-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 07. 2025, 10:24:12

In the fast-paced evolution of modern electronics, the quest for efficient heat management solutions has reached a critical juncture. As electronic devices shrink in size while power density surges, traditional circuit board materials struggle to handle the heat generated. Thermal Conductive Metal Base Laminates (TCMBLs) have emerged as a transformative technology. These specialized laminates are crucial in enhancing the thermal, mechanical, and electrical performance of electronic systems, becoming essential across diverse applications. This article delves into TCMBLs, exploring their structure, properties, applications, design considerations, manufacturing processes, and future trends.

What is a Thermal Conductive Metal Base Laminate?

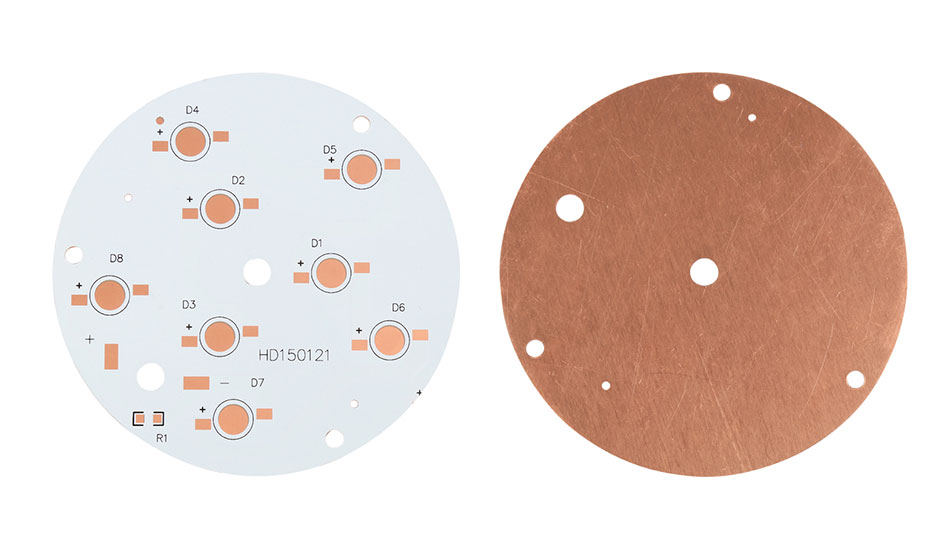

A Thermal Conductive Metal Base Laminate is a composite material predominantly used in fabricating printed circuit boards (PCBs) and other electronic assemblies. At its core, it features a metal substrate, usually aluminum or copper, serving as the base layer. This metal layer, known for its high thermal conductivity, swiftly absorbs and transfers heat from heat-generating components.

Adjacent to the metal base is a thermally conductive dielectric layer. This layer is vital as it provides electrical isolation between the metal substrate and the conductive traces and components on the PCB's top layer. Simultaneously, it enables efficient heat transfer from the components to the metal base. On the surface of the dielectric layer, a copper foil is laminated, forming the circuit layer where electronic components are mounted, and electrical connections are established.

The combination of these layers creates a laminate that balances thermal management, electrical functionality, and mechanical strength, overcoming the limitations of traditional organic-based PCB materials.

Key Components and Their Functions

Metal Substrate

Aluminum: Widely favored for its balance of cost, lightweight nature, and adequate thermal conductivity. Aluminum substrates resist corrosion and offer good mechanical stability, making them suitable for various applications, from consumer electronics to automotive systems.

Copper: Renowned for its superior thermal conductivity compared to aluminum, copper substrates are ideal for high-power applications requiring maximum heat dissipation. However, their higher cost and weight may limit use in cost-sensitive or weight-restricted scenarios.

Thermally Conductive Dielectric Layer

Typically composed of polymers filled with thermally conductive fillers like ceramics or metal oxides, the dielectric layer's performance depends on the filler material and its concentration. These factors significantly impact the laminate's thermal conductivity and electrical insulation. A well-designed dielectric layer minimizes thermal resistance between the circuit layer and the metal base, enabling efficient heat transfer while ensuring high electrical isolation to prevent short circuits.

Copper Foil

The copper foil on the dielectric layer's surface is etched to form the conductive traces and pads of the PCB's electrical circuit. The thickness and quality of the copper foil influence the board's electrical performance, including current-carrying capacity and signal integrity.

Advantages of Thermal Conductive Metal Base Laminates

Exceptional Thermal Management

The standout advantage of TCMBLs is their efficient heat management. Traditional PCBs with organic substrates face challenges due to low thermal conductivity, leading to heat accumulation. TCMBLs, however, leverage the metal base's high thermal conductivity to rapidly dissipate heat from components such as power transistors, LEDs, and integrated circuits. This keeps operating temperatures in check, preventing thermal stress, reducing failure risks, and enhancing device reliability and lifespan.

Mechanical Robustness

The metal base endows TCMBLs with enhanced mechanical strength and durability. They can withstand physical stress, vibrations, and shocks better than conventional PCB materials. This makes them suitable for harsh environments, like those in automotive, aerospace, and industrial applications, where mechanical stability is crucial for continuous component operation.

Cost-Effective Heat Dissipation Solutions

Although TCMBLs may have a higher upfront cost, they offer long-term savings. By efficiently managing heat, they often eliminate the need for complex and expensive external cooling systems, simplifying device design and assembly. Fewer components mean lower manufacturing costs, and the extended component lifespan due to better thermal management further reduces maintenance and replacement expenses.

Design Flexibility

Despite their robust structure, TCMBLs allow for flexible design. Advanced manufacturing techniques enable the creation of complex circuit layouts, multi-layer designs, and precise component placement. Designers can tailor PCB designs to different application requirements, and TCMBLs can be customized with features like electromagnetic shielding or improved signal integrity to enhance device functionality.

Applications of Thermal Conductive Metal Base Laminates

LED Lighting

In the LED lighting industry, heat management is crucial for optimal LED performance and longevity. Excessive heat can reduce light output, cause color shifts, and lead to premature failure. TCMBLs are used in various LED lighting fixtures, efficiently dissipating heat to keep LEDs at lower temperatures, maximizing luminous efficacy and lifespan, and simplifying fixture design.

Automotive Electronics

The automotive environment is harsh, with high temperatures, vibrations, and electrical interference. TCMBLs are used in automotive applications such as ECUs, ADAS, and lighting. The metal base's mechanical strength withstands vehicle - related stress, while thermal management keeps components cool for reliable performance.

Industrial and Power Electronics

In industrial settings, power electronics components generate significant heat. TCMBLs are employed to dissipate this heat, preventing overheating and ensuring continuous equipment operation. Their mechanical durability also makes them suitable for industrial environments with dust, moisture, and mechanical stress.

Consumer Electronics

As consumer electronics become more powerful and compact, TCMBLs help manage the heat generated by components. Their use allows for sleeker designs without sacrificing performance.

Design Considerations for Thermal Conductive Metal Base Laminates

Thermal Design

Metal Core Material Selection: The choice between aluminum and copper depends on factors like cost, weight, and required thermal performance. Aluminum is often a cost-effective and lightweight option, while copper is preferred for high-power applications.

Insulating Layer Thickness and Conductivity: The thickness and thermal conductivity of the dielectric layer impact thermal performance. A thinner layer can enhance heat transfer but may compromise electrical isolation, so careful material selection is necessary.

Component Placement and Heat Path Optimization: Strategic placement of heat-generating components and the use of thermal vias can optimize heat dissipation, reducing the risk of hotspots.

Mechanical Design

Component Mounting: Heavier components may require additional support to prevent PCB damage during handling and operation.

Thermal Expansion Compatibility: Ensuring compatible coefficients of thermal expansion among the metal base, dielectric layer, and circuit layer is essential to prevent delamination or cracking during temperature changes.

Board Shape and Edge Treatment: Unusual board shapes and proper edge treatment, such as rounding or chamfering, can affect mechanical strength and prevent damage during handling.

Electrical Design

Trace Width and Spacing: Determining appropriate trace width and spacing is crucial for electrical performance, preventing resistance-related heat generation and short circuits.

Ground Plane Design: A well-designed ground plane improves signal integrity, reduces electromagnetic interference, and provides a low-impedance current path.

Electrical Insulation: Ensuring the dielectric layer's electrical insulation is vital to prevent short circuits and electrical hazards.

Manufacturing Processes of Thermal Conductive Metal Base Laminates

Core Preparation

The manufacturing process begins with preparing the metal core. The metal surface is cleaned to remove contaminants, followed by applying a thermally conductive dielectric material through lamination. Finally, the copper circuit layer is laminated onto the insulating layer.

Circuit Imaging

Photolithography is commonly used for circuit imaging. A photosensitive resist is applied to the copper surface, and a mask with the circuit pattern is used for exposure. The exposed resist is then developed, leaving the copper traces protected.

Etching

After circuit imaging, the unprotected copper is removed through etching, leaving the conductive traces. The process is carefully controlled to ensure accurate trace dimensions.

Drilling and Plating

Holes are drilled for component leads, vias, and mounting. These holes are then plated with copper to create electrical connections between PCB layers.

Surface Finishing

The final step is surface finishing, which protects the copper traces from oxidation and provides a suitable surface for soldering. Common finishes include HASL, ENIG, and OSP, each with its own advantages depending on the application.

Thermal Management Strategies for Thermal Conductive Metal Base Laminates

Thermal Interface Materials (TIMs)

TIMs, such as thermal pastes, pads, or gels, fill the gaps between components and the TCMBL, reducing thermal resistance and enhancing heat transfer. The choice of TIM depends on factors like component type, operating temperature, and required thermal performance.

Heat Sink Integration

In high-power applications, integrating a heat sink with the TCMBL can enhance heat dissipation. Heat sink design, including shape, size, and fin configuration, is optimized, and materials like aluminum or copper are selected based on performance needs. Forced-air cooling can also be combined with heat sink integration.

Thermal Simulation

Advanced thermal simulation software allows designers to model heat flow within the PCB and system. By inputting material properties, component layout, and operating conditions, potential hotspots can be identified, and the design optimized for efficient thermal management.

Cooling Methods

The choice of cooling method depends on the device's power consumption and operating environment. Natural convection may suffice for low-to-moderate power applications, while forced-air cooling or liquid cooling is required for high-power scenarios.

Material Selection: A Comparative Analysis

Aluminum - Core TCMBLs

Advantages: Cost-effective, lightweight, and corrosion-resistant, aluminum-core TCMBLs are suitable for a wide range of applications where cost and weight are considerations.

Limitations: Their thermal conductivity is lower than copper, which may restrict their use in applications demanding the highest heat dissipation.

Copper - Core TCMBLs

Advantages: Superior thermal conductivity makes copper-core TCMBLs ideal for high-power applications requiring maximum heat dissipation.

Limitations: Higher cost and weight compared to aluminum may limit their adoption in cost-sensitive or weight-restricted applications.

Future Trends

Advancements in Material Science

Ongoing research focuses on developing new materials and improving existing ones for TCMBLs. This includes enhancing the thermal conductivity of dielectric materials, reducing the cost of high-performance metals, and creating composites with better overall performance.

Miniaturization and High-Density Integration

As electronics continue to miniaturize, TCMBLs will need to support high-density component integration while maintaining efficient heat management. This may involve developing thinner laminates with improved thermal and electrical properties.

Sustainability

There is a growing emphasis on sustainability in the electronics industry. Future TCMBLs are likely to incorporate more environmentally friendly materials and manufacturing processes, reducing their environmental impact.

Conclusion

Thermal Conductive Metal Base Laminates have revolutionized heat management in electronics, offering a combination of thermal efficiency, mechanical strength, and design flexibility. As the demand for high-performance, compact electronic devices continues to grow, TCMBLs will play an increasingly important role. By understanding their structure, properties, and design considerations, engineers can leverage TCMBLs to create more reliable, efficient, and innovative electronic systems. Future advancements in material science, miniaturization, and sustainability will further enhance the capabilities of TCMBLs, ensuring their continued relevance in the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB