-

- PCB TYPE

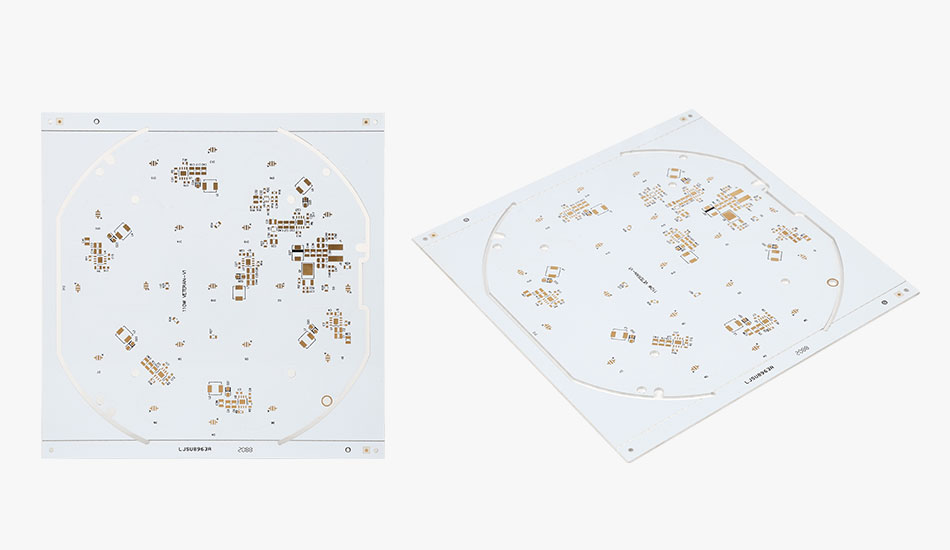

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 07. 2025, 16:37:00

In the rapidly evolving electronics landscape, the demand for high - performance, reliable printed circuit boards (PCBs) is ever - increasing. Among the diverse PCB technologies, Metal Core PCBs (MCPCBs) have emerged as a game - changing solution. These specialized PCBs address critical challenges such as thermal management, mechanical stability, and electrical performance, making them indispensable in a wide range of applications. This article will provide an in - depth exploration of metal core PCBs, covering their definition, structure, advantages, applications, design considerations, manufacturing processes, and future trends.

What is a Metal Core PCB?

A Metal Core PCB is a type of printed circuit board that incorporates a metal layer as its core substrate, distinguishing it from traditional PCBs with organic substrates. The metal core, typically made of aluminum or copper, serves as both a robust mechanical support and an efficient heat dissipation pathway. This unique structure enables MCPCBs to handle high - power components and operate in demanding environments where heat management is crucial.

Structure of Metal Core PCBs

Top Circuit Layer: This is the uppermost layer of the MCPCB, where electronic components are mounted, and conductive traces are patterned. Similar to traditional PCBs, it is responsible for establishing electrical connections between components, ensuring the proper flow of electrical signals within the circuit. The layout of the traces on this layer is carefully designed to meet the specific electrical requirements of the application.

Insulating Layer: Positioned between the top circuit layer and the metal core, the insulating layer is a key component of MCPCBs. It is composed of a thermally conductive dielectric material that provides electrical isolation between the metal core and the electrical components on the top layer. At the same time, it facilitates the transfer of heat from the components to the metal core, acting as a bridge for thermal conduction while maintaining electrical insulation.

Metal Core: The metal core is the defining feature of MCPCBs. Aluminum is commonly used due to its cost - effectiveness, lightweight nature, and adequate thermal conductivity. Copper, on the other hand, offers superior thermal conductivity but comes at a higher cost and is heavier. The metal core efficiently absorbs the heat generated by the components on the top layer and distributes it over a larger surface area for effective dissipation.

Optional Backing or Heat Sink: In some advanced designs, an additional backing or heat sink may be attached to the metal core. This further enhances the heat dissipation capabilities of the MCPCB, making it suitable for extremely high - power applications where the metal core alone may not be sufficient to manage the heat effectively.

Key Advantages of Metal Core PCBs

Exceptional Thermal Management: One of the most significant advantages of MCPCBs is their outstanding thermal management capabilities. Traditional PCBs with organic substrates often struggle with heat dissipation, as these materials have relatively low thermal conductivity. In contrast, the metal core in MCPCBs provides an efficient pathway for heat to flow away from heat - generating components, such as power transistors, LEDs, and integrated circuits. This rapid heat transfer helps to maintain lower and more stable operating temperatures, reducing the risk of component failure due to overheating and extending the overall lifespan of the electronic device.

Enhanced Mechanical Strength: The metal core imparts excellent mechanical strength to MCPCBs, making them more durable and resistant to physical damage compared to traditional PCBs. This added strength allows MCPCBs to withstand harsh operating conditions, including vibrations, shocks, and mechanical stress. As a result, they are well - suited for applications in automotive electronics, aerospace systems, and industrial machinery, where mechanical stability is crucial for reliable operation.

Cost - Efficiency in the Long Run: Although MCPCBs may have a higher upfront cost compared to some traditional PCBs, they offer significant cost - saving benefits in the long term. Their efficient thermal management capabilities often eliminate the need for complex and expensive external cooling systems, such as large heat sinks, fans, or liquid - cooling setups. By reducing the reliance on these additional cooling components, the overall design and assembly process becomes simpler, and production costs are lowered. Moreover, the extended lifespan of components due to better thermal management means fewer component replacements and less maintenance over time, resulting in substantial cost savings throughout the product's lifecycle.

Design Flexibility: Despite their robust metal core, MCPCBs offer a high degree of design flexibility. Advanced manufacturing techniques enable the creation of intricate circuit layouts, multi - layer designs, and precise component placement. This flexibility allows designers to tailor the MCPCB to the specific requirements of different applications, whether it's a compact consumer electronics device or a large - scale industrial system. Additionally, MCPCBs can be customized with features such as electromagnetic shielding or enhanced signal integrity measures to further enhance their functionality.

Applications of Metal Core PCBs

LED Lighting: In the LED lighting industry, heat management is critical for the performance and lifespan of LEDs. Excessive heat can cause a reduction in light output, color shift, and premature failure of the LEDs. MCPCBs are widely used in LED lighting fixtures, including streetlights, high - bay lights, and automotive headlights, due to their excellent thermal management capabilities. The efficient heat dissipation provided by MCPCBs ensures that LEDs operate at optimal temperatures, maximizing their luminous efficacy and lifespan while reducing maintenance costs.

Automotive Electronics: The automotive environment is harsh, with high temperatures, vibrations, and electrical interference. MCPCBs are employed in various automotive applications, such as engine control units (ECUs), advanced driver assistance systems (ADAS), and automotive lighting. Their mechanical strength and thermal management capabilities make them ideal for ensuring the reliable operation of electronic components in vehicles, even under extreme conditions.

Industrial and Power Electronics: In industrial settings, power electronics components like inverters, motor drives, and power supplies generate a significant amount of heat during operation. MCPCBs are used to dissipate this heat effectively, preventing overheating and ensuring the continuous and stable operation of the equipment. The mechanical durability of MCPCBs also makes them suitable for industrial environments where they may be exposed to dust, moisture, and mechanical stress.

Consumer Electronics: With the increasing demand for more powerful and compact consumer electronics devices, such as high - performance laptops, gaming consoles, and smartphones, the need for efficient heat management solutions has become more pressing. MCPCBs are being increasingly adopted in these devices to manage the heat generated by powerful processors, graphics cards, and other components. The integration of heat - dissipation functionality directly into the PCB design allows for a more compact and streamlined device design, eliminating the need for large external cooling components.

Aerospace and Defense: The aerospace and defense industries have stringent requirements for the reliability and performance of electronic systems. These systems often operate in extreme environments, including high altitudes, wide temperature ranges, and high levels of radiation. MCPCBs meet these rigorous standards with their excellent thermal, mechanical, and electrical properties. They are used in avionics systems, radar equipment, and military communication devices, ensuring the safe and reliable operation of these critical systems in challenging conditions.

Design Considerations for Metal Core PCBs

Thermal Design:

Metal Core Material Selection: The choice between aluminum and copper for the metal core depends on various factors. Aluminum is a popular choice for applications where cost and weight are important considerations, as it offers a good balance between thermal performance, affordability, and lightness. Copper, on the other hand, is preferred for applications that demand the highest possible thermal conductivity, such as high - power industrial or aerospace applications, despite its higher cost and weight.

Insulating Layer Thickness and Conductivity: The thickness and thermal conductivity of the insulating layer have a significant impact on the thermal performance of an MCPCB. A thinner insulating layer can facilitate better heat transfer from the components to the metal core, but it may also compromise electrical isolation. Therefore, selecting an insulating material with high thermal conductivity and excellent electrical insulation properties is essential. Additionally, the design should ensure that the insulating layer is evenly applied to avoid any thermal bottlenecks.

Component Placement and Heat Path Optimization: Strategically placing heat - generating components over the metal core and designing an efficient heat path are crucial for effective thermal management. Thermal vias, which are small holes filled with a conductive material, can be used to enhance the heat transfer from the top circuit layer to the metal core. By carefully planning the component layout and the placement of thermal vias, designers can ensure that heat is dissipated as efficiently as possible, reducing the risk of hotspots and maintaining a more uniform temperature distribution across the PCB.

Mechanical Design:

Component Mounting: When mounting components on an MCPCB, it is important to consider the mechanical stress that the components may exert on the board. Heavier components may require additional support, such as brackets or adhesive bonding, to prevent damage to the PCB during handling, assembly, or operation. The mounting method should also ensure that the component is securely attached to the PCB to withstand vibrations and shocks.

Thermal Expansion Compatibility: Different materials in an MCPCB, including the metal core, insulating layer, and top circuit layer, have different coefficients of thermal expansion (CTE). Ensuring that these materials have compatible CTE values is crucial to prevent delamination or cracking of the PCB during temperature changes. This requires careful selection of materials and proper design of the PCB structure to minimize thermal stress.

Board Shape and Edge Treatment: The shape of the MCPCB and the treatment of its edges can also affect its mechanical strength. Unusual or complex board shapes may require additional considerations to ensure that the PCB can withstand mechanical stress without deforming. Rounded edges or chamfers can reduce stress concentrations and prevent damage during handling and assembly, improving the overall durability of the PCB.

Electrical Design:

Trace Width and Spacing: Determining the appropriate trace width and spacing is crucial for ensuring the electrical performance of the MCPCB. Wider traces are required for higher - current applications to minimize resistance and prevent excessive heat generation due to electrical losses. Adequate spacing between traces is necessary to prevent electrical short - circuits, especially in high - voltage applications. The trace width and spacing should be carefully calculated based on the electrical requirements of the circuit and the current - carrying capacity of the PCB materials.

Ground Plane Design:

A well - designed ground plane on the MCPCB can improve signal integrity, reduce electromagnetic interference (EMI), and provide a low - impedance path for electrical current. The ground plane should be continuous and have a sufficient area to effectively shield the signals on the PCB. In some cases, multiple ground planes or a split - plane design may be used to optimize the electrical performance of the PCB for different types of signals.

Electrical Insulation:

Ensuring the electrical insulation of the insulating layer between the metal core and the circuit components is of utmost importance. Any breakdown in electrical insulation can lead to short circuits, component failures, and potentially dangerous electrical hazards. Therefore, the insulating material should have high dielectric strength and be free from any defects or contaminants that could compromise its insulation properties.

Manufacturing Processes of Metal Core PCBs

Core Preparation: The first step in manufacturing an MCPCB is preparing the metal core. This involves cleaning the metal surface thoroughly to remove any contaminants, such as oils, dirt, or oxides, which could affect the adhesion of the insulating layer. After cleaning, a thermally conductive dielectric material is applied to the metal surface to create the insulating layer. This is typically done through a lamination process, where the dielectric material is bonded to the metal core under heat and pressure. Finally, the copper circuit layer is laminated onto the insulating layer, completing the core preparation stage.

Circuit Imaging: Circuit imaging is the process of transferring the circuit design onto the copper layer of the MCPCB. Photolithography is commonly used for this purpose. A photosensitive resist is applied to the copper surface, and a mask with the desired circuit pattern is placed over it. The resist is then exposed to light, which causes a chemical reaction in the exposed areas. The areas of the resist that are exposed to light become soluble in a developer solution, while the unexposed areas remain insoluble. After development, the soluble parts of the resist are removed, leaving the copper traces underneath protected by the remaining resist.

Etching: Once the circuit pattern has been transferred to the resist, the next step is etching. Etching involves using a chemical solution to remove the unprotected copper from the surface of the PCB, leaving only the conductive traces as defined by the circuit design. The etching process is carefully controlled to ensure that the traces are etched accurately and that the dimensions of the traces meet the design requirements. After etching, the remaining resist is removed, revealing the final circuit pattern on the copper layer.

Drilling and Plating: Holes are drilled through the layers of the MCPCB for various purposes, such as for component leads, vias, and mounting holes. Specialized drilling equipment is used to ensure that the holes are drilled accurately and that the edges of the holes are smooth. After drilling, the holes are plated with a conductive material, usually copper, to create electrical connections between the different layers of the PCB. Plating is typically done using an electroplating process, where a thin layer of copper is deposited on the inner walls of the holes and on the surface of the PCB.

Surface Finishing: The final step in the manufacturing process of an MCPCB is surface finishing. The surface finish serves to protect the copper traces from oxidation and corrosion, as well as to provide a suitable surface for soldering components onto the PCB. Common surface finishes for MCPCBs include hot - air solder leveling (HASL), electroless nickel immersion gold (ENIG), and organic solderability preservative (OSP). Each surface finish has its own advantages and disadvantages, and the choice of surface finish depends on the specific requirements of the application, such as the type of components to be soldered, the operating environment, and the cost considerations.

Thermal Management Strategies for Metal Core PCBs

Thermal Interface Materials (TIMs): Thermal interface materials play a crucial role in enhancing the heat transfer between components and the MCPCB. These materials, such as thermal pastes, pads, or gels, are used to fill the microscopic gaps between the component and the PCB surface. By eliminating these air gaps, which have low thermal conductivity, TIMs reduce the thermal resistance at the interface, allowing heat to flow more efficiently from the component to the PCB. The choice of TIM depends on various factors, including the type of component, the operating temperature range, and the required thermal performance.

Heat Sink Integration: In some high - power applications, integrating a heat sink with the MCPCB can significantly enhance the heat dissipation capabilities. A heat sink is a passive cooling device that provides a larger surface area for heat to be dissipated into the surrounding environment. It can be attached to the metal core of the MCPCB using various methods, such as thermal adhesive, mechanical fasteners, or a combination of both. The design of the heat sink, including its shape, size, and fin configuration, is carefully optimized to maximize the heat transfer efficiency. Additionally, the choice of heat sink material, which is usually aluminum or copper, also affects its performance. Forced - air cooling, such as using fans, can be combined with heat sink integration to further improve the heat dissipation in applications where natural convection is not sufficient.

Thermal Simulation: Thermal simulation is an essential tool in the design of MCPCBs. Advanced simulation software allows designers to model the heat flow within the PCB and the entire electronic system. By inputting the physical and thermal properties of the materials, the component layout, and the operating conditions, designers can predict the temperature distribution across the PCB and identify potential hotspots. This enables them to optimize the design of the MCPCB, such as by adjusting the component placement, the size and shape of the metal core, or the use of thermal vias, to ensure efficient thermal management. Thermal simulation also helps in evaluating different thermal management strategies, such as the use of different TIMs or heat sink designs, before the actual manufacturing process begins, saving time and cost in the development cycle.

Cooling Methods: The choice of cooling method for an MCPCB - based system depends on the power consumption and the operating environment of the device. For low - to - moderate - power applications, natural convection cooling, where heat is dissipated through the natural movement of air around the PCB, may be sufficient. In this case, the design of the PCB and the component layout are optimized to facilitate the natural flow of air and heat dissipation. For high - power applications, forced - air cooling using fans or blowers is often required. This method actively moves air over the PCB and the components, increasing the rate of heat transfer and helping to maintain lower operating temperatures. In some extreme cases, liquid - cooling systems may be used, where a coolant fluid, such as water or a specialized coolant, is circulated through a heat exchanger attached to the MCPCB to remove heat more efficiently.

Industry Trends and Future Outlook

Miniaturization and High - Density Integration: As the electronics industry continues to move towards smaller, more powerful devices, there is a growing demand for MCPCBs that can support high - density component integration. Manufacturers are developing thinner and more flexible MCPCBs to meet these requirements, enabling the creation of compact and efficient electronic systems.

Sustainable Materials and Manufacturing: There is an increasing focus on sustainability in the electronics industry. Future MCPCBs are likely to incorporate more environmentally friendly materials and manufacturing processes, reducing their environmental impact. This may include the use of recycled metals, bio - based insulating materials, and more energy - efficient manufacturing techniques.

Integration with Advanced Technologies: MCPCBs are expected to be integrated with emerging technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI). These technologies require high - performance PCBs with excellent thermal management, electrical performance, and mechanical stability, making MCPCBs an ideal choice for future - proof electronic designs.

Customization and Personalization: With the rise of niche markets and the demand for customized electronics, there will be a greater emphasis on the customization of MCPCBs. Manufacturers will offer more flexibility in terms of material selection, layer thickness, and design features to meet the specific needs of different customers and applications.

Conclusion

Metal Core PCBs have emerged as a revolutionary solution in the field of electronics, offering a unique combination of exceptional thermal management, enhanced mechanical strength, and design flexibility. Their wide range of applications, from LED lighting and automotive electronics to aerospace and defense, highlights their importance in modern electronic systems. As the electronics industry continues to evolve, MCPCBs will play an increasingly crucial role in meeting the growing demands for high - performance, reliable, and energy - efficient electronic devices. By understandin

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB