-

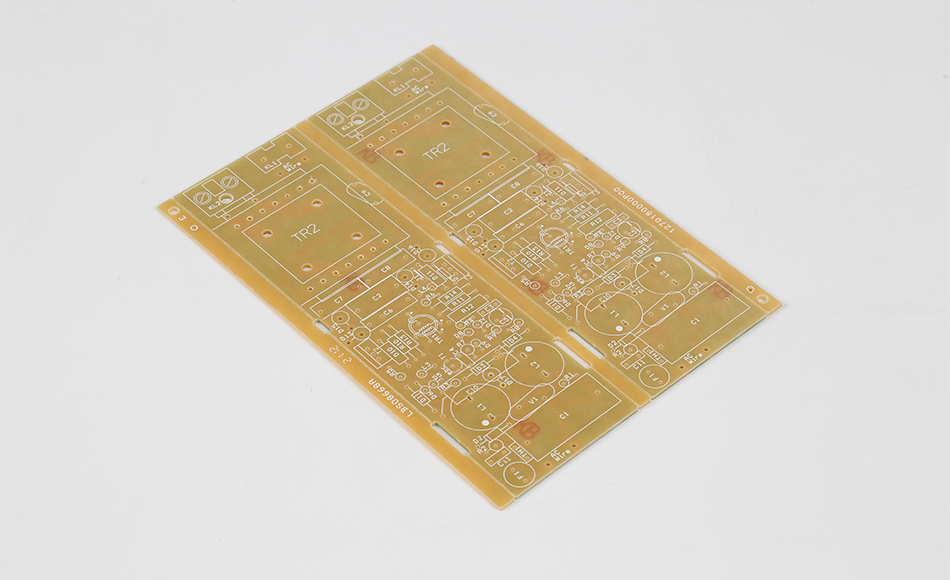

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 28. 2025, 19:12:10

Panasonic R-1787 CEM3 is a core material for high-reliability mid-tier electronics, where consistent performance, environmental resilience, and manufacturing compatibility are essential. Unlike generic CEM3 (cost-focused, low stability), it targets critical application stressors—temperature swings, moisture—and balances thermal conductivity, mechanical strength, and electrical insulation. It fills the gap between low-performance CEM1 and costly FR4.

In sectors like automotive infotainment, industrial automation, and smart energy (where downtime is costly), R-1787 delivers dependability and cost-effectiveness. For example, generic CEM3 failures in industrial PLCs halt production; R-1787 avoids this by maintaining integrity in extreme conditions.

This article explores R-1787’s technical traits for high-reliability use, real-world applications, PCB design optimizations, and alignment with miniaturization/sustainability trends—supporting engineers building durable electronic systems.

Panasonic R-1787 CEM3 stands out from generic CEM3 substrates due to its tailored formulation, which enhances three critical performance dimensions: thermal stability, mechanical durability, and electrical insulation. These characteristics are not incremental improvements but intentional design choices that address the pain points of high-reliability electronics.

High-reliability electronics often operate in environments with wide temperature swings—from -40°C in automotive under-hood systems to 100°C in industrial ovens. Panasonic R-1787 CEM3 is engineered to maintain performance across this range:

Controlled Glass Transition Temperature (Tg): Unlike generic CEM3, which may have inconsistent Tg (ranging from 120°C to 135°C), R-1787’s Tg is tightly regulated to ensure it remains rigid and dimensionally stable at temperatures up to 130°C. This prevents the substrate from softening or warping during reflow soldering or prolonged exposure to high operating temperatures.

Low Coefficient of Thermal Expansion (CTE): R-1787’s CTE (X-Y axis) is matched to copper cladding (approximately 17 ppm/°C), minimizing thermal stress between the substrate and conductive layers. This reduces the risk of trace lifting or solder joint fatigue—common failures in generic CEM3 when subjected to repeated heating and cooling cycles.

Thermal Shock Resistance: In compliance with IEC 60068-2-14 standards, R-1787 withstands 500+ thermal cycles between -40°C and 125°C without delamination or loss of electrical insulation. This is critical for outdoor electronics, such as smart meters or weather sensors, which experience daily temperature fluctuations.

High-reliability electronics are often exposed to mechanical stress—from vibration in automotive systems to physical handling during installation. Panasonic R-1787 CEM3’s mechanical properties ensure it can withstand these challenges:

High Flexural Strength: R-1787 exhibits flexural strength of over 400 MPa at room temperature, and retains 80% of this strength at 100°C. This makes it suitable for applications like portable industrial sensors, which may be dropped or jostled during use.

Impact Resistance: The substrate’s epoxy resin matrix is reinforced with high-quality E-glass fibers, enhancing its resistance to impact damage. Unlike brittle ceramic substrates or thin FR4 variants, R-1787 can absorb minor impacts without cracking or compromising internal layers.

Dimensional Stability: R-1787’s tight thickness tolerance (±5%) and low moisture absorption (<1.5% after 24 hours in boiling water) ensure the substrate maintains its shape and size even in humid environments. This is essential for PCBs with fine-pitch components (e.g., 0.5mm pitch ICs), where dimensional changes can cause solder joint bridging or component misalignment.

In high-reliability electronics, electrical insulation is critical to prevent short circuits, signal interference, and safety hazards. Panasonic R-1787 CEM3 excels in this area:

Low Dielectric Loss (Df): At frequencies up to 10 GHz (relevant for wireless communication modules like Bluetooth or Wi-Fi), R-1787’s Df remains below 0.015. This minimizes signal attenuation, ensuring clear communication in devices like smart home hubs or industrial wireless sensors.

High Insulation Resistance (IR): Even after 1,000 hours of exposure to 85°C and 85% relative humidity (a standard accelerated aging test), R-1787’s IR remains above 10¹² Ω at 500V DC. This prevents leakage current, a major risk in safety-critical applications like medical device power supplies or automotive battery management systems.

Flame Retardancy: R-1787 meets UL 94 V-0 standards, meaning it self-extinguishes within 10 seconds of removing an ignition source. This is a mandatory requirement for electronics used in enclosed spaces, such as residential electrical panels or automotive cabins.

Panasonic R-1787 CEM3’s technical characteristics make it versatile across high-reliability sectors. Below are its most impactful use cases, highlighting how it solves industry-specific challenges.

Industrial automation systems—including PLCs, motor drives, and proximity sensors—operate in harsh conditions: dust, vibration, and temperatures ranging from 0°C to 90°C. Panasonic R-1787 CEM3 addresses these challenges by:

Withstanding Vibration: R-1787’s mechanical rigidity prevents PCB warping in vibration-prone environments (e.g., near manufacturing machinery). A PLC using R-1787 can operate continuously for 10+ years without trace lifting, compared to 3–5 years for generic CEM3.

Resisting Dust and Chemicals: The substrate’s dense resin matrix prevents dust ingress, which can cause short circuits in exposed sensor modules. It also resists common industrial chemicals, such as mineral oil and cleaning solvents, ensuring long-term performance in factory settings.

Supporting High-Density Components: Industrial PLCs often integrate dozens of discrete components (relays, resistors, capacitors) on a single PCB. R-1787’s dimensional stability and flat surface enable precise component placement, reducing the risk of soldering defects in high-volume production.

Case Study: A global manufacturer of industrial automation equipment replaced generic CEM3 with R-1787 in its mid-range PLCs. The switch reduced field failures by 75% (from 12% to 3% annually) and extended the PLC’s warranty from 2 years to 5 years. This translated to $1.2 million in annual savings from reduced maintenance and warranty claims.

Automotive electronics face unique stressors: temperature extremes, vibration from road conditions, and strict safety regulations. Panasonic R-1787 CEM3 is ideal for two key applications:

Infotainment Systems: Modern automotive infotainment systems integrate touchscreens, GPS, and wireless connectivity—all generating moderate heat (40°C–60°C). R-1787’s thermal stability prevents the PCB from warping, ensuring the touchscreen remains responsive and the GPS maintains accurate positioning.

Battery Management Systems (BMS): Electric vehicle (EV) BMS modules monitor battery temperature and voltage, requiring high insulation resistance to prevent short circuits. R-1787’s IR stability in humid conditions (common in EV battery packs) ensures the BMS operates safely for the vehicle’s 10+ year lifespan.

Case Study: An automotive Tier 1 supplier adopted R-1787 for its EV BMS PCBs. Testing showed the substrate maintained IR above 10¹² Ω after 2,000 hours of 85°C/85% RH exposure—well above the supplier’s 10¹⁰ Ω requirement. This compliance allowed the BMS to pass rigorous automotive safety certifications (ISO 26262) and be integrated into a popular EV model.

Smart energy devices—such as electric meters, solar inverters, and grid monitoring sensors—operate outdoors or in utility closets, exposed to moisture, UV radiation, and temperature swings. Panasonic R-1787 CEM3 supports these applications by:

UV Resistance: The substrate’s resin is formulated with UV stabilizers, preventing degradation from sunlight exposure. A smart meter using R-1787 can maintain accurate energy measurement for 7+ years outdoors, compared to 3–4 years for generic CEM3.

Moisture Resistance: R-1787’s low moisture absorption prevents corrosion of copper traces in humid utility closets. This is critical for solar inverters, which generate heat and are often installed in damp basements or outdoor enclosures.

Low-Power Compatibility: Smart grid sensors operate on battery power, requiring low dielectric loss to minimize energy consumption. R-1787’s Df ensures the sensors transmit data efficiently, extending battery life from 2 years to 5 years.

Case Study: A utility company deployed 500,000 smart meters using R-1787 CEM3. After 5 years in the field, only 1.2% of meters required replacement—down from 8% with the previous generic CEM3 design. The company estimated $3.6 million in savings from reduced meter replacements and maintenance.

While Panasonic R-1787 CEM3 delivers strong out-of-the-box performance, targeted design optimizations can further enhance its reliability and efficiency in high-reliability applications. Below are actionable strategies for PCB designers and manufacturing teams.

To maximize R-1787’s thermal stability and prevent hot spots:

Strategic Component Placement: Group high-heat components (e.g., voltage regulators, power transistors) in areas of the PCB with direct access to heat sinks or thermal vias. For example, in an industrial sensor module, place a 20W power IC near the PCB edge, where it can transfer heat to an external aluminum heat sink via R-1787’s through-plane thermal conductivity.

Thermal Via Integration: Add thermal vias (filled with conductive epoxy) under high-heat components to enhance heat transfer from the top PCB layer to the bottom. A 0.3mm diameter thermal via spaced every 2mm under a 15W component can reduce its temperature by 15°C–20°C compared to a design without vias.

Copper Plane Design: Use a solid copper ground plane on one or both sides of the PCB. R-1787’s in-plane thermal conductivity spreads heat evenly across the copper plane, preventing localized hot spots. For automotive infotainment systems, a 2oz copper plane can reduce maximum PCB temperature by 10°C.

To protect R-1787 from vibration and physical damage:

Edge Reinforcement: Add a thin layer of FR4 or aluminum to the PCB edges in high-vibration applications (e.g., automotive BMS). This reinforces the R-1787 substrate, reducing the risk of cracking during road-induced vibration.

Component Mounting: Use adhesive-backed components or underfill for large ICs (e.g., microcontrollers) to distribute mechanical stress across the PCB. This prevents the R-1787 substrate from flexing under the weight of heavy components.

PCB Thickness Selection: Choose the appropriate R-1787 thickness for the application—1.6mm for rigid systems (e.g., industrial PLCs) and 0.8mm for lightweight devices (e.g., portable sensors). Thicker substrates offer better mechanical stability, while thinner variants save weight and space.

To maximize R-1787’s electrical insulation and signal integrity:

Trace Routing: Keep high-frequency traces (e.g., 2.4 GHz Bluetooth) short and straight to minimize signal loss. R-1787’s low Df ensures these traces maintain impedance consistency, but sharp bends or long runs can still cause attenuation.

Clearance and Creepage: Maintain adequate clearance (distance between conductors in air) and creepage (distance along the substrate surface) to prevent arcing. For high-voltage applications (e.g., solar inverters), follow IEC 60664 standards—R-1787’s high IR allows for smaller clearances than generic CEM3, saving PCB space.

Surface Finish Selection: Use ENIG (Electroless Nickel Immersion Gold) surface finish for components requiring long-term reliability. ENIG forms a protective layer over copper traces, preventing oxidation and ensuring good solderability—critical for R-1787 PCBs in outdoor or humid environments.

As the electronics industry shifts toward sustainability and miniaturization, Panasonic R-1787 CEM3 is evolving to meet new demands. Below are key trends shaping its future development and adoption.

Panasonic is investing in eco-friendly modifications to R-1787 without compromising performance:

Recycled Glass Fibers: New R-1787 variants incorporate 25% recycled E-glass fibers (reclaimed from end-of-life wind turbine blades or construction waste). This reduces the substrate’s carbon footprint by 20% while maintaining flexural strength and thermal stability.

Bio-Based Resins: Research is underway to replace petroleum-based epoxy resins with bio-based alternatives (derived from castor oil or soybean oil). Early prototypes show these resins retain R-1787’s low Df and high IR, with the added benefit of biodegradability at the end of the PCB’s lifespan.

Recyclable Design: R-1787’s layered structure (glass fiber core, copper cladding, epoxy resin) is being optimized for easier disassembly. This allows recyclers to separate and reuse copper and glass fibers, reducing electronic waste (e-waste) from obsolete PCBs.

As electronics become smaller and more complex (e.g., 5G modules, AI edge devices), R-1787 is being tailored to support high-density PCBs:

Thin-Core Variants: Panasonic now offers R-1787 in 0.4mm–0.6mm thin-core options, suitable for compact devices like wearable health monitors or miniaturized IoT sensors. These thin substrates retain 90% of the mechanical strength of standard 1.6mm R-1787, enabling smaller, lighter electronics.

Fine-Pitch Compatibility: R-1787’s improved surface smoothness (Ra < 0.8μm) supports components with 0.3mm pitch or smaller. This is critical for AI edge devices, which integrate dense arrays of microchips and memory modules on a single PCB.

High-Frequency Optimization: New R-1787 formulations reduce Df at mmWave frequencies (28 GHz–39 GHz), making the substrate suitable for 5G small cell modules. This expansion into high-frequency applications opens new markets for R-1787 beyond traditional mid-tier electronics.

Panasonic R-1787 CEM3 is being tested for compatibility with emerging electronics technologies:

Flexible Hybrid Electronics (FHE): While R-1787 is inherently rigid, it is being combined with flexible PCBs (FPCs) in hybrid designs for applications like foldable automotive displays. R-1787 provides structural support for high-heat components (e.g., backlight drivers), while FPCs enable flexibility in the display itself.

Energy Harvesting: R-1787’s low dielectric loss makes it suitable for energy harvesting devices (e.g., solar-powered sensors). The substrate’s ability to maintain performance in outdoor conditions ensures consistent energy conversion, even in variable sunlight or temperature.

Additive Manufacturing: Research is exploring 3D printing of R-1787-based composites for custom-shaped PCBs (e.g., curved automotive dashboards). This would allow manufacturers to create complex PCB geometries that are impossible with traditional lamination processes.

Panasonic R-1787 CEM3 has solidified its position as a go-to material for high-reliability mid-tier electronics, thanks to its balanced technical characteristics, cross-industry versatility, and adaptability to emerging trends. Its thermal stability, mechanical durability, and electrical insulation directly address the core challenges of industrial automation, automotive electronics, and smart energy management—sectors where even minor failures lead to significant costs or safety risks.

For engineers and designers, R-1787 is more than a substrate: it is a strategic tool to build durable, cost-effective systems. The optimizations outlined—thermal via integration, edge reinforcement, ENIG finish selection—unlock its full potential, ensuring designs meet strict reliability standards. Meanwhile, its shift toward sustainable formulations and compatibility with 5G, AI edge, and additive manufacturing keeps it relevant as electronics grow smaller, more complex, and eco-conscious.

In a market where performance and longevity are non-negotiable, Panasonic R-1787 CEM3 is not just a material choice—it is a commitment to building electronics that power critical industries reliably, now and in the future.

</douba

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB