-

- PCB TYPE

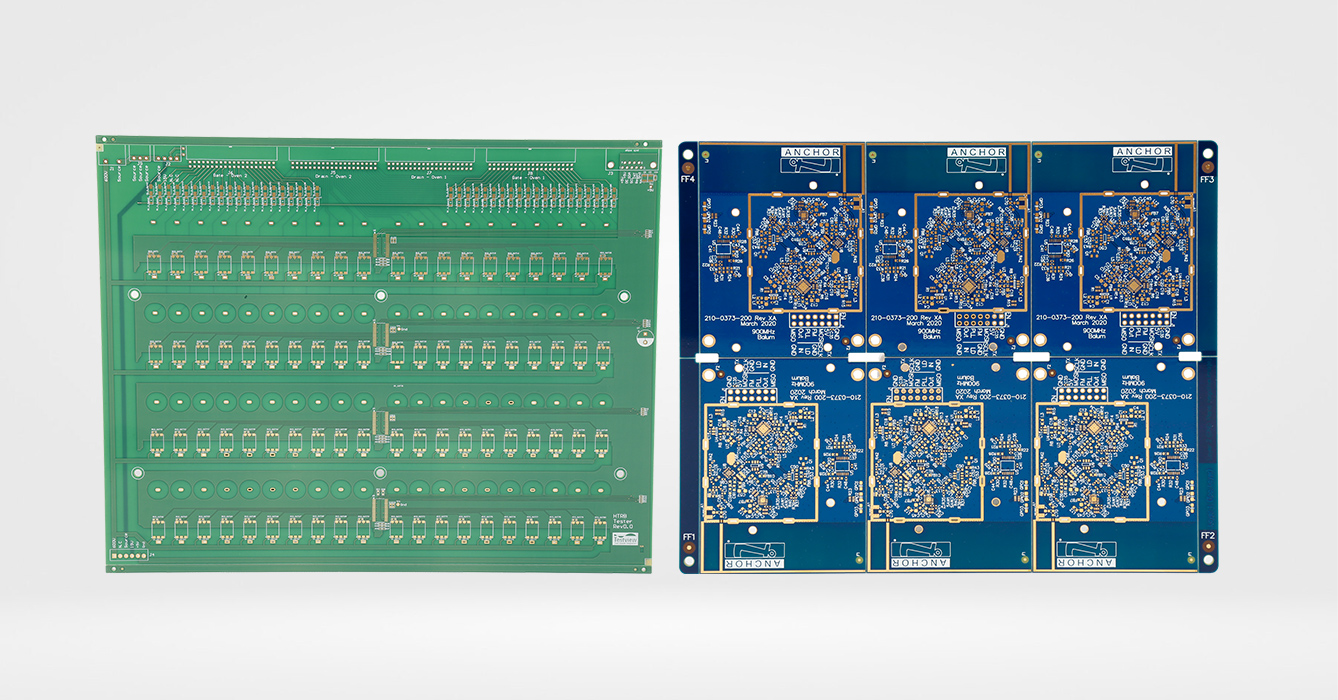

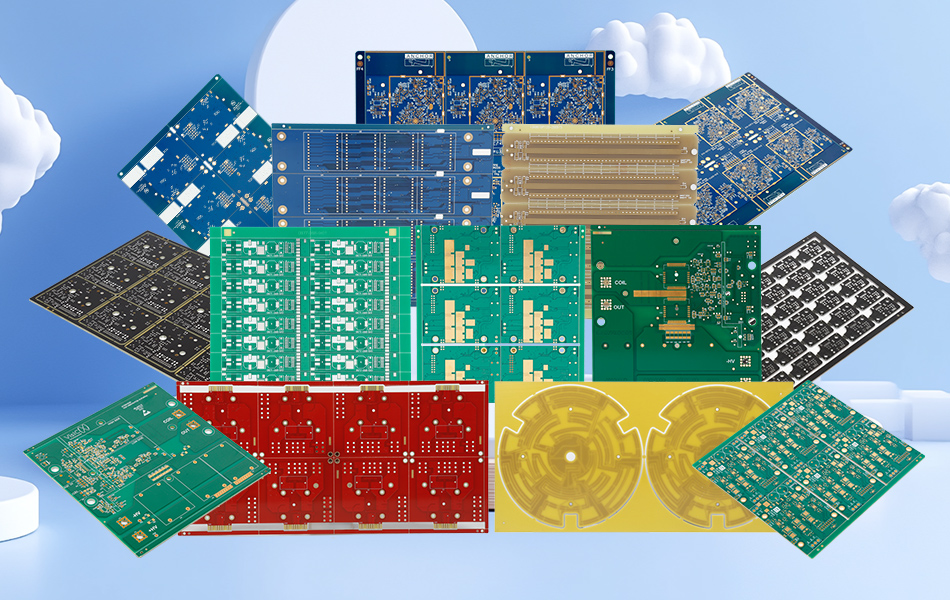

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 05. 2025, 08:58:58

In the realm of high-reliability printed circuit boards (PCBs), Low CTE FR4 PCB Material has emerged as a critical solution for applications demanding exceptional dimensional stability under thermal stress. CTE, or coefficient of thermal expansion, measures how a material changes in size with temperature fluctuations—a parameter of paramount importance in electronics where temperature variations are common, from manufacturing processes like soldering to operational environments such as automotive engine bays or industrial furnaces. Unlike standard FR4, which exhibits moderate thermal expansion, Low CTE FR4 is engineered to minimize this expansion, reducing stress on solder joints, vias, and layer interfaces. This article explores the technical nuances of Low CTE FR4 PCB Material, from its composition and properties to its applications and manufacturing considerations, highlighting its role in preventing failures in temperature-critical electronics.

Low CTE FR4 PCB Material is a specialized variant of glass-reinforced epoxy laminate, designed to address a critical challenge in PCB reliability: thermal expansion mismatch. In standard FR4, temperature changes cause the laminate to expand or contract at rates that often differ from adjacent materials like copper traces, solder, or component leads. This mismatch generates stress, which over time can lead to via cracking, solder joint fatigue, or delamination—failures that are costly and potentially dangerous in safety-critical applications.

Low CTE FR4 solves this by reducing the coefficient of thermal expansion, particularly in the z-axis (thickness direction) and in-plane (x/y axes). While standard FR4 typically has an in-plane CTE of 12–18 ppm/°C (below its glass transition temperature, Tg) and a z-axis CTE of 60–80 ppm/°C (below Tg), Low CTE FR4 achieves in-plane CTE as low as 8–12 ppm/°C and z-axis CTE as low as 40–60 ppm/°C. This reduction is not achieved through incremental tweaks but through deliberate reformulation of the laminate’s composition, making it a material of choice for high-layer-count PCBs, HDI (high-density interconnect) designs, and applications with extreme thermal cycling.

The key to Low CTE FR4 PCB Material’s performance lies in its carefully tailored composition, which balances epoxy resin, glass fiber reinforcement, and specialized additives to suppress thermal expansion:

Modified Epoxy Resin Matrix: Unlike standard FR4, which uses bisphenol-A-based epoxies, Low CTE FR4 often incorporates high-modulus resins blended with novolac or cycloaliphatic hardeners. These resins form a denser cross-linked network that resists expansion when heated. The datasheet for Low CTE FR4 typically notes that the resin system undergoes extended curing (120–150 minutes at 180–200°C) to maximize cross-linking, enhancing dimensional stability.

High-Strength Glass Fiber Reinforcement: Low CTE FR4 uses E-glass fibers with tighter weave patterns (e.g., 1080 or 2116) compared to standard FR4. The fibers act as a "skeleton," limiting the resin’s ability to expand. In some formulations, high-silica glass (with lower inherent CTE than standard E-glass) is used to further reduce in-plane expansion. The fiber-to-resin ratio is also optimized—often 60–65% fiber by weight—to leverage the glass’s low CTE (≈5 ppm/°C) and counteract the resin’s higher expansion tendency.

Low-CTE Fillers: Microscopic inorganic fillers are a defining feature of Low CTE FR4. Materials like fused silica (SiO₂), aluminum oxide (Al₂O₃), or boron nitride (BN) are dispersed in the resin matrix. These fillers have inherently low CTE (silica, for example, has a CTE of ≈0.5 ppm/°C) and act as "spacers," restricting resin expansion. The datasheet specifies filler loading—typically 20–40% by weight—balancing CTE reduction with processability (excess filler can make the laminate brittle).

Coupling Agents: Silane-based coupling agents are added to improve adhesion between fillers, glass fibers, and resin. This ensures the entire composite acts as a unified structure, preventing localized expansion at interfaces and reducing the risk of delamination under thermal stress.

The physical properties of Low CTE FR4 PCB Material are defined by its ability to maintain size and shape across temperature ranges, with the following characteristics highlighted in technical datasheets:

Coefficient of Thermal Expansion (CTE): As the defining property, Low CTE FR4’s CTE is carefully measured and reported. In-plane (x/y) CTE ranges from 8–12 ppm/°C (below Tg) and 30–45 ppm/°C (above Tg), while z-axis CTE is 40–60 ppm/°C (below Tg) and 150–200 ppm/°C (above Tg). These values are significantly lower than standard FR4, bringing the laminate’s expansion closer to that of copper (17 ppm/°C) and solder alloys (≈20–25 ppm/°C).

Density: Slightly higher than standard FR4, typically 1.9–2.1 g/cm³, due to the dense fillers and high fiber content. This increase is minimal but relevant for weight-sensitive applications like aerospace, where every gram matters.

Thickness Uniformity: Critical for impedance control, Low CTE FR4 maintains tight thickness tolerances (±5%) across large panel sizes. This consistency ensures predictable expansion behavior across the entire PCB, avoiding localized stress points.

Moisture Absorption: Low CTE FR4 absorbs slightly more moisture than standard FR4 (≤0.18% vs. ≤0.15% for standard grades) due to increased filler surface area, which can trap water molecules. However, hydrophobic coatings or sealants are often used to mitigate this in humid environments, as noted in application guidelines.

Surface Finish Compatibility: Compatible with all standard PCB finishes (ENIG, HASL, OSP, immersion tin), though the laminate’s harder surface (due to fillers) may require adjusted etching parameters to ensure strong adhesion—details typically specified in manufacturing notes.

While Low CTE FR4 is engineered for thermal stability, its electrical properties remain critical for high-frequency and high-voltage applications, as outlined in technical specifications:

Dielectric Constant (Dk): Slightly higher than standard FR4, ranging from 4.5–5.0 at 1 MHz, due to the dielectric properties of inorganic fillers. However, Dk stability across temperatures is superior: variations are ≤3% between 25°C and 125°C, compared to 5–7% for standard FR4. This stability is vital for maintaining impedance control in high-speed designs (e.g., 10 Gbps Ethernet).

Dissipation Factor (Df): Typically ≤0.025 at 1 MHz, with minimal increase at elevated temperatures (≤0.03 at 150°C). This low energy loss makes Low CTE FR4 suitable for RF applications like 5G base stations, where signal attenuation must be minimized.

Dielectric Strength: ≥20 kV/mm (per ASTM D149), comparable to standard FR4, ensuring insulation integrity in high-voltage devices like power inverters or industrial motor controllers.

Insulation Resistance: Volume resistivity ≥10¹⁴ Ω·cm and surface resistivity ≥10¹³ Ω, even after thermal cycling. This ensures minimal leakage current in humid or high-temperature environments, a key requirement for medical devices or outdoor electronics.

Low CTE FR4 PCB Material’s mechanical properties are optimized to withstand the stresses of thermal cycling while maintaining structural integrity:

Tensile Strength: ≥450 MPa along the fiber direction, 10–15% higher than standard FR4, due to the dense fiber network and filler reinforcement. This resistance to pulling forces is critical for PCBs mounted in vibrating environments, such as automotive engine bays, where thermal expansion and vibration act in tandem.

Flexural Strength: ≥550 MPa at room temperature and ≥350 MPa at 150°C, outperforming standard FR4. This rigidity prevents board warpage during reflow soldering, a common issue in multi-layer PCBs where uneven expansion can cause bowing.

Peel Strength: ≥1.1 N/mm for 1 oz copper, ensuring strong adhesion between copper traces and the laminate. This is particularly important in Low CTE FR4, as reduced expansion can increase localized stress at the copper-resin interface—strong peel strength mitigates this risk.

Impact Resistance: Charpy impact strength ≥16 kJ/m², slightly lower than standard FR4 due to the brittle nature of inorganic fillers. However, this is still sufficient for most applications, and specialized formulations with rubber modifiers are available for impact-sensitive use cases (e.g., portable industrial sensors).

Thermal properties define Low CTE FR4’s suitability for high-temperature environments, with datasheets emphasizing parameters that directly impact reliability:

Glass Transition Temperature (Tg): Typically 150–170°C, higher than standard FR4 (130–140°C), due to the high-modulus resin system. This ensures the laminate remains rigid at elevated temperatures, maintaining its low CTE behavior in operational ranges up to 125°C.

Decomposition Temperature (Td): ≥320°C, ensuring compatibility with lead-free soldering processes (peak temperatures ~260°C) without resin degradation or outgassing, which can contaminate solder joints.

Thermal Conductivity: 0.3–0.4 W/m·K, slightly higher than standard FR4 (0.2–0.3 W/m·K) due to thermally conductive fillers like aluminum oxide. This modest improvement helps dissipate localized heat from components like voltage regulators, reducing hotspots.

Thermal Cycling Resistance: Low CTE FR4 excels in thermal cycling tests (e.g., -55°C to +125°C for 1,000 cycles), with minimal dimensional change (<0.1%) and no delamination. This contrasts with standard FR4, which may show 0.2–0.3% expansion and early signs of via cracking after 500 cycles.

The unique composition of Low CTE FR4 PCB Material requires adjusted manufacturing processes to ensure quality and performance:

Lamination: Higher press pressures (300–450 psi) and longer cure times (120–150 minutes) are needed to ensure proper resin flow around fillers and fibers. The datasheet often specifies a slow ramp-up rate (2–3°C/min) to prevent void formation, which can act as stress concentrators.

Drilling: The abrasive nature of inorganic fillers demands carbide drill bits with diamond coatings to reduce wear. Drill speeds are slightly lower (15,000–50,000 RPM) than standard FR4, with slower feed rates (0.08–0.2 mm/rev) to minimize burring and resin smearing in vias.

Plating: Desmearing processes must be more aggressive (e.g., longer permanganate exposure) to remove resin from drilled holes, as fillers can shield resin from chemical attack. This ensures reliable copper plating and via conductivity.

Solder Mask Application: The laminate’s harder surface may require increased abrasion during surface preparation to ensure solder mask adhesion. UV-cured masks are preferred, as their faster curing reduces thermal exposure.

Low CTE FR4 PCB Material adheres to global standards to ensure reliability across industries:

IPC-4101: Classified under Type 2 (high-performance) with additional requirements for CTE (≤12 ppm/°C in-plane, ≤60 ppm/°C z-axis). IPC-TM-650 2.4.41 specifies test methods for measuring CTE, with Low CTE FR4 consistently meeting or exceeding these criteria.

UL 94: Rated V-0 for flame retardancy, with fillers like alumina enhancing fire resistance by acting as heat sinks during combustion.

Automotive Electronics Council (AEC-Q200): Many Low CTE FR4 variants comply with AEC-Q200, a standard for passive components in automotive applications. This includes testing for thermal shock, humidity, and vibration—critical for underhood PCBs.

RoHS and REACH: Formulations are free from restricted substances, with bromine-free flame retardants available to meet strict EU regulations.

Rigorous testing ensures Low CTE FR4 meets its performance claims, with datasheets detailing the following evaluations:

Thermal Mechanical Analysis (TMA): Measures CTE across temperatures (-55°C to +200°C) to verify in-plane and z-axis values, ensuring consistency across production batches.

Via Reliability Testing: Subjects PCBs to 1,000 thermal cycles (-55°C to +125°C) and inspects vias for cracks using X-ray or cross-sectional analysis. Low CTE FR4 typically shows <5% via failure rates, compared to 20–30% for standard FR4.

Solder Joint Fatigue Testing: Evaluates solder joint integrity under cyclic thermal stress, with Low CTE FR4 demonstrating 2–3x longer fatigue life than standard FR4 in automotive-grade tests.

Moisture Sensitivity Level (MSL) Testing: Confirms performance after exposure to humidity (85°C/85% RH) followed by reflow soldering, ensuring no delamination or "popcorning" in moisture-sensitive components.

Low CTE FR4 PCB Material is indispensable in applications where thermal stability is non-negotiable:

Automotive Electronics: Underhood components like engine control units (ECUs), transmission controllers, and sensor modules rely on Low CTE FR4 to withstand -40°C to +150°C temperature swings, preventing via cracking and solder joint failure.

Aerospace and Defense: Avionics systems (e.g., navigation, radar) and military hardware use Low CTE FR4 to maintain precision in extreme environments, from high-altitude cold to desert heat.

Industrial Automation: Motor drives, PLCs, and robotics controllers in factory settings—where ambient temperatures can exceed 100°C—benefit from reduced expansion, ensuring alignment in multi-layer PCBs with tight component spacing.

High-Density Interconnect (HDI) PCBs: Fine-pitch designs (≤0.1 mm vias) in smartphones, medical devices, and 5G transceivers require Low CTE FR4 to prevent layer misalignment, which can short adjacent traces.

Power Electronics: Inverters, converters, and battery management systems (BMS) for electric vehicles (EVs) use Low CTE FR4 to handle thermal cycling from high-current operation, extending service life.

While highly effective, Low CTE FR4 PCB Material has limitations that guide material selection:

Cost: 30–50% more expensive than standard FR4 due to specialized fillers and manufacturing processes, making it impractical for low-cost consumer electronics.

Processability: The abrasive fillers increase tool wear, raising manufacturing costs. This is offset in high-reliability applications but prohibitive for low-margin products.

Thermal Conductivity: Still lower than metal-core PCBs (1–2 W/m·K) or ceramic substrates (10–300 W/m·K), limiting use in ultra-high-power applications (e.g., 200W+ LEDs).

Alternatives include ceramic-filled PCBs (higher thermal conductivity but more brittle) and metal-core laminates (superior heat dissipation but higher weight), though Low CTE FR4 remains the balance of cost, performance, and processability for most thermal-critical designs.

Ongoing advancements continue to expand Low CTE FR4’s capabilities:

Nano-Filler Integration: Carbon nanotubes and graphene additives further reduce CTE (in-plane ≤8 ppm/°C) while improving thermal conductivity (0.5–0.6 W/m·K), targeting next-gen 6G and aerospace applications.

Sustainable Formulations: Bio-based epoxy resins, derived from plant oils, are being combined with low-CTE fillers to reduce environmental impact without sacrificing performance, aligning with EU circular economy goals.

Hybrid Laminates: Low CTE FR4 layers bonded with thin aluminum sheets (for enhanced heat dissipation) create "thermo-stable" PCBs for EV power modules, combining dimensional stability with thermal management.

Low CTE FR4 PCB Material represents a critical advancement in PCB technology, addressing the longstanding challenge of thermal expansion mismatch in high-reliability electronics. By minimizing dimensional changes across temperature ranges, it reduces stress on vias, solder joints, and layers—extending PCB life and preventing costly failures. From automotive underhood systems to aerospace avionics, its unique combination of thermal stability, electrical performance, and processability makes it indispensable in temperature-critical applications. As electronics continue to push the boundaries of power and miniaturization, Low CTE FR4 will remain a cornerstone of reliable design, with ongoing innovations ensuring it evolves to meet future demands.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB