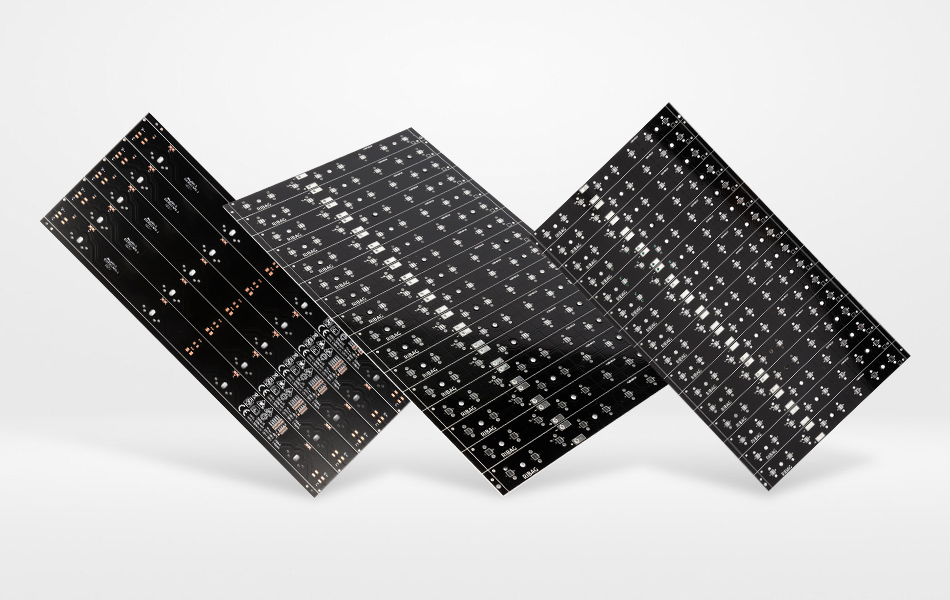

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 30. 2025, 11:57:30

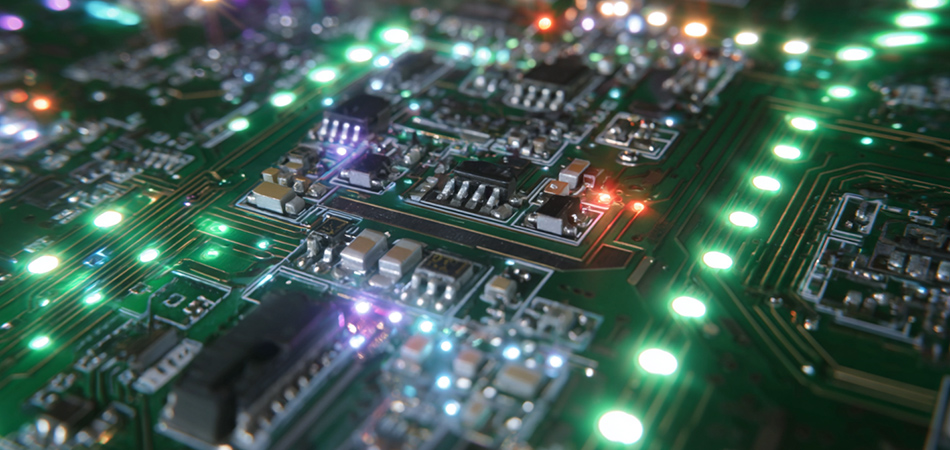

The Convergence of Lighting and Engineering

In the dynamic landscape of modern illumination, LED light systems have emerged as the vanguard of energy - efficient technology. Central to their reliability and performance lies the aluminum printed circuit board (PCB), a foundational component that seamlessly integrates thermal management, electrical conductivity, and mechanical robustness. This article delves into the technical intricacies of LED light aluminum PCBs, exploring their layered architecture, thermal management mechanisms, manufacturing methodologies, and diverse industry applications. As the demand for sustainable, high - performance lighting continues to escalate, understanding the role of aluminum PCBs becomes essential for engineers, designers, and industry professionals seeking to optimize LED system performance.

The Multilayer Architecture of LED Light Aluminum PCBs

The Copper Circuit Layer: Navigating Electrical Signals

The uppermost layer of an aluminum PCB for LED lighting consists of a high - purity copper foil, meticulously etched to form a network of conductive traces. This layer serves as the neural network of the lighting system, directing electrical current to each LED chip with minimal resistance. The copper’s thickness is tailored to the power requirements of the LED array, with thicker foils (typically ranging from 18μm to 105μm) employed in high - power applications to accommodate higher currents and reduce ohmic losses. The trace geometry is optimized using advanced CAD software, ensuring uniform current distribution and minimizing voltage drops across the array.

The Dielectric Layer: Balancing Insulation and Thermal Transfer

Sandwiched between the copper circuit layer and the aluminum substrate, the dielectric layer plays a dual role: electrical isolation and thermal conduction. Composed of thermally conductive polymers embedded with ceramic fillers (such as aluminum oxide or boron nitride), this layer acts as a thermal bridge, facilitating heat transfer from the copper traces to the aluminum base while preventing short - circuits. The dielectric constant and thermal conductivity of this layer are critical parameters, with modern formulations achieving thermal conductivities exceeding 1.5 W/m·K to ensure efficient heat dissipation.

Thermal Management: The Core Challenge in LED Lighting

The Impact of Thermal Stress on LED Performance

LEDs are highly sensitive to temperature fluctuations, with excessive heat leading to:

Luminous Efficacy Degradation: A decrease in light output per watt as junction temperature rises.

Color Shift: Alterations in the LED’s chromaticity coordinates, affecting light quality.

Premature Failure: Reduced lifespan due to thermal cycling and material degradation.

Aluminum PCBs address these challenges by providing a low - resistance thermal pathway from the LED junction to the ambient environment. The thermal resistance (Rth) of the PCB, a key performance metric, is influenced by the combined thermal properties of the copper layer, dielectric, and aluminum substrate, as well as the design of thermal vias and heat sink interfaces.

Thermal Via Design and Heat Sink Integration

Thermal vias, plated through - holes that penetrate the PCB layers, play a pivotal role in vertical heat transfer. These vias, often filled with thermally conductive materials like silver epoxy, create direct pathways for heat to travel from the copper traces to the aluminum substrate. In high - power applications, thermal vias are strategically placed beneath LED chips to minimize thermal gradients.

For optimal heat dissipation, aluminum PCBs are often integrated with external heat sinks, which extend the surface area available for convection and radiation. The interface between the PCB and heat sink is critical, with thermal interface materials (TIMs) such as gap pads or thermal paste used to eliminate air gaps and enhance thermal contact.

Design Considerations for LED Light Aluminum PCBs

LED Layout and Thermal Spacing

The spatial arrangement of LEDs on the aluminum PCB directly impacts thermal performance and light distribution. Designers must consider:

Heat Source Clustering: Grouping LEDs to facilitate collective heat dissipation through shared thermal pathways.

Thermal Spacing: Maintaining adequate distance between LEDs to prevent mutual heating, with typical spacing guidelines based on the LED package size and power output.

Symmetric Layouts: Ensuring uniform heat distribution to avoid hotspots and maintain consistent light output across the array.

Electrical Design Principles

Trace Width Calculation: Determining trace dimensions to handle operating currents without excessive heating, considering factors such as copper thickness and ambient temperature.

Ground Plane Optimization: Employing large copper areas as ground planes to serve as heat spreaders and reduce electrical noise.

Voltage Clearance: Maintaining sufficient distance between high - voltage traces and the aluminum substrate to prevent electrical arcing.

Environmental and Mechanical Factors

Corrosion Protection: Selecting aluminum alloys and surface treatments (e.g., anodizing, powder coating) for outdoor applications to withstand moisture, UV radiation, and atmospheric pollutants.

Vibration Resistance: Designing the PCB with appropriate thickness and mounting features to endure mechanical stress in transportation or industrial settings.

Thermal Expansion Matching: Ensuring compatibility between the coefficients of thermal expansion (CTE) of the PCB layers to prevent delamination during thermal cycling.

Manufacturing Processes for LED Light Aluminum PCBs

Material Preparation and Lamination

Aluminum Substrate Pretreatment: Cleaning and surface activation to remove contaminants and enhance adhesion of the dielectric layer, often involving degreasing, alkaline etching, or plasma treatment.

Dielectric Lamination: Bonding the copper foil, dielectric prepreg, and aluminum substrate under controlled heat (150–200°C) and pressure (5–10 MPa) in a vacuum laminator to ensure void - free bonding and uniform thickness.

Circuit Patterning and Via Formation

Photolithography: Using laser direct imaging (LDI) for high - resolution trace definition, followed by etching with eco - friendly solutions like ammonium persulfate to form the copper circuitry.

Precision Drilling: Employing diamond - coated drill bits for accurate via placement in the aluminum substrate, with coolant systems to minimize burr formation and tool wear.

Via Plating and Filling: Applying electroless copper plating to via walls for electrical connectivity, with optional filling using thermally conductive materials to enhance heat transfer.

Surface Finishing and Quality Assurance

Lead - Free Surface Finishes: Implementing tin - based alloys (e.g., Sn - Ag - Cu), electroless nickel immersion gold (ENIG), or organic solderability preservatives (OSP) to ensure solderability and corrosion resistance.

Thermal Resistance Testing: Using standardized methods (e.g., JEDEC JESD51) to measure heat dissipation efficiency and validate thermal performance.

Environmental Testing: Subjecting PCBs to temperature cycling, humidity, and vibration tests to ensure reliability in target applications.

Industry Applications of LED Light Aluminum PCBs

Outdoor Lighting Solutions

Street and Area Lighting

Aluminum PCBs enable energy - efficient LED streetlights that offer up to 80% energy savings compared to traditional technologies. Their thermal management capabilities ensure consistent light output and prolonged lifespan, reducing maintenance costs for urban infrastructure. In area lighting, aluminum PCBs support high - power LED arrays for stadiums, parking lots, and public spaces, delivering uniform illumination and withstand ing harsh weather conditions.

Architectural and Landscape Lighting

Architects and designers leverage aluminum PCBs to create dynamic lighting schemes for building facades, monuments, and natural landscapes. The mechanical flexibility of aluminum allows for complex form factors, while thermal efficiency ensures reliable operation in outdoor environments. Anodized coatings on aluminum substrates provide both corrosion resistance and aesthetic appeal, making them ideal for long - lasting architectural installations.

Commercial and Industrial Lighting

High - Bay and Low - Bay Lighting

In industrial facilities and commercial spaces, aluminum PCBs power high - bay LED fixtures that replace traditional metal halide or fluorescent lamps. The ability to manage heat in large - scale lighting systems ensures consistent brightness in warehouses, factories, and retail environments, while reducing energy consumption and maintenance requirements.

Refrigeration and Cold Storage Lighting

Aluminum PCBs excel in low - temperature environments, maintaining LED performance in refrigeration units and cold storage facilities. Unlike traditional lighting, LEDs with aluminum PCBs do not suffer from reduced efficacy at low temperatures, making them ideal for food storage and logistics applications.

Automotive Lighting Systems

Exterior Lighting

Aluminum PCBs are integral to automotive LED headlights, taillights, and daytime running lights. Their thermal and mechanical properties enable high - brightness illumination while withstanding the vibrations, temperature fluctuations, and moisture exposure typical of vehicle operation. The compact form factor of aluminum PCBs also supports sleek, aerodynamic lighting designs.

Interior Lighting

For automotive interior lighting, aluminum PCBs facilitate customizable solutions for ambient lighting, instrument panels, and display backlighting. Their thermal efficiency ensures that LEDs operate at optimal temperatures, even in confined spaces with limited airflow.

Specialty Lighting Applications

Horticultural Lighting

Aluminum PCBs play a crucial role in LED grow lights, where precise thermal management is essential for maintaining the spectral output and efficacy of LEDs used in plant cultivation. By dissipating heat efficiently, aluminum PCBs enable consistent light quality, promoting optimal plant growth in greenhouses and vertical farming systems.

Medical and Surgical Lighting

In medical facilities, aluminum PCBs support high - intensity LED lighting for surgical rooms, examination areas, and diagnostic equipment. Their reliability and thermal stability are critical in environments where consistent, shadow - free illumination is essential for precision medical procedures.

Future Trends in LED Light Aluminum PCB Technology

Advanced Material Innovations

Nano - Enhanced Dielectrics: Incorporating nanomaterials like graphene or boron nitride to significantly enhance thermal conductivity and electrical insulation.

Biodegradable and Recyclable Materials: Developing eco - friendly dielectrics and recycled aluminum substrates to reduce the environmental impact of PCB manufacturing.

Metal Matrix Composites: Combining aluminum with ceramic fillers to create substrates with tailored thermal and mechanical properties for specific lighting applications.

Manufacturing Process Advancements

Additive Manufacturing: Utilizing 3D printing techniques for rapid prototyping and customized aluminum PCB designs, enabling complex geometries and integrated heat sink structures.

Laser - Based Fabrication: Employing laser drilling and etching for microvias and fine - line traces in high - density LED arrays, improving thermal performance and component integration.

Automated Quality Control: Implementing AI - driven inspection systems for real - time defect detection and process optimization in PCB manufacturing.

Integration with Smart Lighting Ecosystems

IoT - Enabled PCBs: Integrating sensors, wireless communication modules, and microcontrollers directly onto aluminum PCBs to create smart lighting systems with adaptive control capabilities.

Energy Harvesting Integration: Designing aluminum PCBs to incorporate energy - harvesting technologies, such as solar cells or thermoelectric generators, for self - sufficient lighting solutions.

Miniaturization and High - Density Integration

Micro - LED and Mini - LED Technologies: Developing aluminum PCBs with advanced thermal management for next - generation LED arrays, supporting higher pixel densities and compact form factors in displays and lighting.

3D Packaging: Enabling stacked LED and driver configurations on aluminum PCBs to create ultra - compact lighting modules for portable and wearable applications.

Conclusion: The Indispensable Role of Aluminum PCBs in LED Lighting

LED light aluminum PCBs stand as a testament to the marriage of materials science and engineering innovation, enabling the transformation of lighting from a mere functional necessity to a sustainable, high - performance solution. From urban streetlights to specialized medical illumination, these PCBs silently yet profoundly impact how we interact with light in our daily lives. As LED technology continues to evolve, aluminum PCBs will remain at the forefront, adapting to new materials, manufacturing techniques, and application requirements. Their ability to balance thermal management, electrical reliability, and mechanical resilience makes them an indispensable component in the ongoing revolution of modern lighting, ensuring that the glow of LEDs remains bright, efficient, and enduring for years to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB