-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 13. 2025, 14:42:01

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. They connect various components, allowing the device to function as intended. Understanding the PCB manufacturing process flow is crucial for anyone interested in electronics, from hobbyists to professional engineers. This article breaks down the steps involved in creating a PCB, providing insights into the intricate process that brings your electronic devices to life.

Before diving into the manufacturing process, it's essential to understand the design phase. The PCB design process involves creating a blueprint for the circuit board, which serves as a guide for manufacturing. This stage includes schematic capture, layout design, and design rule checks.

The schematic capture is the first step in the PCB design process. Engineers use specialized software to create a schematic diagram, representing the electrical connections between components. This blueprint ensures that all necessary components are included and correctly connected.

Once the schematic is complete, the layout design begins. This involves placing components on the board and routing the electrical connections between them. The layout must consider factors such as component placement, signal integrity, and thermal management.

Design rule checks (DRC) are essential to ensure the design meets manufacturing requirements. These checks verify that the layout adheres to specific guidelines, such as trace width, spacing, and via sizes. This step helps prevent errors during manufacturing.

With the design finalized, the manufacturing process can begin. The PCB manufacturing process flow consists of several steps, each crucial for producing a high-quality circuit board.

The first step in manufacturing is creating the PCB layer stackup. This process defines the number of layers in the board and the arrangement of copper layers and insulating materials. The stackup is crucial for determining the board's electrical properties and mechanical strength.

Once the stackup is complete, the circuit pattern is printed onto the board. This step involves applying a photoresist layer to the board and exposing it to ultraviolet (UV) light through a mask. The UV light hardens the photoresist in areas where the circuit pattern will be etched, creating a protective layer.

After printing the circuit pattern, the board undergoes an etching process. This involves immersing the board in a chemical solution that removes the unwanted copper, leaving only the desired circuit pattern. The etching process must be precise to ensure the circuit's integrity.

Drilling holes is a critical step in the PCB manufacturing process flow. These holes serve as vias, connecting different layers of the board and allowing components to be mounted. Advanced drilling machines ensure precise hole placement and size, which is crucial for the board's functionality.

After drilling, the board undergoes plating and copper deposition. This process involves depositing a thin layer of copper onto the drilled holes and exposed areas of the board. The copper layer ensures electrical connectivity between different layers and components.

The solder mask is applied to protect the circuit and prevent solder bridges between closely spaced components. This green (or sometimes other colored) layer is essential for ensuring the board's reliability and longevity. The application involves covering the entire board with a liquid solder mask and then exposing it to UV light to harden the desired areas.

The surface finish is applied to protect the exposed copper areas and improve solderability. Common finishes include Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), and others. The choice of finish depends on factors like cost, performance, and environmental considerations.

Silk screening adds labels and markings to the PCB, providing information about components, test points, and other critical details. This step is essential for assembly and troubleshooting, ensuring that technicians can quickly identify components and connections.

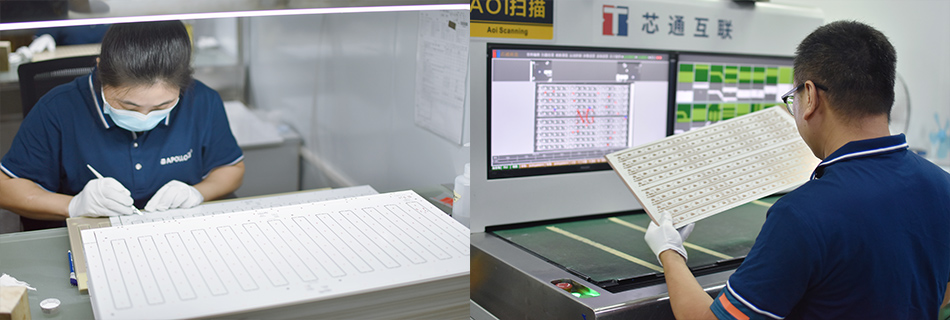

Once the board is complete, it undergoes electrical testing to ensure all connections are correct and the board functions as intended. This process involves using automated testing equipment to check for short circuits, open circuits, and other defects.

The final step in the PCB manufacturing process flow is inspection and quality control. This involves visually inspecting the board and conducting additional tests to ensure it meets all specifications. Quality control is crucial for preventing defects and ensuring customer satisfaction.

Understanding the PCB manufacturing process flow is essential for anyone involved in electronics. From design to final inspection, each step plays a critical role in producing a functional, reliable circuit board. By understanding this process, you can appreciate the complexity and precision involved in creating the electronic devices we rely on every day.

With this knowledge, you can better design, manufacture, and troubleshoot PCBs, whether you're a hobbyist, engineer, or industry professional. Embrace the intricacies of PCB manufacturing, and you'll be well-equipped to tackle the challenges of modern electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB