-

- PCB TYPE

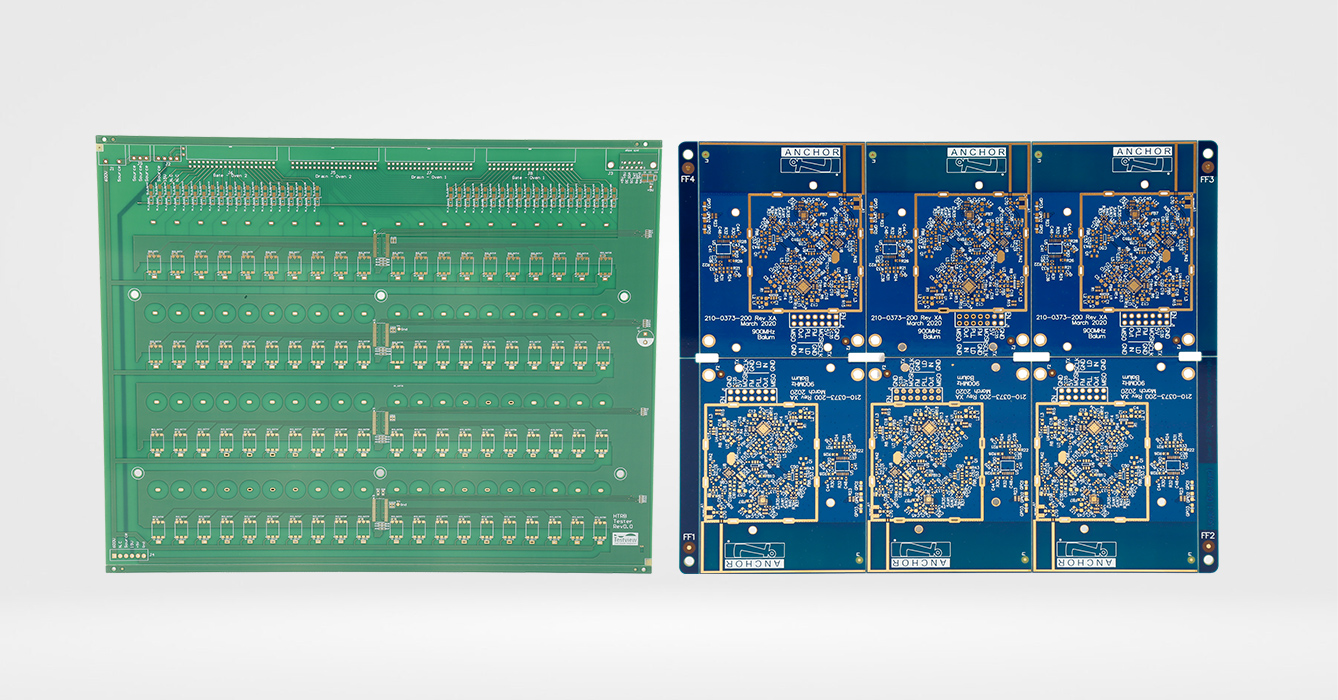

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 04. 2025, 11:54:29

In the world of electronics, FR4 PCB stands as a foundational element, underpinning the functionality of devices ranging from everyday consumer gadgets to complex industrial systems. As a glass-reinforced epoxy laminate-based printed circuit board, FR4 PCB has earned its reputation through a unique combination of durability, electrical insulation, and cost-effectiveness. This article delves into the intricacies of FR4 PCB, exploring its manufacturing processes, performance characteristics, application versatility, and evolving role in advancing electronic technologies. By examining its structural makeup and functional capabilities, we uncover why FR4 remains the material of choice for engineers and manufacturers across diverse industries.

FR4 PCB derives its name from its core material: FR4, a thermoset composite that forms the substrate of the board. The "FR" designation signifies "flame-retardant," a critical safety feature that prevents the material from sustaining combustion, making it compliant with global safety standards. Unlike other PCB substrates, FR4’s composition—epoxy resin reinforced with woven glass fibers—endows it with a balanced set of properties that cater to both structural and electrical requirements.

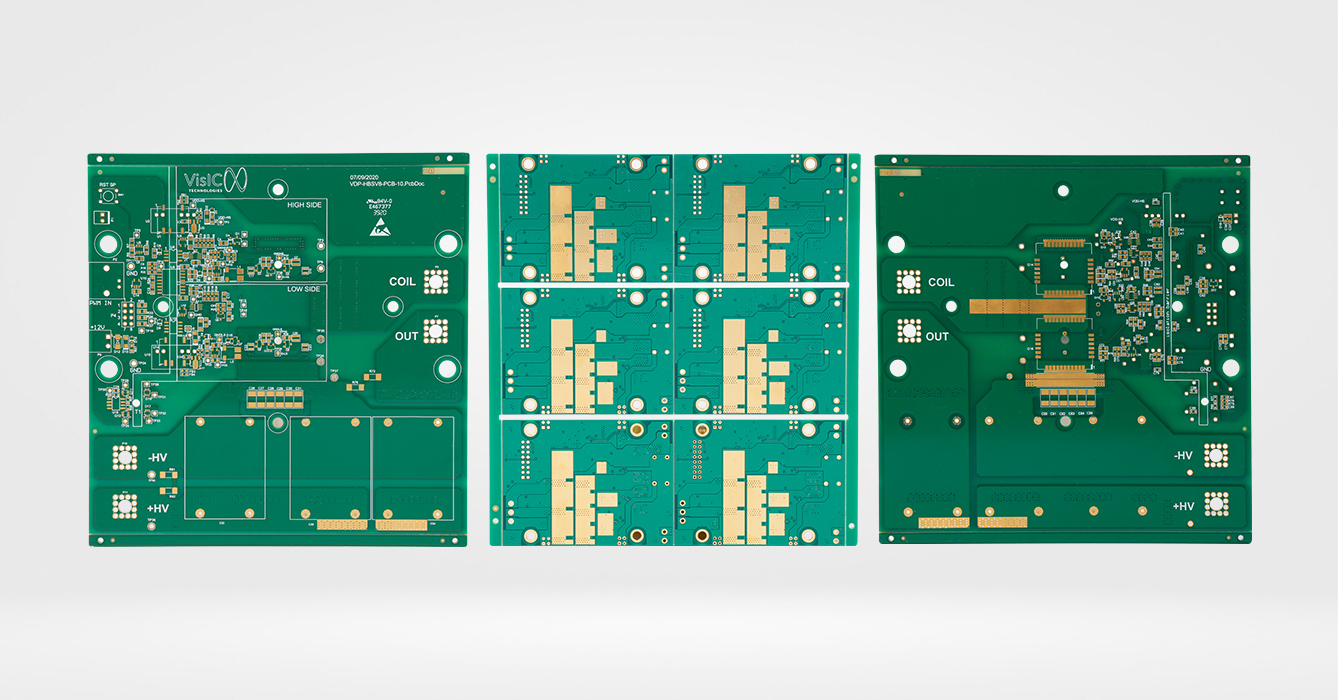

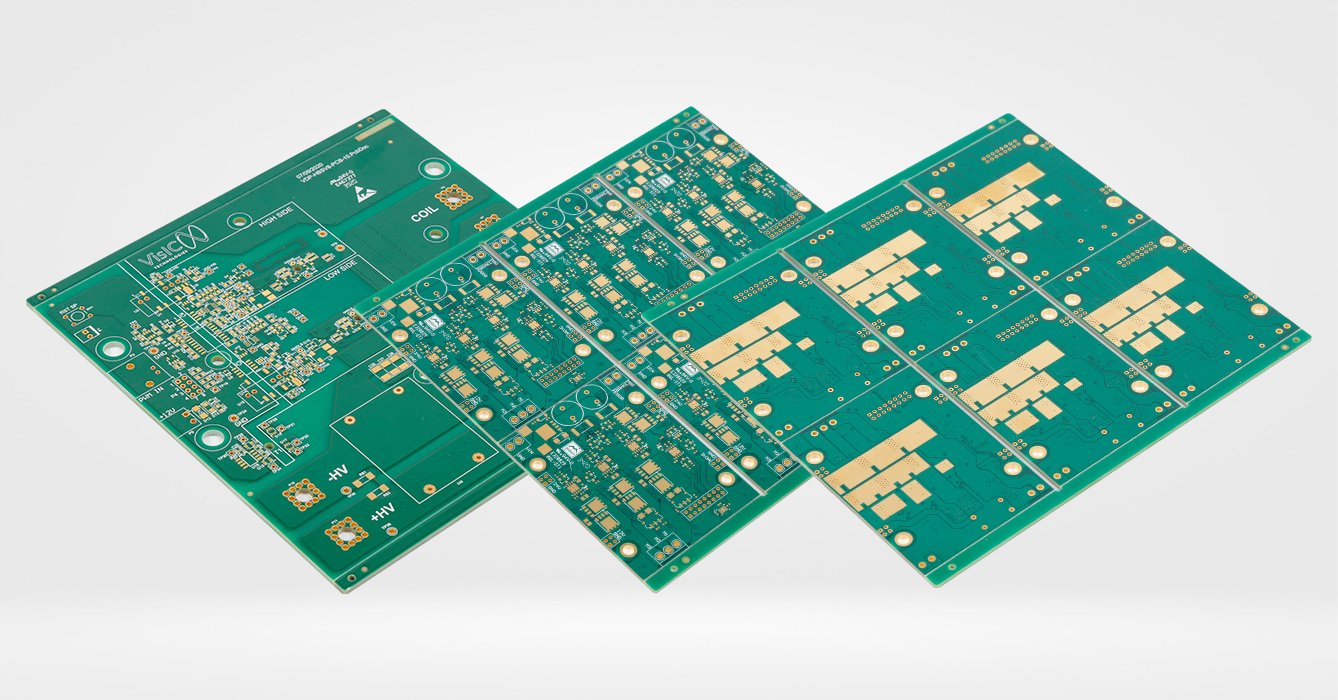

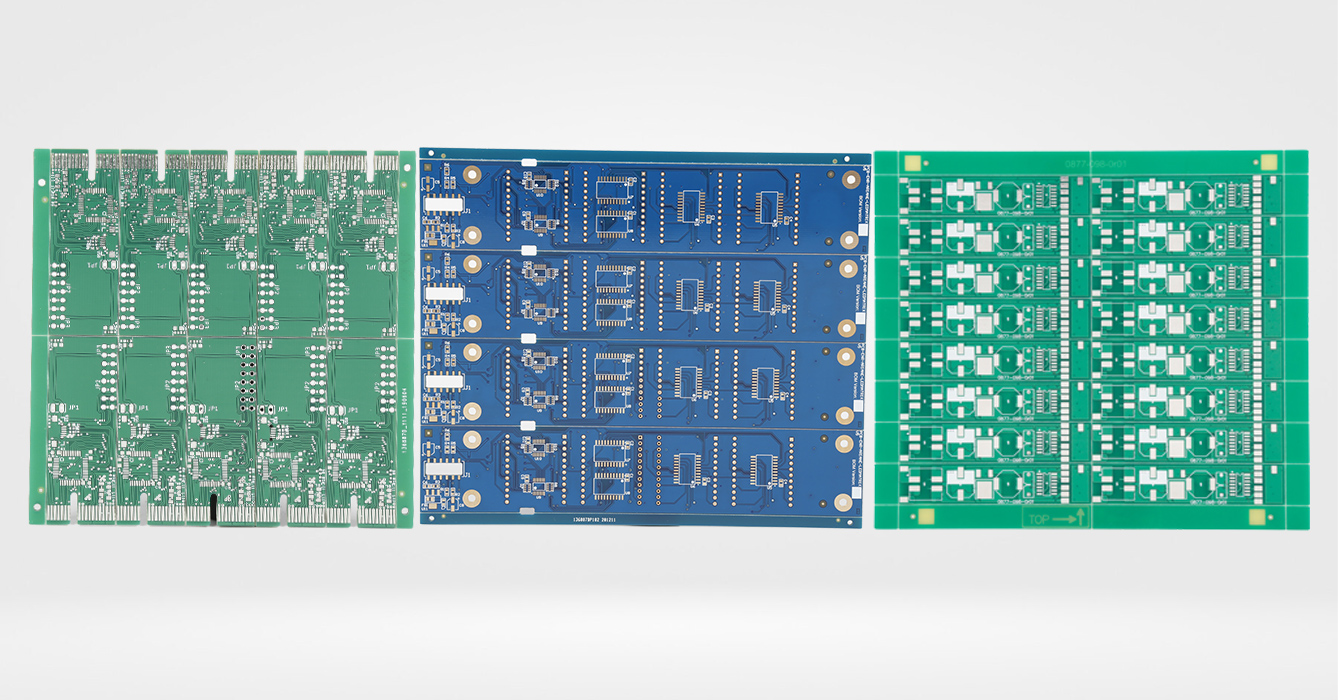

At its most basic level, an FR4 PCB consists of multiple layers: the FR4 substrate, conductive copper traces bonded to its surface, and additional layers such as solder masks and surface finishes. The number of layers can vary widely, from simple single-layer boards used in basic electronics to complex multi-layer boards with 20 or more layers, employed in high-performance computing and telecommunications equipment. This flexibility in layer configuration is one of FR4 PCB’s key strengths, allowing it to adapt to the varying complexity of electronic designs.

The choice of FR4 as a substrate is no accident. Its epoxy resin matrix provides excellent electrical insulation, while the glass fiber reinforcement ensures mechanical rigidity, preventing warping or deformation during manufacturing and operation. This combination makes FR4 PCB suitable for environments where both electrical stability and structural integrity are paramount, from indoor consumer devices to outdoor industrial sensors.

The production of FR4 PCB involves a series of precision-driven steps, each critical to ensuring the final product meets performance specifications:

Substrate Preparation: The process begins with cutting FR4 laminate sheets to the required dimensions. These sheets are pre-treated to remove contaminants and ensure proper adhesion of copper layers. The thickness of the laminate is selected based on the application—thinner sheets for lightweight devices like wearables, and thicker sheets for rugged industrial PCBs.

Copper Cladding: The cleaned FR4 substrate is clad with copper foil, either on one side (single-sided PCBs) or both sides (double-sided PCBs). The copper is bonded to the substrate using heat and pressure, creating a strong mechanical and electrical connection. For multi-layer PCBs, additional layers of FR4 and copper are stacked and bonded together in a lamination press, with precise alignment to ensure layer-to-layer connectivity.

Circuit Pattern Transfer: A photolithographic process is used to transfer the circuit design onto the copper-clad substrate. The copper surface is coated with a photosensitive resist, which is then exposed to UV light through a mask bearing the circuit pattern. The unexposed resist is removed, leaving the desired pattern, which is then etched into the copper using chemical solutions. This step defines the conductive traces that carry electrical signals across the board.

Drilling and Plating: Holes are drilled through the PCB to create vias (electrical connections between layers) and component mounting points. These holes are plated with copper to ensure conductivity between layers, a process that involves electroless copper deposition followed by electrolytic plating to build up the required thickness.

Solder Mask Application: A protective solder mask is applied to the PCB, covering all areas except the component pads and connector points. This mask prevents unintended solder bridges during assembly and protects the copper traces from corrosion and physical damage. The most common color for solder masks is green, though other colors like red, blue, or black are used for specific applications, such as high-contrast visibility in medical devices.

Surface Finishing: To ensure solderability and protect exposed copper, a surface finish is applied. Common finishes include hot-air solder leveling (HASL), electroless nickel immersion gold (ENIG), and organic solderability preservatives (OSP). Each finish offers distinct advantages: ENIG provides excellent corrosion resistance for high-reliability applications, while OSP is cost-effective for consumer electronics.

The mechanical performance of FR4 PCB is a key factor in its widespread adoption, as it must withstand the stresses of manufacturing, assembly, and operation:

Rigidity and Flexural Strength: FR4 PCB exhibits high flexural strength, allowing it to resist bending forces without breaking. This rigidity is crucial for maintaining the alignment of components and traces, especially in multi-layer boards where misalignment can cause short circuits. The glass fiber reinforcement ensures that the PCB retains its shape even under temperature fluctuations, a property known as dimensional stability.

Impact Resistance: While FR4 is inherently rigid, it possesses sufficient toughness to withstand accidental impacts, such as those encountered during handling or transportation. This makes FR4 PCB suitable for portable electronics like smartphones and tablets, which are prone to drops and bumps.

Peel Strength: The bond between the copper foil and FR4 substrate, known as peel strength, is critical for preventing trace lifting. FR4 PCB is designed to maintain strong peel strength even after exposure to high temperatures during soldering, ensuring long-term reliability. This is achieved through careful selection of adhesives and bonding processes during manufacturing.

Weight Efficiency: Compared to other rigid substrates like ceramic, FR4 is relatively lightweight, making it ideal for applications where weight is a concern, such as aerospace and automotive electronics. Its density of 1.8–2.0 g/cm³ strikes a balance between structural strength and weight, contributing to fuel efficiency in vehicles and reduced payload in aircraft.

As a carrier of electrical signals, FR4 PCB must deliver consistent and reliable electrical performance:

Insulation Resistance: The epoxy resin in FR4 provides high insulation resistance, preventing leakage current between adjacent traces. This is essential for maintaining signal integrity, especially in high-density PCBs where traces are closely spaced. The insulation resistance remains stable even in humid environments, though proper sealing is recommended for extreme conditions.

Dielectric Properties: FR4’s dielectric constant (Dk) and dissipation factor (Df) determine its suitability for high-frequency applications. While standard FR4 has a Dk of around 4.5 at 1 MHz, which is sufficient for most consumer electronics, low-Dk variants are available for high-speed signals in telecommunications and 5G equipment. These variants minimize signal loss and delay, ensuring efficient data transmission.

Signal Integrity: The controlled impedance of FR4 PCB traces is critical for high-frequency designs. Manufacturers can adjust the trace width, substrate thickness, and dielectric constant to achieve the desired impedance (typically 50Ω for RF applications), ensuring signals propagate without reflection or distortion.

High-Voltage Performance: FR4 PCB can withstand moderate voltages, making it suitable for power supply circuits and industrial control systems. Its dielectric strength—typically above 20 kV/mm—prevents electrical breakdown, even in applications with voltage spikes.

Managing heat is a key challenge in electronic design, and FR4 PCB’s thermal properties play a vital role in ensuring device reliability:

Heat Dissipation: While FR4 is not as thermally conductive as metal-core PCBs, it can dissipate moderate amounts of heat through its copper traces and vias. For high-power components, thermal vias—small holes filled with copper—are used to transfer heat from the component to the opposite side of the PCB, where it can be dissipated into the environment or via a heat sink.

Glass Transition Temperature (Tg): The Tg of FR4, around 130–140°C for standard grades, is the temperature at which the epoxy resin begins to soften. For applications exposed to high temperatures, such as automotive underhood systems, high-Tg FR4 (Tg ≥170°C) is used to maintain structural and electrical stability. This ensures the PCB performs reliably even in environments with sustained high temperatures.

Thermal Cycling Resistance: FR4 PCB must withstand repeated temperature changes without delamination or cracking. The material’s coefficient of thermal expansion (CTE) is carefully matched to that of copper to minimize stress during thermal cycling, a critical factor in automotive and aerospace applications where temperature fluctuations are common.

FR4 PCB’s versatility makes it suitable for a wide range of applications across industries:

Consumer Electronics: From smartphones and laptops to televisions and gaming consoles, FR4 PCB is the backbone of most consumer devices. Its cost-effectiveness and reliability make it ideal for mass-produced electronics, where performance and affordability are equally important.

Industrial Automation: In industrial control systems, motor drives, and sensors, FR4 PCB provides the robustness needed to withstand harsh factory environments. Its resistance to vibration, temperature changes, and chemical exposure ensures consistent operation in manufacturing facilities.

Telecommunications: Routers, switches, and base stations rely on FR4 PCB for high-frequency signal transmission. Low-Dk variants are used in 5G equipment to minimize signal loss, enabling faster data rates and broader coverage.

Automotive Electronics: Modern vehicles contain dozens of PCBs, from infotainment systems to engine control units (ECUs). FR4 PCB, especially high-Tg and low-CTE variants, is used in these applications to withstand the extreme temperatures and vibrations of automotive environments.

Medical Devices: In medical equipment like monitors, imaging devices, and diagnostic tools, FR4 PCB offers the reliability and precision required for life-critical applications. Its compatibility with sterilization processes and resistance to chemical exposure make it a safe choice for healthcare settings.

As sustainability becomes increasingly important, FR4 PCB manufacturers are adapting to meet environmental standards:

RoHS Compliance: Most FR4 PCBs are RoHS-compliant, meaning they are free from hazardous substances like lead, cadmium, and hexavalent chromium. This ensures they can be sold in global markets without violating environmental regulations.

Bromine-Free Options: Traditional FR4 uses brominated flame retardants, but bromine-free alternatives are now available, using phosphorus-based additives instead. These formulations meet the same flame-retardant standards while reducing environmental impact.

Recyclability: While recycling PCBs is challenging due to their complex composition, efforts are underway to recover copper and other valuable materials from discarded FR4 PCBs. Some manufacturers also offer take-back programs to promote responsible disposal.

Energy Efficiency in Manufacturing: PCB producers are adopting energy-efficient processes, such as low-temperature curing and water recycling, to reduce the carbon footprint of FR4 PCB production.

Despite its widespread use, FR4 PCB has limitations that engineers must consider:

High-Temperature Limitations: Standard FR4 begins to degrade above its Tg, making it unsuitable for applications with sustained temperatures above 125°C. While high-Tg variants extend this range, they are more expensive and may not meet the needs of extreme environments like aerospace engines.

Thermal Conductivity: For high-power devices generating significant heat, FR4’s low thermal conductivity can lead to hotspots, reducing component lifespan. In such cases, metal-core PCBs or ceramic substrates are better alternatives.

High-Frequency Performance: While low-Dk FR4 improves high-frequency performance, it still lags behind specialized materials like PTFE in millimeter-wave applications (30–300 GHz). These materials offer lower Dk and Df but are more costly and harder to process.

Flexibility: FR4 is inherently rigid, so flexible PCBs for applications like wearable devices require alternative substrates such as polyimide.

To address its limitations, ongoing research and development are pushing the boundaries of FR4 PCB:

Thermally Enhanced FR4: By incorporating ceramic fillers like aluminum oxide, manufacturers are improving FR4’s thermal conductivity, making it suitable for mid-power applications that previously required metal-core PCBs. These enhanced variants offer a cost-effective balance between thermal performance and processability.

High-Frequency Optimizations: New resin formulations and glass fiber weaves are reducing Dk and Df in FR4, extending its usability in 5G and radar systems. These advancements allow FR4 to compete with more expensive materials in certain high-frequency applications.

Additive Manufacturing: Experimental techniques are exploring 3D printing of FR4 PCBs, enabling complex geometries and rapid prototyping. This could revolutionize PCB design by allowing custom shapes and integrated components that are difficult to achieve with traditional manufacturing.

Sustainable Materials: Bio-based epoxy resins, derived from plant oils, are being tested as alternatives to petroleum-based resins in FR4. These materials reduce reliance on fossil fuels and improve recyclability, aligning with global sustainability goals.

The future of FR4 PCB is shaped by the evolving needs of the electronics industry:

Miniaturization: As electronic devices become smaller and more complex, FR4 PCBs are being designed with finer trace widths and smaller vias, enabling higher component density. This trend is driven by the demand for compact devices like IoT sensors and wearable technology.

Integration with Advanced Components: FR4 PCBs are increasingly being combined with embedded components, such as resistors and capacitors, reducing the size and weight of electronic assemblies. This integration improves performance by minimizing signal paths and reducing parasitic effects.

Smart Manufacturing: Automation and artificial intelligence are optimizing FR4 PCB production, improving precision, reducing waste, and enabling faster turnaround times. Machine learning algorithms are used to predict and prevent defects, ensuring higher quality and reliability.

Circular Economy Practices: Manufacturers are developing closed-loop systems for FR4 PCB production, reusing waste materials and recycling end-of-life boards to reduce environmental impact. This includes techniques for separating copper from FR4 substrates and reprocessing the resin for new applications.

FR4 PCB has firmly established itself as the workhorse of the electronics industry, offering a winning combination of performance, versatility, and cost-effectiveness. Its ability to adapt to diverse applications—from consumer gadgets to industrial machinery—speaks to its robust design and ongoing innovation. While it faces challenges in extreme environments and high-performance applications, advancements in materials and manufacturing are expanding its capabilities. As the electronics industry continues to evolve, FR4 PCB will remain a critical component, driving progress in technology while adapting to the demands of sustainability and miniaturization. Its role in shaping the future of electronics is as strong as ever, ensuring that FR4 PCB will remain a cornerstone of electronic design for years to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB