-

- PCB TYPE

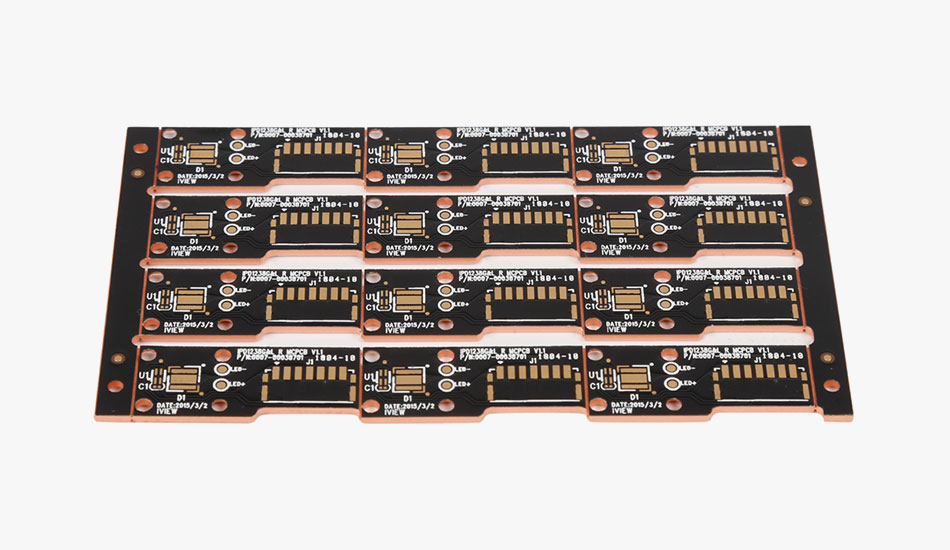

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 06. 2025, 10:40:03

In the ever - evolving landscape of electronics, where the pursuit of higher power densities, enhanced performance, and compact designs is relentless, Metal Core Printed Circuit Boards (MCPCBs) have emerged as a revolutionary solution. As electronic devices continue to shrink in size while packing more functionality, the effective management of heat generated by components has become a critical challenge. MCPCBs, with their unique construction and material properties, offer an innovative approach to thermal management, making them an essential component in a wide range of applications.

Unlike traditional PCBs, which primarily rely on organic materials like fiberglass - reinforced epoxy (FR - 4), MCPCBs incorporate a metal core as a fundamental part of their structure. This metal core, typically made of materials such as aluminum, copper, or steel, serves as a highly efficient heat sink, enabling rapid dissipation of heat away from the heat - generating components. This not only helps in maintaining optimal operating temperatures but also significantly improves the reliability and lifespan of the electronic devices.

This article delves deep into the world of Metal Core PCBs, exploring their structure, materials, manufacturing process, applications, design considerations, and the advantages they offer over conventional PCBs. By understanding the intricacies of MCPCBs, engineers, designers, and electronics enthusiasts can unlock their full potential and drive the development of next - generation electronic systems.

Structure and Material Composition

Metal Core Layer

The metal core is the defining feature of an MCPCB, and its material selection plays a pivotal role in determining the board's thermal and mechanical properties. Aluminum is one of the most commonly used materials for the metal core due to its favorable combination of high thermal conductivity, relatively low cost, and lightweight nature. With a thermal conductivity that allows efficient heat transfer, aluminum can efficiently absorb and transfer heat, making it ideal for applications where heat dissipation is crucial.

Copper, on the other hand, boasts an even higher thermal conductivity, making copper - core PCBs particularly suitable for high - power applications where extreme heat management is required. However, copper is denser and more expensive than aluminum, which may limit its use in some cost - sensitive or weight - constrained applications.

Steel, although not as thermally conductive as aluminum or copper, offers excellent mechanical strength and rigidity. It is often used in applications where the PCB needs to withstand significant mechanical stress, such as in automotive and industrial environments. The choice of metal core material thus depends on a careful balance of thermal, mechanical, and cost requirements for each specific application.

Dielectric Layer

Sandwiched between the metal core and the copper circuit layer, the dielectric layer in an MCPCB serves two critical functions: electrical insulation and thermal conduction. It must prevent electrical short - circuits between the conductive metal core and the copper traces while also facilitating the transfer of heat from the circuit layer to the metal core.

To achieve this balance, specialized dielectric materials are used. These materials often incorporate fillers, such as ceramic particles or thermally conductive polymers, to enhance their thermal conductivity while maintaining good electrical insulation properties. The thickness of the dielectric layer is an important design parameter, requiring a careful balance between thermal and electrical performance.

Copper Circuit Layer

The copper circuit layer in an MCPCB is responsible for carrying electrical current and providing the necessary electrical connections between components. High - purity copper is typically used for this layer due to its excellent electrical conductivity, which minimizes signal loss and power dissipation. Surface finishing processes are applied to the copper circuit layer to protect it from oxidation and corrosion, improve solderability, and enhance the overall reliability of the PCB.

Manufacturing Process

Material Preparation

The manufacturing process of an MCPCB begins with the careful selection and preparation of high - quality materials. The metal core is sourced from reliable suppliers and undergoes thorough inspection and cleaning to ensure its quality and suitability for the lamination process. The dielectric material and copper foil are also carefully prepared to meet the required specifications.

Lamination

Lamination is a critical step in the manufacturing of an MCPCB, as it determines the integrity and performance of the final product. During lamination, the dielectric layer is placed between the metal core and the copper foil, and the three layers are pressed together under high pressure and temperature to ensure a uniform and void - free bond.

Circuit Pattern Formation

Once the lamination process is complete, the circuit pattern is created on the copper layer using a photolithography process. This involves applying a photosensitive resist material, exposing it to UV light through a mask, and etching away the unwanted copper to form the electrical pathways.

Drilling and Plating

Holes are drilled through the PCB for component mounting, vias, and electrical connections, which are then plated with copper to create conductive pathways between the different layers of the PCB.

Surface Finishing

Surface finishing processes are applied to the copper circuit layer to protect it and improve solderability. Common surface finishes include electroless nickel immersion gold (ENIG), immersion tin, and organic solderability preservative (OSP).

Quality Control

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the MCPCBs meet the highest standards of quality and performance. This includes visual inspection, electrical testing, thermal testing, and mechanical testing to identify and reject any defective boards.

Applications in Diverse Industries

LED Lighting

MCPCBs are widely used in the LED lighting industry to manage the heat generated by high - power LEDs. Their high - thermal - conductivity metal cores ensure efficient heat dissipation, maintaining the optimal operating temperature of the LEDs and enhancing their performance and lifespan.

Power Electronics

In power electronics applications, such as power supplies and motor control units, MCPCBs play a crucial role in managing high power densities and heat generation. They efficiently transfer heat from power components to the metal core, improving the efficiency and reliability of these systems.

Automotive Electronics

The automotive industry relies on MCPCBs for their thermal management, electrical reliability, and mechanical durability. They are used in various applications, including engine control units (ECUs), advanced driver - assistance systems (ADAS), and lighting, where they withstand harsh conditions such as high temperatures and vibrations.

Consumer Electronics

In consumer electronics, MCPCBs help manage the heat generated by high - performance components in devices like smartphones and gaming consoles. Their lightweight and compact design contributes to the sleekness and portability of these devices while improving performance and battery life.

Aerospace and Defense

Aerospace and defense applications require electronic components that can withstand extreme environments. MCPCBs provide the necessary thermal management and mechanical stability for avionics systems, radar systems, and other critical defense equipment.

Industrial Electronics

Industrial electronics, including factory automation and robotics, benefit from MCPCBs' ability to dissipate heat and withstand harsh industrial environments with high temperatures, dust, and vibrations.

Design Considerations

Thermal Design

Thermal design is crucial for MCPCBs, involving careful placement of heat - generating components and the use of thermal vias to enhance heat flow to the metal core. Optimizing the PCB layout for proper airflow also aids in heat dissipation.

Mechanical Design

Mechanical design considerations include using appropriate mounting techniques and reinforced mounting holes to ensure the PCB's mechanical integrity and withstand mechanical stress, vibrations, and shocks.

Electrical Design

Electrical design focuses on designing the copper circuit layer to carry the required current while minimizing signal loss and electromagnetic interference, and selecting the right dielectric layer for proper electrical insulation.

Compatibility with Components

Ensuring compatibility with components involves considering their mechanical, electrical, and thermal requirements, as well as the thermal interface and surface finish compatibility.

Advantages Over Traditional PCBs

Superior Thermal Performance

MCPCBs offer superior thermal performance compared to traditional PCBs, efficiently dissipating heat and reducing component temperatures, which improves reliability and may eliminate the need for additional cooling mechanisms.

Improved Mechanical Strength

The metal core provides improved mechanical strength, protecting the PCB and components from mechanical stress, vibrations, and shocks, making MCPCBs more reliable in harsh environments.

Lightweight Design (in some cases)

Aluminum - core MCPCBs offer a lightweight design advantage, which is beneficial in aerospace and portable electronics where weight reduction is crucial.

Design Flexibility

MCPCBs can be designed in various configurations, including single - sided, double - sided, or multilayer, providing designers with the flexibility to meet different circuit complexity and functionality requirements.

Future Trends and Innovations

Advanced Materials and Manufacturing Techniques

Future developments in MCPCBs will focus on advanced materials, such as graphene - enhanced dielectrics, and manufacturing techniques like 3D printing to create complex internal structures for better heat dissipation.

Integration with Emerging Technologies

MCPCBs will play a key role in emerging technologies like autonomous vehicles, 5G infrastructure, and high - performance computing, where efficient heat management is essential for compact and reliable systems.

Sustainable and Eco - Friendly Solutions

The industry is moving towards sustainable practices, including the use of recycled metals and bio - based dielectric materials, to make MCPCBs more environmentally friendly.

Miniaturization and Multilayer Designs

As electronics continue to miniaturize, MCPCBs will support multilayer configurations and finer trace geometries, enabling more complex and compact designs for high - density applications.

Conclusion

Metal Core PCBs have revolutionized the electronics industry by addressing the critical challenge of thermal management while offering mechanical robustness and electrical reliability. Their unique combination of metal core materials, advanced dielectrics, and innovative manufacturing techniques has made them indispensable in a wide range of applications.

As technology continues to advance, MCPCBs will continue to evolve, driven by the demand for more efficient, compact, and sustainable electronic solutions. For engineers and designers, embracing MCPCB technology is essential for developing next - generation electronics that meet the evolving needs of various industries, from consumer electronics to aerospace and defense. With their superior performance and adaptability, MCPCBs are set to remain a cornerstone of electronic design for years to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB