-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 16. 2025, 09:10:48

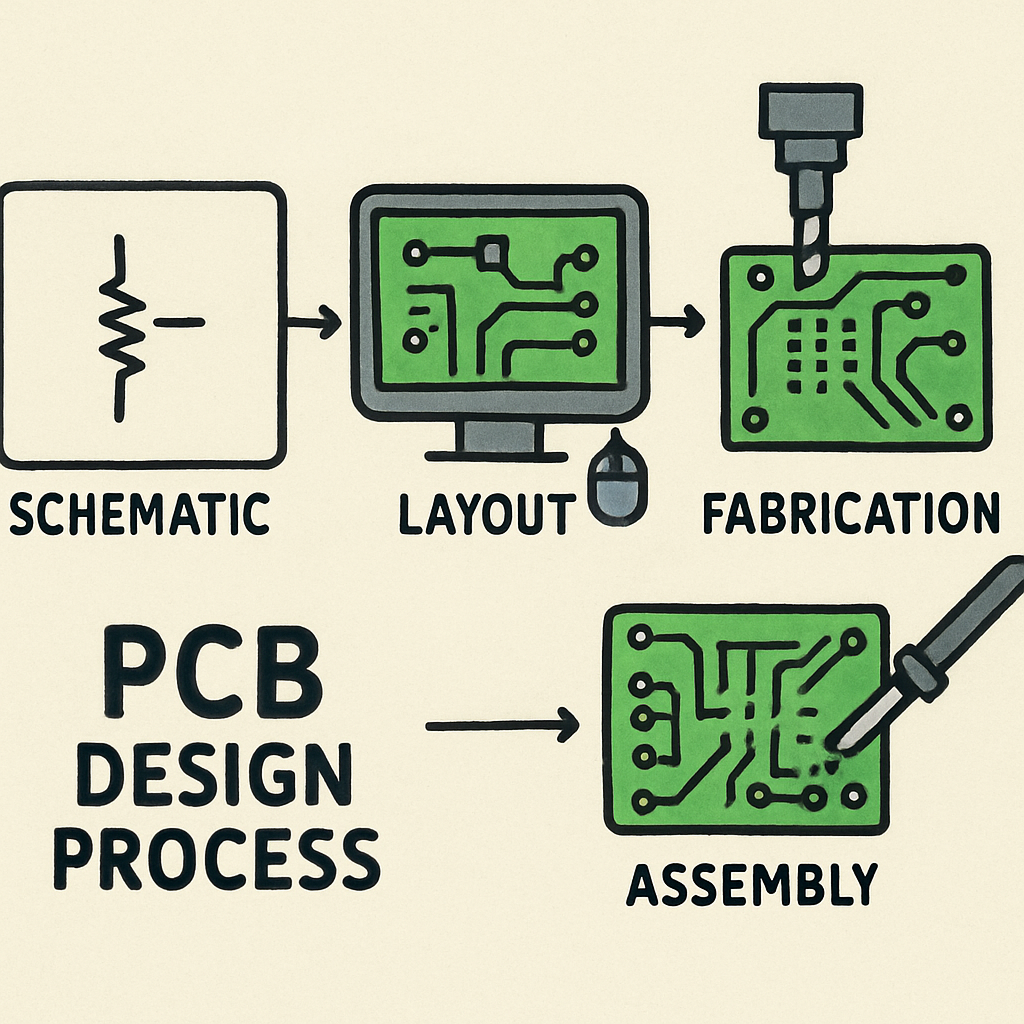

Designing a printed circuit board (PCB) with high density blind vias can be a complex task, but it is essential for achieving compact and efficient electronic products. As technology advances, the demand for smaller and more powerful devices continues to grow, making high density PCB designs crucial. In this article, we will explore essential tips and best practices for designing PCBs with high density blind vias, ensuring optimal performance and reliability. By understanding the intricacies of PCB design, engineers can push the boundaries of innovation and bring to life the next generation of electronic devices.

High density PCBs are characterized by their ability to accommodate a large number of components and interconnections on a smaller board area. This is achieved through techniques such as blind vias, which are holes drilled only partially through the board. These vias connect different layers within a multi-layer PCB without passing through the entire board, allowing for more efficient use of space and enhanced electrical performance. The strategic use of blind vias helps designers maximize the real estate on a PCB, enabling them to meet the increasing demand for compact and multifunctional electronic devices.

As devices become more sophisticated, the complexity of PCBs increases, necessitating innovative approaches to design and fabrication. High density PCBs are not only about cramming more components onto a board but also about maintaining signal integrity and ensuring thermal management. These factors are crucial for the functionality and longevity of the product. Understanding the specific requirements of high density PCBs is fundamental for engineers aiming to create robust and reliable electronic solutions that can withstand the challenges of modern applications.

Blind vias offer several advantages in PCB design, including:

Space Optimization: By connecting only the required layers, blind vias free up space on other layers for additional routing and components. This is particularly important in applications where size and weight are critical, such as in aerospace and wearable technology. The ability to pack more functionality into a smaller footprint is a significant competitive advantage in the electronics market.

Improved Signal Integrity: Shorter signal paths reduce the chances of signal degradation, leading to better performance. High density blind vias minimize the loop area and inductance, which can be crucial for high-speed digital circuits and radio frequency (RF) applications. This improvement in signal integrity translates to faster data rates and more reliable communication between components.

Reduced Manufacturing Complexity: Blind vias minimize the need for through-hole vias, which can complicate the manufacturing process. By reducing the number of layers that vias need to penetrate, designers can simplify the drilling process and reduce potential errors during fabrication. This simplification can lead to lower production costs and faster turnaround times, making it easier to bring products to market quickly.

Designing a high density PCB with blind vias requires careful planning and attention to detail. Here are some key tips to guide you through the process:

The layer stackup is the arrangement of conductive and insulating layers within a PCB. A well-planned stackup is crucial for high density designs, as it determines the routing possibilities and thermal management of the board. The stackup influences the electrical performance by affecting factors such as impedance and crosstalk. Therefore, it is essential to carefully consider the materials and thicknesses of each layer to optimize performance.

Determine the Number of Layers: Evaluate the complexity of your circuit to decide the number of layers needed. High density designs typically require multiple layers to accommodate all connections. A higher number of layers can offer more routing options but also increases cost and manufacturing complexity. Balancing these factors is key to a successful design.

Optimize Layer Order: Place power and ground layers strategically to minimize electromagnetic interference and ensure efficient power distribution. Proper placement of these layers can also aid in heat dissipation, further enhancing the PCB’s reliability and performance. Ensuring that the stackup is symmetrical can also help prevent warping during the manufacturing process.

Leverage advanced computer-aided design (CAD) tools to streamline the design process. These tools offer features such as automatic routing, design rule checks, and simulation capabilities that can significantly enhance the quality of your design. They provide real-time feedback and allow for the simulation of electrical and thermal performance before a physical prototype is built.

Auto-routing: Use auto-routing features to efficiently manage complex connections, especially in high density areas. These tools can optimize trace paths to reduce impedance and crosstalk, which are critical in high-speed applications. However, manual intervention may still be necessary to refine critical signal paths.

Design Rule Checks: Regularly perform design rule checks to ensure compliance with manufacturing constraints and electrical specifications. These checks can catch potential issues early in the design process, preventing costly revisions later. By verifying that the design adheres to the manufacturer’s capabilities, you can avoid delays and ensure a smoother production process.

Blind vias are a powerful tool in high density PCB design, but they must be used judiciously to avoid complications. Overuse or improper implementation of blind vias can lead to increased manufacturing complexity and costs.

Limit Via Sizes: Use the smallest possible via sizes to save space and reduce parasitic capacitance. Smaller vias also help in maintaining the structural integrity of the PCB, especially in areas with high via density. Advanced drilling technologies can create smaller vias with greater precision, offering more flexibility in design.

Avoid Overuse: While blind vias are beneficial, excessive use can complicate the manufacturing process and increase costs. It’s important to evaluate each via's necessity and explore alternative routing solutions when possible. Collaborating with your manufacturer during the design phase can provide insights into the optimal use of blind vias for your specific application.

High density designs can lead to increased heat generation, which can affect the performance and reliability of the PCB. Implement effective thermal management strategies to dissipate heat efficiently. Without proper heat management, components can overheat, leading to failure or reduced lifespan.

Thermal Vias: Use thermal vias to conduct heat away from hot components to cooler areas of the board. These vias act as heat conduits, transferring thermal energy to areas where it can be dissipated more effectively. The placement and size of thermal vias should be optimized based on the thermal profile of the PCB.

Heat Sinks and Thermal Pads: Integrate heat sinks and thermal pads to enhance heat dissipation. These components can be strategically placed to absorb and dissipate heat away from critical areas. Selecting materials with high thermal conductivity can significantly improve the efficiency of these heat management solutions.

When designing a high density PCB with blind vias, it is essential to consider the manufacturing process and limitations. Here are some factors to keep in mind:

Select a manufacturer with experience in high density PCB fabrication and blind via technology. Their expertise will ensure that your design is manufactured accurately and efficiently. Experienced manufacturers can provide valuable feedback during the design phase to optimize for manufacturability, potentially reducing costs and improving yield.

Partnering with a manufacturer who understands the specific requirements of high density designs can also help mitigate risks associated with complex processes. Look for manufacturers with a track record of producing high-quality PCBs for industries similar to yours, as they will be familiar with the standards and challenges associated with your application.

Provide clear documentation of your design intent to the manufacturer. This includes detailed drawings, specifications, and any special requirements for blind vias. Clear communication is crucial to ensure that the final product meets your expectations and functions as intended.

By maintaining an open line of communication with your manufacturer, you can address potential issues before they arise. Regular updates and feedback loops during the production process can help identify and rectify any deviations from the original design, ensuring a smooth transition from design to final product.

Design for Manufacturability (DFM) and Design for Testability (DFT) are critical aspects of PCB design. Ensure that your design can be manufactured and tested effectively by considering these factors:

DFM: Optimize your design for the manufacturing process to reduce costs and improve yield. This includes selecting materials and processes that are compatible with high density PCB fabrication and considering the limitations of your chosen manufacturing partner. A well-optimized design can lead to more efficient production and fewer defects.

DFT: Implement test points and access features to facilitate testing and troubleshooting. Designing with testability in mind can save time and resources during the validation phase, allowing for quicker identification and resolution of issues. Consideration of DFT during the design phase ensures that the PCB can be thoroughly tested before deployment, reducing the risk of field failures.

After manufacturing, thorough testing and validation are essential to ensure the performance and reliability of your high density PCB design. This step is crucial for verifying that the design meets all specified requirements and functions correctly under real-world conditions.

Conduct electrical tests to verify that all connections and components function as intended. This includes continuity tests, impedance measurements, and signal integrity analysis. These tests ensure that the PCB meets the electrical specifications and performs reliably in its intended application.

Advanced testing equipment can simulate operating conditions and detect issues such as shorts, opens, or incorrect component placement. By conducting comprehensive electrical testing, you can identify potential problems early and make necessary adjustments before mass production.

Subject your PCB to environmental tests to evaluate its performance under different conditions. This may include thermal cycling, vibration testing, and humidity exposure. These tests are designed to simulate the conditions the PCB will encounter in its operational environment, ensuring that it can withstand the stresses of real-world use.

Environmental testing helps identify weaknesses in the design that could lead to failure under extreme conditions. By addressing these issues early, you can improve the robustness and reliability of your product, enhancing its reputation in the marketplace.

Designing a high density PCB with blind vias is a challenging but rewarding endeavor. By following these tips and best practices, you can create a compact, efficient, and reliable design that meets the demands of modern electronic devices. With careful planning, the right tools, and collaboration with experienced manufacturers, you can successfully navigate the complexities of high density PCB design and deliver products that excel in performance and durability.

The ability to design high density PCBs opens up new possibilities for innovation in various industries, from consumer electronics to telecommunications and automotive applications. As the demand for smaller, faster, and more efficient devices continues to grow, mastering the art of high density PCB design will be essential for engineers looking to stay at the forefront of technological advancement. By embracing these techniques and continually refining your design process, you can contribute to the development of cutting-edge electronic solutions that redefine the capabilities of modern technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB