-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 13. 2025, 14:44:34

In the world of electronics, the printed circuit board (PCB) is the unsung hero. It serves as the foundation for most electronic devices, connecting all the components and ensuring they work together seamlessly. When it comes to custom PCBs, finding the right manufacturer is crucial for your electronic circuit design to succeed. In this guide, we'll walk you through the essential steps to choosing the best custom PCB manufacturing services for your needs.

Before diving into how to select a PCB manufacturer, it's important to understand the PCB manufacturing process. This knowledge will help you communicate effectively with potential manufacturers and ensure that they can meet your specific requirements.

The first step in the PCB manufacturing process involves creating a detailed design and layout of the circuit board. This design is typically created using specialized software that allows you to visualize the placement of components and the routing of electrical connections.

The choice of materials used in PCB manufacturing can significantly impact the performance and durability of the final product. Common materials include FR-4 (a type of fiberglass), metal, and various laminates. Your choice of material will depend on factors such as the intended application, environmental conditions, and cost.

Prototyping is a critical step in the PCB manufacturing process. It allows you to test the design and make any necessary adjustments before moving on to full-scale production. A reliable PCB manufacturer should offer prototyping services to ensure that the final product meets your specifications.

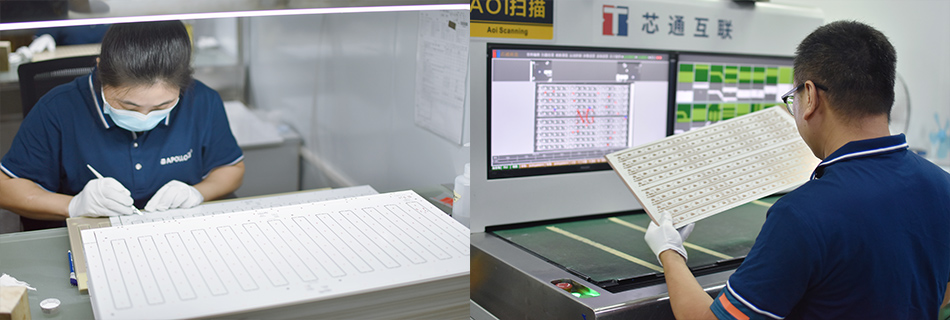

Once the prototype is approved, the manufacturer will proceed with assembling the PCBs. This involves soldering components onto the board and performing rigorous testing to ensure functionality and reliability. Quality control is essential during this phase to catch any defects before the products are shipped.

Selecting the right PCB manufacturer is not a decision to be taken lightly. Here are some key factors to consider when evaluating potential partners:

One of the most important factors to consider is the manufacturer's experience and expertise in the field of custom PCB manufacturing services. Look for a manufacturer with a proven track record of delivering high-quality PCBs for a variety of applications. This experience will ensure that they have the knowledge and skills to handle any challenges that may arise during the manufacturing process.

Quality is paramount when it comes to PCBs, as even minor defects can lead to significant performance issues. Ensure that the manufacturer adheres to recognized quality standards, such as ISO 9001 or IPC-A-610. These certifications indicate that the manufacturer follows strict quality control procedures to deliver reliable products.

Every electronic circuit design is unique, and your PCB manufacturer should offer customization capabilities to meet your specific needs. This includes the ability to work with different materials, layer counts, and board sizes. A manufacturer with a wide range of customization options will be better equipped to handle complex and specialized projects.

Time is often a critical factor in product development, so it's important to choose a manufacturer that can deliver your PCBs within the required timeframe. Inquire about their lead times for prototyping and full-scale production, and ensure that they can meet your deadlines without compromising on quality.

While cost should not be the sole determining factor, it's important to find a manufacturer that offers competitive pricing without sacrificing quality. Request quotes from multiple manufacturers and compare their pricing structures to find the best value for your budget.

To further narrow down your options, consider asking potential PCB manufacturers the following questions:

What types of PCBs do you specialize in?

Can you provide references or case studies from previous clients?

What is your process for handling design changes or revisions?

How do you ensure quality control throughout the manufacturing process?

What is your standard lead time for prototyping and production?

Do you offer any additional services, such as assembly or testing?

Choosing the right custom PCB manufacturer is a critical step in bringing your electronic circuit design to life. By understanding the PCB manufacturing process and considering key factors such as experience, quality standards, customization capabilities, turnaround time, and cost, you can make an informed decision that aligns with your project goals.

Remember to ask potential manufacturers the right questions and thoroughly evaluate their capabilities before making your final choice. With the right partner, you can ensure that your custom PCBs are manufactured to the highest standards of quality and performance.

By following these guidelines, you'll be well on your way to selecting the perfect PCB manufacturer for your needs. Whether you're developing a new product or improving an existing one, the right manufacturer can make all the difference in the success of your project.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB