-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Feb 20. 2026, 17:02:47

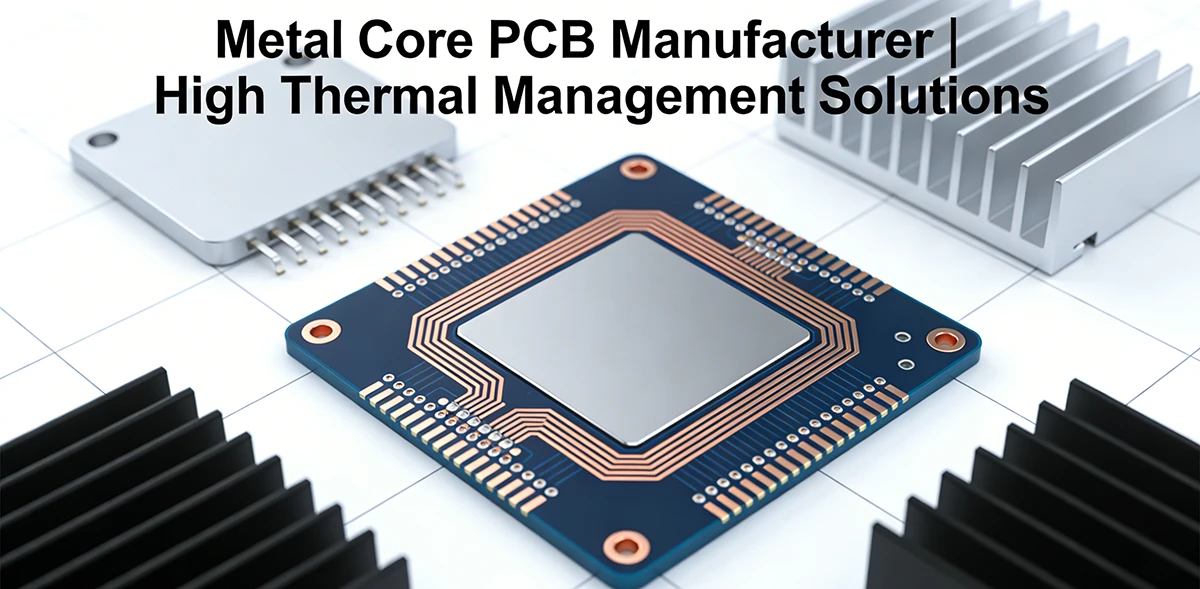

In the demanding world of industrial electronics, heat is the ultimate enemy of reliability. As power densities in LED lighting, automotive systems, and power converters continue to climb, traditional resin-based substrates often reach their physical limits. This is where the Metal Core PCB (MCPCB) becomes an indispensable solution for factory-scale production.

For procurement managers and hardware engineers, selecting a qualified metal core pcb manufacturer is not just about sourcing a component—it is about securing a thermal management strategy that ensures the longevity of high-power devices.

For decades, FR4 (Flame Retardant 4) has been the default substrate for the electronics industry.

Below is a deep dive into why high-power industrial applications are moving toward metal-based solutions.

The most critical advantage of an MCPCB is its ability to move heat. FR4 is essentially a thermal insulator, with a thermal conductivity of approximately 0.25W/m.K.

By transferring heat from the junction of high-power components (like LEDs or MOSFETs) directly to the metal base, MCPCBs prevent "heat pooling."

Industrial environments are often subject to extreme temperature fluctuations.

FR4: When exposed to high heat, FR4 substrates can expand at different rates (Coefficient of Thermal Expansion), leading to "warping" or "bowing."

Metal Core: Whether you use an aluminium core pcb or a copper core pcb, the metal base provides superior rigidity.

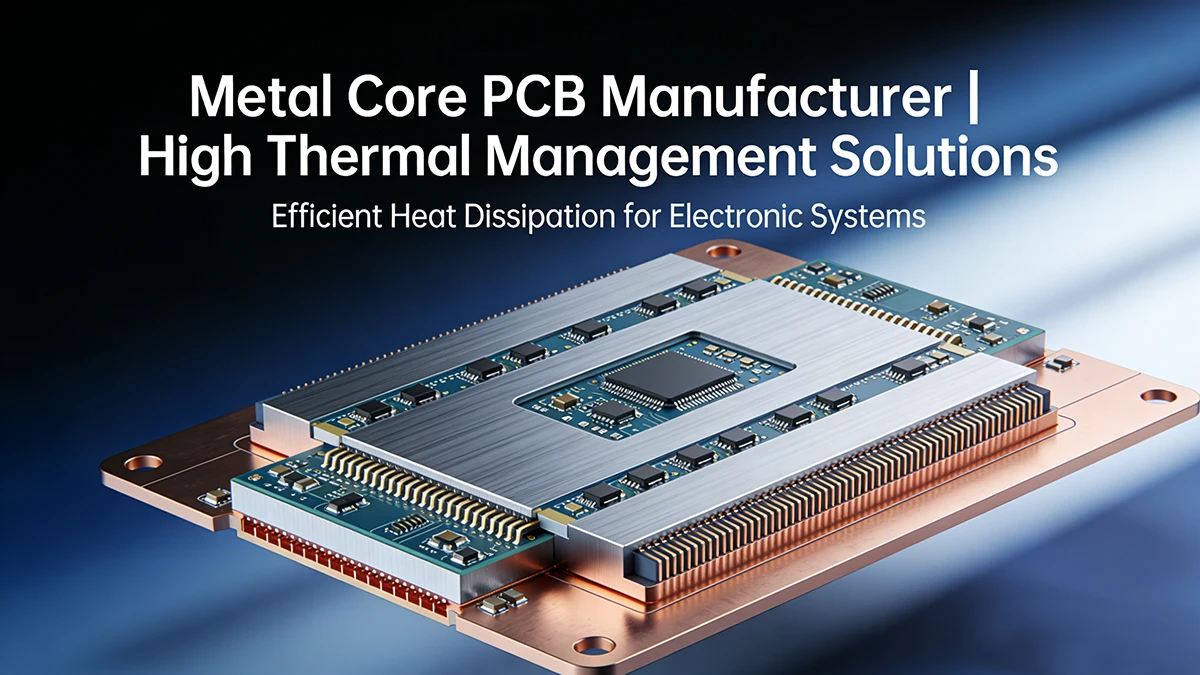

In many designs, a Metal Core PCB serves a dual purpose: it is both the circuit provider and a structural component.

Eliminating Heat Sinks: Because the metal base itself acts as a large-area heat spreader, many designs can eliminate bulky, expensive external heat sinks and cooling fans.

Weight vs. Durability: While a metal core board is heavier than FR4, it is significantly more durable against mechanical shock and vibration, which is a key requirement for automotive and aerospace metal core pcb design guidelines.

The metal base in an MCPCB can also act as an electromagnetic shield.

While the metal core pcb manufacturing process remains similar across different metals, the physical properties of the base material dictate the final performance of your device. Choosing between Aluminum and Copper is a balance of thermal requirements (W/mK), weight constraints, and target price points.

The aluminium core pcb is the most widely utilized metal-base substrate globally.

Thermal Performance: Typically ranges from 1.0W/m.K to 3.0W/m.K. While lower than copper, it is still roughly 10 times more efficient at heat dissipation than standard FR4.

Weight Advantage: Aluminum is lightweight, making it ideal for large-scale LED arrays and automotive lighting where overall vehicle weight impacts fuel efficiency.

Machinability: Aluminum is easier to drill, route, and V-score, which reduces manufacturing time and wear on factory tooling.

Cost-Effectiveness: It offers the lowest entry price for thermal management, making it perfect for LED street lights, high-bay lighting, and automotive ignitions.

For applications where heat density is so extreme that aluminum cannot keep up, the copper core pcb is the premium choice. Copper’s thermal conductivity is significantly higher than aluminum’s, making it the elite tier of metal core pcb material.

Elite Thermal Performance: Copper core boards can achieve thermal conductivity levels of 400W/m.K or more (if using direct-to-copper "thermo-electric separation" designs).

Superior Heat Spread: Copper dissipates heat laterally across the board much faster than aluminum, preventing localized "hot spots" that can degrade high-frequency chips.

Weight & Durability: Copper is much denser and heavier than aluminum.

Primary Use Cases: High-frequency microwave communications, concentrated solar power (CPV), ultra-high-power COB LEDs, and 5G base station power amplifiers where every fraction of a degree is critical for signal integrity.

A successful production run starts with adhering to strict metal core pcb design guidelines. Unlike standard boards, MCPCBs require specific considerations to ensure manufacturability and electrical safety.

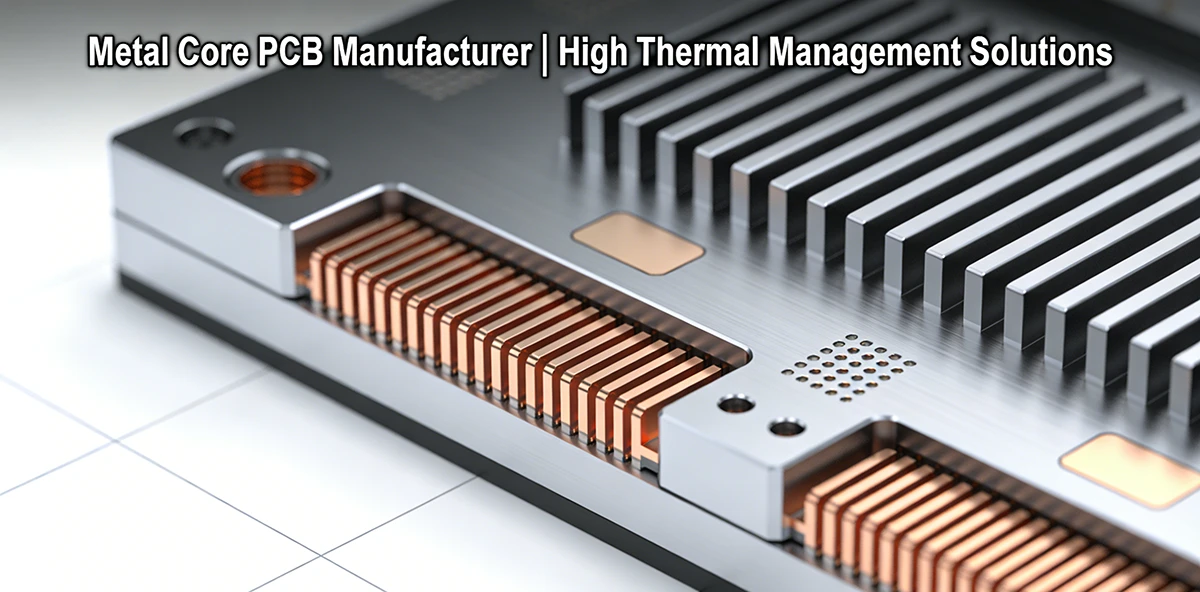

A typical metal core pcb stackup consists of three distinct layers:

Circuit Layer: A copper foil layer where components are soldered.

Dielectric Layer: The "heart" of the MCPCB. This must be thermally conductive but electrically insulating to prevent shorts to the metal base.

Base Layer: The metal substrate (Aluminium or Copper).

For LED applications, using a high-reflectivity white solder mask is essential to maximize light output. Popular finishes include OSP (Organic Solderability Preservatives) or HASL, though ENIG is preferred for high-reliability industrial sensors.

Manufacturing a metal core pcb is vastly different from producing a standard fiberglass board. Because the substrate is a solid slab of conductive metal, every step—from lamination to final inspection—requires specialized heavy-duty equipment and strict environmental controls to prevent electrical failure.

The process begins with the "Stackup." Unlike FR4, where prepreg bonds layers of glass cloth, MCPCB lamination involves bonding a high-conductivity dielectric layer and a copper foil to the metal base (usually Aluminum 5052 or 6061).

Pressure & Vacuum: The lamination must occur in a vacuum press to ensure zero air bubbles (voids) remain in the dielectric.

Bond Strength: A top-tier metal core pcb manufacturer will perform "peel strength" tests to ensure the copper won't delaminate from the metal base during high-temperature soldering.

Drilling through a metal core requires more than just standard bits; it requires specialized CNC parameters and carbide tools.

The PTH Challenge: In standard FR4, Plated Through-Holes (PTH) are common. In a single-sided aluminium core pcb, we generally avoid PTH to prevent the circuit from shorting against the metal core.

Insulated Holes: If a through-hole is required for a double-sided MCPCB, the factory must first "over-drill" the metal core, fill it with an insulating resin, and then drill a smaller hole through that resin to plate it. This is a high-cost, high-precision step.

Once the copper is bonded, the circuit pattern is defined.

LDI (Laser Direct Imaging): For high-precision industrial designs, ApolloPCB uses LDI to project the circuit layout directly onto the photoresist. This is superior to traditional film masking as it prevents "light bleed" and ensures the ultra-sharp trace edges necessary for high-power stability.

Chemical Etching: The board is passed through an acidic bath to remove excess copper. For thick copper boards (2oz- 4oz), the etching time must be perfectly calibrated to avoid "undercutting" the traces.

Because the base is a solid metal alloy, standard PCB routers won't cut it.

V-Scoring: For panelized LED boards, V-scoring machines with diamond-tipped blades create precise grooves. The depth of the score must be precisely controlled to leave enough material for structural integrity while allowing for clean "snapping" after assembly.

CNC Routing: For complex outlines or internal cutouts, heavy-duty CNC milling machines are used.

This is arguably the most important step in the metal core pcb manufacturing process.

The Test: Every board is subjected to a "Hi-Pot" (High Potential) test.

The Goal: To ensure the dielectric layer can withstand electrical surges without leaking current to the metal core. At ApolloPCB, we provide the Hi-Pot test report for every batch, ensuring your metal core pcb design guidelines for safety are fully met.

The effectiveness of an MCPCB is defined by its ability to move heat away from sensitive components and spread it across the metal substrate.

In a standard circuit board, the material acts like an insulator, trapping heat around the components.

The Thickness Trade-off: A thinner dielectric layer allows heat to reach the metal core more quickly, similar to how a thinner pane of glass allows heat to pass through more easily. However, if the layer is too thin, it may not be able to withstand high voltage surges.

The Material Quality: High-performance dielectrics are infused with ceramic particles. These particles create a path for heat to flow, ensuring that even as power levels rise, the components stay within their safe operating temperatures.

Finding the "sweet spot" in metal core pcb design guidelines involves matching the board's insulation strength with your specific cooling needs.

High-Voltage Safety: For industrial power supplies or automotive systems, the dielectric must be robust enough to pass rigorous safety tests (such as Hi-Pot testing) without failing.

Heat Spreading: Once the heat passes through the dielectric, the metal base (usually Aluminum or Copper) takes over.

When evaluating a metal core pcb manufacturer, it is more useful to look at the total thermal impedance rather than just raw material ratings. Thermal impedance describes how much the temperature will rise for every watt of power generated. Factors that lower this impedance include:

Optimal bonding of the layers to ensure there are no microscopic air gaps.

Using high-purity metal bases that lack internal impurities.

Selecting dielectric resins that maintain their conductive properties even after thousands of heating and cooling cycles.

For the most demanding applications, such as high-intensity LED arrays or 5G telecommunications, we utilize a technique called Thermo-Electric Separation. In this advanced design, the thermal pad of the component is directly connected to a metal pedestal that is part of the core itself. This removes the dielectric "bottleneck" entirely for the heat path while keeping the electrical signals safely insulated on the side. This results in the highest possible cooling efficiency available in modern PCB manufacturing.

Metal core boards are primarily used where heat dissipation is critical. Common applications include LED lighting (street lights, high-bays), automotive power modules (converters, ignitions), power industry (rectifiers, relays), and telecommunications (high-frequency amplifiers).

The main advantages include superior thermal management, high dimensional stability, excellent power density support, and the ability to integrate a heat sink directly into the board structure, which reduces the overall size of the device.

Aluminum is the most common due to its low cost and weight. Copper is used for higher thermal demands, and stainless steel is occasionally used for applications requiring extreme mechanical strength and corrosion resistance.

An aluminum printed board (or aluminum pcb) is a type of MCPCB where the base material is an aluminum alloy. It consists of a copper circuit layer, a thermally conductive dielectric layer, and the aluminum substrate.

At ApolloPCB, we provide 5052 and 6061 aluminum alloys as standard. We also manufacture high-end copper core pcb units for advanced thermal requirements and specialized stainless steel bases for rugged industrial environments.

Optimizing thermal management is a mechanical, chemical, and electrical challenge. By following the right metal core pcb design guidelines and choosing the appropriate metal core pcb material, factories can significantly improve the ROI of their electronic products.

[Contact ApolloPCB Today for a Free DFM Review and Precision Quote]

Related Articles:

The Ultimate Guide to Metal Core PCB: Boosting Thermal Efficiency in High-Power Electronics

Countersink Holes in Metal - Core PCBs: A Deep - Dive into Design, Manufacturing, and Applications

Tapped Counterbore in Metal - Core PCBs: A Comprehensive Technical Analysis

Metal Core PCBs Electrical Excellence in Electronics

Metal Core PCB: Revolutionizing Thermal Management and Performance in Electronics

Metal Core PCB: Transforming Thermal and Electrical Performance in Modern Electronics

Metal Core PCB Pioneering Thermal and Electrical Excellence in Electronics

Metal Core PCB: Benefits, Applications, and Why It's the Best Choice for Your Electronics

Understanding Metal Core PCB: Key Advantages and Applications in Electronics Manufacturing

Metal Core PCB: Benefits, Applications, and Key Considerations

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB