-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 14. 2025, 09:48:45

Printed Circuit Board (PCB) assembly is a vital process in the manufacturing of electronic devices. It involves the mounting of various electronic components onto a PCB to create a functional electronic circuit. In this article, we will explore the essentials of PCB assembly, from the manufacturing process to the types of assembly techniques used.

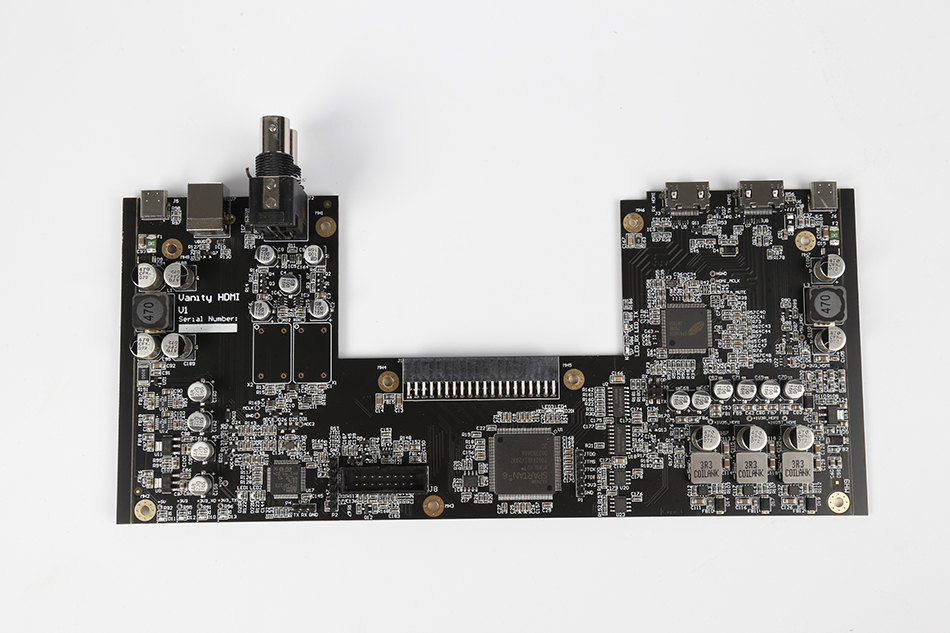

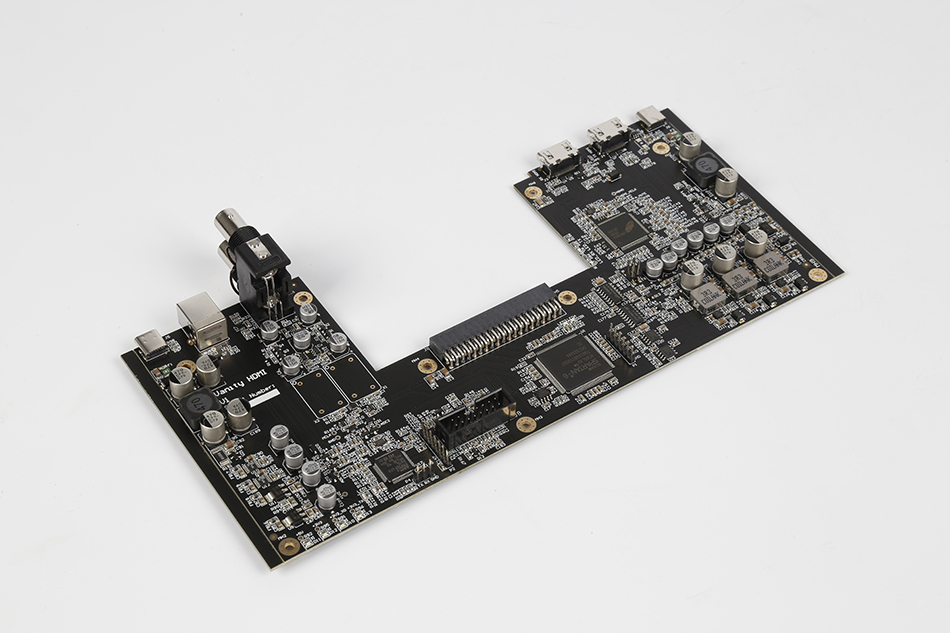

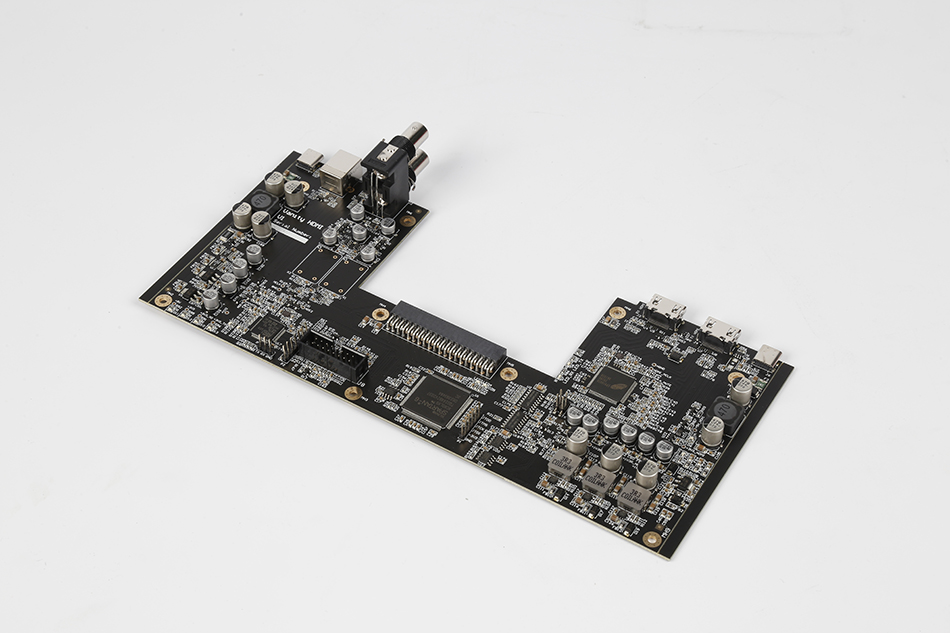

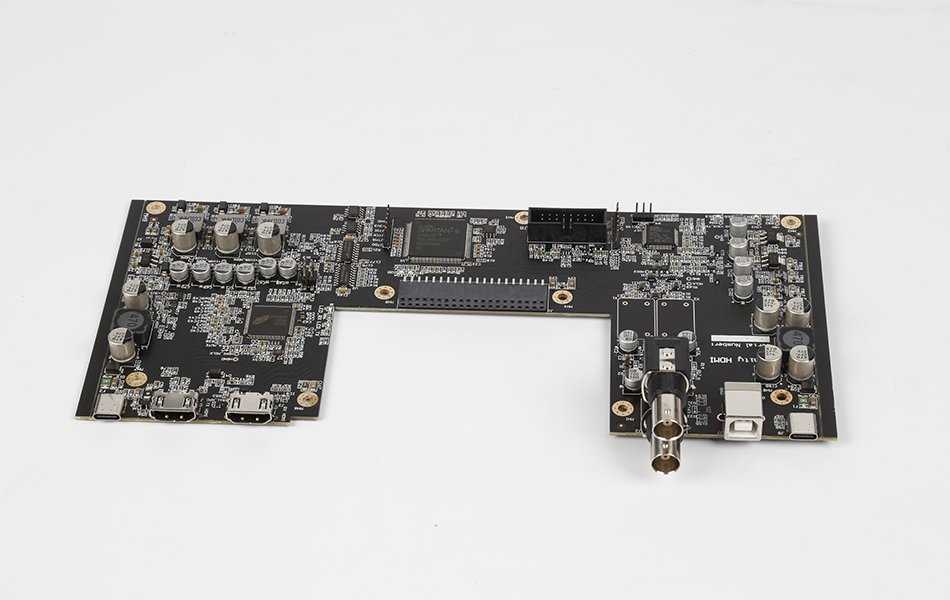

PCB assembly is the stage where electronic components are connected to the circuit board. This process transforms a bare board into a fully operational device. The components used in the assembly may include resistors, capacitors, diodes, transistors, and integrated circuits (ICs), among others. Each component is strategically placed and soldered onto the board to ensure proper function.

Before delving into PCB assembly, it is essential to understand how PCBs are manufactured. The process involves several steps:

The first step in PCB manufacturing is designing the board layout. Engineers use specialized software to create a schematic representation of the circuit. This design outlines the placement of components and the routing of electrical connections.

Once the design is finalized, the fabrication process begins. This includes creating the board's physical structure, typically made from fiberglass or other insulating materials. Conductive copper layers are added to form the electrical pathways.

Holes are drilled into the board to accommodate component leads and vias, which connect different layers of the board. These holes are then plated with metal to ensure electrical connectivity.

The unwanted copper is etched away, leaving only the necessary conductive traces. A solder mask is then applied to protect the board and prevent solder bridges during assembly.

The final step in fabrication is silkscreen printing. This involves printing labels and symbols on the board to indicate component placement and other important information.

There are two primary techniques used in PCB assembly: Surface Mount Technology (SMT) and Through-Hole Technology (THT).

SMT is the most common assembly method used today. It involves mounting components directly onto the surface of the PCB. This technique allows for smaller, more compact designs and is ideal for high-volume production.

Compact Design: SMT components are smaller and can be placed on both sides of the PCB.

High-Speed Production: Automated machines can place components quickly, reducing production time.

Improved Performance: Shorter leads and smaller components result in better electrical performance.

THT involves inserting component leads through pre-drilled holes in the PCB. These leads are then soldered to pads on the opposite side of the board. While less common than SMT, THT is still used for components that require strong mechanical connections.

Strong Connections: Components are securely attached to the board, making THT suitable for high-stress environments.

Ease of Prototyping: THT is often used in prototyping and testing due to the ease of manually placing and replacing components.

Soldering is a critical process in PCB assembly. It involves using molten metal to create electrical connections between components and the PCB. There are two main types of soldering used in PCB assembly: reflow soldering and wave soldering.

Reflow soldering is primarily used with SMT. It involves applying solder paste to the board, placing components, and then heating the assembly in a reflow oven. The heat melts the solder, forming secure connections.

Wave soldering is typically used with THT. The board is passed over a wave of molten solder, which attaches the component leads to the board. This method is efficient for producing large quantities of boards.

Quality control is essential to ensure the reliability and performance of the assembled PCBs. Several methods are used to inspect and test PCBs during and after assembly:

Automated Optical Inspection (AOI): AOI systems use cameras to inspect PCBs for defects such as missing components or solder bridges.

X-ray Inspection: X-rays can detect defects beneath components, such as voids in solder joints.

Functional Testing: This involves testing the assembled PCB to ensure it operates correctly within its intended application.

Understanding the basics of PCB assembly is crucial for anyone involved in electronics manufacturing. From design and fabrication to assembly and quality control, each step is vital to creating reliable and functional electronic devices. Whether using SMT for high-volume production or THT for strong mechanical connections, the right assembly technique can make all the difference in your product's performance.

PCB assembly is a fascinating and complex process that brings electronic devices to life. By mastering the fundamentals, you can ensure your products meet the highest standards of quality and reliability.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB