-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 09. 2025, 11:36:27

In the fast - paced world of electronics, Printed Circuit Boards (PCBs) are the unsung heroes that enable the functionality of countless devices. Among the diverse range of PCBs, Metal Core PCBs stand out for their unique combination of properties, making them essential for applications where thermal management, mechanical strength, and electrical performance are crucial. This article delves deep into the world of Metal Core PCBs, covering their structure, benefits, applications, design considerations, manufacturing processes, and future trends.

What is a Metal Core PCB?

A Metal Core PCB, as the name implies, incorporates a metal layer within its structure. This metal layer, typically made of aluminum or copper, serves as a core that provides several key advantages. Unlike traditional PCBs with organic substrates, Metal Core PCBs are designed to handle high - power applications more effectively. They consist of a metal base layer, an insulating dielectric layer, and one or more conductive copper layers on top. The metal core not only acts as a heat sink but also provides mechanical support to the overall PCB structure.

Structure of Metal Core PCBs

Metal Core Layer:

Aluminum vs. Copper: Aluminum is a popular choice for the metal core due to its relatively low cost, lightweight nature, and good thermal conductivity. It has a thermal conductivity of around 200 - 237 W/(m·K), which allows it to dissipate heat efficiently. Copper, on the other hand, offers even higher thermal conductivity, with values up to 401 W/(m·K). Although more expensive, copper is preferred in applications where superior heat dissipation is required, such as high - power electronics.

Function as a Heat Sink: The metal core acts as a large heat sink, absorbing heat generated by components on the PCB. Heat is transferred from the components through the copper traces, across the insulating layer, and into the metal core. From there, it can be dissipated into the surrounding environment, either through natural convection or with the help of additional cooling mechanisms like heat sinks or fans.

Mechanical Support: In addition to its thermal role, the metal core provides significant mechanical strength to the PCB. It makes the board more rigid and less prone to bending, cracking, or warping, especially in applications where the PCB may be subject to physical stress, vibrations, or shocks.

Insulating Dielectric Layer:

Thermal and Electrical Properties: The insulating dielectric layer, positioned between the metal core and the copper layers, plays a crucial role. It must have good electrical insulation properties to prevent short - circuits between the conductive layers and the metal core. At the same time, it should have a relatively high thermal conductivity to facilitate the transfer of heat from the copper layers to the metal core. Materials such as thermally conductive epoxy resins or polyimide are commonly used for this layer.

Thickness Considerations: The thickness of the insulating layer is a critical design parameter. A thinner layer allows for better heat transfer but may compromise electrical insulation. Designers need to strike a balance based on the specific requirements of the application, considering factors such as operating voltage, temperature, and the desired level of thermal performance.

Conductive Copper Layers:

Component Mounting and Signal Routing: The copper layers on a Metal Core PCB are where electronic components are mounted and electrical signals are routed. These layers are etched to create traces that connect components, forming the electrical circuit. The design of the copper traces must account for factors such as current - carrying capacity, signal integrity, and impedance matching, similar to traditional PCBs. However, in Metal Core PCBs, the presence of the metal core can also influence the electrical performance, and designers need to take this into account.

Multilayer Options: Metal Core PCBs can be designed with multiple copper layers, similar to traditional multilayer PCBs. This allows for more complex circuit designs, with increased routing options and the ability to accommodate a larger number of components. Multilayer Metal Core PCBs are often used in applications where space is limited but high - density circuit integration is required.

Advantages of Metal Core PCBs

Enhanced Thermal Management:

Reduced Component Temperatures: The primary advantage of Metal Core PCBs is their ability to manage heat effectively. By dissipating heat away from components, they help to keep component temperatures within acceptable limits. This is crucial for the reliability and lifespan of components, as high temperatures can lead to accelerated wear, reduced performance, and premature failure. In applications such as high - power LED lighting, where LEDs generate a significant amount of heat, Metal Core PCBs ensure that the LEDs operate at optimal temperatures, resulting in longer - lasting and more efficient lighting systems.

Improved System Reliability: Effective thermal management also contributes to the overall reliability of the electronic system. By reducing thermal stress on components, Metal Core PCBs help to prevent issues such as solder joint failures, which can occur due to thermal cycling. This is particularly important in applications where the PCB is exposed to varying temperatures, such as in automotive electronics or industrial control systems.

Mechanical Robustness:

Resistance to Physical Stress: The metal core provides enhanced mechanical strength to the PCB. It can withstand greater physical stress, including bending, twisting, and vibration, compared to traditional PCBs with organic substrates. This makes Metal Core PCBs suitable for applications in harsh environments, such as in automotive, aerospace, and industrial settings. For example, in a car engine compartment, where the PCB may be subject to high temperatures, vibrations, and mechanical shocks, a Metal Core PCB can ensure reliable operation.

Larger Board Sizes and Higher Component Densities: The mechanical strength of Metal Core PCBs allows for the design of larger - sized boards without significant risk of warping or deformation. Additionally, they can support higher component densities, as the metal core can better handle the weight of components. This is beneficial in applications where space is at a premium, such as in miniaturized electronic devices or high - density circuit assemblies.

Electrical Performance:

Low - Impedance Paths: The metal core in a Metal Core PCB can be used as a ground plane or a power plane, providing low - impedance paths for electrical current. This helps to reduce voltage drops and power losses in the circuit, improving the overall electrical efficiency of the system. In power electronics applications, such as inverters and power supplies, the ability to provide low - impedance paths is essential for efficient power transfer.

Electromagnetic Interference (EMI) Shielding: The metal core can also act as an electromagnetic shield, reducing the amount of EMI generated by the PCB and protecting other components from external electromagnetic interference. This is important in applications where sensitive electronic components need to be shielded from electromagnetic fields, such as in medical devices or communication equipment.

Applications of Metal Core PCBs

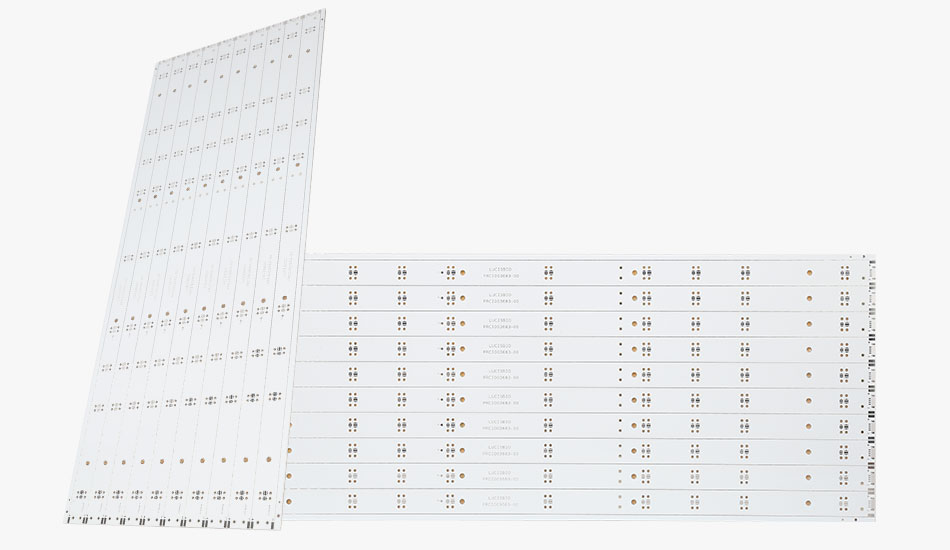

LED Lighting:

High - Power LED Applications: Metal Core PCBs are widely used in high - power LED lighting applications, such as streetlights, floodlights, and industrial lighting. LEDs generate heat during operation, and efficient thermal management is crucial for their performance and lifespan. Metal Core PCBs provide the necessary heat dissipation capabilities, ensuring that the LEDs operate at optimal temperatures. This results in brighter, more efficient, and longer - lasting LED lighting systems.

LED Array Design: In LED arrays, where multiple LEDs are grouped together, Metal Core PCBs are used to provide a common heat sink for all the LEDs. This helps to ensure uniform heat dissipation across the array, preventing hotspots and improving the overall performance of the lighting system.

Automotive Electronics:

Engine Control Units (ECUs): ECUs are critical components in modern vehicles, responsible for controlling various engine functions. They are exposed to high temperatures, vibrations, and electrical interference in the engine compartment. Metal Core PCBs are used in ECUs due to their ability to withstand these harsh conditions while providing reliable electrical performance. The metal core helps to dissipate heat generated by the components, ensuring the proper operation of the ECU.

Automotive Lighting: Metal Core PCBs are also used in automotive lighting, including headlights, taillights, and interior lighting. In automotive headlights, for example, high - power LEDs are used to provide bright illumination. Metal Core PCBs are essential for managing the heat generated by these LEDs, ensuring long - lasting and reliable lighting performance.

Power Electronics:

Inverters and Converters: Inverters and converters are used in a wide range of applications, from renewable energy systems to electric vehicle charging stations. These devices handle high power levels and generate a significant amount of heat. Metal Core PCBs are used in inverters and converters to dissipate heat effectively and provide the necessary electrical performance. The metal core acts as a heat sink, allowing for efficient operation of these power - electronic devices.

Power Supplies: Metal Core PCBs are also commonly used in power supplies, where they help to manage heat and provide stable electrical power. In a computer power supply, for example, the Metal Core PCB ensures that the components, such as power transistors and diodes, operate at safe temperatures, resulting in a reliable and efficient power supply.

Consumer Electronics:

Smartphones and Tablets: In smartphones and tablets, where space is limited and high - performance components are used, Metal Core PCBs can be found. They help to manage the heat generated by the powerful processors, graphics chips, and other components in these devices. By dissipating heat effectively, Metal Core PCBs contribute to the overall performance and reliability of smartphones and tablets, ensuring that they operate smoothly even under heavy usage.

High - End Audio Equipment: High - end audio equipment, such as amplifiers, also benefits from the use of Metal Core PCBs. These PCBs help to reduce electrical interference and provide better thermal management, resulting in improved audio quality. The metal core can act as a shield against electromagnetic interference, ensuring that the audio signals are not distorted.

Industrial Electronics:

Industrial Control Systems: Industrial control systems, such as programmable logic controllers (PLCs) and motor drives, are often exposed to harsh environments, including high temperatures, humidity, and mechanical stress. Metal Core PCBs are used in these systems due to their mechanical robustness and thermal management capabilities. They can withstand the rigors of the industrial environment while providing reliable control and monitoring functions.

Automation Equipment: In automation equipment, such as robotic arms and conveyor systems, Metal Core PCBs are used to control the movement of the machinery. These PCBs can handle the high - power requirements of the motors and other components while dissipating heat effectively, ensuring the smooth operation of the automation equipment.

Design Considerations for Metal Core PCBs

Thermal Design:

Component Placement: When designing a Metal Core PCB, the placement of heat - generating components is crucial. Components should be placed in close proximity to the metal core to ensure efficient heat transfer. Thermal vias, which are small holes filled with a conductive material, can be used to connect the copper layers to the metal core, further enhancing heat dissipation. The layout of components should also consider the airflow within the enclosure, as natural or forced convection can play a role in heat removal.

Thermal Interface Materials: The use of thermal interface materials (TIMs) between the components and the PCB can improve heat transfer. TIMs, such as thermal paste or pads, help to fill the gaps between the components and the PCB, reducing the thermal resistance and enhancing the efficiency of heat transfer. The choice of TIM depends on factors such as the operating temperature, the type of components, and the cost.

Mechanical Design:

Board Thickness and Shape: The thickness of the Metal Core PCB is an important design consideration. A thicker board may provide more mechanical strength but can also increase the weight and cost. The shape of the board should be designed to fit the enclosure and to minimize stress concentrations. Unusual or complex board shapes may require additional reinforcement to ensure mechanical integrity.

Mounting and Fastening: The method of mounting and fastening the PCB to the enclosure is also important. The metal core can be used to provide additional mounting points, and appropriate fasteners, such as screws or clips, should be used to secure the PCB. The design should ensure that the PCB is firmly mounted to prevent vibrations and to protect against physical damage.

Electrical Design:

Trace Width and Spacing: The width and spacing of the copper traces on a Metal Core PCB are determined by the current - carrying capacity and the electrical performance requirements of the circuit. Wider traces are required for higher - current applications to reduce resistance and prevent overheating. Adequate spacing between traces is necessary to prevent electrical short - circuits, especially in high - voltage applications.

Ground and Power Planes: The design of the ground and power planes on a Metal Core PCB is critical for electrical performance. The metal core can be used as a ground plane or a power plane, and the layout of these planes should be optimized to reduce impedance and to improve signal integrity. In some cases, multiple ground and power planes may be used to further enhance the electrical performance.

Manufacturing Processes of Metal Core PCBs

Layer Preparation:

Metal Core Preparation: The metal core, whether aluminum or copper, is first cleaned to remove any contaminants, such as oils, dirt, or oxides. This ensures good adhesion of the insulating layer. The surface of the metal core may also be roughened or treated to improve the bonding process.

Insulating Layer Application: The insulating dielectric layer is then applied to the metal core. This can be done using various methods, such as laminating a pre - fabricated insulating film or applying a liquid resin and curing it. The insulating layer must be applied evenly and with the correct thickness to ensure proper electrical insulation and thermal conductivity.

Copper Layer Preparation: The copper layers are prepared by laminating copper foils onto the insulating layer. The copper foils are typically cleaned and treated to enhance adhesion. Photolithography techniques are then used to pattern the copper layers, creating the desired electrical traces and pads.

Lamination:

Heat and Pressure Application: The prepared layers, including the metal core, insulating layer, and copper layers, are stacked together and subjected to heat and pressure in a laminator. The heat softens the insulating material, allowing it to flow and bond the layers together, while the pressure ensures good adhesion and a uniform laminate structure. The lamination process parameters, such as temperature, pressure, and time, are carefully controlled to ensure the quality of the laminate.

Quality Control: After lamination, the PCB is inspected for any signs of delamination, voids, or other defects. Non - destructive testing methods, such as X - ray inspection, may be used to check the integrity of the internal layers. Any defective PCBs are either reworked or discarded.

Circuit Imaging and Etching:

Photolithography Process: Photolithography is used to transfer the circuit design onto the copper layers. A photosensitive resist is applied to the surface of the copper foils, and a mask with the desired circuit pattern is used to expose the resist to light. The exposed areas of the resist are then developed, leaving the copper traces underneath protected by the unexposed resist.

Etching Process: The unprotected copper is then etched away using a chemical solution, leaving the conductive traces and pads that form the electrical circuit of the PCB. The etching process must be carefully controlled to ensure that the traces are of the correct width and that there is no over - etching or under - etching.

Drilling and Plating:

Hole Drilling: Holes are drilled through the PCB layers for various purposes, such as for component leads, vias, and mounting holes. Specialized drilling equipment is used to ensure accurate hole placement and smooth hole edges. The diameter and depth of the holes are determined by the design requirements.

Plating Process: After drilling, the holes are plated with a conductive material, usually copper, to create electrical connections between the different layers of the PCB. The plating process also helps to improve the mechanical strength of the holes. The plating thickness is carefully controlled to ensure good electrical conductivity and reliability.

Surface Finishing:

Options for Surface Finishing: The surface of the PCB is then finished to protect the copper traces from oxidation and corrosion and to provide a suitable surface for soldering components. Common surface finishing options for Metal Core PCBs include hot - air solder leveling (HASL), electroless nickel immersion gold (ENIG), and organic solderability preservative (OSP). The choice of surface finishing depends on factors such as the application requirements, cost, and environmental considerations.

Quality Assurance: The surface finish is inspected to ensure that it meets the required standards. Visual inspection, as well as various testing methods, such as solderability testing and adhesion testing, are used to verify the quality of the surface finish.

Challenges and Solutions in Metal Core PCB Technology

Cost:

High Manufacturing Costs: The manufacturing process of Metal Core PCBs can be more expensive than traditional PCBs. The use of specialized materials, such as the metal core and thermally conductive insulating materials, and the need for precise manufacturing processes contribute to the higher cost. Additionally, the relatively low volume of production for some applications can also drive up the cost per unit.

Solutions: To reduce costs, manufacturers can explore alternative materials that offer similar performance at a lower cost. For example, some new composite materials may be used instead of traditional metals or insulating materials. Economies of scale can also be achieved by increasing production volumes. Furthermore, optimizing the design to reduce the complexity of the manufacturing process can help to lower costs.

Thermal Expansion Mismatch:

Problem Description: Different materials in a Metal Core PCB, such as the metal core, insulating layer, and copper layers, have different coefficients of thermal expansion (CTE). During operation, as the temperature changes, these materials expand and contract at different rates, which can lead to thermal stress and potential delamination or cracking of the PCB.

Solutions: Designers can choose materials with compatible CTE values to minimize thermal stress. For example, using an insulating material with a CTE that is close to that of the metal core and copper layers can help. Additionally, proper thermal management design, such as providing sufficient space for thermal expansion and using flexible interconnects, can also mitigate the effects of thermal expansion mismatch.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB