-

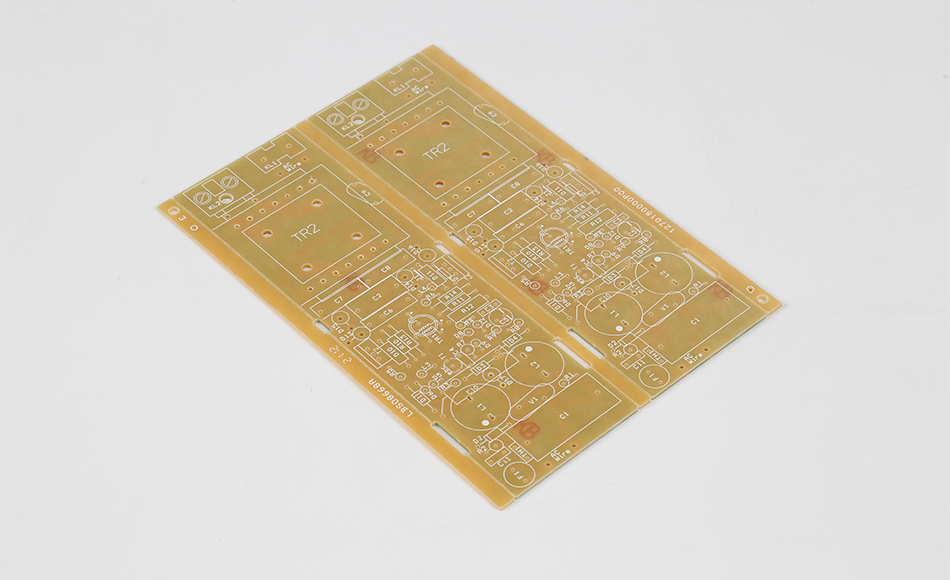

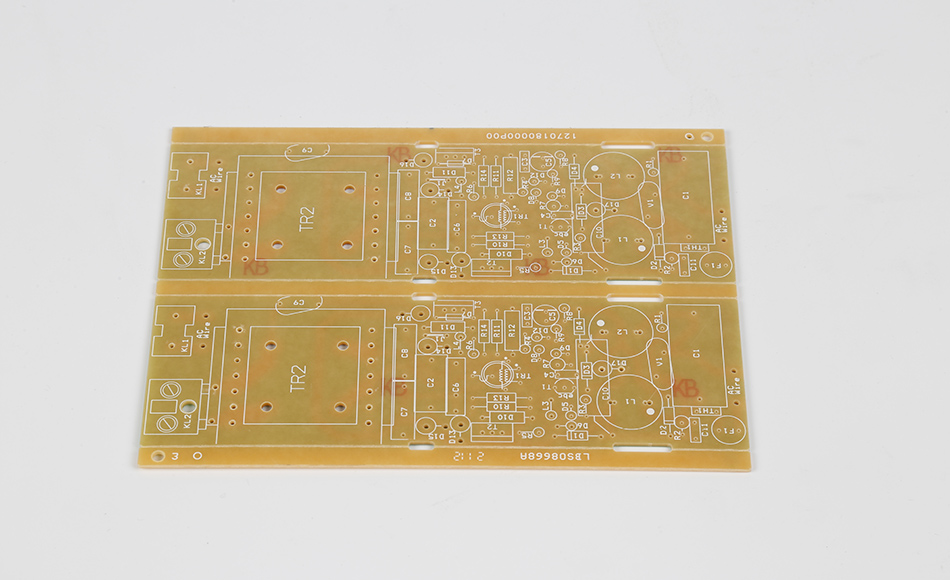

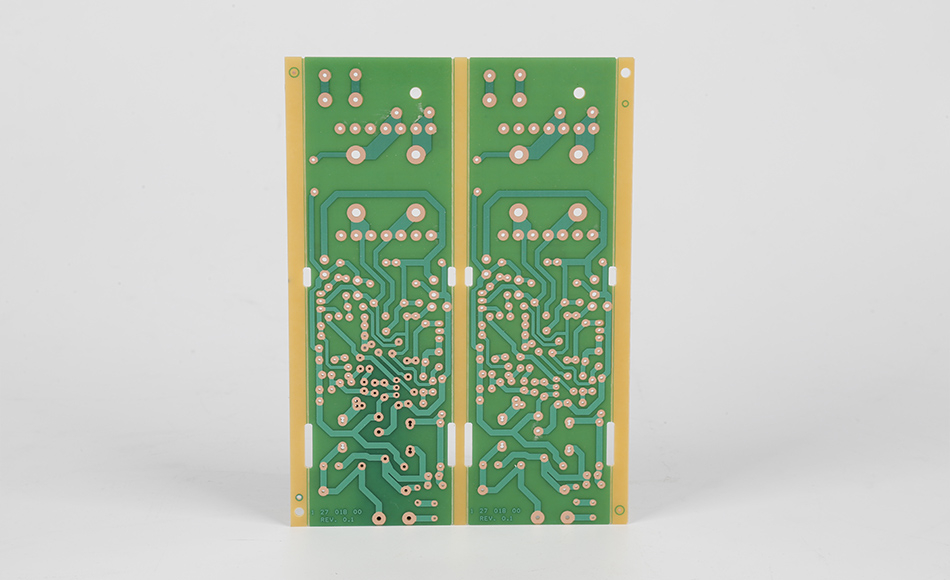

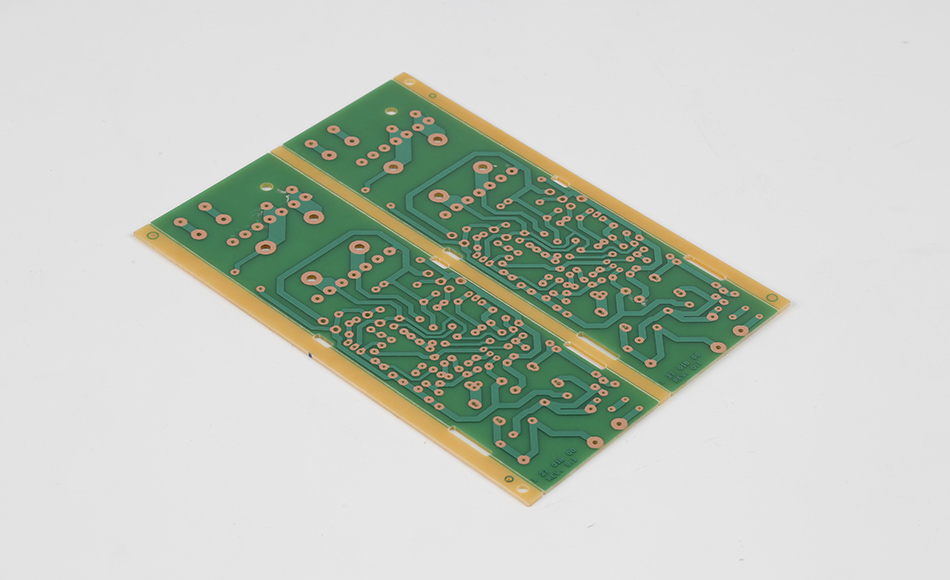

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 28. 2025, 18:53:52

The Panasonic R-1787 CEM3 Datasheet is more than a catalog of technical values—it is a strategic risk-mitigation tool that unifies cross-functional teams (design engineers, manufacturing specialists, quality assurance, and procurement) around a shared understanding of CEM3 substrate performance. In electronics development, where even small mismatches between material capabilities and application demands can lead to costly field failures, this datasheet provides the granular, application-specific data needed to make informed decisions. Unlike generic CEM3 datasheets that list isolated specs (e.g., dielectric constant or flexural strength) without context, the Panasonic R-1787 document ties every property to real-world outcomes: How will the material behave during reflow soldering? Will it maintain insulation resistance in humid industrial environments? Can it withstand the mechanical stress of automated assembly?

For industries relying on mid-tier electronics—from industrial automation (dusty, vibration-prone factories) to consumer appliances (cost-durability balance)—the Panasonic R-1787 CEM3 Datasheet acts as a "safety net." It prevents overengineering (e.g., specifying premium FR4 when R-1787 suffices) and underdesign (e.g., generic CEM3 failing in temperature swings). This article explores how to leverage the datasheet to identify/mitigate PCB risks, align teams on performance standards, and validate designs for end-use reliability. By focusing on "datasheet as a collaboration and risk-management tool," it delivers unique insights distinct from broader CEM3 discussions—critical for professionals delivering consistent, failure-free electronics.

Generic CEM3 datasheets contribute to PCB failures by omitting context, masking batch variability, or ignoring application stressors. The Panasonic R-1787 CEM3 Datasheet addresses these gaps with transparency, specificity, and real-world relevance.

Generic CEM3 datasheets list a single glass transition temperature (Tg) without explaining behavior across -40°C to 125°C (typical electronics range). This causes:

Delamination in Thermal Cycling: A generic CEM3 with Tg=130°C may soften at 100°C (e.g., industrial oven controllers), separating layers and wasting design time.

Solder Joint Failure: Without temperature-dependent coefficient of thermal expansion (CTE) data, mismatched components lead to fatigue in automotive/consumer electronics.

How Panasonic R-1787 Datasheet Mitigates This:

The "Thermal Performance" section includes graphs of CTE (X-Y/Z axes, -40°C to 150°C) and Tg measured at industrial curing rates (2°C/min). It also shares thermal shock results (500 cycles, -40°C to 125°C, <0.1% delamination). For a 90°C factory PCB, engineers confirm R-1787’s CTE aligns with copper, eliminating thermal stress.

Generic datasheets list "typical" values (no tolerances for thickness or dielectric constant), leading to:

High Scrap Rates: 15% thickness variation in generic CEM3 causes 20–30% scrap in high-volume production.

Inconsistent Signal Integrity: ±10% impedance variation (no Dk tolerances) causes reflections in high-speed circuits (e.g., USB 3.0).

How Panasonic R-1787 Datasheet Mitigates This:

Strict tolerances are defined: thickness uniformity (±5%), Dk (±3% at 1 MHz), flexural strength (±7%). The "Batch Consistency" section details quality control (20 samples/batch tested, rejected if out of range). This cuts scrap to <5% and ensures accurate impedance calculations.

Generic datasheets skip moisture/chemical/UV testing, critical for outdoor/industrial PCBs:

Moisture-Induced Shorts: Generic CEM3 in outdoor IoT sensors absorbs 5% weight in water (6 months), dropping insulation resistance below safety limits.

Chemical Degradation: Swelling in food processing cleaners detaches components.

How Panasonic R-1787 Datasheet Mitigates This:

The "Environmental Resistance" section includes:

Moisture absorption: <1.5% weight gain (24h boiling water, IPC-TM-650).

Chemical immersion: No degradation (1,000h in mineral oil/isopropyl alcohol/food cleaners).

UV stability: <5% flexural strength loss (1,000h UV, 5 years outdoor use).

Food processing sensor teams use this data to confirm R-1787 withstands caustic cleaners.

The datasheet acts as a common language for teams with distinct priorities, ensuring alignment on reliability and cost.

Match Material to Demands: For 85°C automotive infotainment, confirm R-1787’s Tg/CTE (avoid premium FR4) and Dk/Df at 2.4 GHz (Bluetooth) for signal integrity.

Optimize Components: Use "Solder Compatibility" data (lead-free alloys, reflow profiles) to select temperature-compatible parts, preventing solder failure.

Predict Reliability: Model lifespan via accelerated aging results (10,000h at 85°C/85% RH) to meet 5-year warranties.

Set Process Parameters: "Manufacturing Guidelines" provide lamination (temp/pressure/time), drill speeds (18,000 RPM for 0.4mm holes), and routing specs—no trial-and-error.

Troubleshoot: If reflow delamination occurs, check if peak temp exceeds the datasheet’s 260°C limit.

Train Staff: Clear format teaches new technicians material limitations and process needs.

Incoming Inspection: Use "Quality Control" data (test thickness/Dk/flexural strength) to reject non-compliant batches.

Validate Outgoing PCBs: For medical devices, set test thresholds using insulation resistance/dielectric strength data.

Compliance Docs: "Regulatory Certifications" (UL 94 V-0, IEC 60068, REACH) simplify global market certification.

Evaluate Suppliers: Use batch consistency/certifications to verify authorized Panasonic suppliers, avoiding counterfeits.

Negotiate Pricing: Clear specs enable volume discount negotiations without quality risks.

Manage Inventory: "Storage and Handling" (6-month shelf life, <60% RH) prevents pre-use degradation.

Challenge: 15% delamination in generic CEM3 PLCs (0°C–90°C factories) caused $200k/year in warranty claims.

Solution: Switched to R-1787, used datasheet to:

Confirm CTE alignment (90°C, 16 ppm/°C vs. copper’s 17 ppm/°C).

Adjust reflow to 250°C (8s) from generic’s unvalidated 260°C.

Verify 500+ thermal cycles resistance.

Result: Delamination <1%, warranty claims down $180k/year, warranty extended to 5 years.

Challenge: 22% scrap (500k PCBs/year) from generic CEM3 thickness variation, costing $350k/year.

Solution: Adopted R-1787, used datasheet to:

Set ±5% thickness inspection standards.

Optimize lamination (28 psi, 165°C).

Train staff on quality requirements.

Result: Scrap down to 4%, $300k/year saved, lead times cut 10%.

Challenge: Generic CEM3 air quality sensors failed in 12 months (moisture absorption), missing 3-year target.

Solution: Switched to R-1787, used datasheet to:

Confirm <1.5% moisture absorption (vs. generic’s 4%).

Select UV-compatible conformal coating.

Model 5-year lifespan via 10,000h aging data.

Result: 4-year lifespan, $5M city contract secured.

Role-Specific Summaries: One-page docs for engineers (electrical/thermal data), manufacturing (process specs), QA (test standards).

Link to Requirements: For 5-year outdoor use, cross-reference UV/moisture data; document in design reviews.

Compare to Generic CEM3: Matrix critical properties (CTE, Dk tolerance, environmental resistance) to quantify R-1787’s value (e.g., 50% lower moisture absorption).

Evaluate Upgrades/Downgrades: Adjust substrate choice if requirements change (e.g., indoor → outdoor use).

CAD Software: Input Dk/thickness for accurate impedance/trace routing (Altium, KiCad).

MES Systems: Program lamination/drilling parameters to automate control, reducing error.

New Hire Workshops: Teach linking properties to risks (e.g., CTE mismatch = delamination).

Monthly Reviews: Use datasheet to analyze issues (e.g., signal loss) and prevent recurrence.

As electronics grow more complex (higher power density, miniaturization) and sustainability becomes critical, the R-1787 datasheet will evolve to address new challenges.

Future versions will include carbon footprint per square meter, recycled content (e.g., 25% recycled glass fibers), and end-of-life recyclability (e.g., 90% copper/glass fiber recovery). This helps teams meet corporate ESG goals (e.g., Apple’s carbon-neutral targets) and comply with regulations (EU’s Carbon Border Adjustment Mechanism).

The datasheet will shift to digital formats with interactive features:

3D Material Models: Import into CAD software for real-time performance simulations (e.g., thermal stress during reflow).

AI-Driven Recommendations: Input application parameters (temp, environment) to get datasheet-derived design tips (e.g., "Use 2oz copper for 85°C industrial use").

Cloud Sync: Update automatically with new test data (e.g., long-term aging results), ensuring teams use the latest specs.

As electronics adopt new technologies (5G, AI edge computing), the datasheet will add application-specific sections:

High-Frequency Data: Extended Dk/Df data up to 6 GHz for 5G small cells.

Low-Power Optimization: Guidance for IoT devices (e.g., minimizing leakage current via R-1787’s insulation properties).

The Panasonic R-1787 CEM3 Datasheet redefines what a technical document can achieve—it is not just a list of specs, but a strategic partner in PCB development. By mitigating risks that generic datasheets ignore (unvalidated temperature performance, undefined tolerances, inadequate environmental data), it prevents costly failures and streamlines production. Its ability to align cross-functional teams—from engineers to procurement—ensures everyone works toward the same reliability and cost goals, eliminating silos that delay projects.

Real-world case studies prove its impact: cutting delamination rates, slashing scrap costs, and extending product lifespans. As electronics evolve, the datasheet will grow with the industry, integrating sustainability metrics, digital tools, and advanced application support to meet future challenges.

For professionals in mid-tier electronics, the Panasonic R-1787 CEM3 Datasheet is more than a resource—it is a competitive advantage. It enables the design and production of reliable, cost-effective PCBs that meet the demands of today’s markets while preparing for tomorrow’s innovations. In a world where quality and efficiency are non-negotiable, this datasheet is the foundation of successful PCB development.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB