-

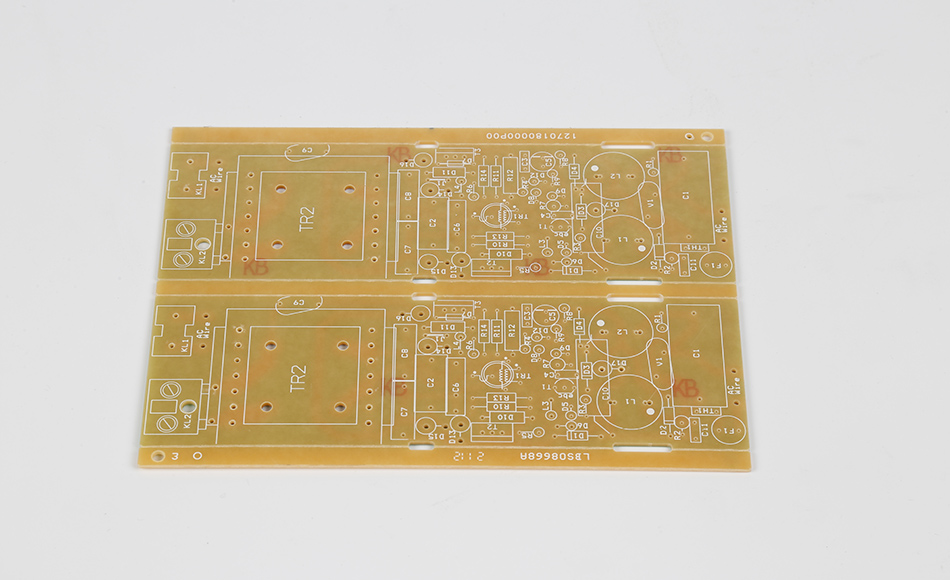

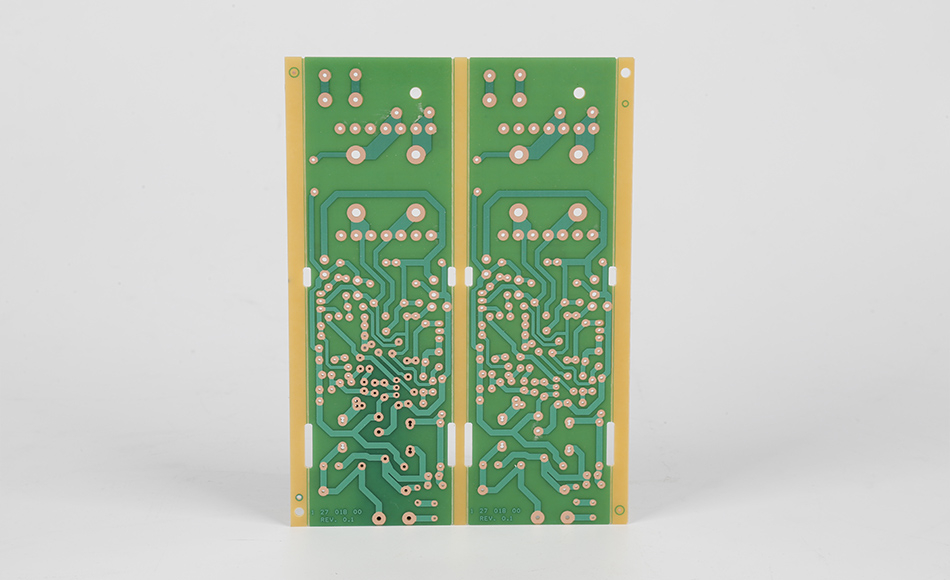

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 28. 2025, 19:00:48

A R-1787 CEM3 Material Supplier acts as a strategic collaborator for PCB manufacturers, directly impacting their bottom line—far beyond basic substrate delivery. Unlike generic CEM3 suppliers (transactional vendors), top R-1787 suppliers use expertise in Panasonic’s formulation to create solutions that cut waste, streamline production, and adapt to market demands. For mid-tier electronics manufacturers (industrial control, consumer appliances), this collaboration is key to balancing R-1787’s required reliability with cost competitiveness.

Missteps in R-1787 supplier selection cause hidden costs: overstocking (capital tied up), stockouts (production halts), or rework (inconsistent quality). Collaborative suppliers align with production cycles, anticipate bottlenecks, and optimize material use.

This article explores how forward-thinking R-1787 suppliers drive cost efficiency via tailored supply chains, joint problem-solving, and adapting to trends like miniaturization—equipping procurement/operations teams to build partnerships that boost reliability and profitability.

One of the most significant cost drains for PCB manufacturers is misalignment between material supply and production schedules—either excess inventory (tying up capital and risking material degradation) or stockouts (halting lines and delaying orders). Leading R-1787 CEM3 Material Suppliers address this by designing customized supply chain solutions that adapt to the manufacturer’s unique workflow.

Instead of forcing manufacturers into rigid "one-size-fits-all" delivery schedules, top R-1787 suppliers implement demand-driven systems that integrate with the manufacturer’s ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System) platforms. This integration enables:

Real-Time Stock Visibility: The supplier gains access to the manufacturer’s upcoming production runs (e.g., a 10,000-unit order for industrial sensors) and adjusts inventory levels accordingly. For example, if the manufacturer’s MES signals a 20% increase in R-1787 demand for the next quarter, the supplier pre-positions additional material at a regional warehouse—eliminating rush shipping costs and stockout risks.

Just-in-Time (JIT) with Buffer Flexibility: Unlike generic suppliers that struggle with JIT due to limited capacity, R-1787 specialists maintain a 2–3 week buffer of validated material (compliant with Panasonic’s specs) to accommodate sudden demand spikes. A consumer appliance manufacturer, for instance, might receive a last-minute order for 5,000 washing machine PCBs; the supplier can accelerate delivery from the buffer without compromising batch consistency.

Consignment Inventory Models: For high-volume manufacturers, suppliers offer consignment arrangements where R-1787 material is stored at the manufacturer’s facility but owned by the supplier until used. This reduces the manufacturer’s inventory holding costs (e.g., warehouse space, capital tied up in unused material) and minimizes waste from expired stock (R-1787 has a 6-month shelf life under standard conditions).

A 2024 study of PCB manufacturers using collaborative R-1787 suppliers found that demand-driven inventory management reduced inventory costs by 18–22% and cut stockout-related downtime by 30% compared to those using transactional suppliers.

Global PCB manufacturers face unique challenges: shipping R-1787 across continents increases lead times, raises transportation costs, and exposes material to environmental risks (e.g., humidity during ocean transit). Leading R-1787 CEM3 Material Suppliers mitigate these issues by building regionalized distribution networks:

Localized Warehousing: Suppliers maintain warehouses in key manufacturing hubs (e.g., Southeast Asia, Eastern Europe, North America) stocked with pre-tested R-1787 material. A manufacturer with facilities in Vietnam and Mexico can receive material within 48 hours of ordering, compared to 2–3 weeks for ocean shipping from a single global warehouse.

Climate-Controlled Transit: For regions with extreme weather (e.g., high humidity in Thailand, temperature fluctuations in Canada), suppliers use climate-controlled containers and desiccant packaging to preserve R-1787’s properties. This eliminates the need for manufacturers to reprocess or discard material damaged during transit—a common issue with generic CEM3 suppliers that use standard shipping.

Cross-Regional Backup: In the event of a regional disruption (e.g., a port strike in China), suppliers can reroute R-1787 from adjacent regions. During the 2023 Red Sea shipping crisis, for example, a European PCB manufacturer avoided a 3-week production halt by sourcing R-1787 from the supplier’s Turkish warehouse instead of its original Chinese facility.

R-1787 CEM3 is used across diverse applications, each with unique requirements (e.g., thinner laminates for IoT sensors, thicker substrates for industrial PLCs). Generic suppliers often force manufacturers to purchase standard-sized batches (e.g., 100m rolls), leading to waste if the manufacturer only needs 60m for a specific order. Collaborative R-1787 suppliers solve this by offering batch-sized customization:

Variable Roll Lengths: Manufacturers can order R-1787 in rolls tailored to their exact production needs—whether 30m for a small-batch medical device PCB or 500m for a high-volume appliance run. This reduces material waste by 15–20% compared to standard batches.

Pre-Cut Panel Options: For manufacturers without in-house cutting capabilities, suppliers offer pre-cut R-1787 panels in custom dimensions (e.g., 300mm × 400mm for a specific PCB design). This eliminates the time and labor costs of trimming large rolls and reduces the risk of material damage during cutting.

Custom Surface Treatments: At the manufacturer’s request, suppliers can apply specialized surface treatments (e.g., anti-static coatings for electronics used in dusty environments) to R-1787 batches. This eliminates the need for the manufacturer to outsource additional processing, cutting lead times by 1–2 weeks.

PCB manufacturers often face production challenges directly tied to material performance—from delamination during reflow soldering to signal integrity issues in high-speed circuits. Generic CEM3 suppliers typically offer little support beyond replacing defective batches, but collaborative R-1787 CEM3 Material Suppliers use their deep knowledge of the substrate to resolve root causes, preventing recurring issues and reducing long-term costs.

R-1787 CEM3’s performance is heavily influenced by a manufacturer’s production processes (e.g., lamination temperature, drilling speed). A common pain point is delamination during reflow soldering—a problem that may stem not from defective material, but from misalignment between the material’s properties and the manufacturer’s process parameters. Collaborative suppliers address this by:

On-Site Process Audits: A team of R-1787 specialists visits the manufacturer’s facility to review lamination, drilling, and reflow processes. For example, during an audit of a European PCB manufacturer, a supplier discovered that the manufacturer’s reflow oven was operating at 265°C (5°C above R-1787’s recommended peak temperature), causing resin degradation and delamination. The supplier recommended adjusting the oven to 255°C and provided a customized reflow profile—reducing delamination rates from 8% to 0.5%.

Shared Testing Data: Suppliers share detailed testing data on how R-1787 performs under different process conditions (e.g., how lamination pressure affects void formation). This enables manufacturers to optimize parameters without costly trial-and-error. A North American manufacturer, for instance, used supplier-provided data to reduce lamination time by 15% (from 90 minutes to 77 minutes) while maintaining void-free laminates—increasing production throughput by 12%.

Customized Material Adjustments: With Panasonic’s approval, suppliers can make minor adjustments to R-1787’s formulation to better suit a manufacturer’s processes. For a manufacturer struggling with drill breakage (due to the material’s rigidity), the supplier adjusted the resin’s flexibility slightly—reducing drill breakage by 40% and cutting tool replacement costs by $15,000 per month.

PCB manufacturers that produce multiple product lines (e.g., industrial sensors, consumer routers) with R-1787 often face quality variability—material that performs well for one product may struggle with another. Collaborative suppliers resolve this by:

Application-Specific Material Validation: Before a new product launch, the supplier tests R-1787 against the product’s unique requirements (e.g., thermal cycling for automotive PCBs, moisture resistance for outdoor IoT devices). For a manufacturer launching a smart meter PCB, the supplier validated that R-1787 maintained insulation resistance above 10¹² Ω after 1,000 hours of 85°C/85% RH exposure—ensuring compliance with utility industry standards and avoiding costly redesigns.

Batch-to-Batch Consistency Guarantees: Unlike generic suppliers that only guarantee compliance with broad specs, R-1787 specialists offer batch-to-batch consistency guarantees (e.g., ±3% variation in dielectric constant). This is critical for high-mix manufacturers, where a 5% Dk variation could cause signal integrity issues in one product line but not another. A manufacturer producing both industrial and consumer PCBs reported a 25% reduction in rework after switching to a supplier with strict consistency guarantees.

Root Cause Collaboration: When quality issues arise, suppliers work with manufacturers to conduct joint root cause analysis (RCA), using tools like fishbone diagrams and statistical process control (SPC). For a manufacturer experiencing intermittent short circuits in a PCB design, the joint RCA revealed that the issue stemmed from a combination of the manufacturer’s trace spacing and the material’s surface roughness. The supplier recommended a minor adjustment to R-1787’s surface finish, and the manufacturer adjusted trace spacing—eliminating the short circuits entirely.

Design for Manufacturability (DFM) is critical for reducing production costs, but many PCB designers lack deep knowledge of R-1787’s capabilities. Collaborative R-1787 CEM3 Material Suppliers fill this gap by:

DFM Workshops: Suppliers host workshops for designers, teaching them how to optimize PCB layouts for R-1787 (e.g., minimizing trace length to reduce signal loss, placing thermal vias to prevent hot spots). A consumer electronics manufacturer reported a 30% reduction in design iterations after its design team attended these workshops—cutting time-to-market by 4 weeks per product.

Early-Stage Design Reviews: Suppliers review PCB designs in the early stages (before prototyping) to identify potential issues. For example, a supplier noticed that a manufacturer’s IoT sensor design had traces too close to the PCB edge—risking damage during assembly. The supplier recommended moving the traces 0.2mm inward, preventing a 50% prototype failure rate and saving $20,000 in prototyping costs.

Material-Specific Design Tools: Suppliers provide designers with access to R-1787-specific design tools (e.g., impedance calculators tailored to the material’s Dk, thermal simulation models). A manufacturer designing a high-speed Ethernet PCB used the supplier’s impedance calculator to optimize trace width—reducing signal reflection by 60% and eliminating the need for costly signal boosters.

The PCB industry is evolving rapidly, driven by trends like miniaturization, sustainability, and the rise of 5G/AI edge devices. Generic CEM3 suppliers often struggle to keep pace, but collaborative R-1787 CEM3 Material Suppliers adapt their offerings to help manufacturers stay competitive—turning industry challenges into cost-saving opportunities.

As electronics shrink (e.g., wearable health monitors, mini IoT sensors), PCB manufacturers need R-1787 material that supports finer features and tighter tolerances. Collaborative suppliers enable this by:

Thin-Core R-1787 Variants: Suppliers offer thin-core R-1787 (0.4mm–0.6mm thickness) that retains the material’s mechanical strength and electrical performance. This allows manufacturers to produce thinner PCBs (critical for wearables) without switching to more expensive substrates like thin FR4. A manufacturer of fitness trackers reduced PCB thickness by 40% using thin-core R-1787, enabling a sleeker design and reducing material costs by 18%.

Fine-Pitch Compatibility: Suppliers optimize R-1787’s surface smoothness (Ra < 0.6μm) to support components with 0.3mm pitch or smaller. This eliminates the risk of solder bridging (a common issue with rough-surface materials) and reduces rework costs. A manufacturer producing AI edge modules reported a 70% reduction in solder defects after switching to fine-pitch-optimized R-1787.

Micro-Drilling Support: Suppliers provide technical guidance on micro-drilling R-1787 (e.g., optimal drill bit speeds, coolant types) for holes as small as 0.15mm. This enables manufacturers to produce dense PCBs with more vias—critical for high-density interconnect (HDI) designs—without investing in specialized equipment. A manufacturer of 5G small cell PCBs increased via density by 50% using the supplier’s micro-drilling guidance, improving signal integrity and reducing the number of PCB layers needed (from 8 to 6), cutting costs by 22%.

Sustainability is no longer a niche concern—it is a business imperative, with customers and regulators demanding eco-friendly practices. Collaborative R-1787 suppliers help manufacturers reduce their environmental footprint while cutting costs by:

Recyclable R-1787 Packaging: Suppliers use 100% recyclable packaging (e.g., cardboard tubes, biodegradable plastic films) for R-1787 material, eliminating the need for manufacturers to dispose of non-recyclable waste. A European manufacturer reduced packaging waste by 90% and saved $8,000 per year in waste disposal fees.

Take-Back Programs: Suppliers offer take-back programs for unused or expired R-1787 material, which is then recycled or repurposed (e.g., ground into composite materials for non-electronic applications). This reduces landfill waste and helps manufacturers avoid the costs of hazardous material disposal. A North American manufacturer recovered $12,000 in value from unused R-1787 through a supplier’s take-back program.

Low-Energy Production Processes: Suppliers optimize their R-1787 production processes to use less energy (e.g., solar-powered curing ovens) and pass savings to manufacturers. A manufacturer sourcing R-1787 from a low-energy supplier reduced its material costs by 7% while cutting its Scope 3 carbon emissions (from purchased materials) by 15%.

The growth of 5G and AI edge devices (e.g., smart cameras, industrial AI controllers) requires R-1787 material that performs well at high frequencies (up to 10 GHz). Collaborative suppliers meet this need by:

High-Frequency Optimized R-1787: Suppliers adjust R-1787’s resin formulation to reduce dielectric loss (Df < 0.012 at 10 GHz) at high frequencies. This ensures signal integrity for 5G PCBs without switching to expensive high-frequency substrates like PTFE. A manufacturer of 5G routers improved signal transmission efficiency by 35% using high-frequency-optimized R-1787, reducing the need for signal amplifiers and cutting component costs by $10 per unit.

EMI Shielding Integration: Suppliers offer R-1787 material pre-laminated with thin EMI shielding layers (e.g., copper-nickel films), eliminating the need for manufacturers to add shielding post-production. This reduces assembly time by 20% and improves shielding effectiveness (critical for AI edge devices in noisy industrial environments). A manufacturer of industrial AI controllers reduced assembly costs by 18% and improved EMI performance by 40% using pre-shielded R-1787.

Thermal Management Enhancements: Suppliers add thermally conductive fillers to R-1787 (with Panasonic’s approval) to improve heat dissipation—critical for AI edge devices that generate high heat. A manufacturer of AI-powered smart cameras reduced PCB operating temperature by 12°C using thermally enhanced R-1787, extending component lifespan by 50% and reducing warranty claims by 30%.

For PCB manufacturers relying on R-1787 CEM3, a collaborative supplier is not just a vendor—it is a strategic partner that unlocks cost efficiency, enhances reliability, and fuels innovation. Unlike transactional generic suppliers that only deliver material, top R-1787 CEM3 Material Suppliers tailor supply chains to align with production cycles (cutting inventory costs and stockouts), resolve production pain points through joint problem-solving (reducing rework and downtime), and adapt to industry trends (supporting miniaturization, sustainability, and high-frequency needs).

These partnerships deliver tangible value: lower total cost of ownership, faster time-to-market, and the ability to meet evolving customer and regulatory demands. For mid-tier electronics manufacturers competing in industries like industrial automation, consumer appliances, and smart energy, this collaboration is the difference between merely surviving and thriving.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB